Method and device for permanent-magnet arc-shaped groove inner surface axial sorting

An arc groove and inner surface technology, applied in the field of environmental protection equipment, can solve the problems of limited scope and capacity, large adsorption capacity, short residence time of selected materials, etc., to reduce the content of valuable substances and the separation of valuable substances. The effect of loss, expanding the sorting range and saving permanent magnet materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

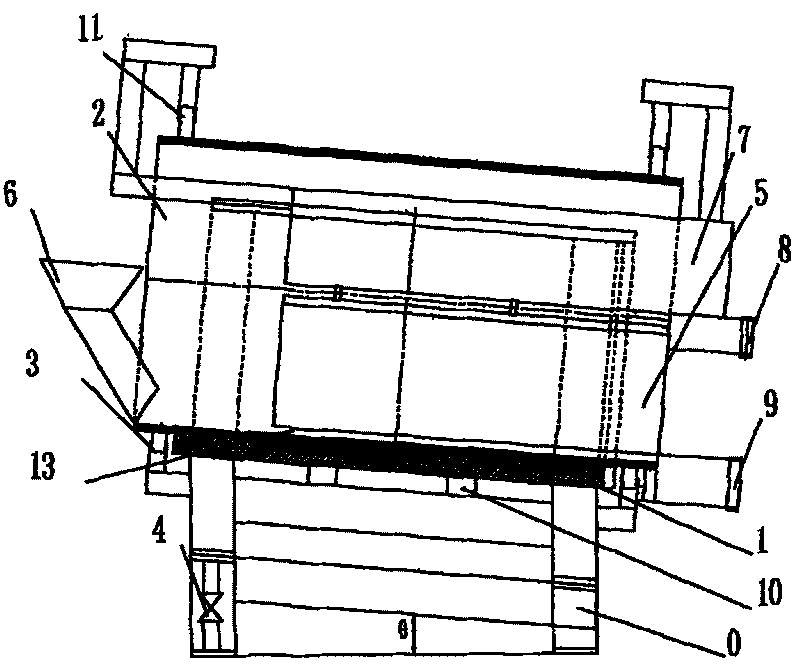

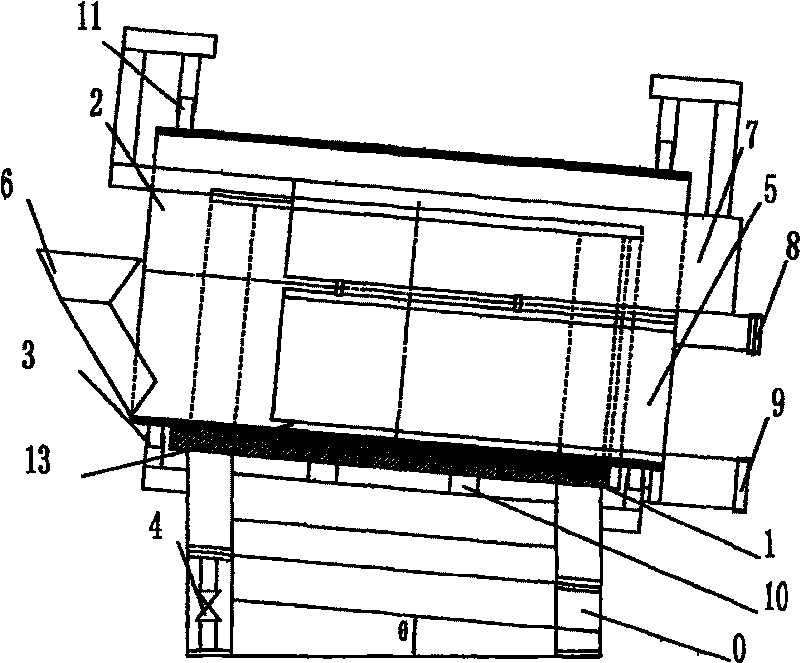

[0025] A method for axially separating the inner surface of a permanent magnet arc-shaped groove, comprising: selecting the waste residue discharged after manganese carbonate electrolysis of metal manganese as the selected material. The average manganese content in manganese carbonate waste residue is 6.47%, and the average particle size -40 mesh accounts for about 90%. The specific magnetic susceptibility coefficient of manganese carbonate is about 100~600×10-6cm3 / g, and it is the best to adjust the field strength and gradient to absorb the material with the specific magnetic susceptibility coefficient. The waste residue is mixed with water into a flowable slurry, which flows from the selected material inlet bin 6 through the inner surface of the rotating separation drum 2 into the selected material channel 13, where the permanent magnetic arc groove 1 and the field strength and gradient adjustment mechanism 5 are separated. Under the action of the generated field strength an...

Embodiment 2

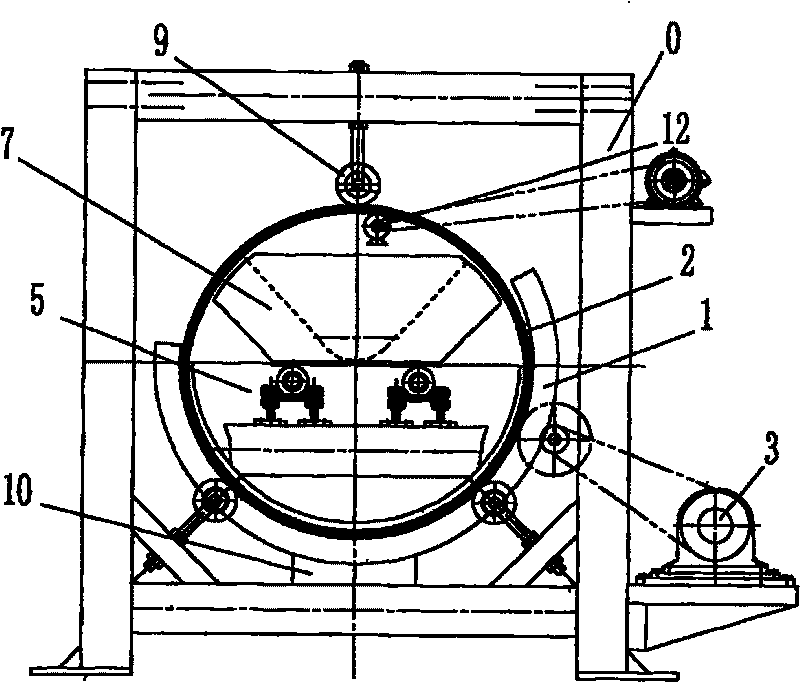

[0027] according to figure 1 , figure 2 As shown, an axial separation device for the inner surface of a permanent magnet arc-shaped groove includes: a bracket 0 and a separation cylinder assembly, and the separation cylinder 2 of the separation cylinder assembly is equipped with a permanent magnet arc-shaped groove of a concentric permanent magnet arc-shaped groove assembly 1. The upper part of the permanent magnet arc-shaped groove 1 is open, and the materials adsorbed in the separation cylinder 2 with a higher magnetic susceptibility coefficient fall directly into the high magnetic material groove 7 by their own gravity.

[0028] The permanent magnet arc slot assembly includes: a permanent magnet arc slot 1 and a permanent magnet arc slot support 10 . The permanent magnet arc groove 1 and the permanent magnet arc groove support 10 are directly welded into one body or connected by bolts, and the permanent magnet arc groove support 10 is installed and fixed on the bracket 0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com