Magazine device

A storage box and conveying device technology, used in packaging, transportation and packaging, thin material handling, etc., can solve problems such as failures, limit the maximum capacity of reserve storage boxes, etc., and achieve the effect of improving loading and conveying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

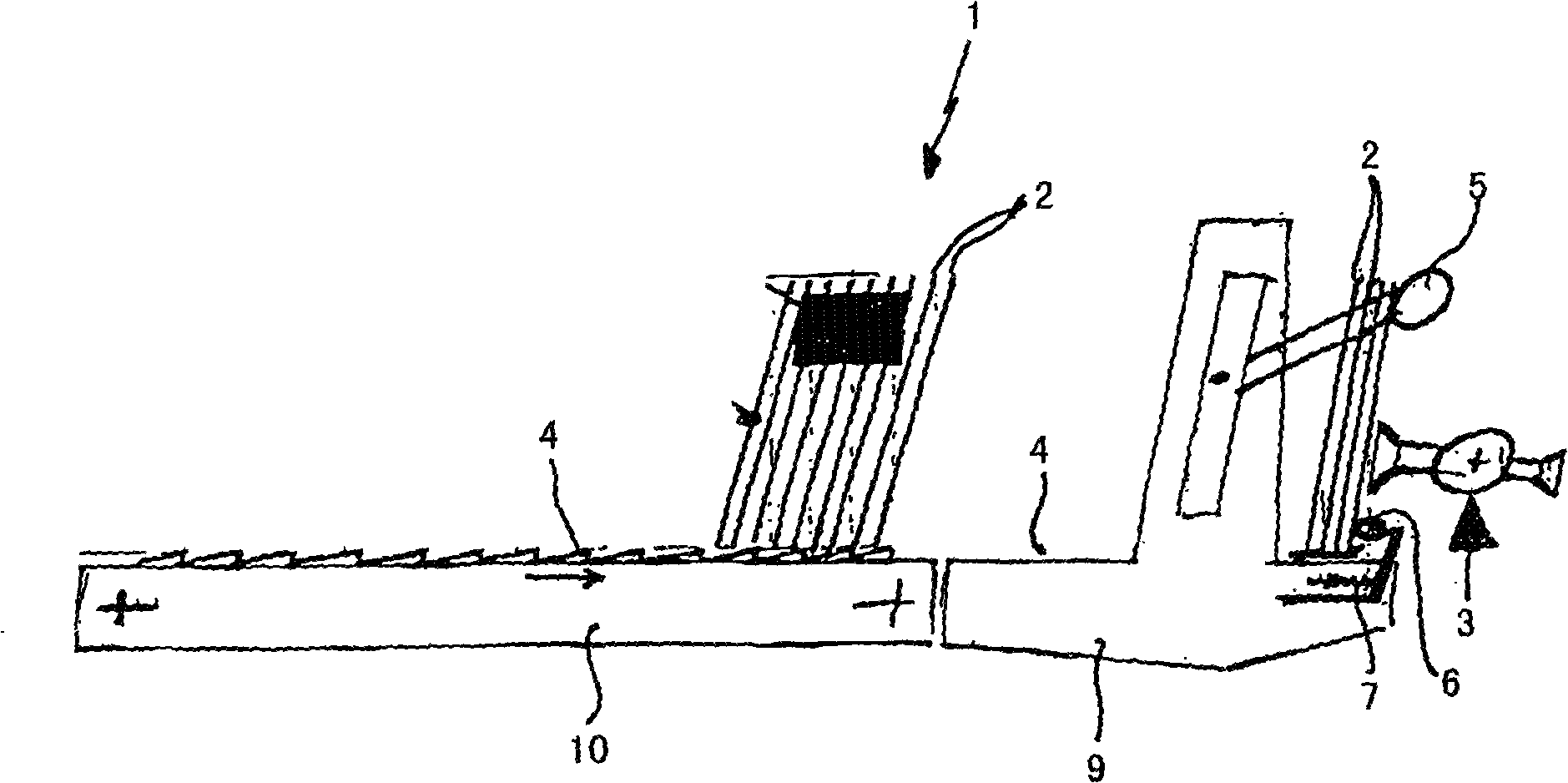

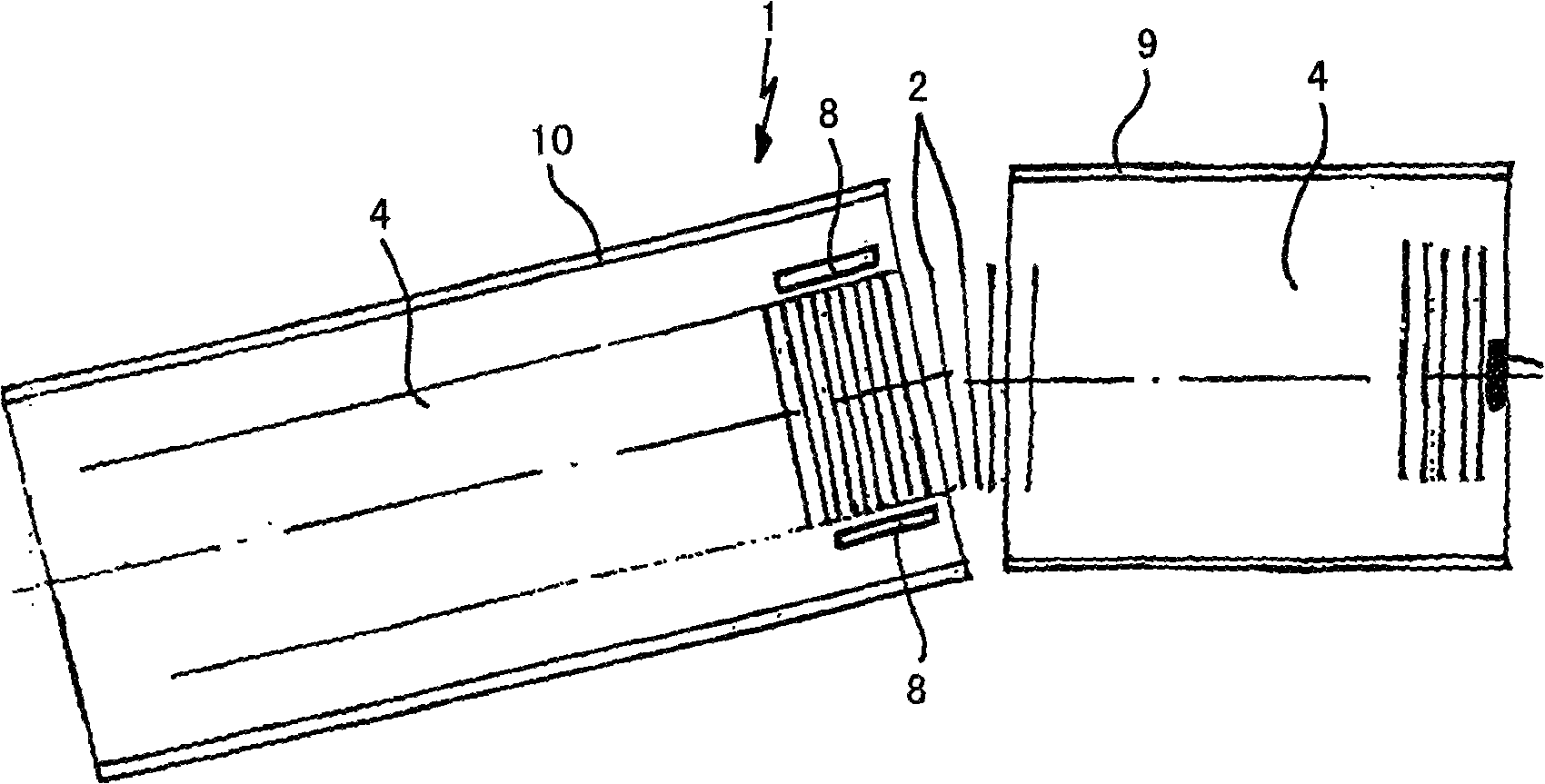

[0018] exist figure 1 and figure 2 The magazine arrangement indicated generally at 1 is shown in detail in . The magazine arrangement serves to store and transport a series of flat elements made of cardboard, for example blanks 2 . A removal device, indicated generally at 3 , in the form of a vacuum gripper removes the blanks 2 at the end of the device 1 in order to feed these blanks to the packaging machine. The blanks 2 are placed upright on the conveyor chain 4 in the region of the magazine part 10 of the device 1 and moved along the conveying direction of the chain 4 until they abut against the blanks 2 already present. The inclination of the individual links of the conveyor chain 4 in the conveying direction makes it possible to easily move in this direction and at the same time prevent the lower parts of the elements from slipping away.

[0019] In the region of the vacuum gripper 3 there is provided a stop 5 against which the blank 2 rests with its upper edge. At t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com