Anti-pollution anti-pressure seal assembly of seabed tubular sampling instrument

A technology of sealing components and samplers, which is applied in the direction of shaft seals, sampling devices, engine components, etc., can solve the problems of sample falling off, and achieve the effects of improving the influence of gravity, saving space and mechanism settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In conjunction with the accompanying drawings, the present invention will be described in detail below through specific embodiments.

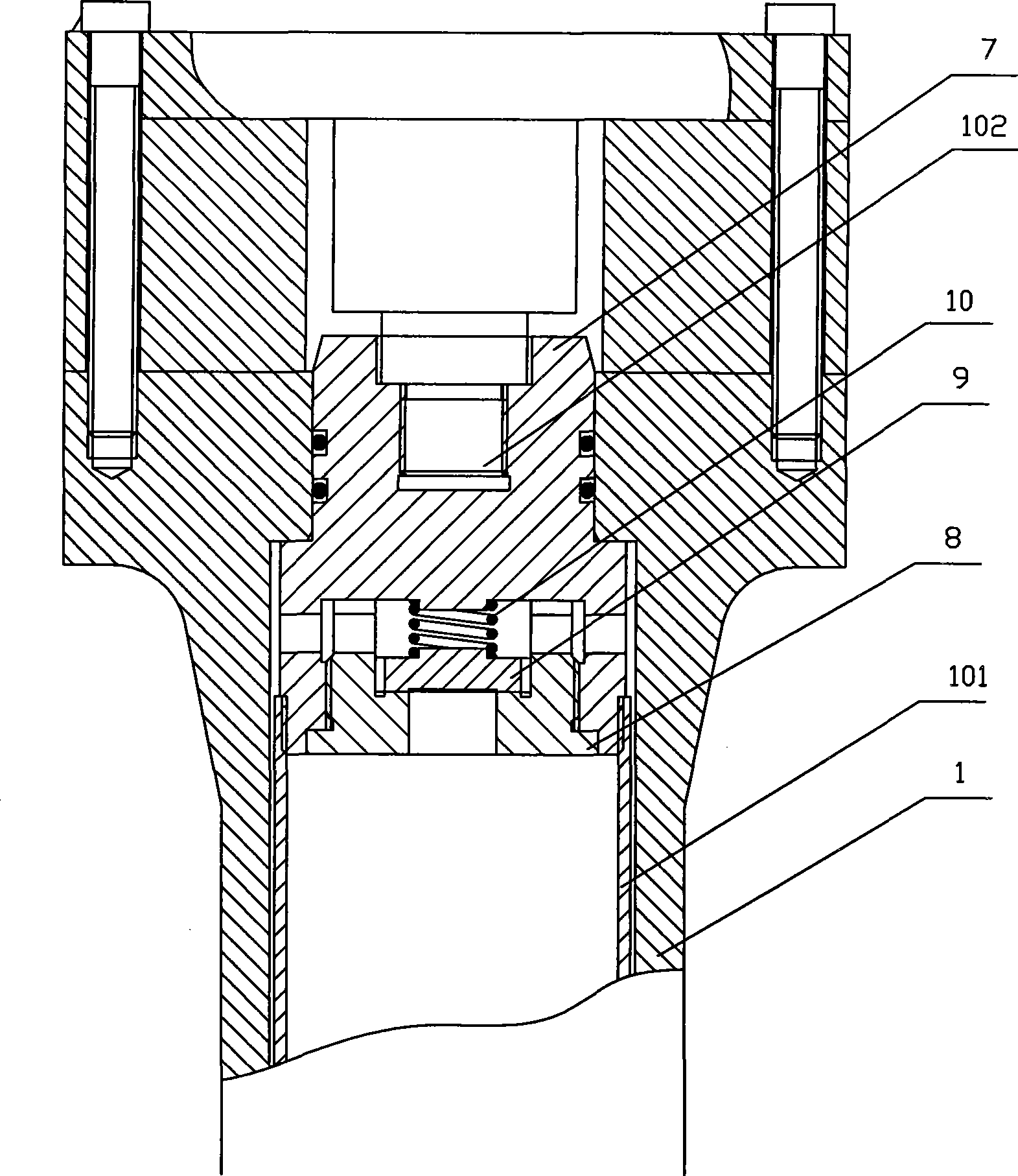

[0025] The anti-pollution and anti-pressure sealing assembly of the submarine tubular sampler in this specific embodiment includes a round tubular sampling tube 101, and a pressure-holding cylinder 1 is sheathed outside the sampling tube 101, and the pressure-holding cylinder 1 communicates with an accumulator.

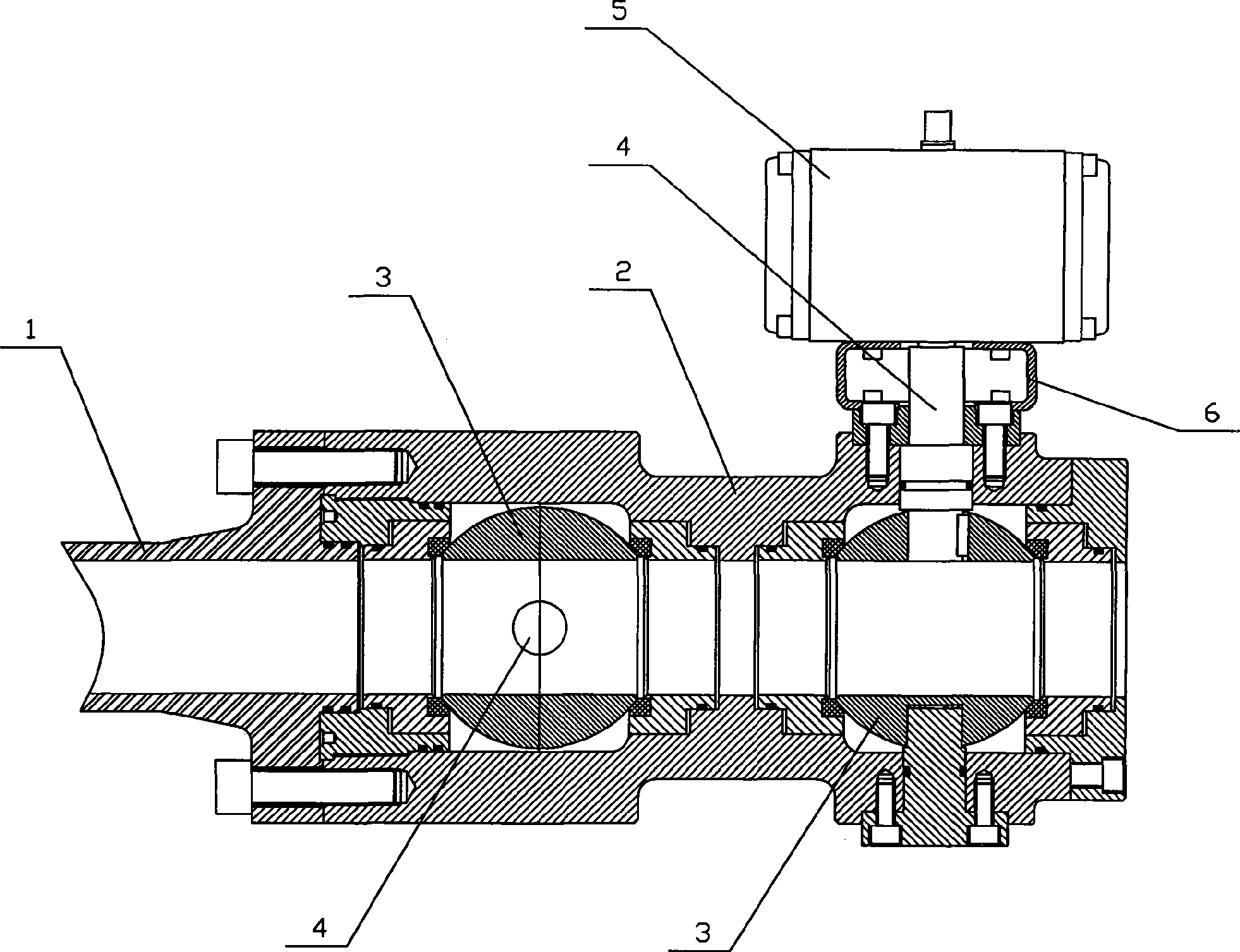

[0026] One end flange of the pressure-holding cylinder 1 is connected to the valve body 2 of the ball valve through bolts; two ball valve spools 3 are arranged in the valve body 2, and each ball valve spool 3 has an independent valve stem 4 and a valve stem driving device 5. The valve body 2 of the ball valve is connected with the valve rod driving device 5 through the valve rod 4 . A frame structure 6 is arranged between the ball valve body 2 and the valve stem driving device 5, and the frame structure 6 is respectively connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com