Platform modules as a pallet, flooring, formwork or stand

A platform and flat technology, applied in packaging, construction, floors, etc., can solve problems such as complex construction and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

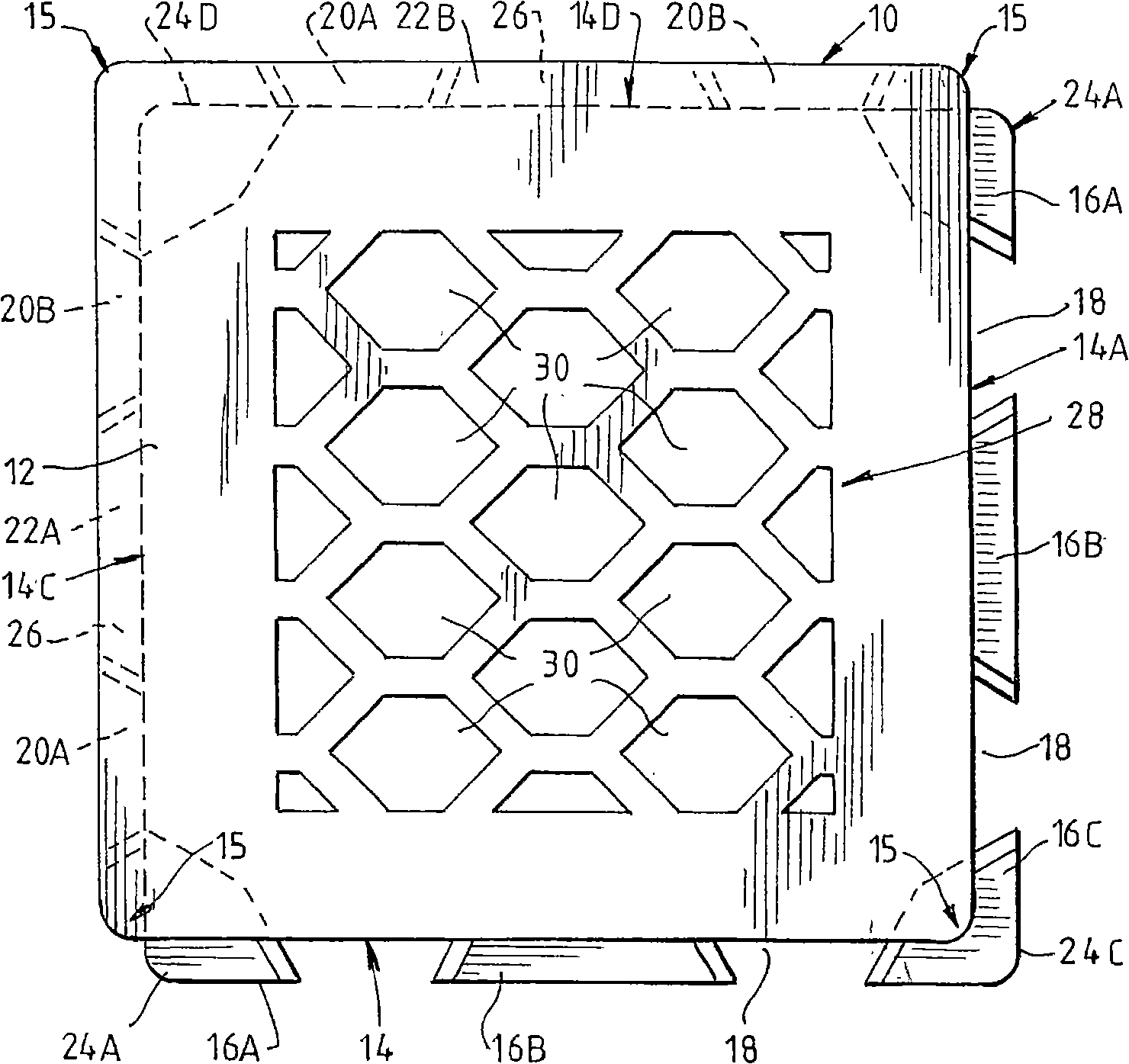

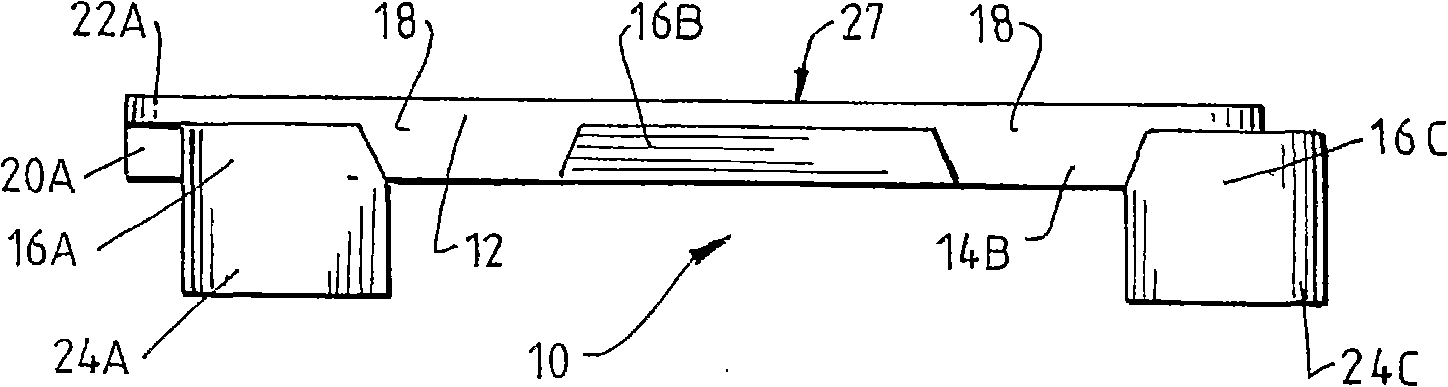

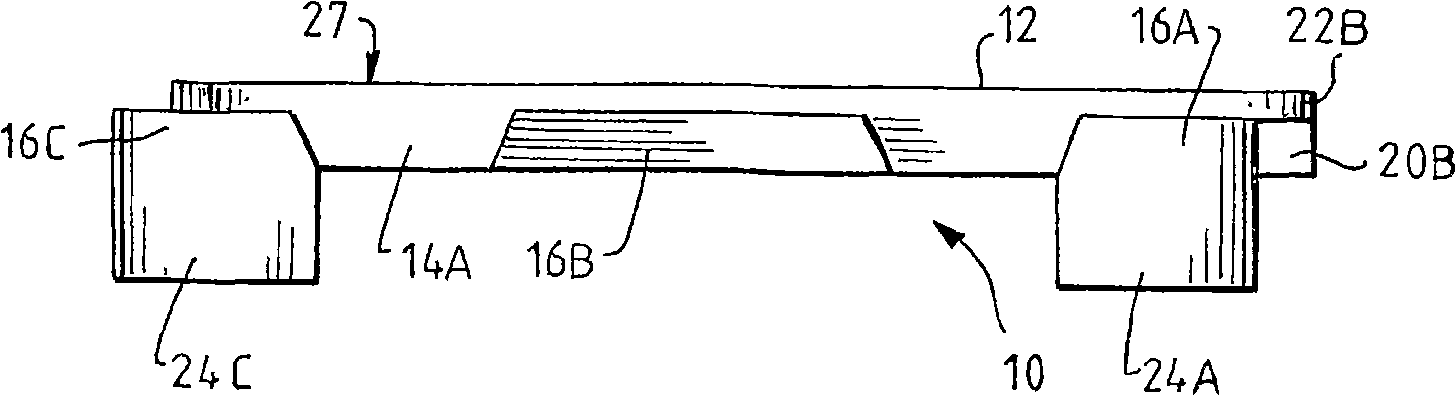

[0063] In the following description of Figures 1 to 4, reference will be made to modules and platforms embodied as pallets. However, it should be understood that the text is equally relevant to modules and platforms embodied as floors and frames and the like.

[0064] Referring first to FIG. 1 , the module is shown in the form of a first pallet tile 10 capable of forming a facile (removable) pallet for construction that can be easily transported and stored. the basic unit of .

[0065] Brick 10 constitutes a first embodiment of a pallet module and includes a generally square body portion 12 having four sides 14A-14D, each of which is adapted to be connected to another (usually the same) molding brick. One of the sides is tightly joined (or connected) face-to-face. In plan view, the brick body has a generally square shape with adjacent sides 14A-14B, 14B-14C, etc. at right angles (90°) to each other. However, the corners 15 of the main body portion 12 can be rounded for func...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com