Three-layered jacquard towel weaving technique thereof

A technology of towels and craftsmanship, applied in textiles, papermaking, fabrics, textiles, etc., can solve the problems of monotonous color expression and poor pattern layering, and achieve the effect of strong pattern layering, diverse colors, and soft hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] The weaving process of the three-layer jacquard towel includes steps:

[0021] a. Yarn matching The arrangement ratio of the towel ground warp to the wool warp is 5:1, 5 ground warps are matched with 1 wool warp, and the ground warp and wool warp of the original white pure cotton are used;

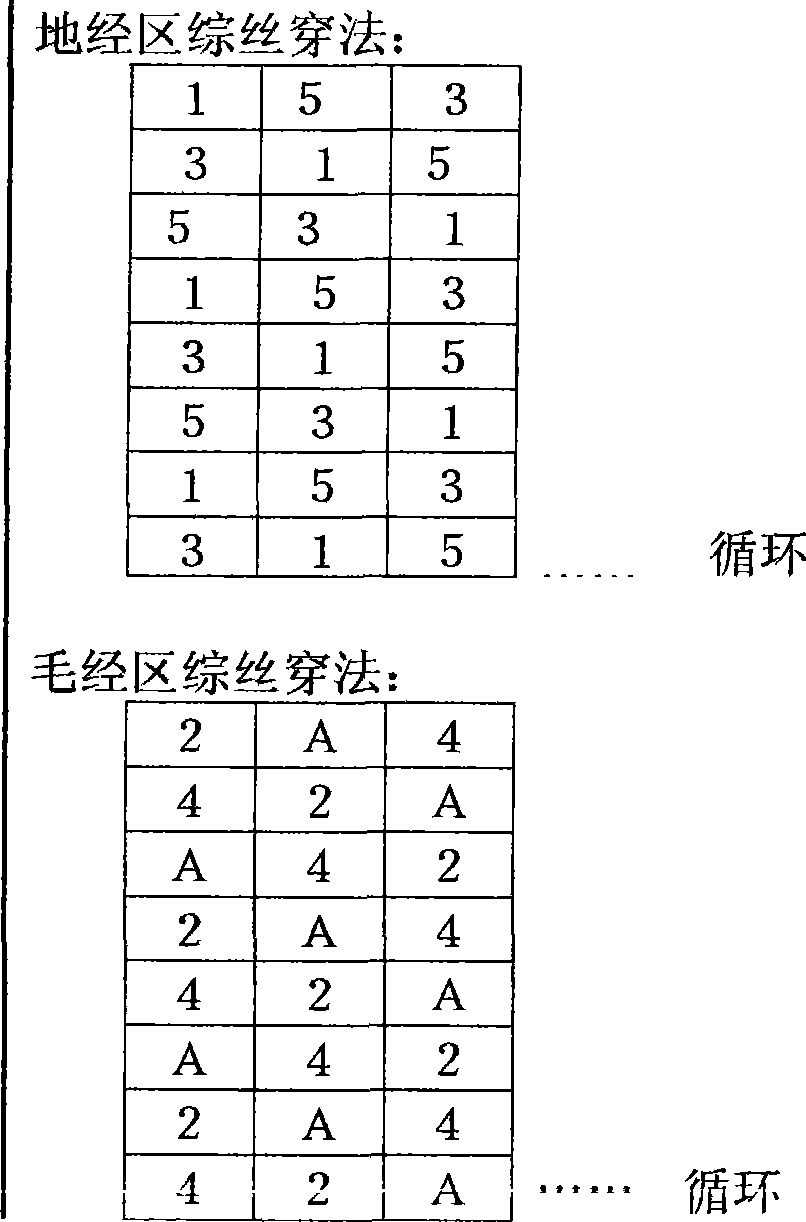

[0022] b. 3 / 5 of the number of ground warps used for threading the mesh plate and entering the heald penetrates into the back ground warp area of the mesh plate heald, and 2 / 5 penetrates into the front wool warp area, and the yarns are arranged according to 5 ground warps and 1 wool. The warps are arranged sequentially; the first, third and fifth ground warps of the 5 ground warps arranged in sequence in each cycle are sequentially penetrated into the rear warp area of the mesh heddle, and the ground warps arranged in sequence in each cycle The second and fourth ground warps and hair warps of the five ground warps penetrate into the front hair warp area;

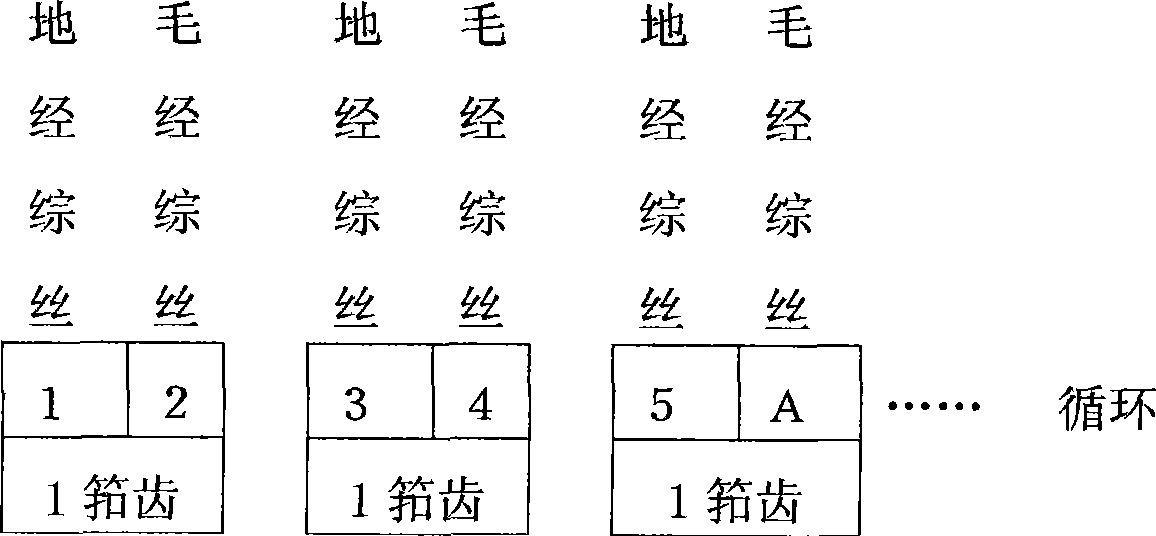

[0023] c. Reeding In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com