Manufacture method for layered arrangement of multilayer cable cores

A cable core wire and manufacturing method technology, which is applied in the layered field of cable multi-layer core wire, can solve problems such as low efficiency and unstable performance, and achieve the effects of improving quality stability, improving efficiency, and simplifying cabling operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

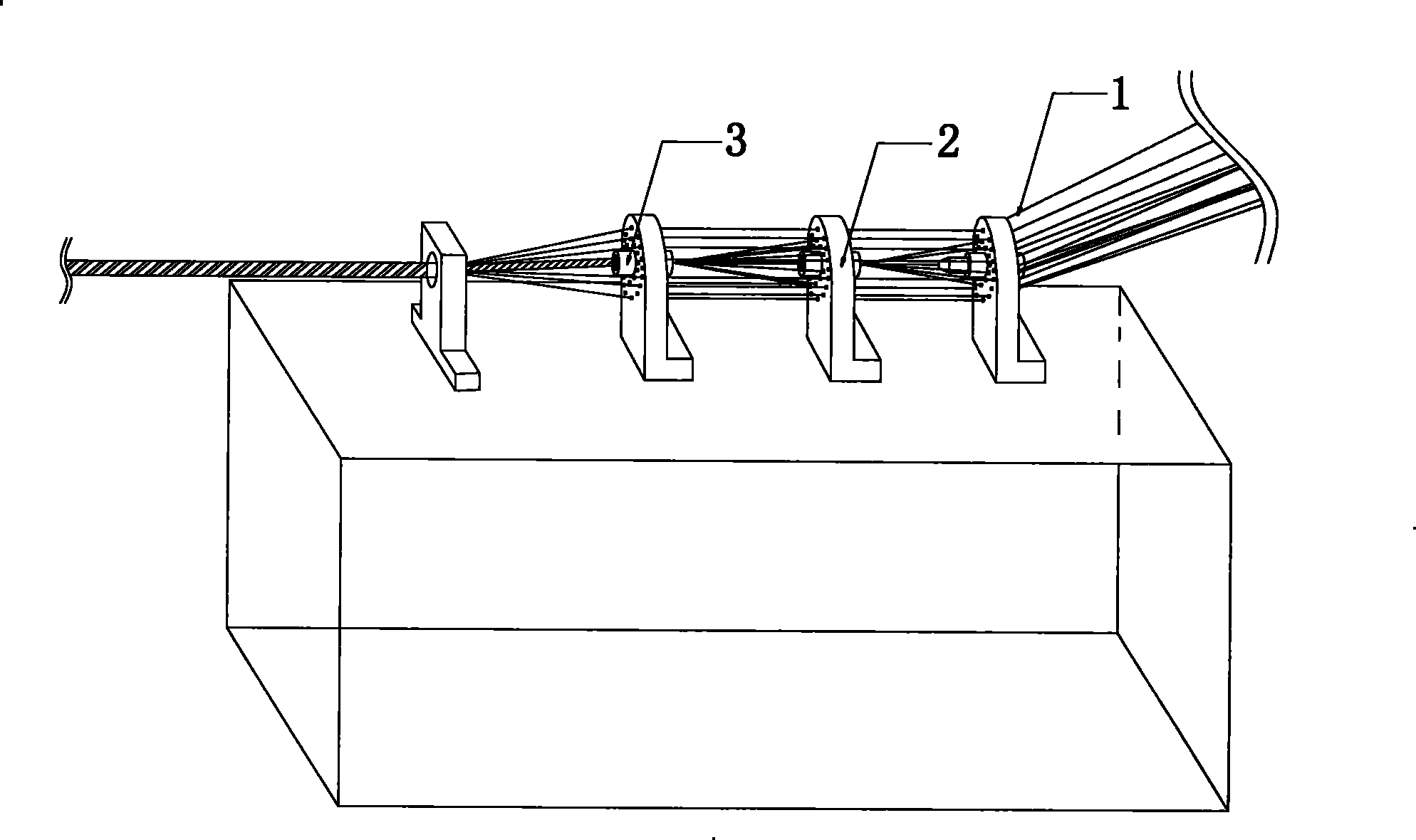

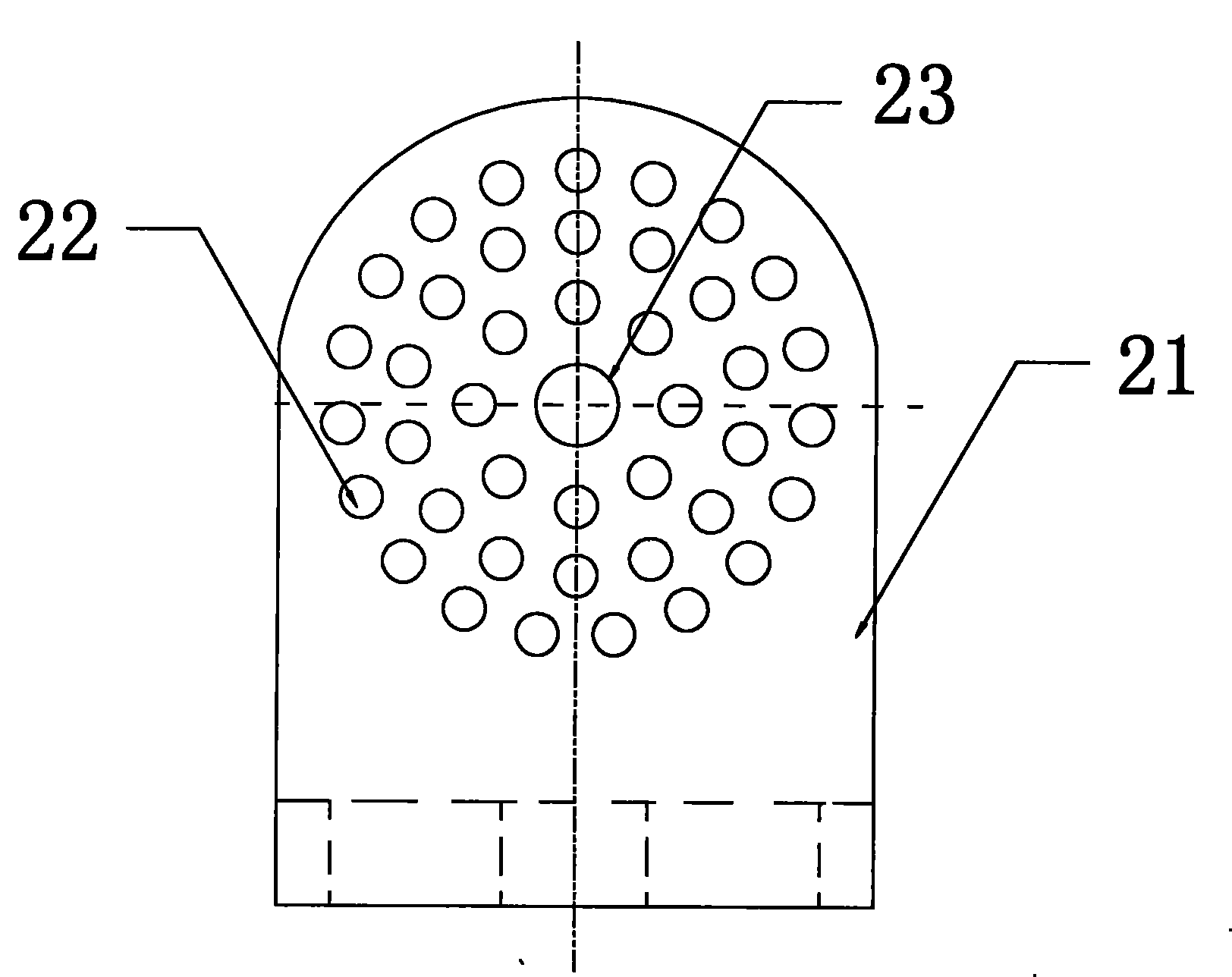

[0022] The present invention will be further described below in conjunction with accompanying drawing.

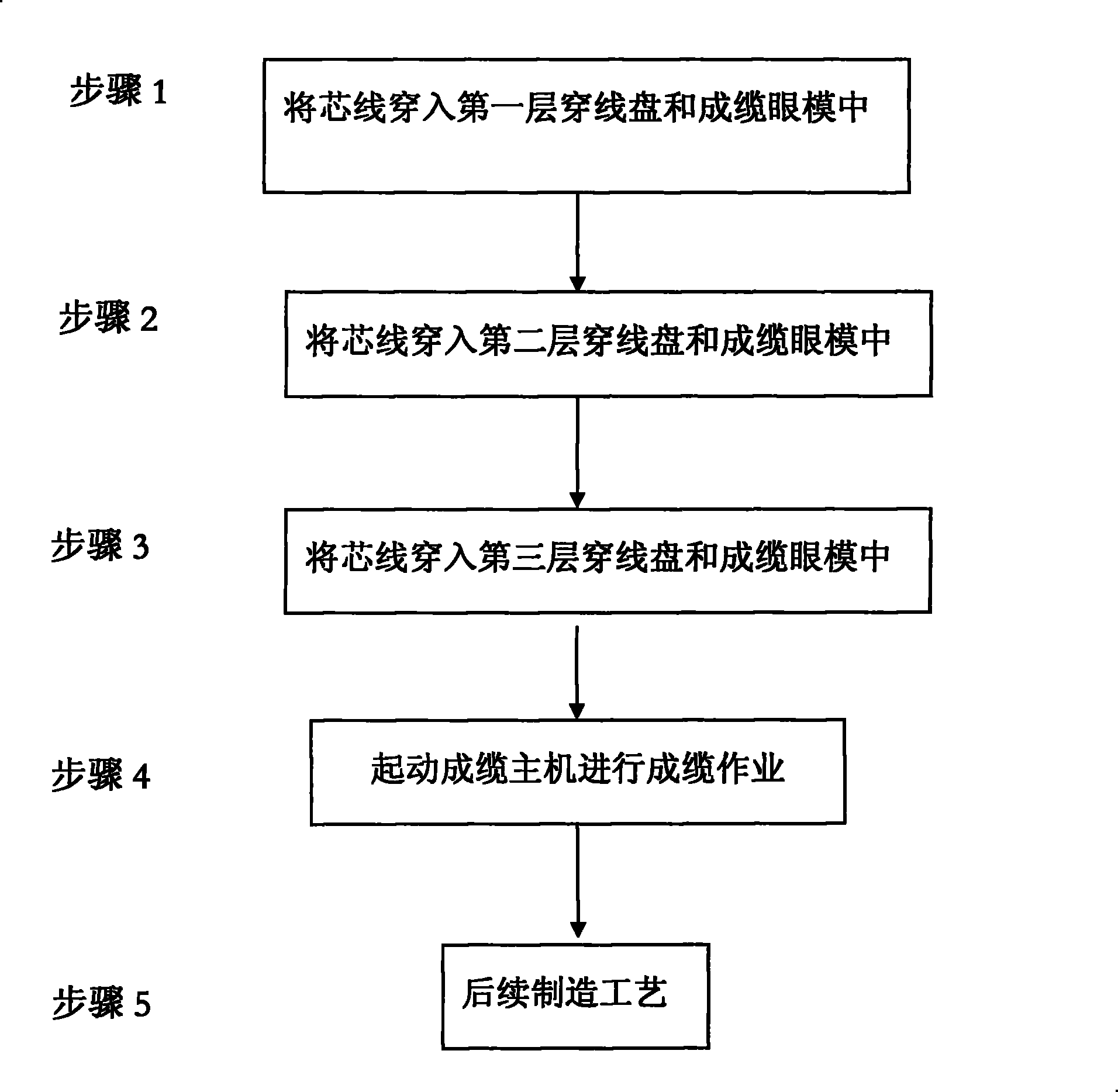

[0023] Such as figure 1 Flowchart of the manufacturing method for layered arrangement of multilayer core wires of cables,

[0024] A cabling manufacturing method in which multilayer core wires of cables are arranged in layers, comprising the steps of:

[0025] Step 1. Pass the cable core wires through the core wire arrangement positioning plate and the cable eye mold according to the first rearrangement position;

[0026] Step 2. Pass the cable core wires through the core wire arrangement positioning plate and the cable eye mold according to the second rearrangement position;

[0027] Step 3, pass the cable core wires through the core wire arrangement positioning plate and the cable eye mold according to the third arrangement position;

[0028] Step 4, start the cabling host to carry out the cabling operation;

[0029] Step 5, performing a subsequent manufacturing proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com