Sweeping and descaling device for rough rolling of band steel with wind and water

A technology of rough rolling and strip steel, which is applied in the direction of metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of shortening the service life of rolls, spalling, and increasing rolling costs, so as to improve the quality of strip steel and reduce costs The effect of fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

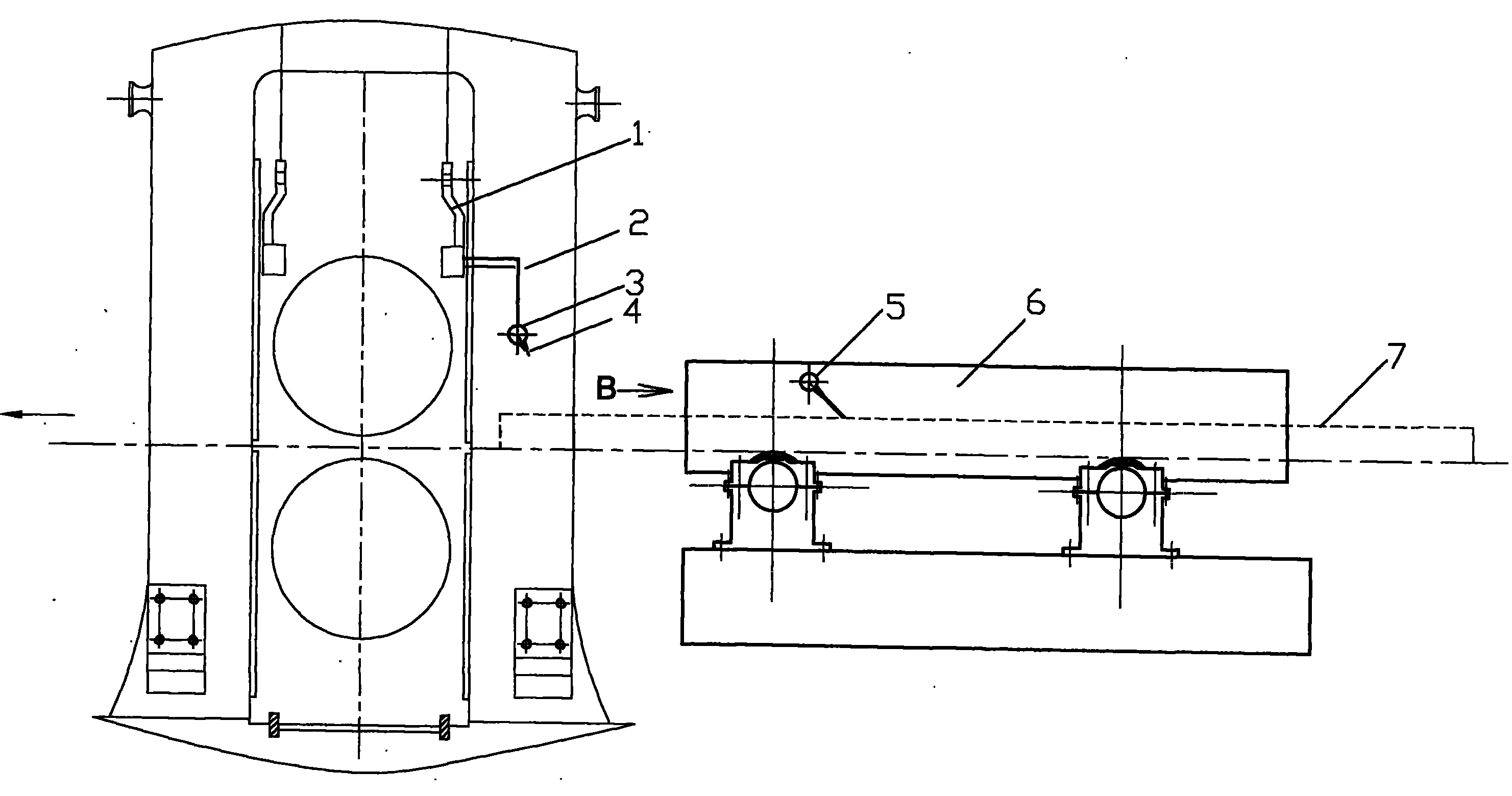

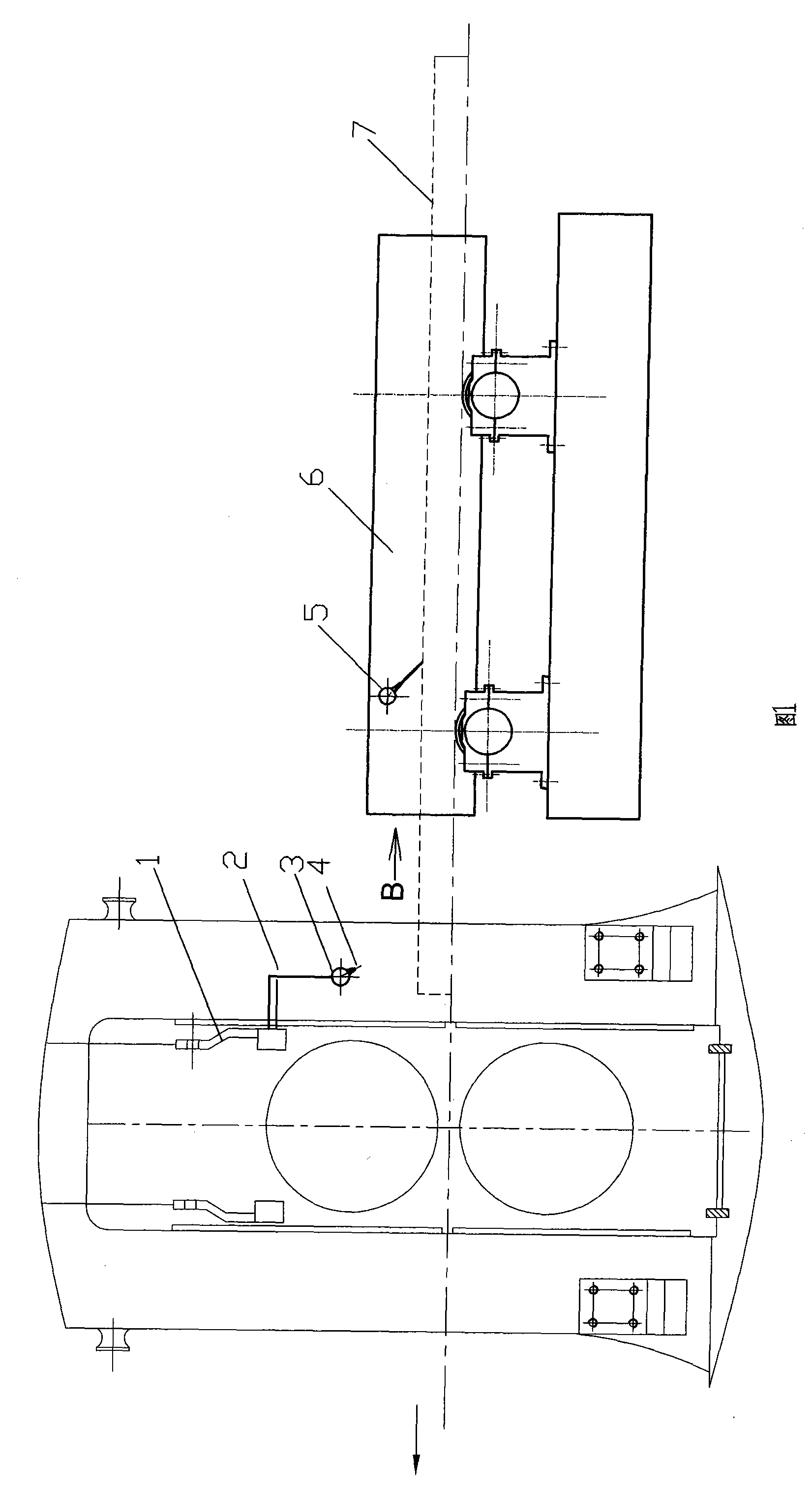

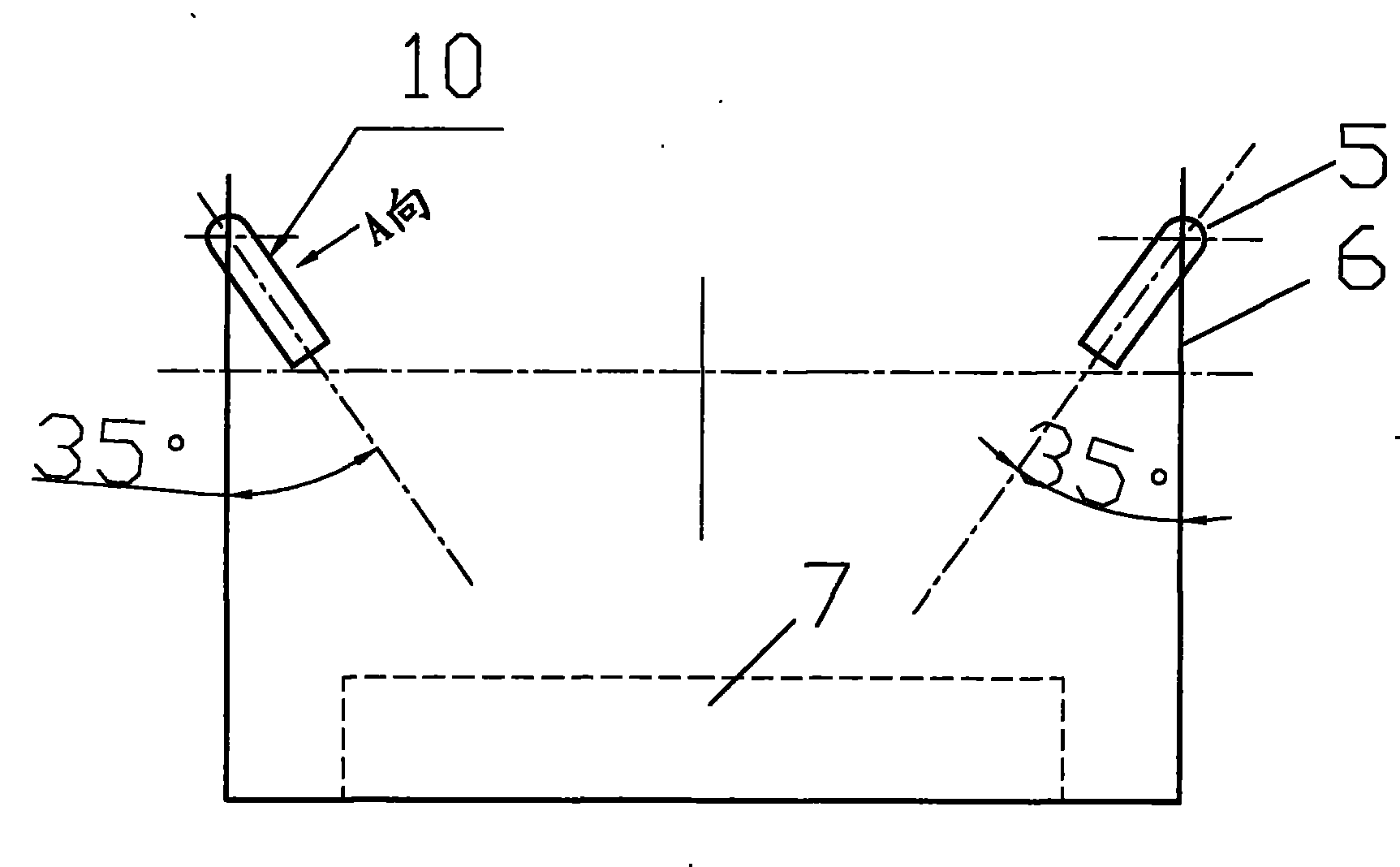

[0023] As shown in the figure, a wind and water blowing and descaling device for rough rolling of strip steel is installed on the balance beam 1 of the rough rolling steel strip on the side where the billet enters the rolling mill. 3 is arranged in parallel with the rolls of the rolling mill, and a plurality of nozzles 4 are arranged on the nozzle 3. The plurality of nozzles 4 are evenly distributed in the axial direction of the rolls. The water purging devices 5 are installed on the roller frame guards 6 on both sides. The nozzles of the water purging devices on the left roller frame guard 6 are sprayed towards the steel plate 7 in the right and rear direction, and the right roller frame guard 6 The nozzle of the water purging device above sprays the steel plate 7 in the left rear direction. The nozzle 3 is provided with 5 nozzles 4, and the center line of the nozzle 4 is at an angle of 45° with the vertical direction. The center line of the nozzle of the water purging devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com