Manufacture of varistors comprising a passivation layer

一种烧结抑制、陶瓷的技术,应用在电阻制造、电阻器、具有正温度系数的电阻器等方向,能够解决缺乏一致性等问题,达到提高产品产量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

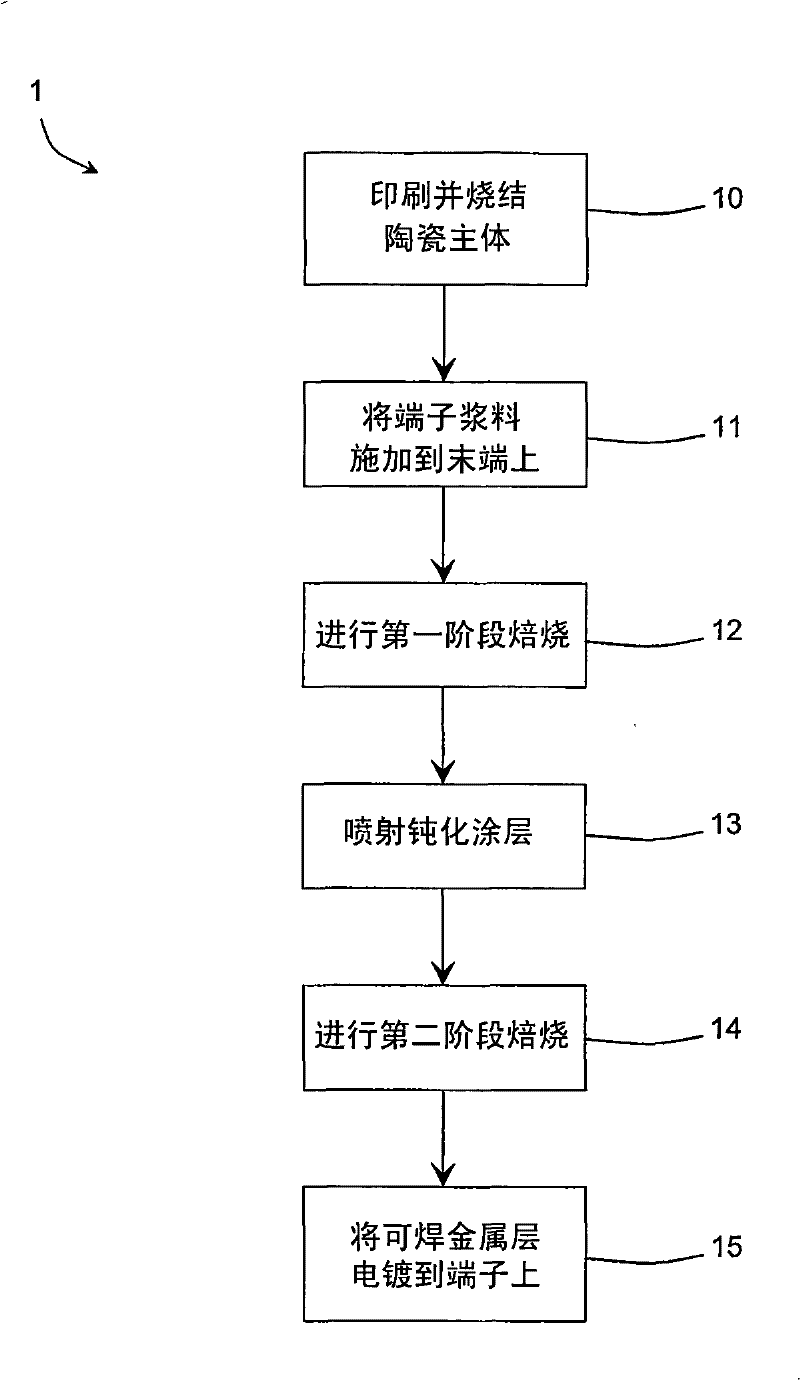

[0033] refer to figure 1 , which shows method 1 for manufacturing a varistor.

[0034] In step 10, a ZnO ceramic body with internal electrodes is fabricated by conventional fabrication techniques. In step 11, a terminal paste consisting of Ag, Pt, glass frit and a vehicle is applied by dipping the terminal into the paste. Adding Pt as a sintering inhibitor to the termination material (at a concentration range of 0.1wt% to 4.0wt%) is very advantageous as it helps to control the level of porosity by controlling the time / temperature of the firing process. The inhibitor is platinum, for example, it can be known in the commercial field as "platinum black" with 12-18m 2 / g specific surface area of platinum. In this embodiment, the terminal paste material includes 74wt% (Ag) and 1.5wt% (Pt), and the rest is glass frit and dielectric.

[0035] In step 12, the first stage is fired to a plateau temperature in the range of 420°C to 510°C, as shown in the graph of Figure 3(a). Figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com