Building embedded part

A technology of pre-embedded parts and construction, which is applied in the field preparation of construction and building components, building construction, etc. It can solve the problems affecting the appearance of the wall, and achieve the effect of maintaining the overall appearance and maintaining the appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

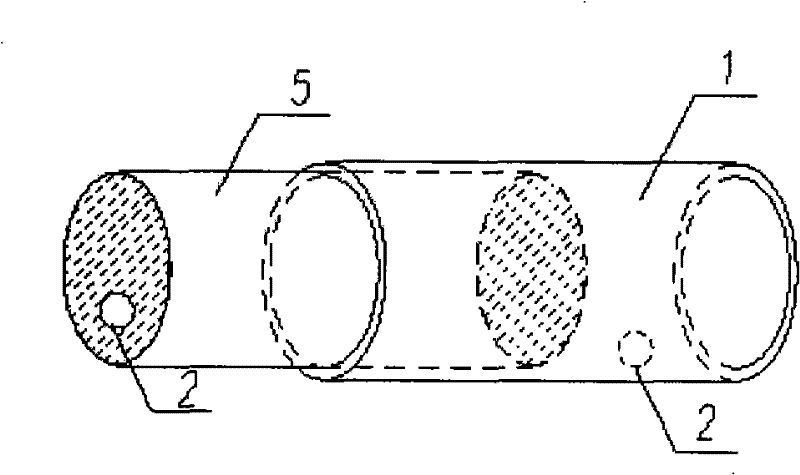

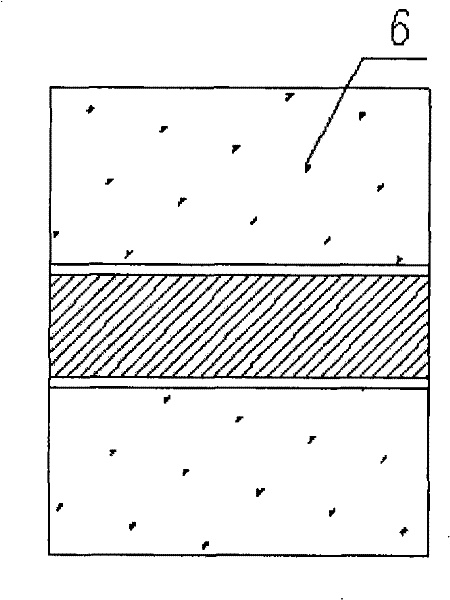

[0021] refer to figure 1 , The building embedded part is composed of a shell 1 with a channel, a filler 5 and a magnetic steel 2 located in the channel. The filler 5 is located in the channel of the casing 1 and can be drawn out from the casing 1 . The magnetic steel 2 is arranged on the filler 5 or on the casing 1 . refer to image 3 , the embedded part is pre-buried in the wall or beam 6. After the construction is completed, there is no need to take out the embedded part. The surface of the wall 6 can be painted and decorated normally without affecting the surface treatment of the wall or beam 6. When it is necessary to install the pipeline, the position of the embedded part can be known only by detecting the magnetic steel 2 left in the embedded part through the detector, and the filling 5 in the channel of the embedded part can be taken out to proceed. The plumbing is installed.

Embodiment 2

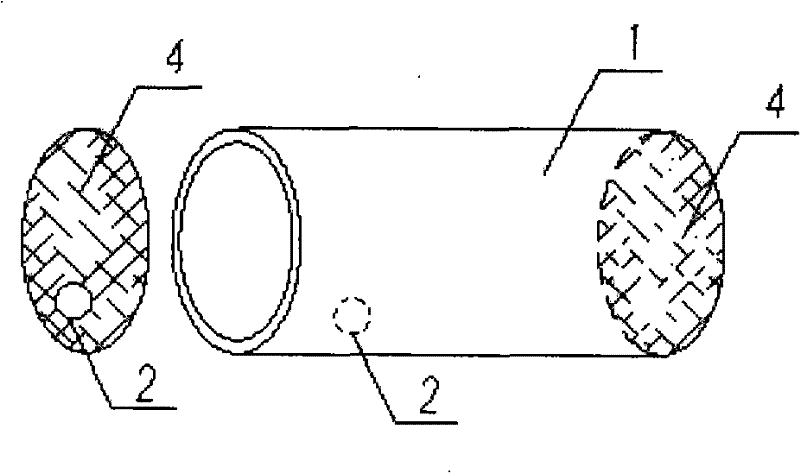

[0023] refer to figure 2 , The building embedded parts are composed of a shell 1 with a channel, end plates 4 and magnetic steel 2 at both ends of the channel. The end plate 4 can be removed freely, and the magnetic steel 2 is arranged on the end plate 4 or on the shell 1 . refer to Figure 4 , the embedded part is pre-buried in the wall or beam 6, after the construction is completed, there is no need to take out the embedded part, the surface of the wall 6 can be painted or decorated normally, without affecting the surface treatment of the wall or beam 6. When it is necessary to install the pipeline, the position of the embedded part can be known only by detecting the magnetic steel 2 left in the embedded part, and then the end plates 4 at both ends of the channel in the embedded part can be removed to proceed. The plumbing is installed.

Embodiment 3

[0025] refer to Figure 5 , The building embedded part is composed of a shell 1 provided with two channels, a filler 5 and a protrusion (or rope) 3 located in the two channels. The filler 5 can be extracted from the channel of the shell 1, and the embedded parts are pre-buried in the wall or beam 6. After the construction is completed, there is no need to take out the embedded parts. When the surface of the wall 6 is painted or decorated in the normal way, the A small part of the protrusion (or rope) 3 stretches out of the body of wall or the beam 6, which can be observed with the naked eye, and does not affect the overall appearance of the body of wall 6. When it is necessary to install the pipeline, the position of the embedded part can be known according to the protrusion (or rope) 3 observed by the naked eye, and then installed according to the user's requirements for the number of pipelines. When the user needs to install two pipes at the same time, he only needs to take...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com