High precision dynamic weighing method and high precision dynamic weighing instrument

A dynamic weighing, high-precision technology, applied in the field of metrology, can solve the problems of low weighing accuracy, lost data, lost axes, etc., and achieve the effect of solving low dynamic measuring accuracy and fair work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

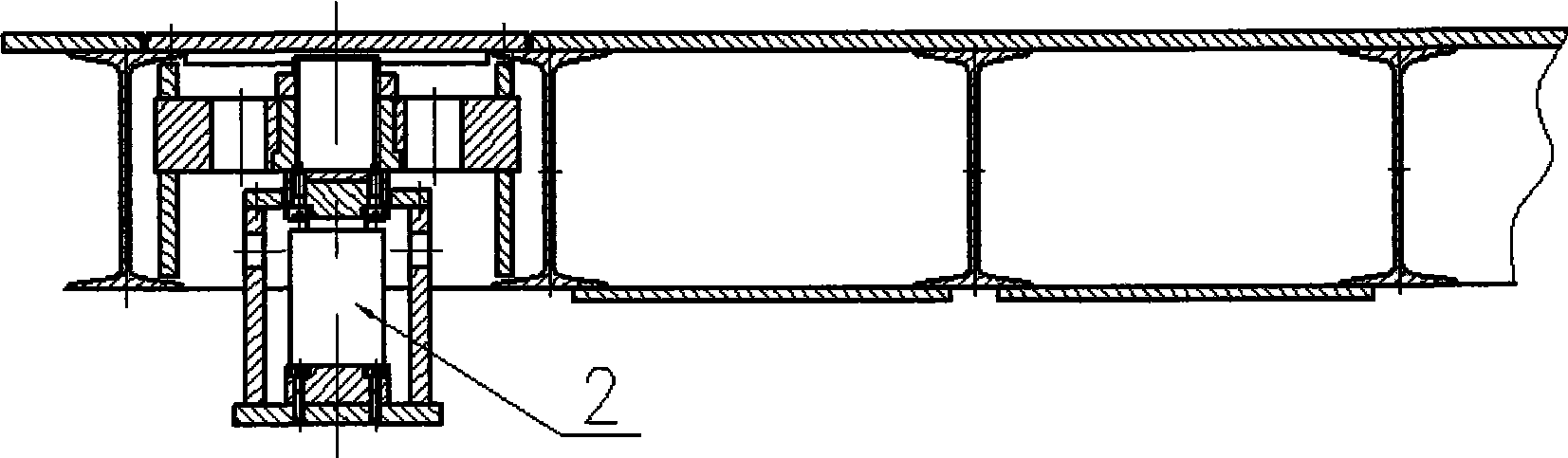

[0014] A high-precision dynamic weighing method, which is to fix the load cells at the four corners of the scale body, and the load cells located at the four corners of the scale body are respectively connected to the data processor, and the data processor changes the force of each point of the four corners of the scale body respectively. The analysis, real-time calculation of the position of the axle on the scale body, and accurate judgment of the wheelbase, number of axles, axle load, and total weight.

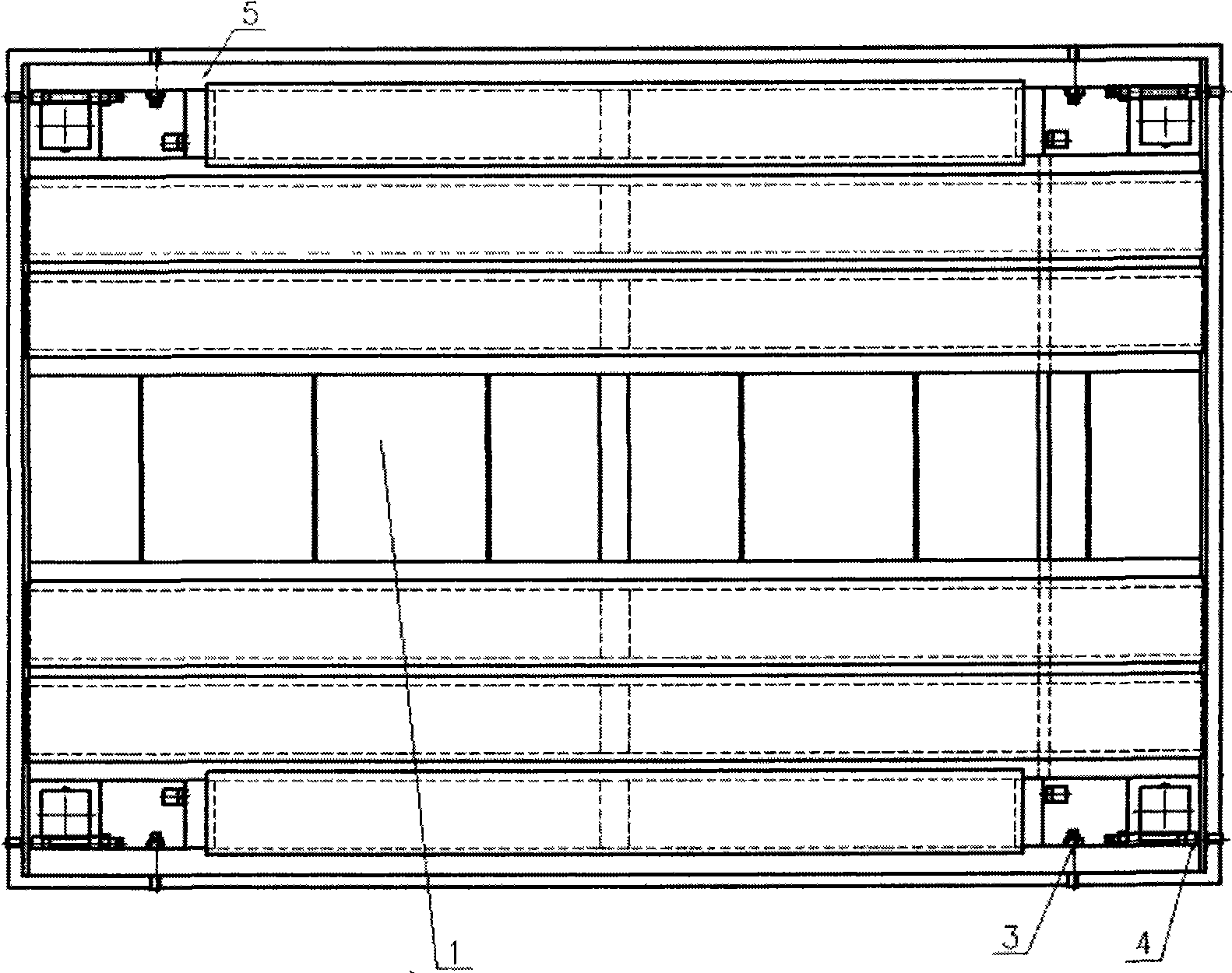

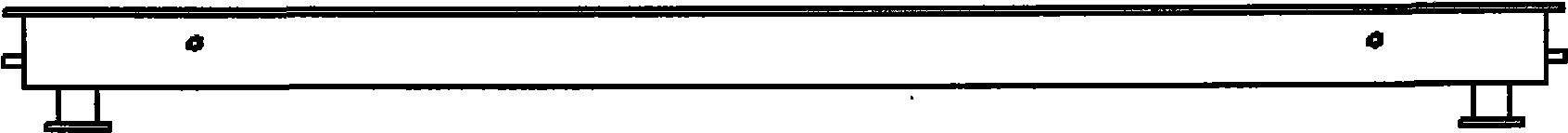

[0015] Such as Figure 1-3 As shown, the high-precision dynamic weighing instrument realizing the above method has a scale body 1 carrying a vehicle, and load cells 2 are installed at the four corners of the scale body 1, and the load cells 2 are respectively connected to the data processor. The four corners of the scale body 1 adjust the gap with the frame 5 through the horizontal limit screw 3 and the vertical limit screw 4, and the scale body has a length of 3.6-4.2 meter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com