Method and device for drying printed corrugated board

A technology of corrugated cardboard and drying equipment, applied in printing, printing machines, post-processing of printing, etc., to achieve the effects of reducing production costs, improving light source utilization, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

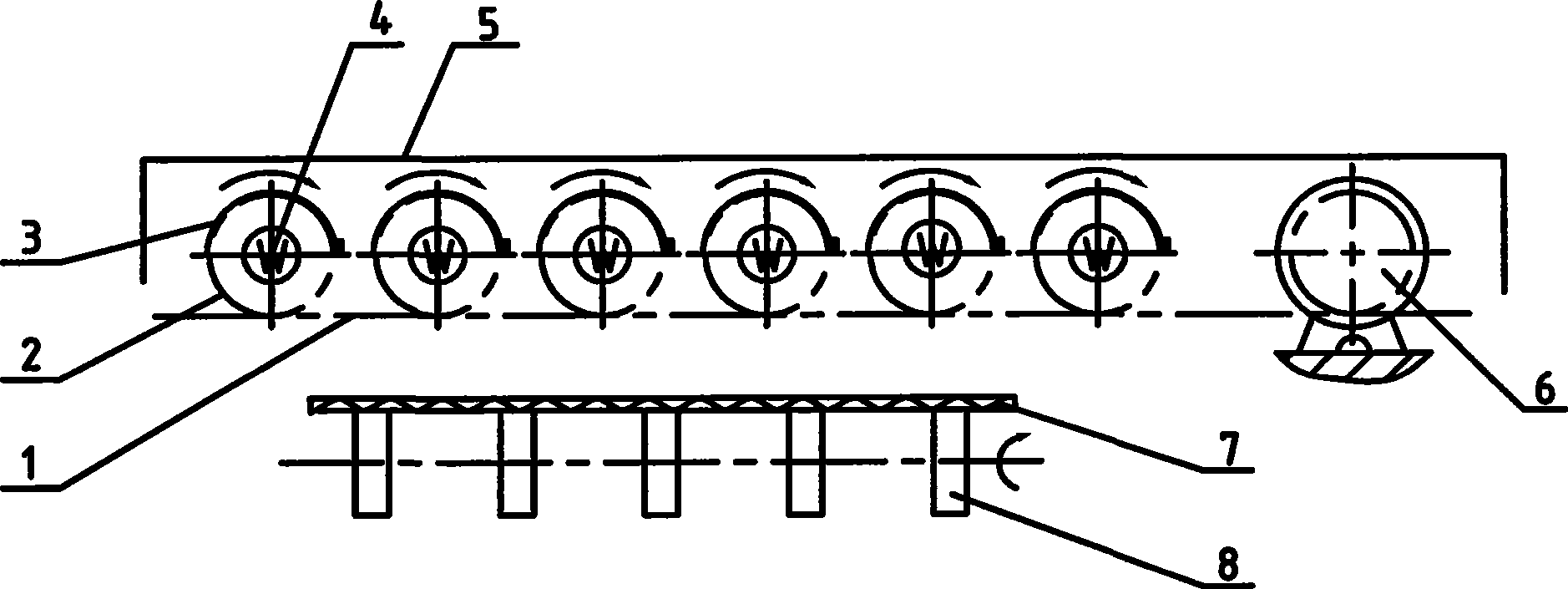

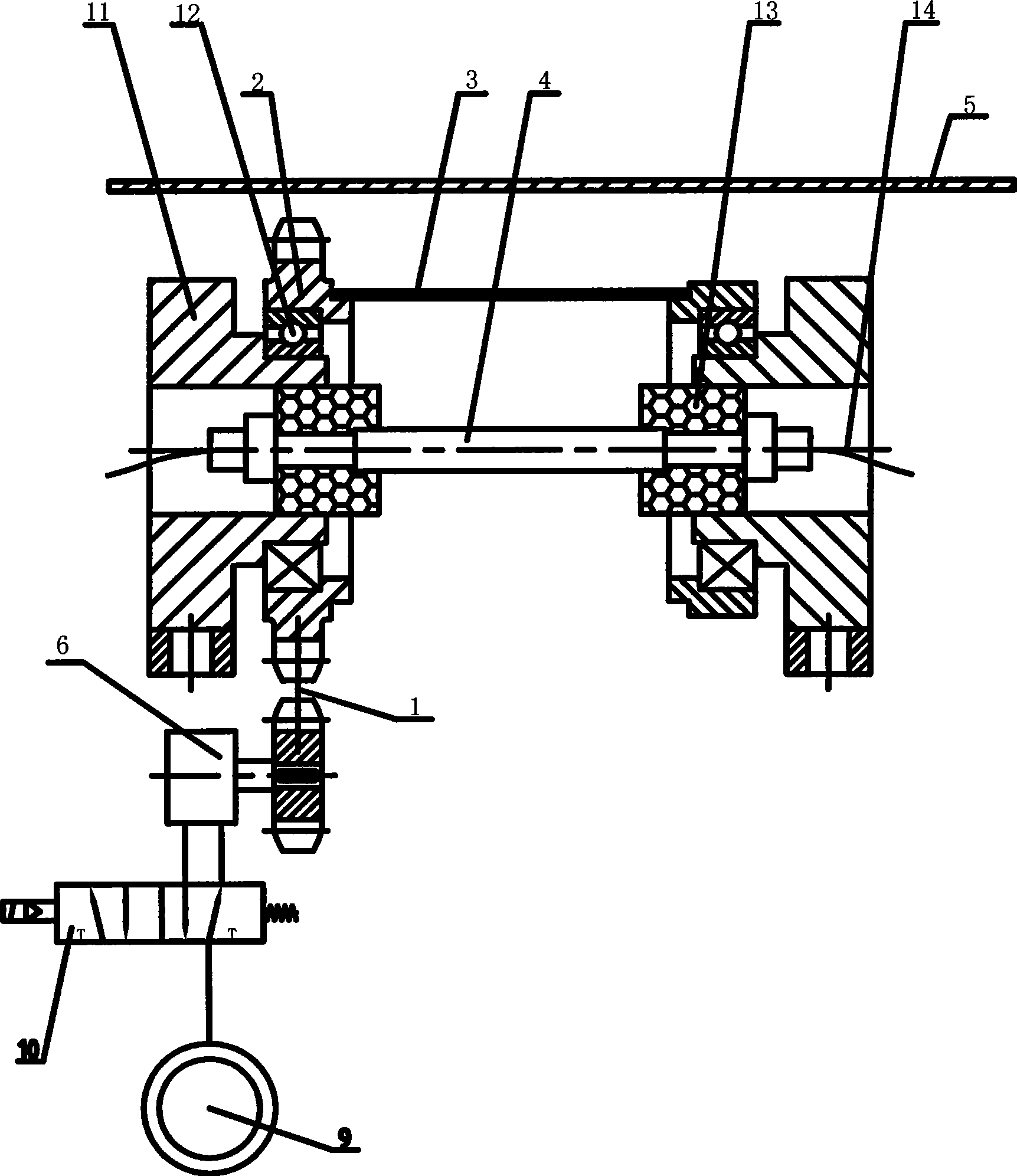

[0028] A printing and drying method for corrugated cardboard, which uses infrared rays to directly irradiate the corrugated cardboard to make it dry. The infrared rays are emitted by the infrared lamp tube, and the length direction of the infrared lamp tube is set to be parallel to the traveling direction of the corrugated cardboard. Six infrared lamps are arranged in parallel in one group, and the number of groups is two groups, and each infrared lamp and each group of infrared lamps are independently controlled. Each infrared lamp tube is provided with a reflective shield that can reflect the emitted rays to the corrugated cardboard or block the emitted rays from the corrugated cardboard. The reflective protective cover is an active mode, and the activity of the reflective protective cover is an automatic control mode.

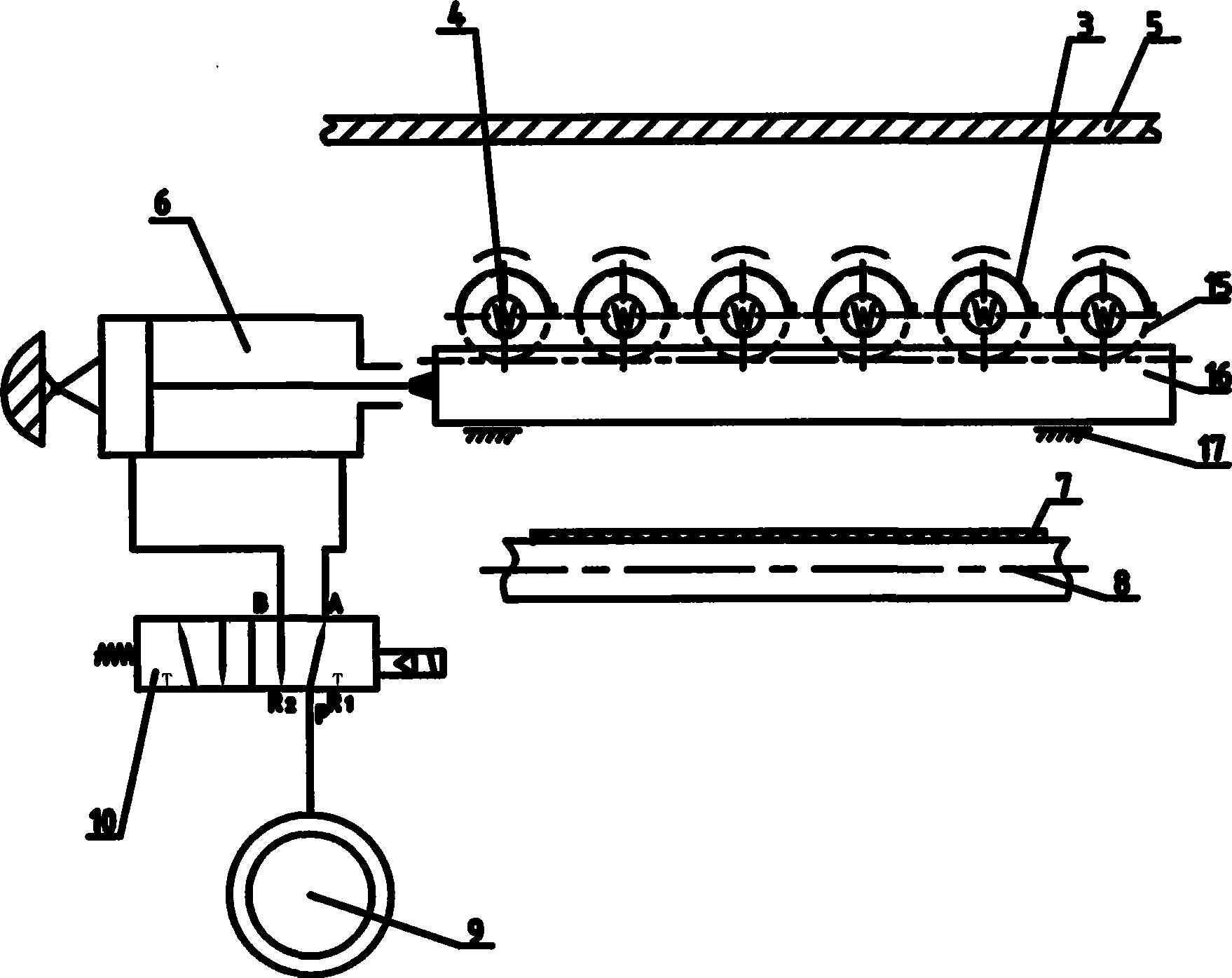

[0029] A corrugated cardboard printing and drying device implementing the above method, such as figure 1 and figure 2 As shown, it is set on the plane c...

Embodiment 2

[0036] The invention relates to a printing and drying method of corrugated cardboard, which uses infrared rays to directly irradiate the corrugated cardboard to make it dry. The infrared rays are emitted by the infrared lamp tube, and the length direction of the infrared lamp tube is set to be parallel to the traveling direction of the corrugated cardboard. Six infrared lamps are arranged in parallel in one group, and the number of groups is two groups, and each infrared lamp is independently controlled. Each infrared lamp tube is provided with a reflective shield that can reflect the emitted rays to the corrugated cardboard or block the emitted rays from the corrugated cardboard. The reflective protective cover is an active mode, and the activity of the reflective protective cover is an automatic control mode.

[0037] A corrugated cardboard printing and drying device implementing the above method, such as figure 1 , Figure 4 As shown, it is set on the flat corrugated car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com