Special-shaped concrete pipe

A concrete pipe pile and special-shaped technology, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering, can solve the problems of collapsed holes, high cost of semi-rigid pile-soil composite foundation, and affecting the quality of the foundation, so as to increase the surface area and increase the quality of the foundation. Large bearing capacity and the effect of reducing the amount of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

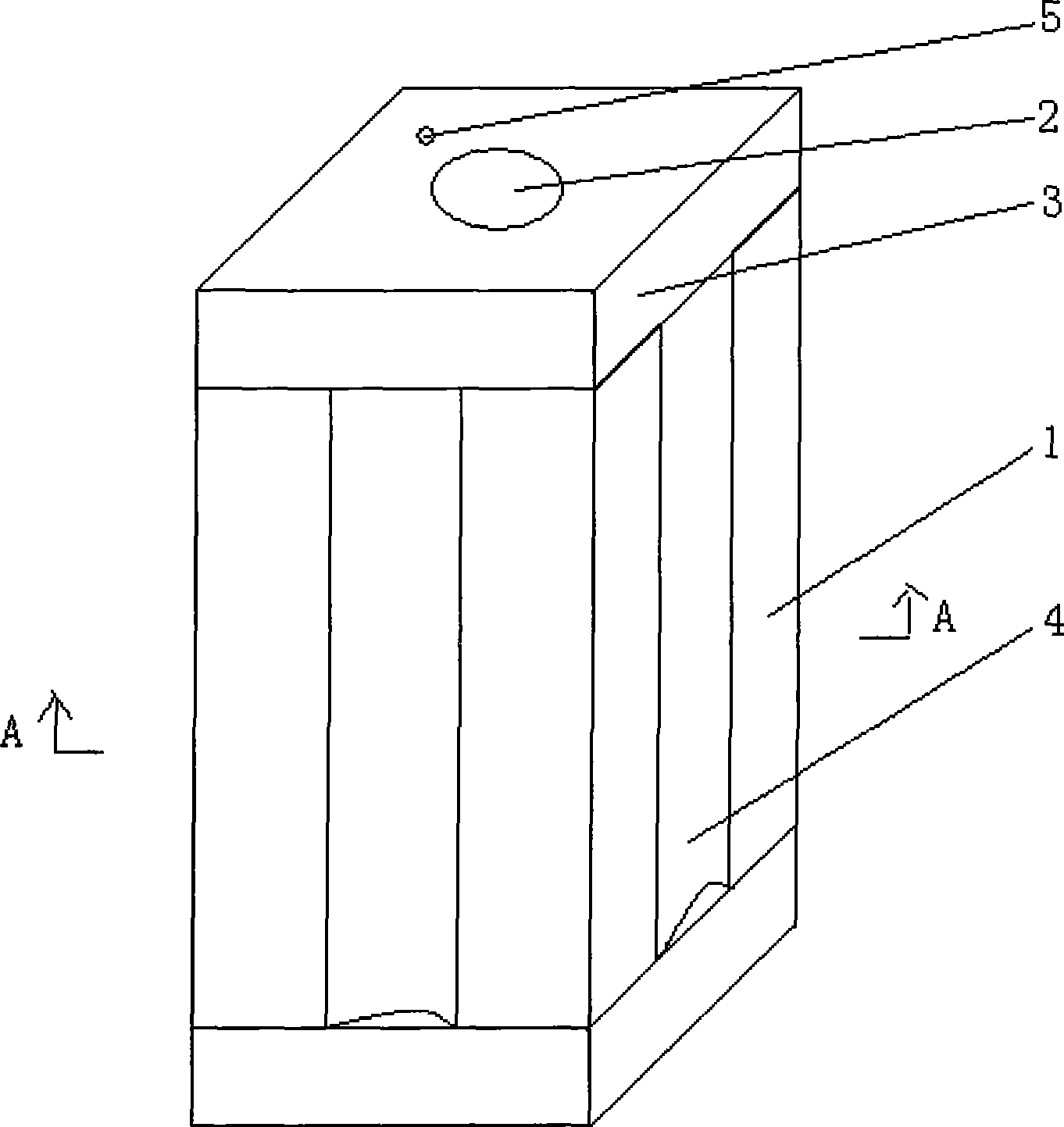

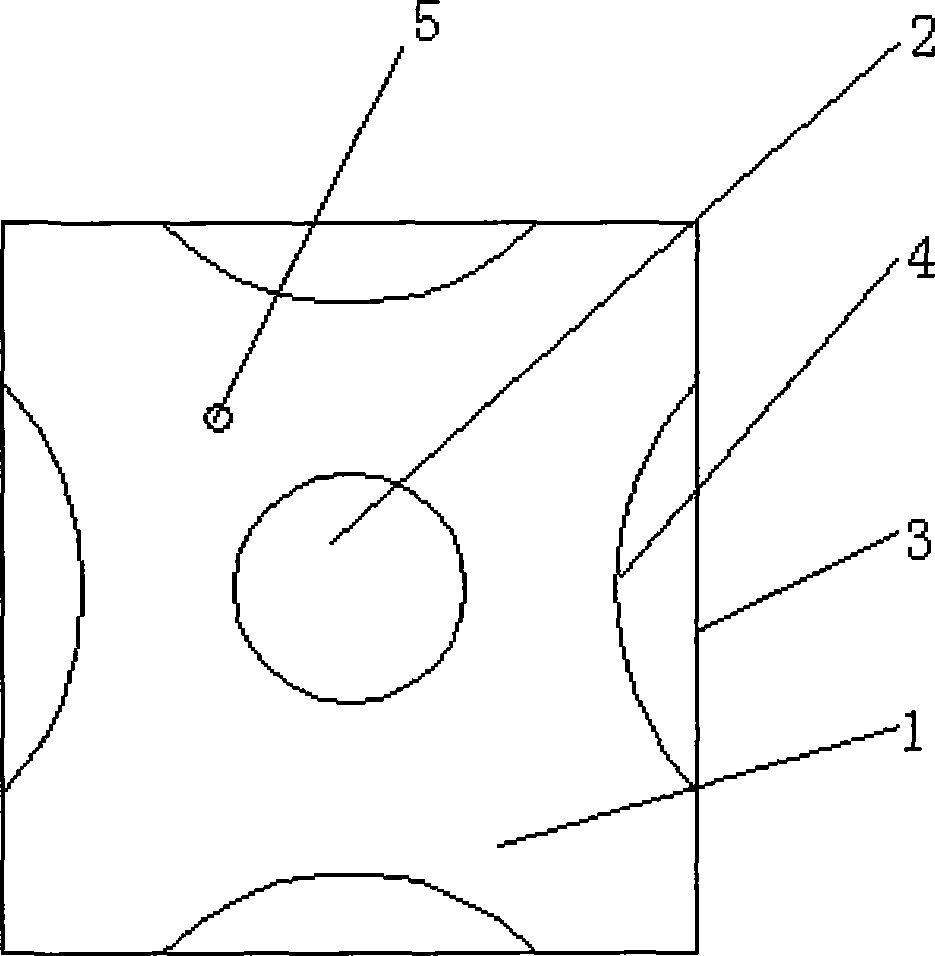

[0015] like figure 1 , 2 As shown, a special-shaped concrete pipe pile includes a central hole 2 arranged coaxially with the pile body 1 , and end plates 3 arranged at both ends of the pile body 1 .

[0016] still as figure 1 , 2 As shown, grooves 4 are coaxially arranged on the pile body 1 between the end plates 3 . like figure 2 As shown, the cross section of the pile body is rectangular, the cross section of the groove 4 is semicircular, and the groove 4 is symmetrically arranged on the surrounding surface of the pile body 1 .

[0017] like figure 1 , 2 As shown, a grouting hole 5 is coaxially arranged on one side of the central hole 2 of the pile body 1 .

Embodiment 2

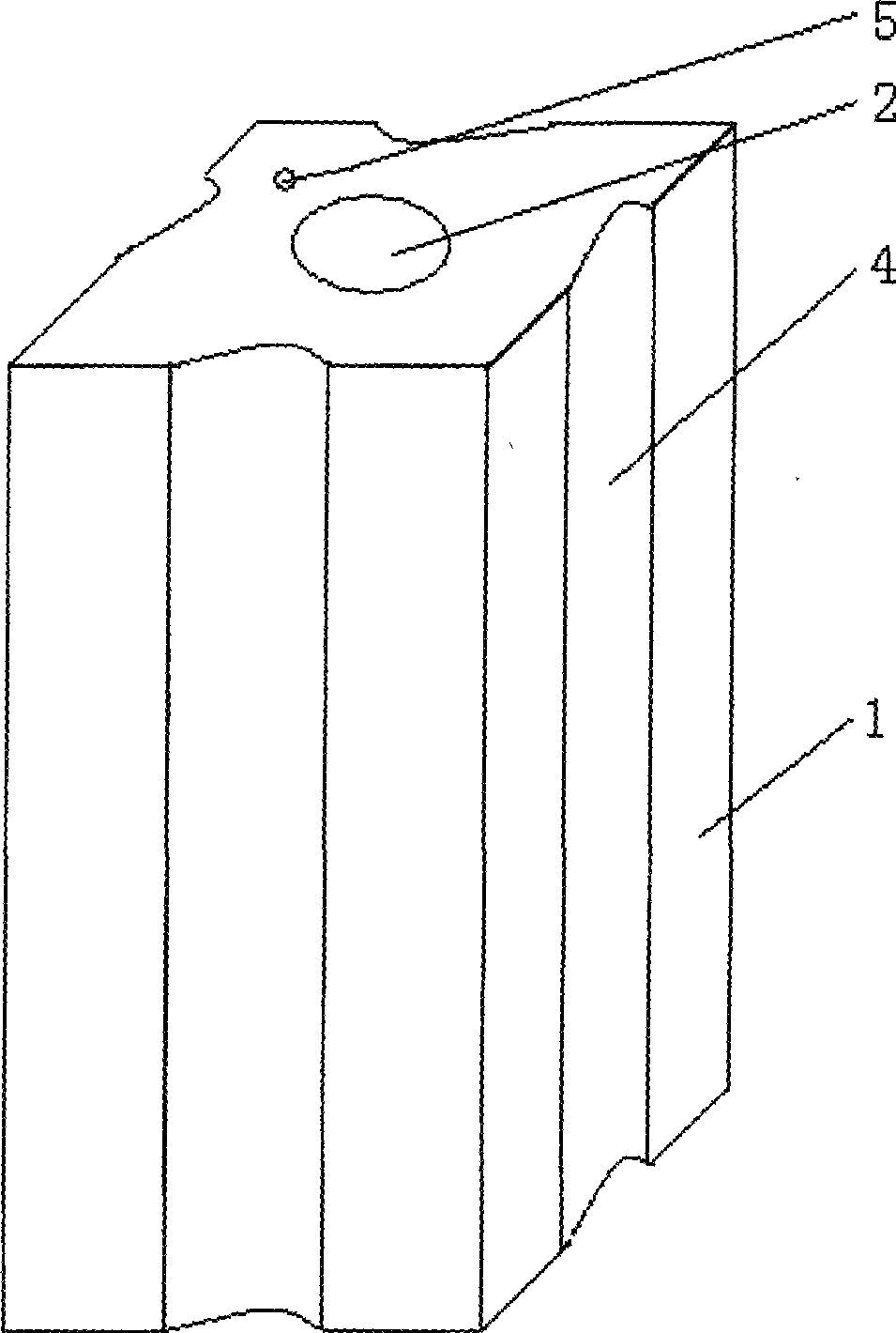

[0019] like image 3 As shown, a special-shaped concrete pipe pile includes a central hole 2 arranged coaxially with the pile body 1, and a groove 4 is arranged coaxially on the pile body 1, and the groove 4 is symmetrically arranged on the surrounding surface of the pile body 1.

[0020] All the other implementations are as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com