Substrate inspecting apparatus

A substrate inspection and substrate technology, which is applied to measurement devices, optical testing flaws/defects, instruments, etc., can solve the problems of complicated assembly, deviation of glass substrates, unstable conveying posture of glass substrates, etc., to achieve the effect of simple transportation and reduced freight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

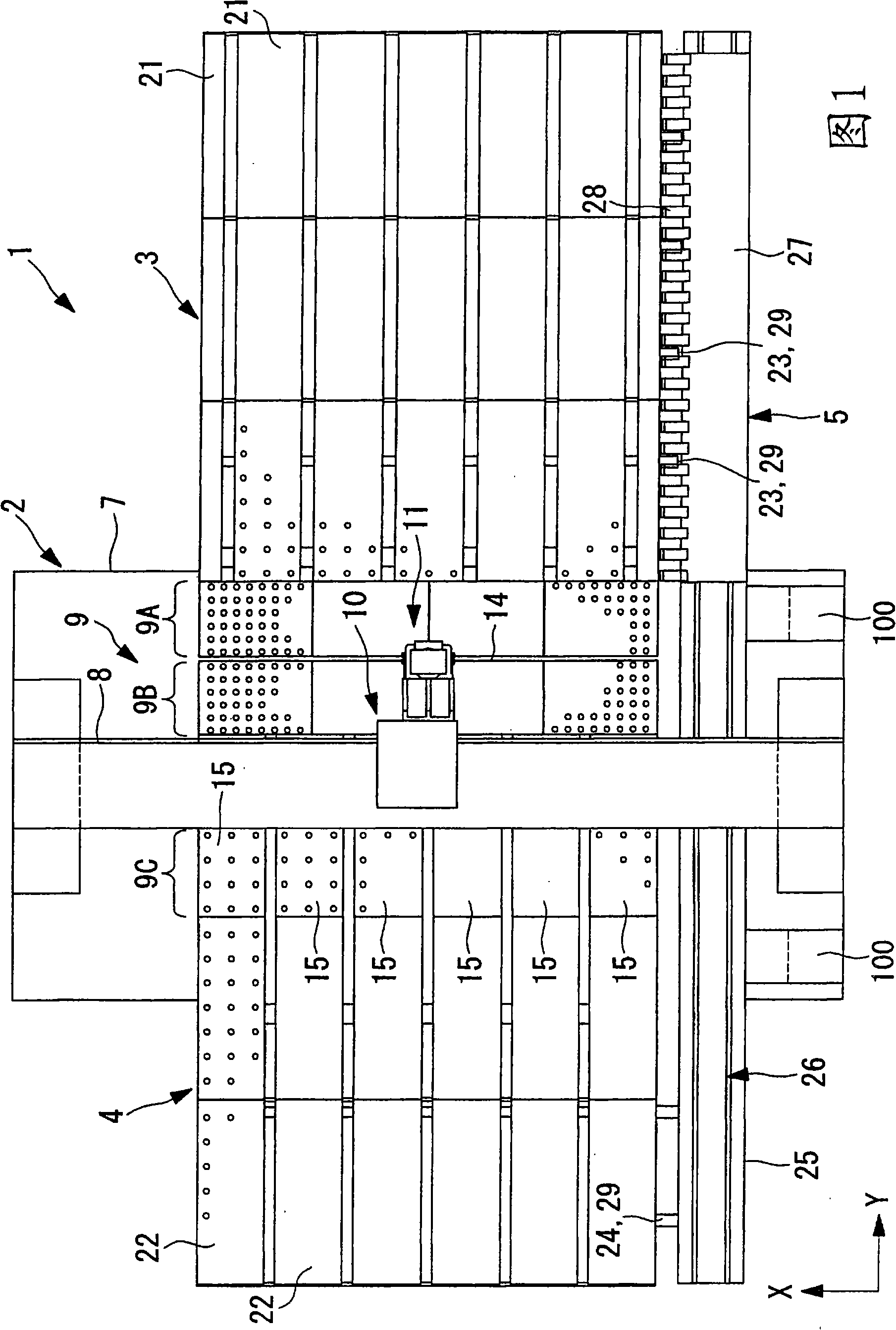

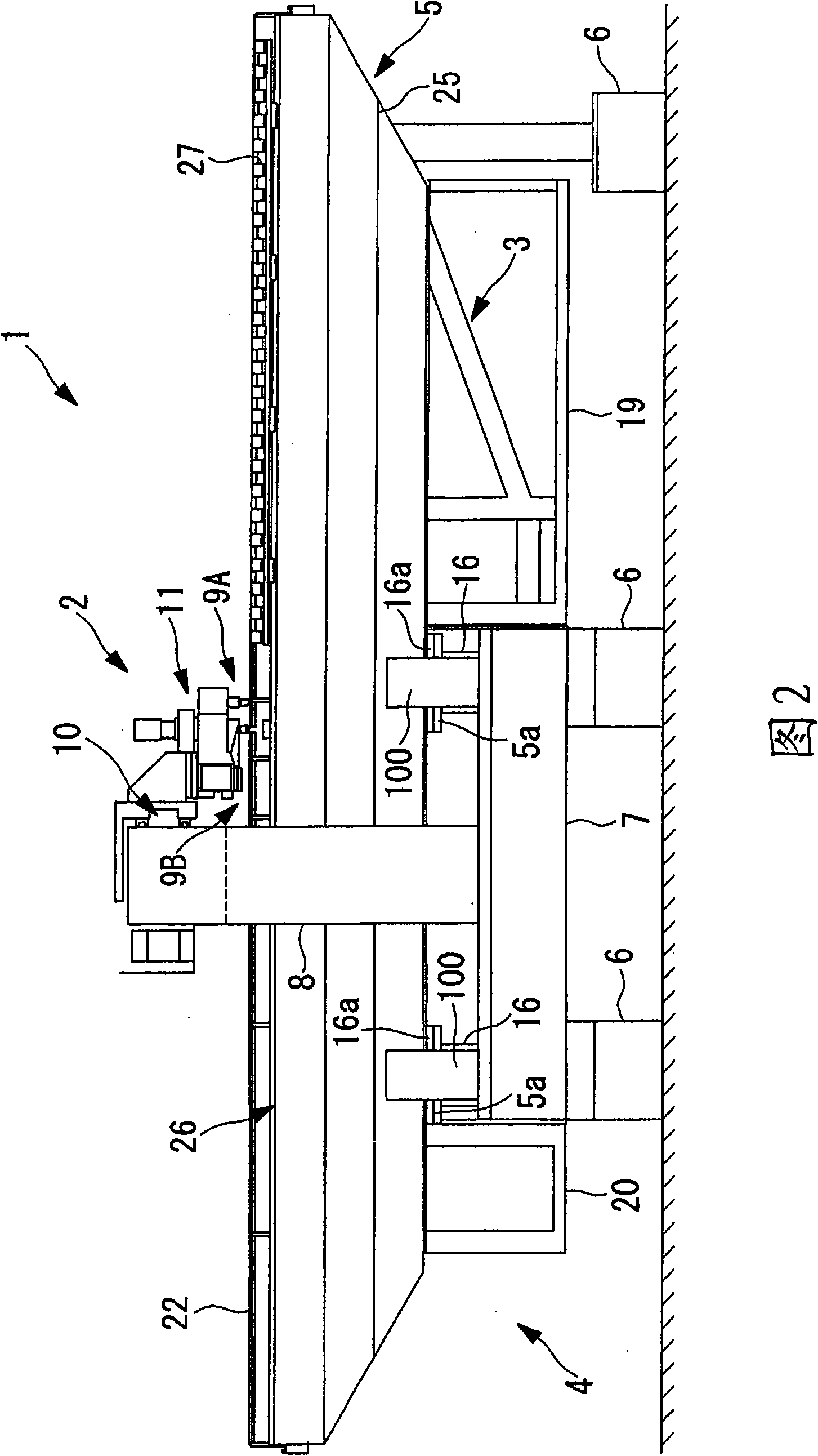

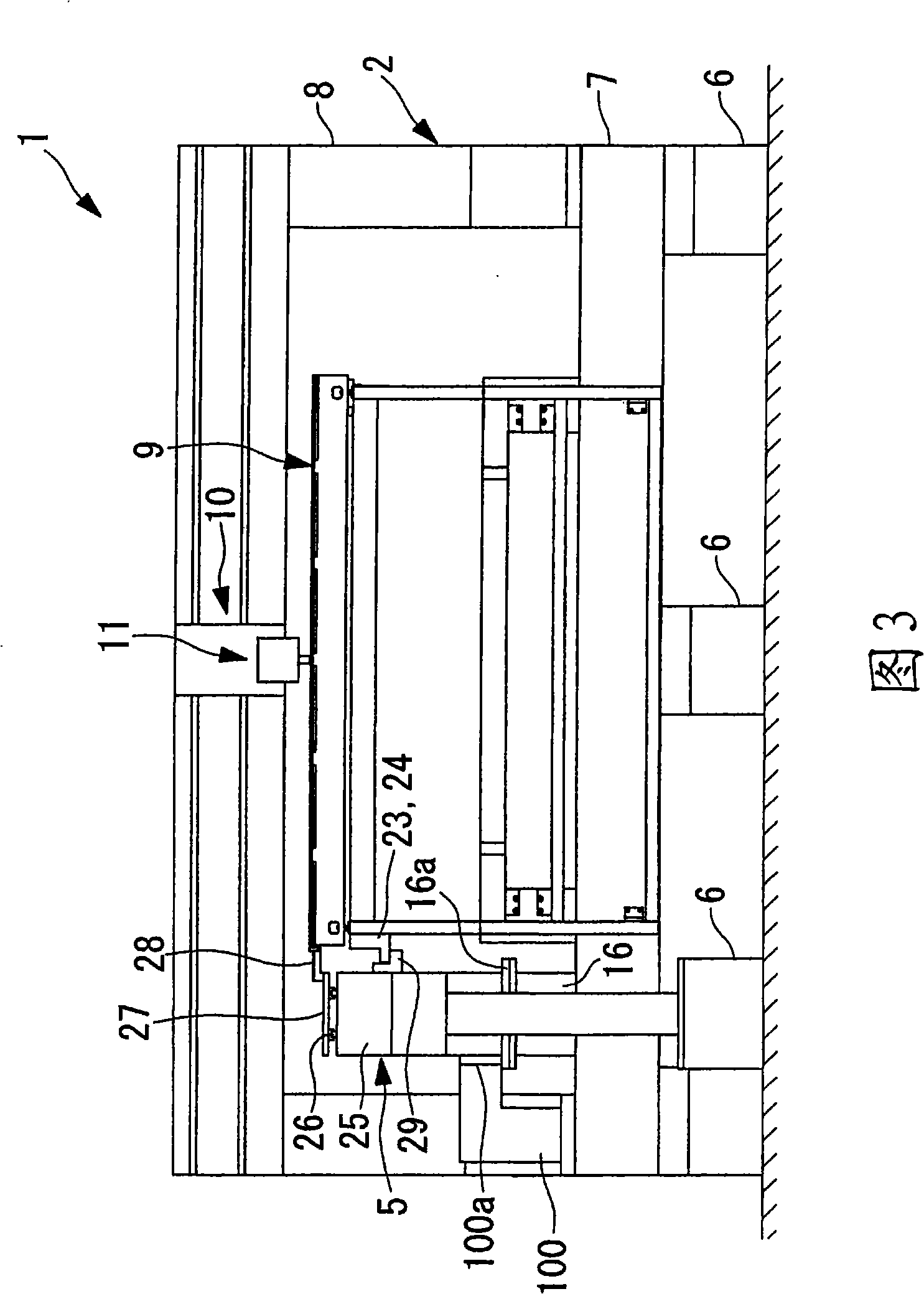

[0054] Below, refer to Figure 1 to Figure 23 The substrate inspection apparatus 1 according to the first embodiment of the present invention will be described.

[0055] like Figure 1 to Figure 4 As shown, the substrate inspection device 1 of this embodiment is a device for inspecting thin plate-shaped substrates such as plain glass used in the mass production of flat panel displays (FPDs) in a photolithography process line. The substrate inspection device 1 has an inspection unit 2, an extension Floating platform units 3, 4 and transfer unit 5. One side of the inspection unit 2 is provided with a transfer unit 5 at right angles to the inspection axis (x-axis) of the inspection unit 2, and the transfer unit 5 holds and transfers one side edge of the rectangular glass substrate.

[0056] like Figure 5 ~ Figure 7 As shown, the inspection unit 2 has: a base 7 for inspection placed on a vibration-damping table 6; a gate-shaped frame 8 fixed on the base 7 for inspection; Floa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com