Strong test method for peeling adhesive bonding sample of sealant and substrate

A technology of peel strength and testing methods, applied in the direction of measuring devices, analysis materials, instruments, etc., to achieve significant guidance and reference value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

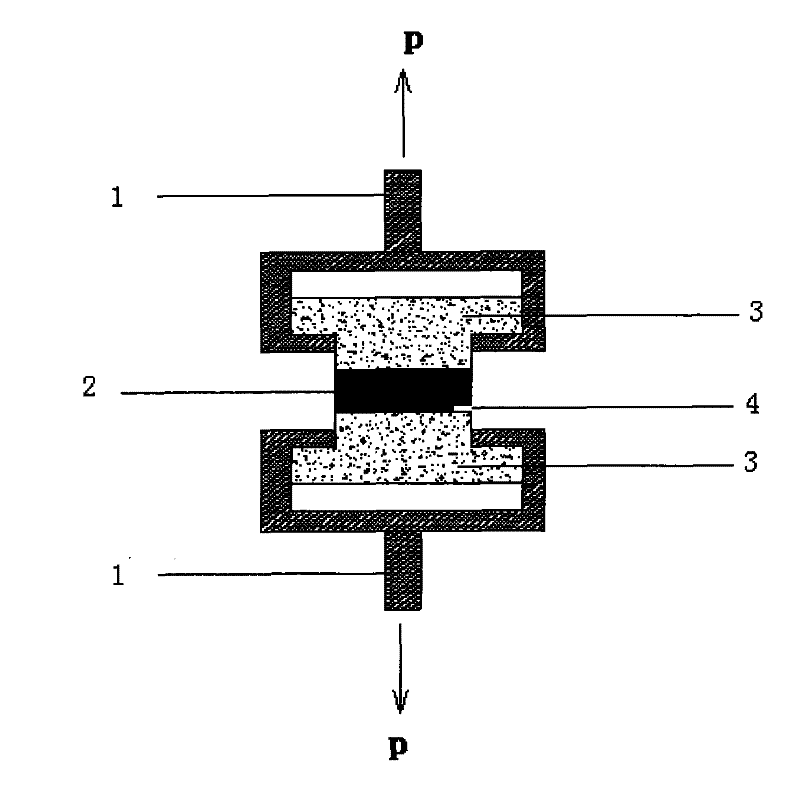

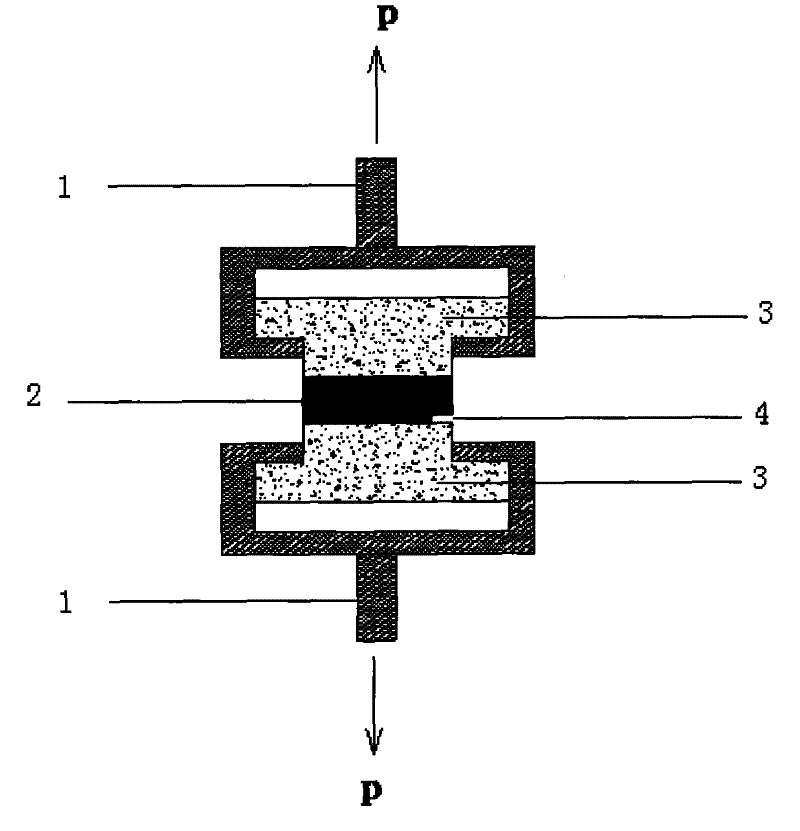

[0011] Referring to Fig. 1, according to the technical scheme of the present invention, the concrete 3 is made into two T-shaped samples, and a gap cavity of a certain size is reserved in the middle of the two T-shaped samples, and the sealant 2 is poured into the gap cavity, so that the concrete And the sealant becomes a bonded sample as a whole, and the bonded sample is maintained in an environment with a temperature of 20±2°C and a relative humidity of 65±5% for 28 days.

[0012] During the test, use a sharp blade to cut a hole whose length is not more than one-tenth of the total length of the joint interface as the peeling port 4 on the bonding surface of the sealant 2 and the concrete 3, and place the two ends of the concrete 3 in the fixture 1 respectively , connect fixture 1 to the tension machine, start the tension machine at a rate of 5mm / min, and stretch fixture 1 in the opposite direction until the sealant 2 and concrete 3 are completely peeled off. At this time, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com