Self-balancing rock full end face true three-axial compression test apparatus

A compression test, true triaxial technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of small measurement range, large test device size, and bulky instruments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] Below in conjunction with accompanying drawing, the present invention will be further described.

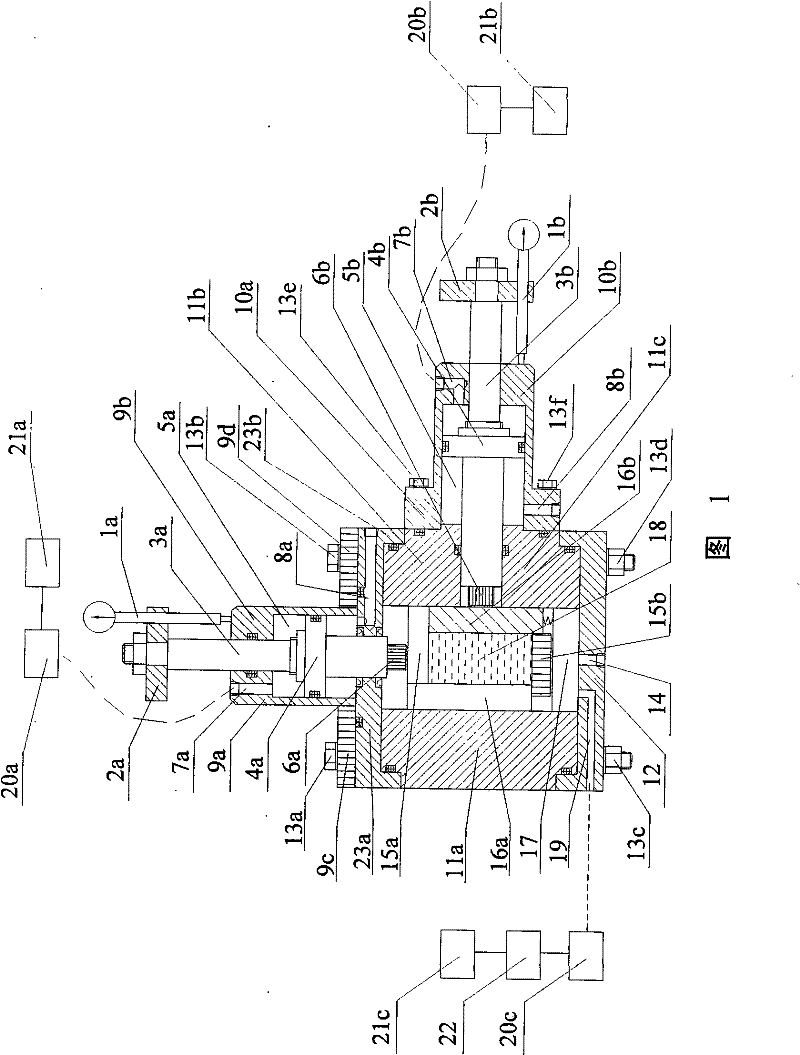

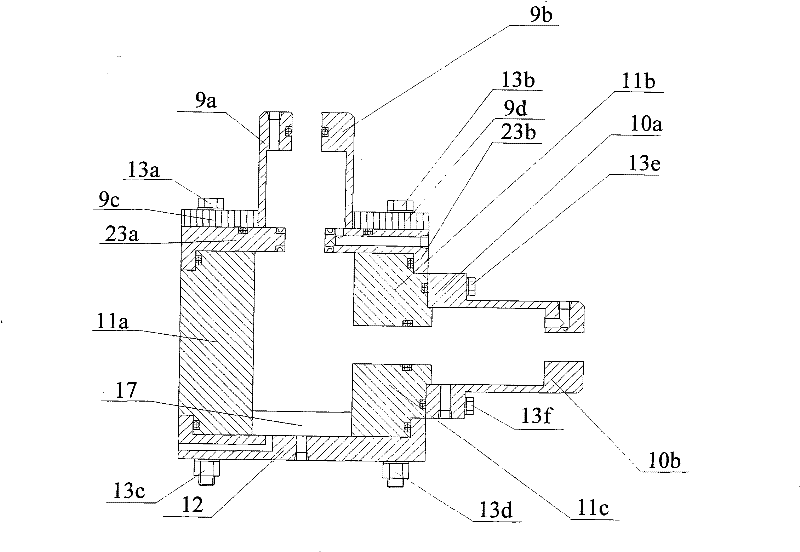

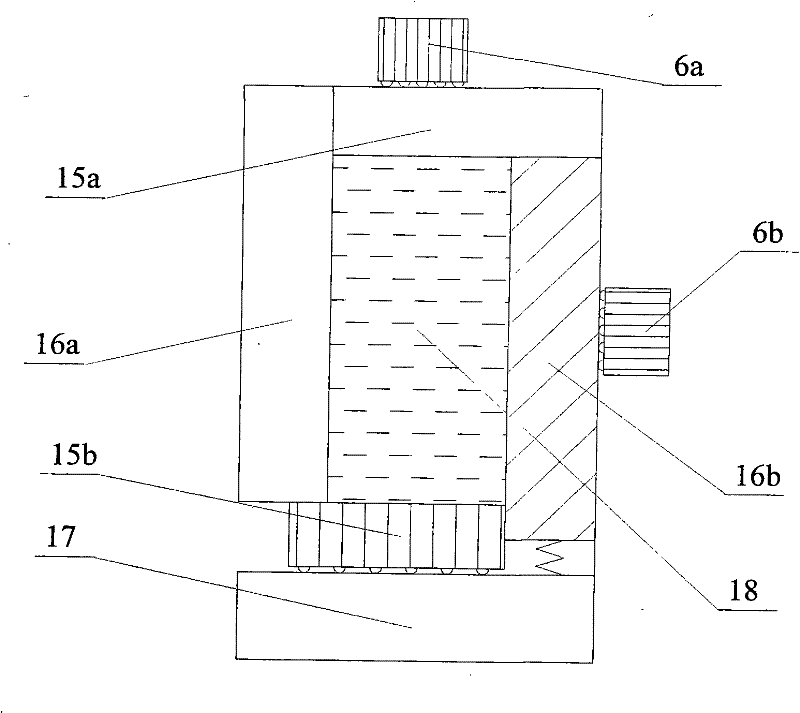

[0066] Depend on figure 1 , figure 2 , image 3 and Figure 4 It can be seen that the test device consists of a triaxial pressure chamber I, a "quadruple plate" mechanism II, σ 1 Loading transfer system III, σ 2 Load delivery system IV and σ 3 The loading transfer system V consists of, σ 1 The load transfer system III is located at the upper end of the triaxial pressure chamber I, through σ 1 The direction piston 3a is connected with the triaxial pressure chamber I; σ 2 The load transfer system IV is located at the side end of the triaxial pressure chamber I, through σ 2 The direction piston 3b is connected with the triaxial pressure chamber I; σ 3 The load transmission system V is connected to the triaxial pressure chamber I through the drain hole 14 and the water inlet hole 19; the "quadruple plate" mechanism II is located inside the triaxial pressure chamber I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com