Method for cleaning a circumferential surface of a cylinder of a printing press

A technology for printing machines and coats, which is applied to the general parts of printing machinery, printing machines, printing, etc., and can solve the problems of reducing the productivity of printing machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

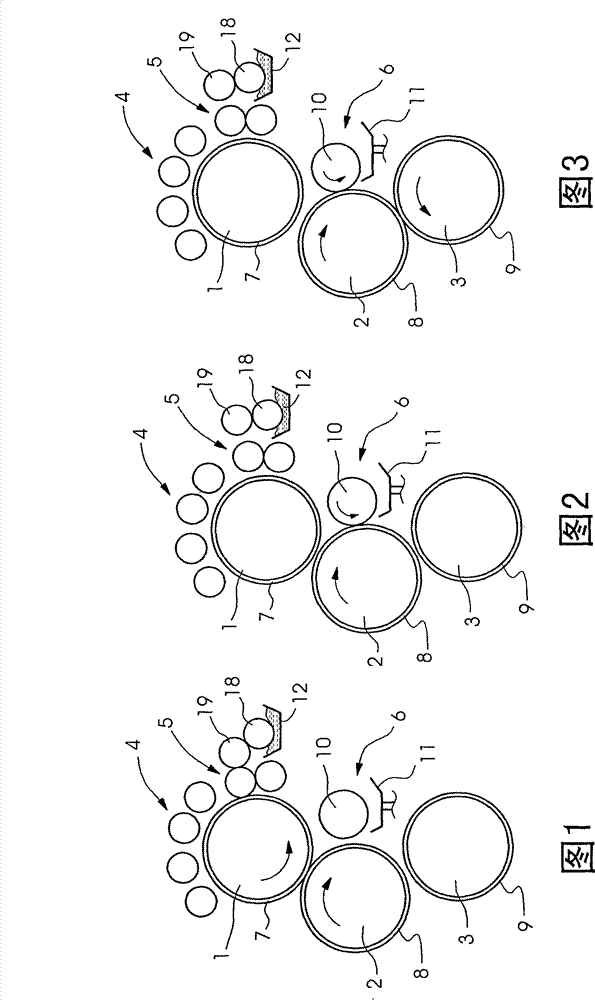

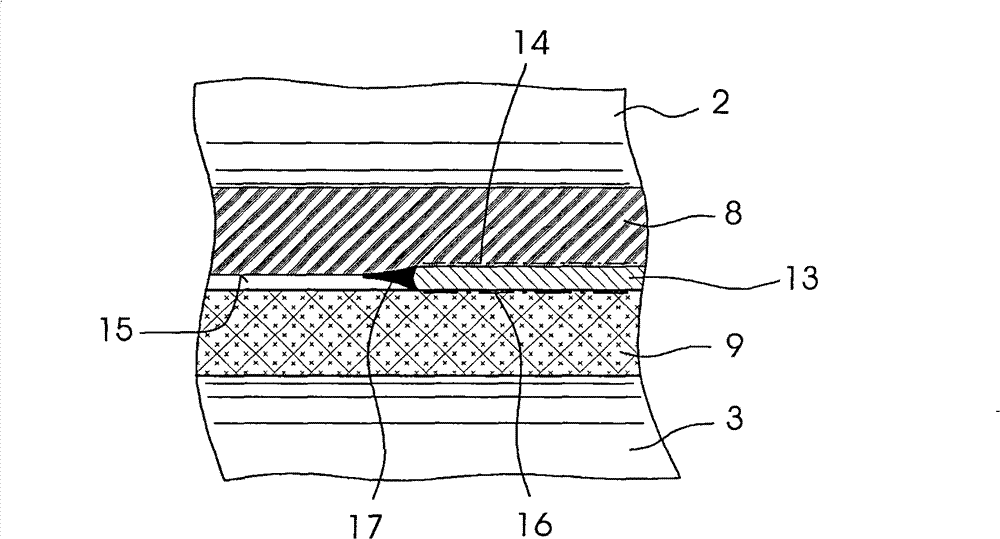

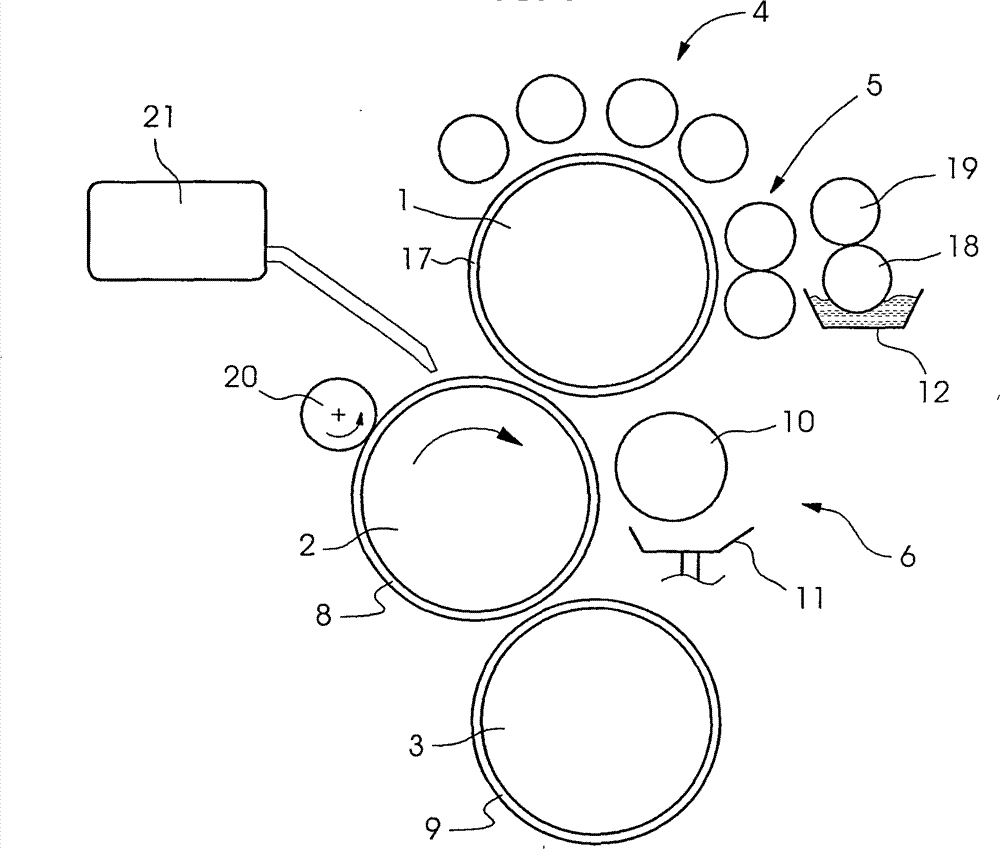

[0020] Figure 1-3 A schematic diagram of the printing unit of a wet offset printing press is shown. The printing unit essentially comprises a plate cylinder 1 , a blanket cylinder 2 , an impression cylinder 3 , ink form rollers 4 , dampening agent application rollers 5 and a brush cleaning unit 6 . A printing forme 7 is tensioned on the cylinder body of the printing forme cylinder 1 . An elastic blanket 8 is stretched over the cylinder body of the blanket cylinder 2 . The cylinder body of the impression cylinder 3 has a lining 9 which repels printing ink. The cylinders 1 - 3 are held in the side walls of the printing press and are mounted rotatably in the direction of the arrow by means of a drive. The drive can be via a gear train or by means of a separate drive. The blanket cylinder 2 can be pressed selectively with the plate cylinder 1 or with the impression cylinder 3 or simultaneously with the plate cylinder 1 and the impression cylinder 3 by means of a device. The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com