Wire inlet and outlet cabinet capable of bunching wires

A wire cabinet and wire harness technology, applied in busbar/line layout, electrical components, substation/power distribution device shell, etc., can solve problems such as difficult later maintenance and damage to the wire harness surface, and achieve easy maintenance, simple operation, and easy use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

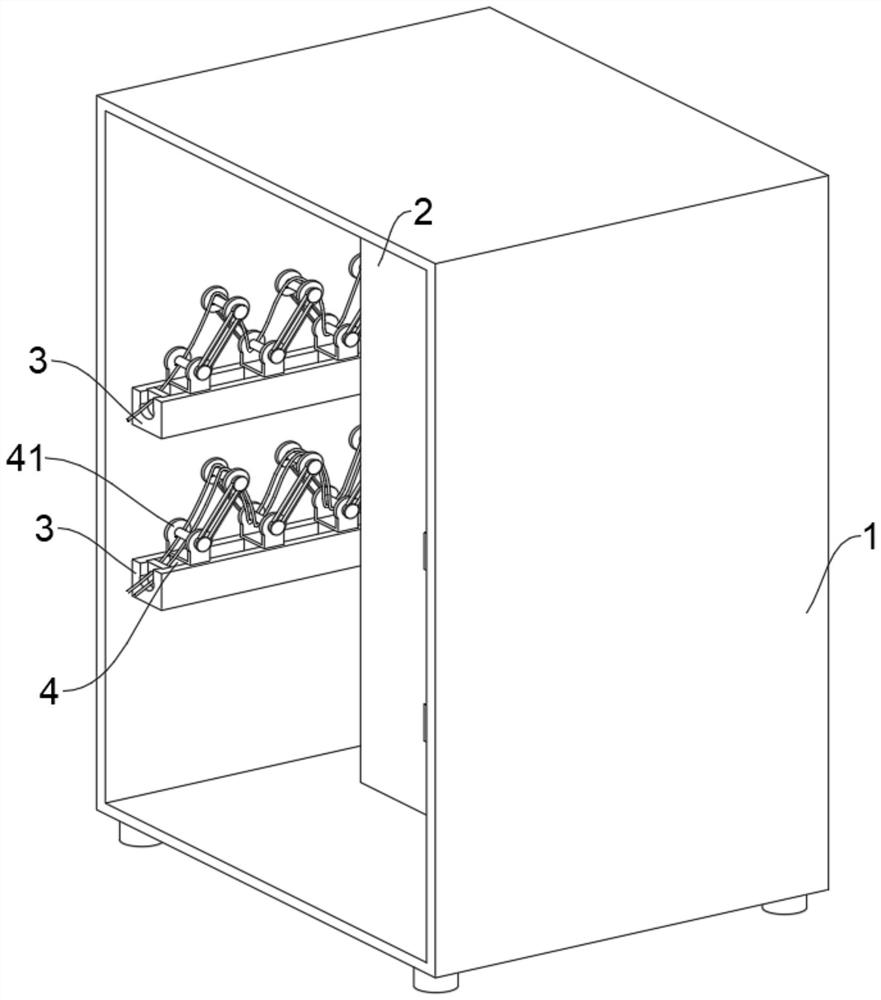

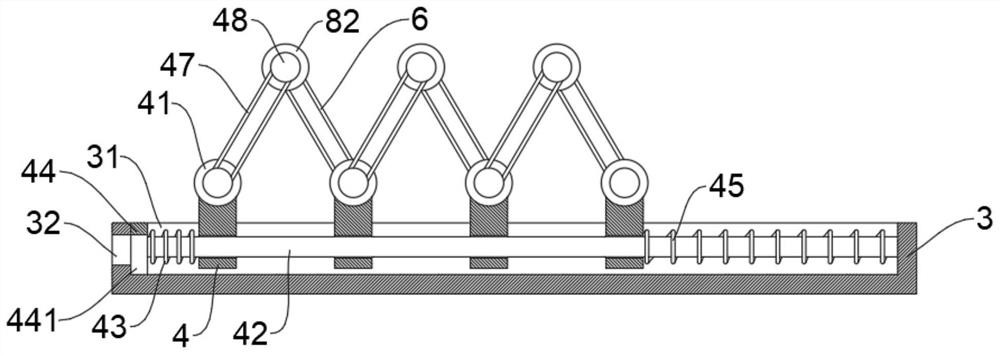

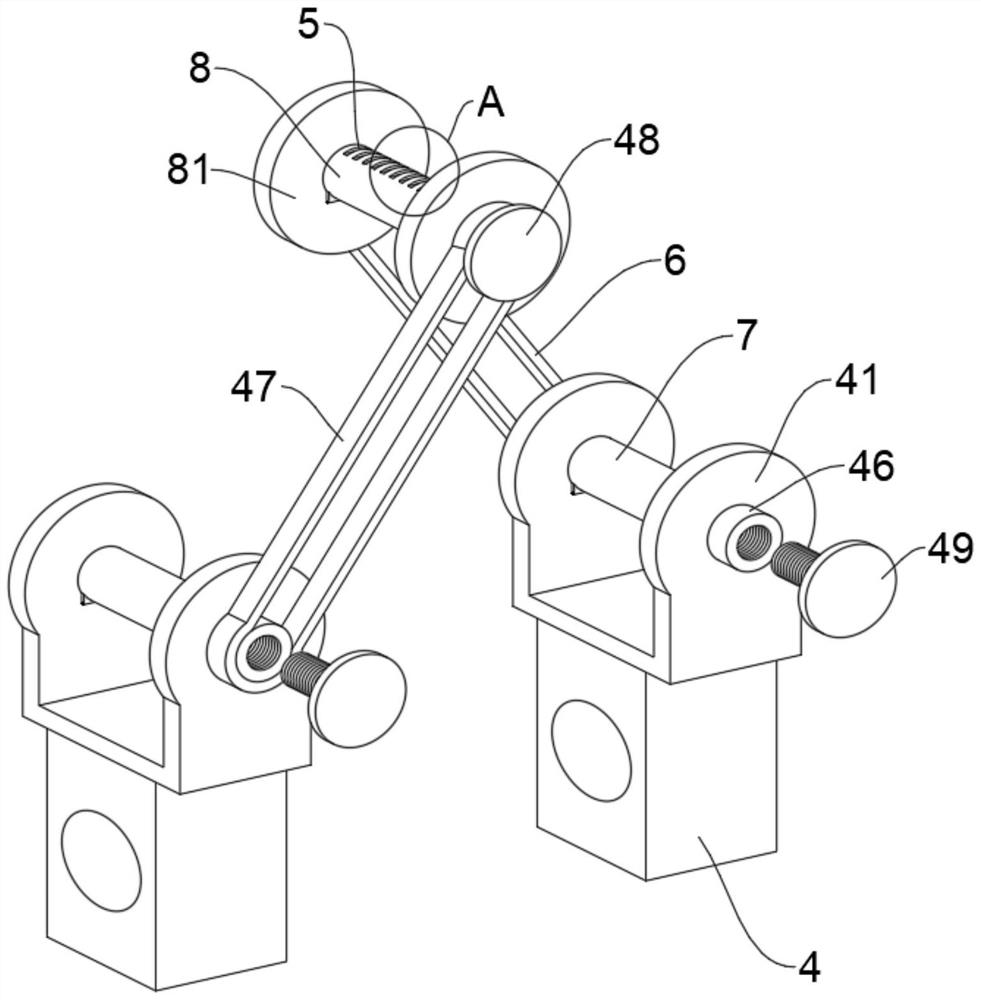

[0032] This embodiment is intended to facilitate solving the problem of how to organize the wiring harness, please refer to Figure 1-4 , the present embodiment discloses an incoming and outgoing wire cabinet that can bundle wires, including an incoming and outgoing wire cabinet body 1 and an electrical component 2 installed in the incoming and outgoing wire cabinet body 1, and a holder 3 is installed on the inner wall of the incoming and outgoing wire cabinet body 1, A chute 31 is provided on the retainer 3, and a harness slider 4 is slidably installed in the chute 31. The harness slider 4 slides in the chute 31, and a first bearing seat 41 is slidably installed on the harness slider 4. The first bearing A first wire roller shaft 7 is installed on the seat 41, a first protruding block 46 is connected to the outer side of the middle of the first bearing seat 41, and a first connecting rod 47 is sleeved on the first protruding block 46, and the first connecting rod 47 One end a...

Embodiment 2

[0038] This embodiment is intended to facilitate solving the problem of how to install the wire harness on the first wire roller shaft 7. This embodiment is an improvement made on the basis of Embodiment 1. For details, please refer to Figure 2-4 , a rubber abutting block 411 is installed on the inner wall of the first bearing seat 41 , one end of the rubber abutting block 411 is connected to a limiting block 412 , and the limiting blocking block 412 and the rubber abutting block 411 are threadedly connected with the middle of the first bearing seat 41 Limit bar 49.

[0039] Under the action of the rubber abutting block 411 , both ends of the wire harness can abut against the rubber abutting block 411 , which can protect the wire harness.

[0040] By installing the limiting rod 49 , it is convenient to limit the first connecting rod 47 and the second connecting rod 6 to prevent them from sliding out of the outer side of the first protruding block 46 , and the protection effec...

Embodiment 3

[0047] This embodiment is intended to facilitate solving the problem of how to organize multiple wire harnesses. This embodiment is an improvement made on the basis of Embodiment 2. For details, please refer to figure 2 , image 3 and Figure 5 , a limit slot 5 is set on the second wire roller 8, and the wire harness of the electrical component 2 is inserted into the limit slot 5.

[0048] Multiple wire harnesses can be respectively clamped in the limiting slot 5, so that the wire harnesses can be fixed in a regular and orderly manner without being cluttered.

[0049] A U-shaped wire outlet slot 32 is opened on the side wall of the holder 3 , and the U-shaped wire outlet slot 32 is matched with the chute 31 .

[0050] After the installation of the multiple wire harnesses is completed, they are finally uniformly extended from the U-shaped wire outlet slot 32, which is convenient for arranging the multiple wire harnesses of the wire harness so that they will not be loosened f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com