Connector

A connector and cable connection technology, applied in the direction of connection, bipolar connection, conductive connection, etc., can solve problems such as lack of reliability, and achieve the effect of improving the reliability of crimp connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

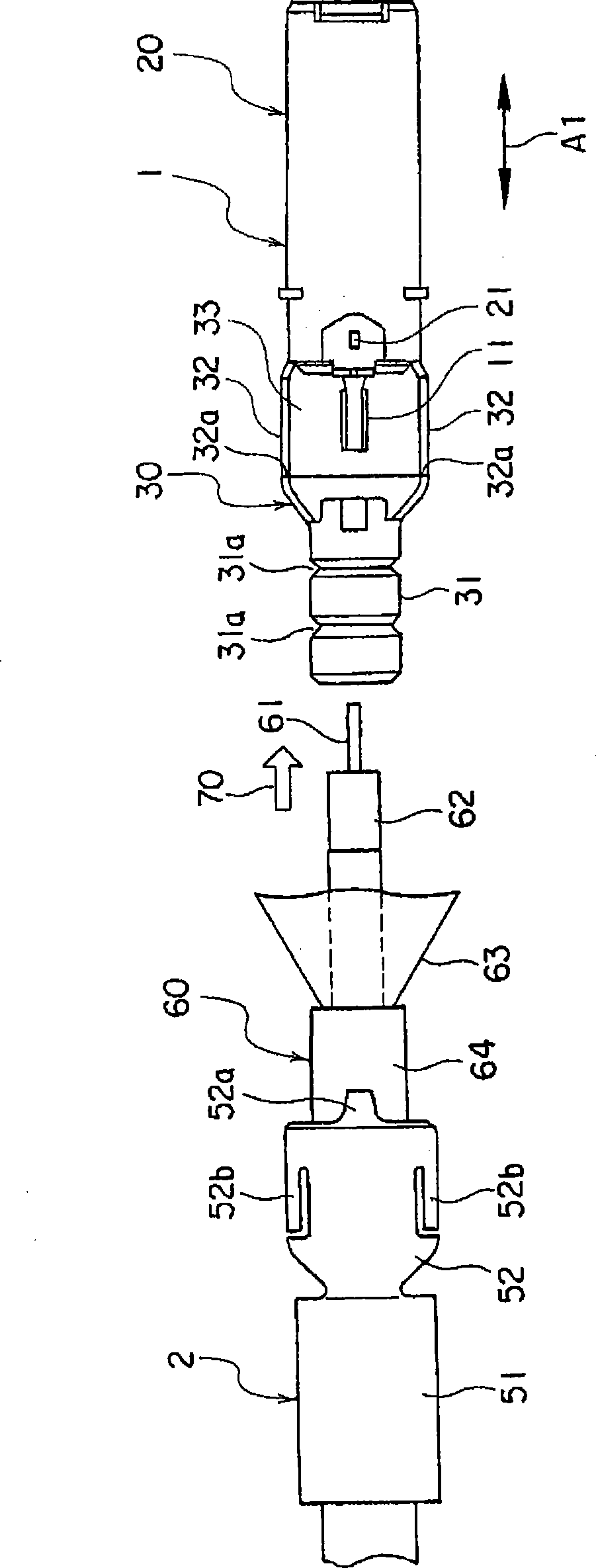

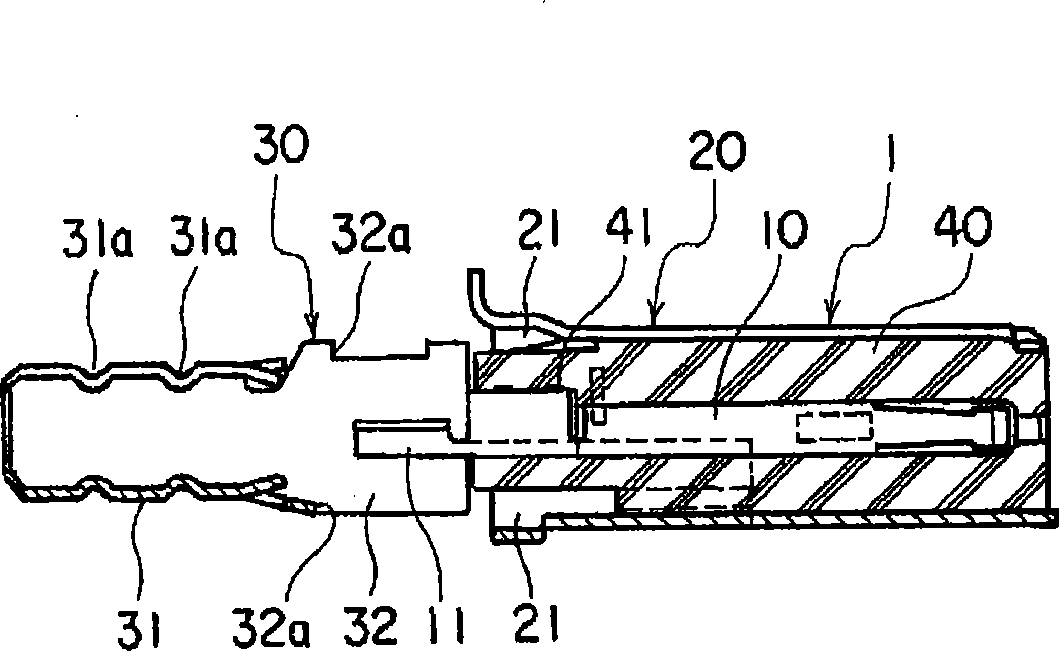

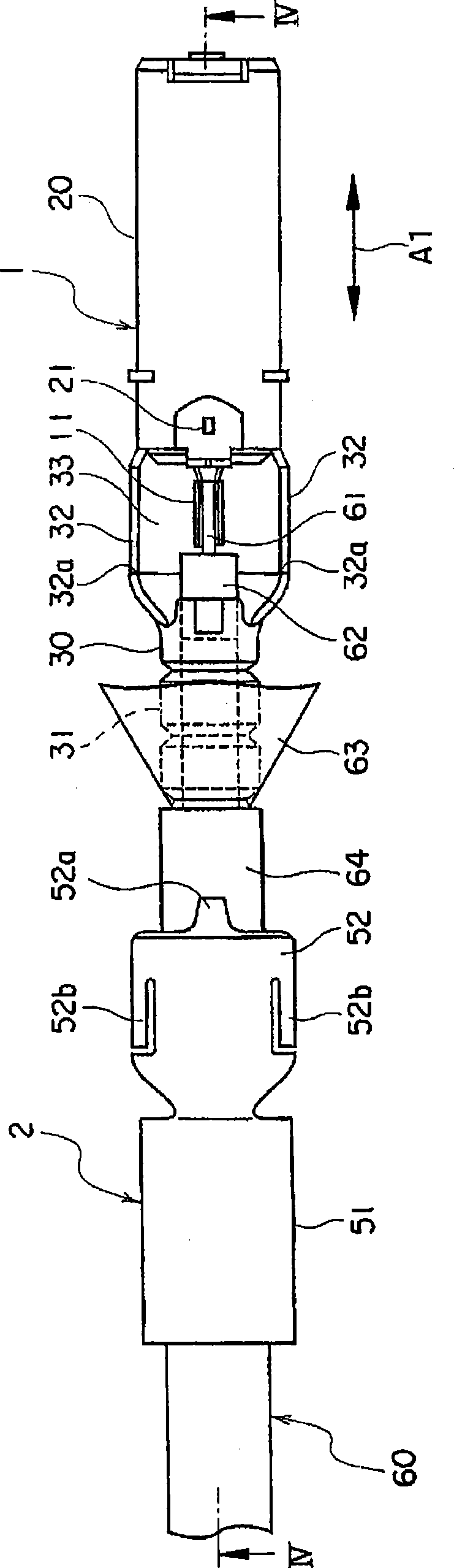

[0026] refer to figure 1 and figure 2 , the connector according to the exemplary embodiment of the present invention and the shielded electric wire connected thereto will be described.

[0027] The illustrated connector is a coaxial connector and includes a coaxial unit 1 as a connector body and a crimping member 2 as an auxiliary part for connecting a coaxial cable 60 as a shielded electric wire to the coaxial unit 1 . The coaxial unit 1 includes an insulating housing 40, a conductive signal contact 10 held at the center of the housing 40 by a contact holder 41, a conductive shielding outer cylinder 20 wrapped around the housing 40, and a shielding outer cylinder 20 made of Integral outer conductor 30. The shielding outer cylinder 20 has a positioned portion 21 near the outer conductor 30 .

[0028] The outer conductor 30 has a substantially cylindrical shield connection portion 31 and a pair of flat plate-shaped shield pieces 32 extending from the axial end of the shield...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com