0 degree belt edge filter of all steel radial tire and its preparation technique and tire using the same

A radial tire and belt layer technology, applied in the field of all-steel radial tires, can solve problems such as tire shoulder damage, achieve the effects of less stress concentration, simplify the process, and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

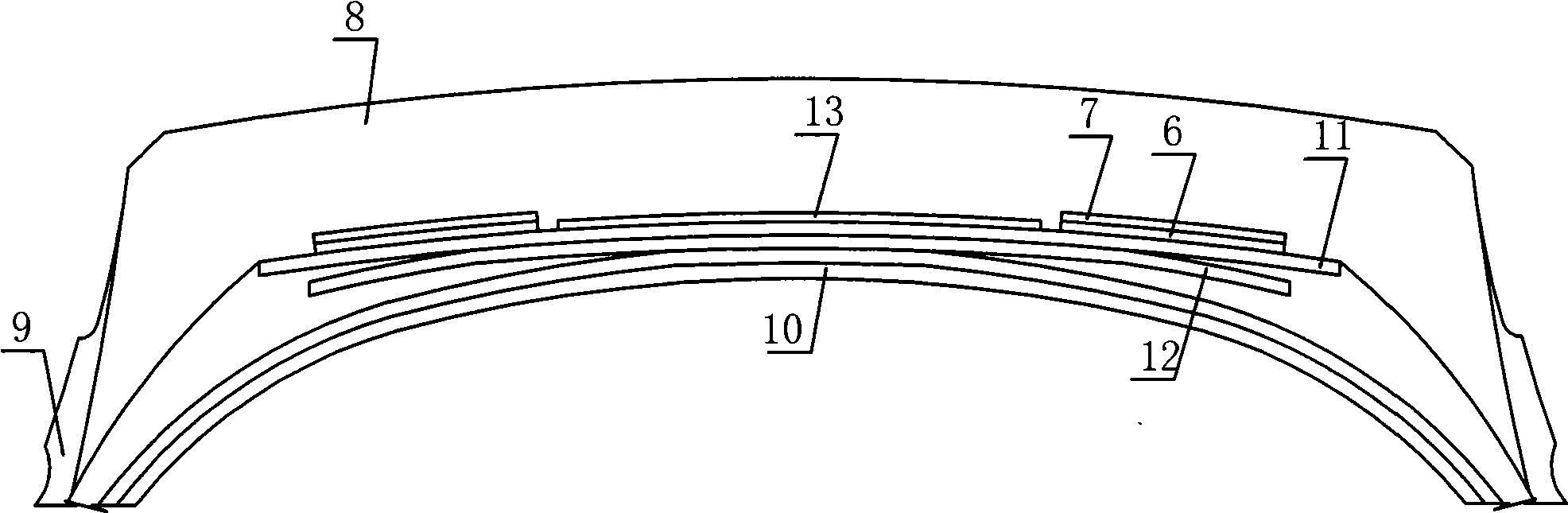

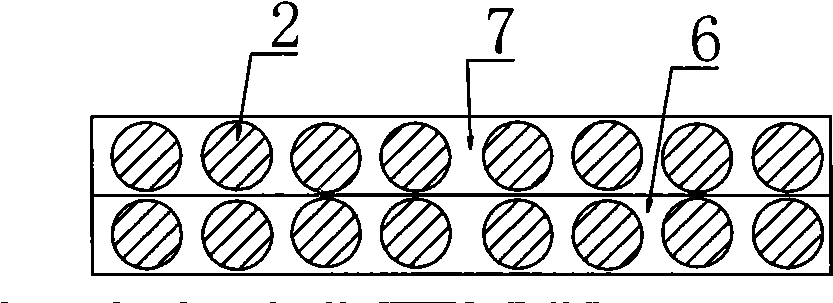

[0022] Such as figure 2 The shown all-steel radial tire includes a table portion 8, a sidewall portion 9, a bead portion and a ply 10, and the outside of the ply 10 is sequentially 1# belt layer 12, 2# belt layer 11 and 0# Degree belt layer 6,7, 0 degree belt layer 6,7 middle part is 3# belt layer 13. Such as image 3 As shown, the 0° belt layers 6 and 7 include two layers, respectively an inner layer 6 and an outer layer 7, and the two layers of 0° belt layers are formed by winding two layers of the same extruded rubber-covered steel wire 2, each Layer steel wire 2 is wound 8 turns.

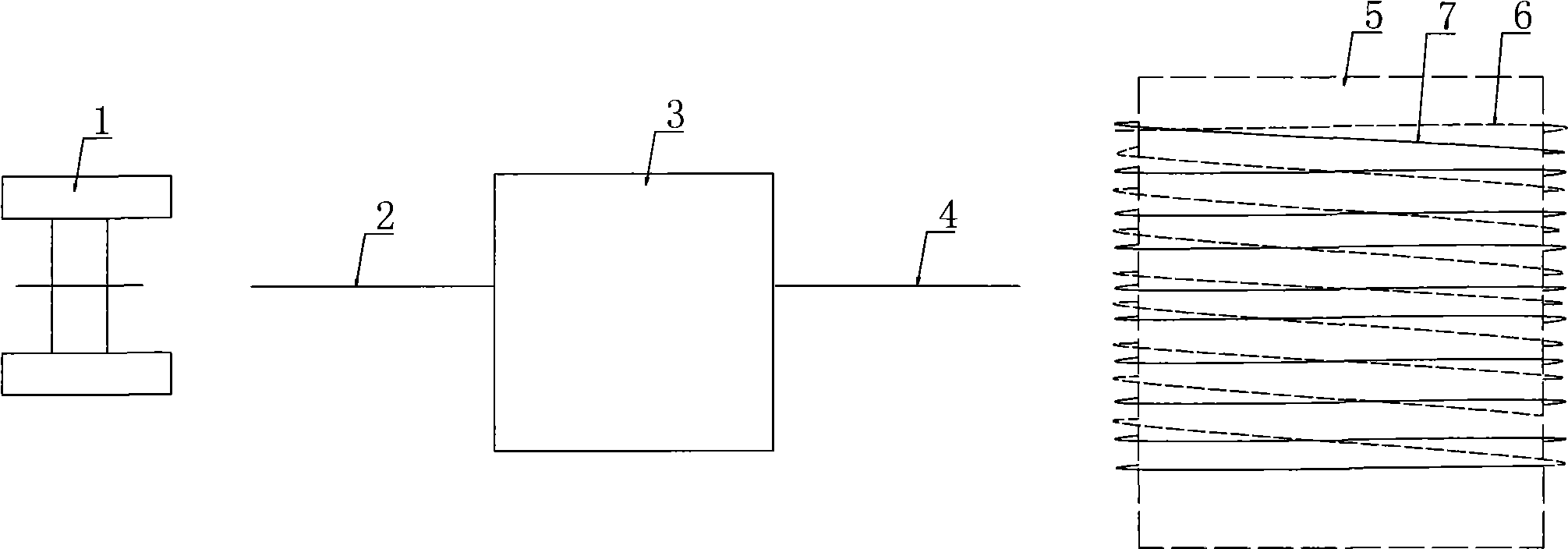

[0023] Such as figure 1 The process of the 0° belt layers 6 and 7 shown is as follows: the steel wire 2 is guided from the spindle 1, and the steel wire 2 is extruded through the rubber coating machine 3 to be coated with rubber, and then cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com