Hydraulically driving seabed multi-column shaped sampling and sealing system

A sealing system and columnar technology, which is applied in the field of subsea multi-tubular columnar sample sampling and sealing system, can solve problems such as vibration and sample falling off, and achieve the effect of improving the influence of gravity, saving space and mechanism settings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

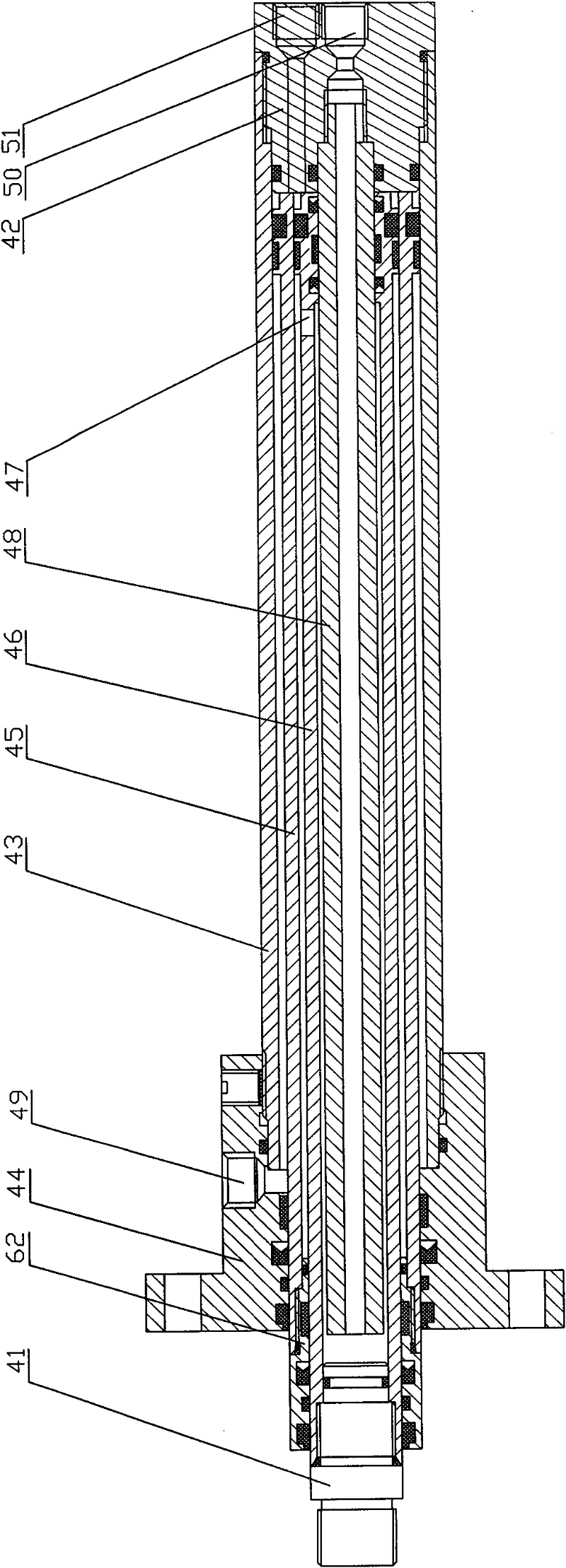

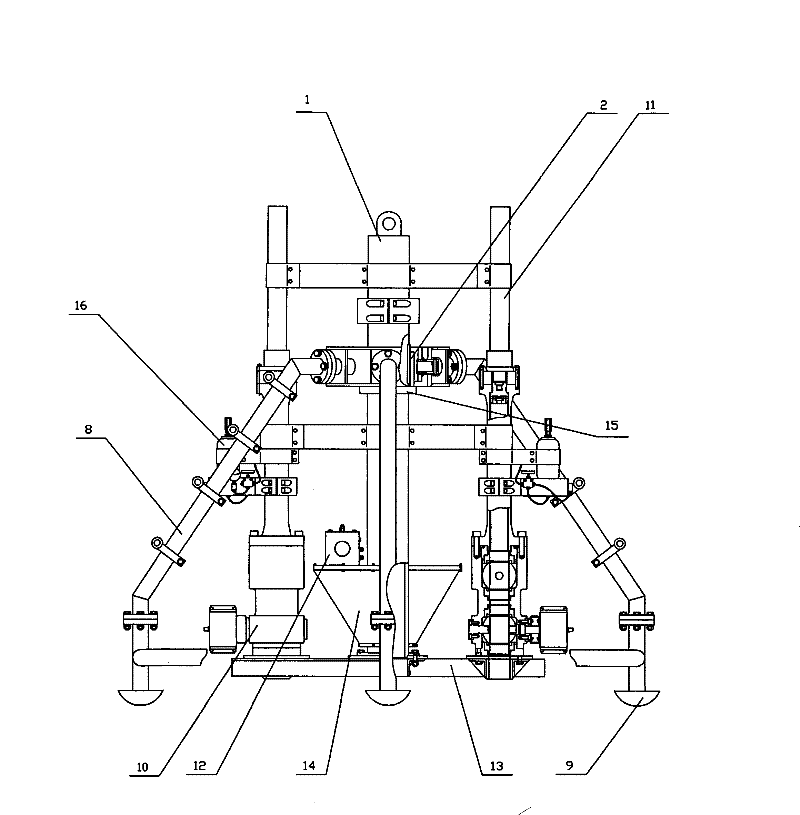

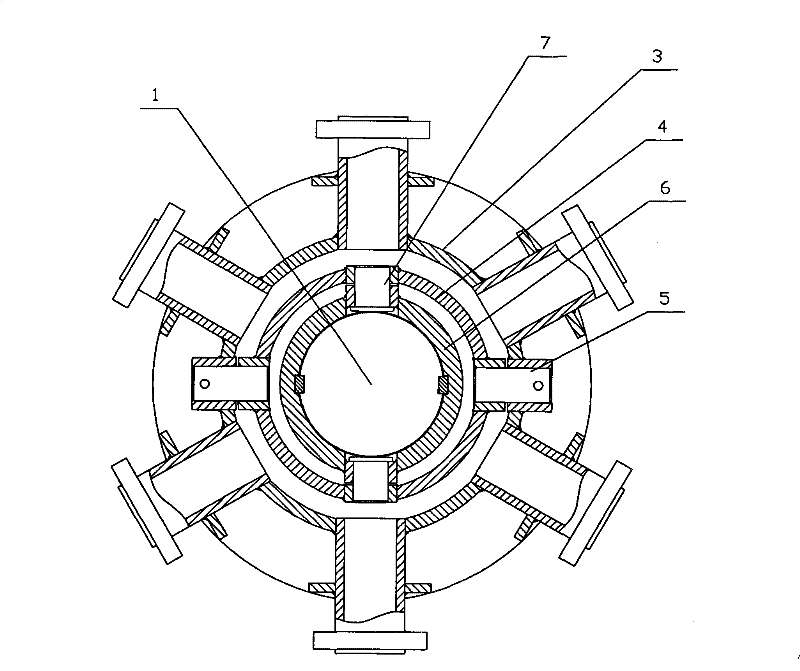

[0037] In conjunction with the accompanying drawings, the present invention will be described in detail below through specific embodiments.

[0038] In this embodiment, there are several circular tube-shaped samplers with ball valve seals. The system has a vertical main shaft 1, and a cross hinge 2 is fixed on the main shaft 1; Composition: the outer round tube 3 and the middle round tube 4 are flexibly connected by the pin 5, the middle round tube 4 and the inner round tube 6 are flexibly connected by the pin 7, and the directions of the two sets of pins 5 and 7 are orthogonal to form Cross hinge 2; a spindle hoop or positioning key for limiting the movement distance of cross hinge 2 is respectively arranged on the main shaft 1 above and below the cross hinge 2; several support frames 8 are fixed on the outer round tube 3 to support The ends of the frames 8 are supporting feet 9, and adjacent supporting frames 8 are connected by brackets.

[0039] The samplers are arranged v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com