Discharge lamp, particularly low-pressure discharge lamp

A technology for low-pressure discharge lamps and discharge lamps, which is applied to discharge lamps, gas discharge lamps, and parts of gas discharge lamps, etc., can solve the problems of not being equipped with debris protection UV protection or color effects, and not being able to use coloring or coloring, etc. Reliable debris protection and effective oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

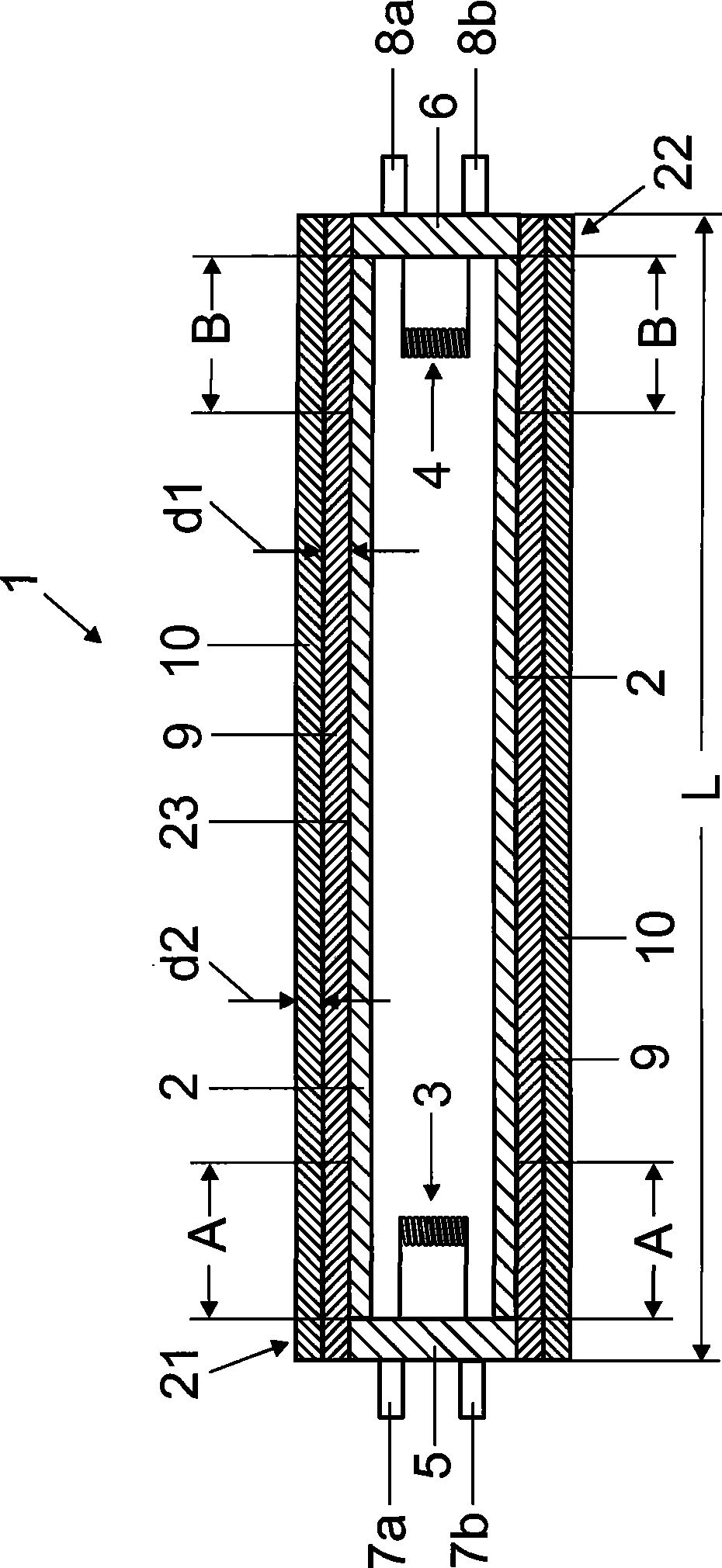

[0020] exist figure 1 A cross-sectional view of a low-pressure discharge lamp constructed as a fluorescent lamp 1 is schematically shown in . The fluorescent lamp 1 comprises a tubular discharge vessel 2 which can be, for example, a glass bulb. The electrodes 3 or 4 are respectively arranged on opposite end regions 21 and 22 of the discharge vessel 2 and are fastened to the associated base 5 or 6 . Two electrical contact rods 7a and 7b and 8a and 8b extend outwardly from the lamp caps 5 and 6, respectively. A first coating 9 is formed on the outer side 23 of the discharge vessel 2 . In the exemplary embodiment, the first coating 9 is a plastic made of polycarbonate, polyester, polymethyl methacrylate or polyolefin. The first coating 9 has at least one spectral filtering function for the light generated in the discharge vessel 2 . In particular, the first coating 9 is designed as a UV protection layer.

[0021] The first coating 9 extends over the entire length L, which in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com