A novel ball water-boiling machine

A technology of water boiling machine and meatballs, which is applied in application, food preparation, food science, etc., can solve the problems of increasing labor intensity of workers, the boiling temperature cannot be automatically controlled and regulated, and cannot replace the operation mode, etc., so as to reduce the labor intensity of workers , The effect of improving the boiling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

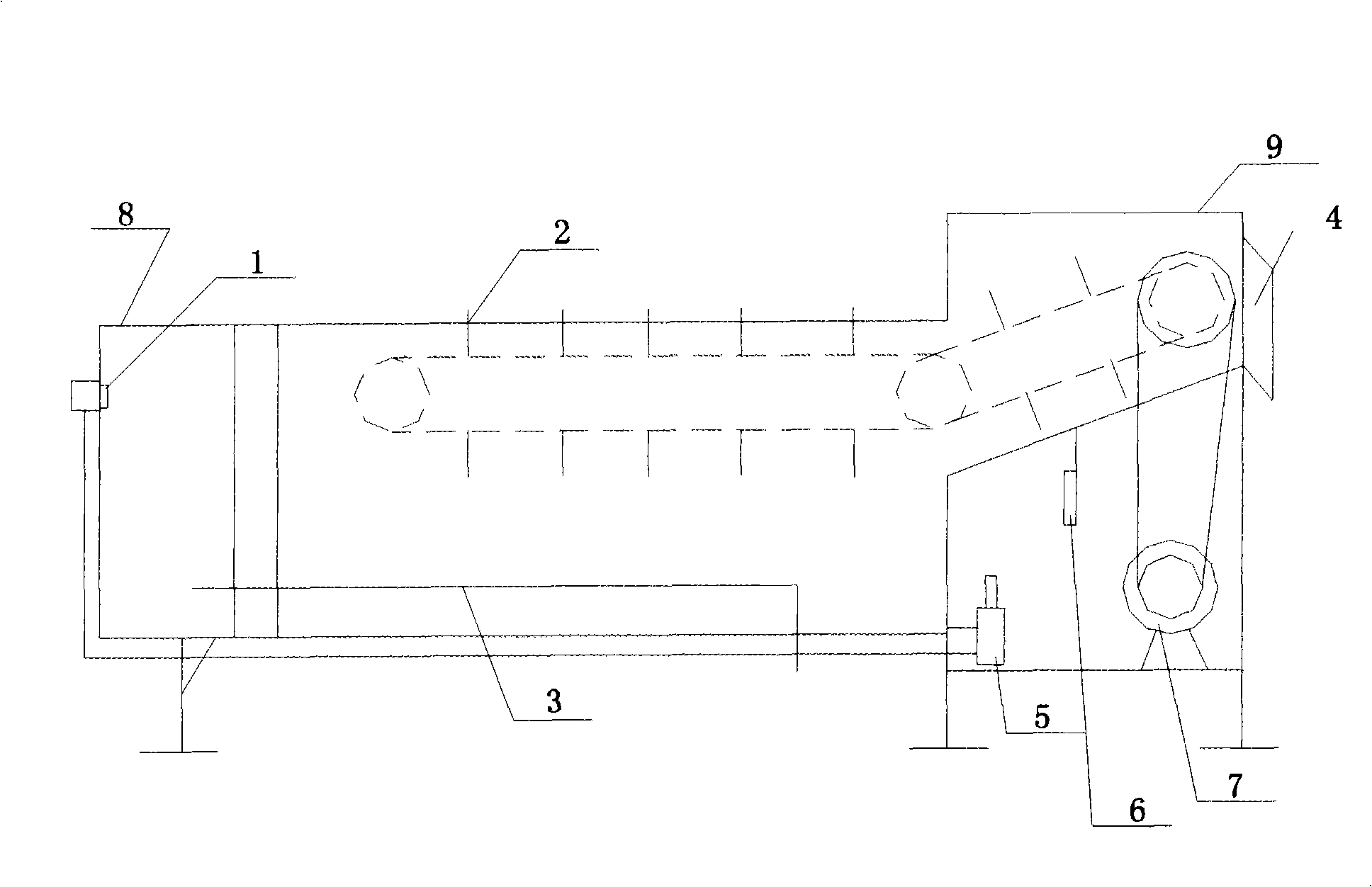

[0008] This specific embodiment adopts a technical solution: it is composed of a hot water distribution box 1, a scraper 2, a steam pipeline 3, a chute 4, a hot water circulation pipeline pump 5, a cooling fan 6 and a motor reducer 7; The box 1 is set under the inlet 8, the scraper 2 is set on the right side of the hot water distribution box 1, the steam pipe 3 is set under the scraper 2, the chute 4 is set under the outlet 9, and the hot water circulation pipeline pump 5 It is arranged on the left side of the cooling fan 6, and the motor reducer 7 is arranged on the right side of the cooling fan 6. It can be used for the purpose of automatic boiling, transportation and transportation of meatballs, which can reduce the labor intensity of workers, improve the efficiency of boiling, and can replace the boiling operation mode. It adopts stainless steel mesh belt conveying, and the conveying speed of the mesh belt is steplessly adjustable. The temperature is automatically controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com