Film spray no-back mixing column plate

A technology of mixing towers and spray hoods, which is applied in the field of membrane spraying non-return mixing trays, can solve the problems of unfavorable trays and reduce the driving force of gas-liquid mass transfer, so as to avoid liquid back mixing, improve the driving force of mass transfer and tower The effect of plate efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

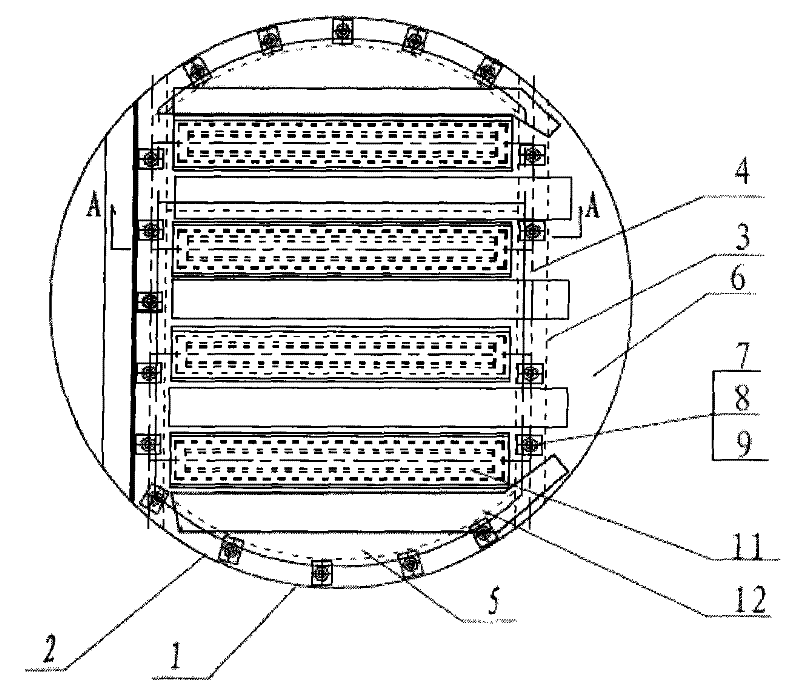

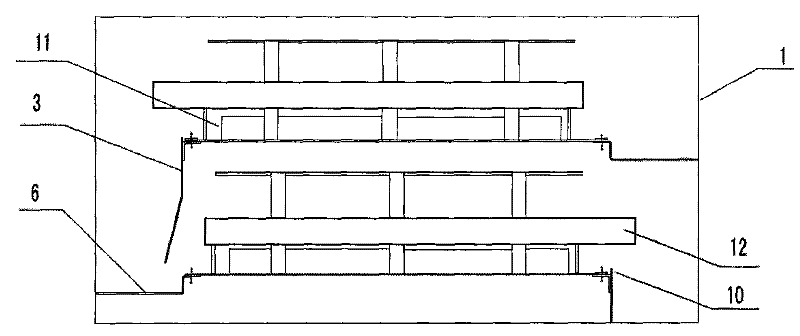

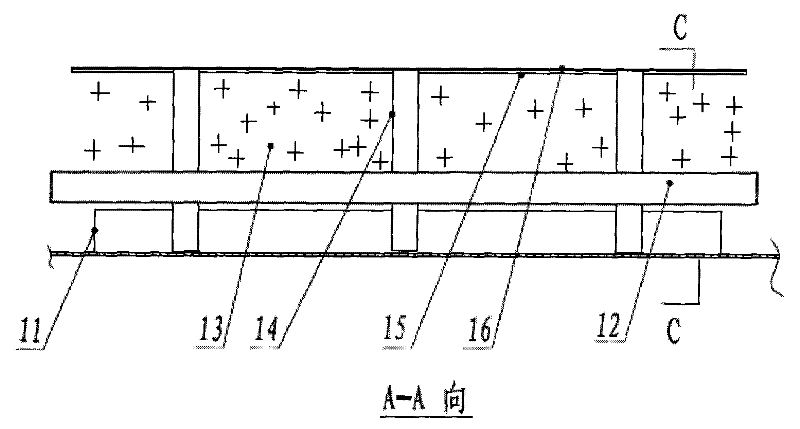

[0011] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof:

[0012] The film spraying of the present invention design has no back-mixing tray (abbreviation tray, see Figure 1-4 ), horizontally installed in the tower shell 1, including the spray cover, the tray ring 2 and the downcomer plate 3, the tray 5 is provided with air holes and the air riser 11 is installed, and the downcomer plate 3 and the tray 5 are formed The downcomer 6 is fixed with the top cover 16 through the support plate 14 at the position corresponding to the air hole of the tray 5, and there is a gap between the bottom of the spray cover and the tray 5, and the gap forms a passage for the liquid to enter the spray cover. The two side walls of the spray cover are provided with spray holes 13, which are characterized in that the gas rise holes on the tray 5 are rectangular, and the gas rise holes are welded with a rectangular gas riser 11, the gas rise...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap