Grounding method of primary coil N end of relatively semi-insulating electromagnetic voltage transformer and iron core

A technology of voltage transformer and grounding method, which is applied in the direction of transformer/inductor coil/winding/connection, inductor, transformer/inductor core, etc., which can solve the problems of burning transformer and affecting product insulation performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

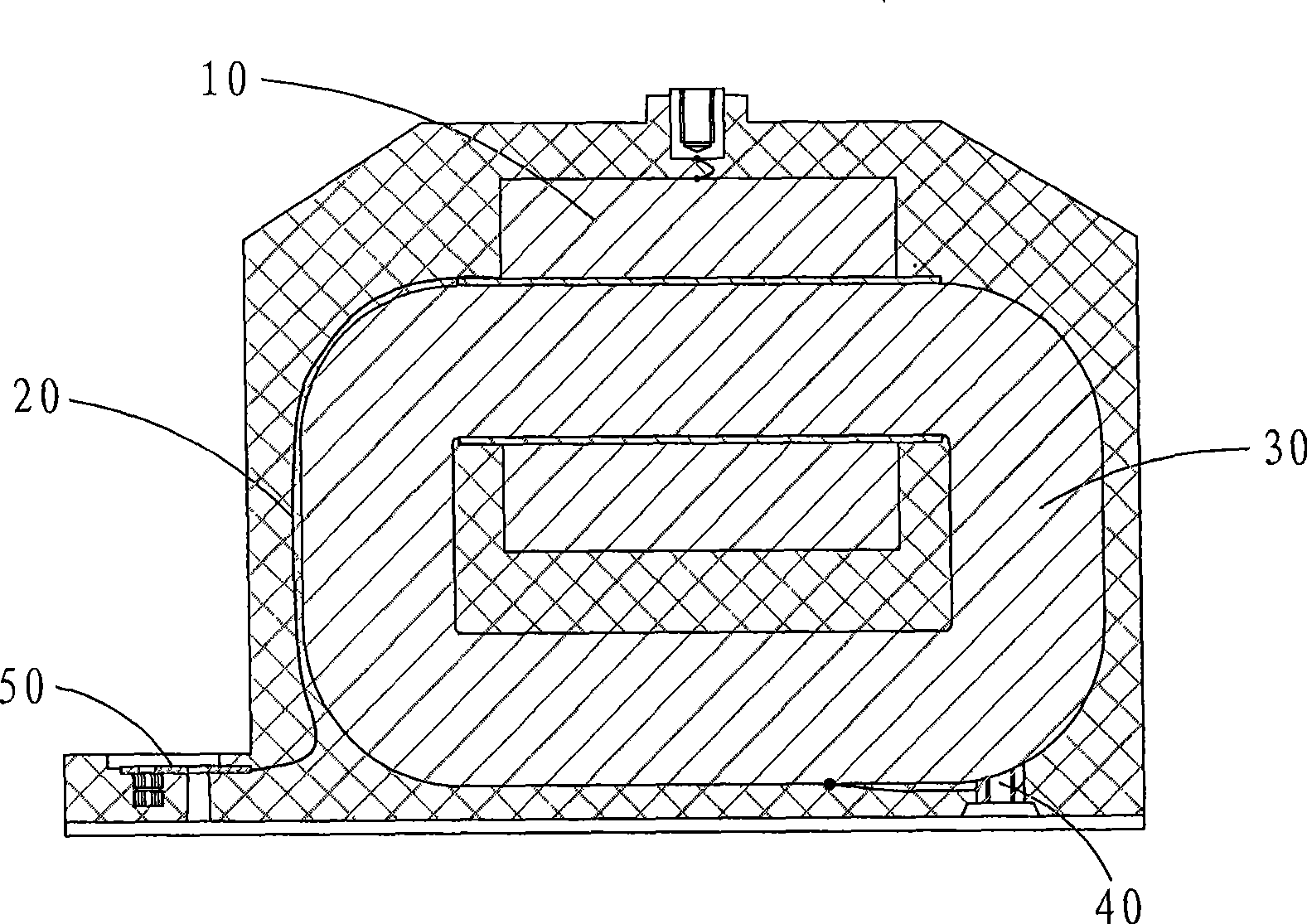

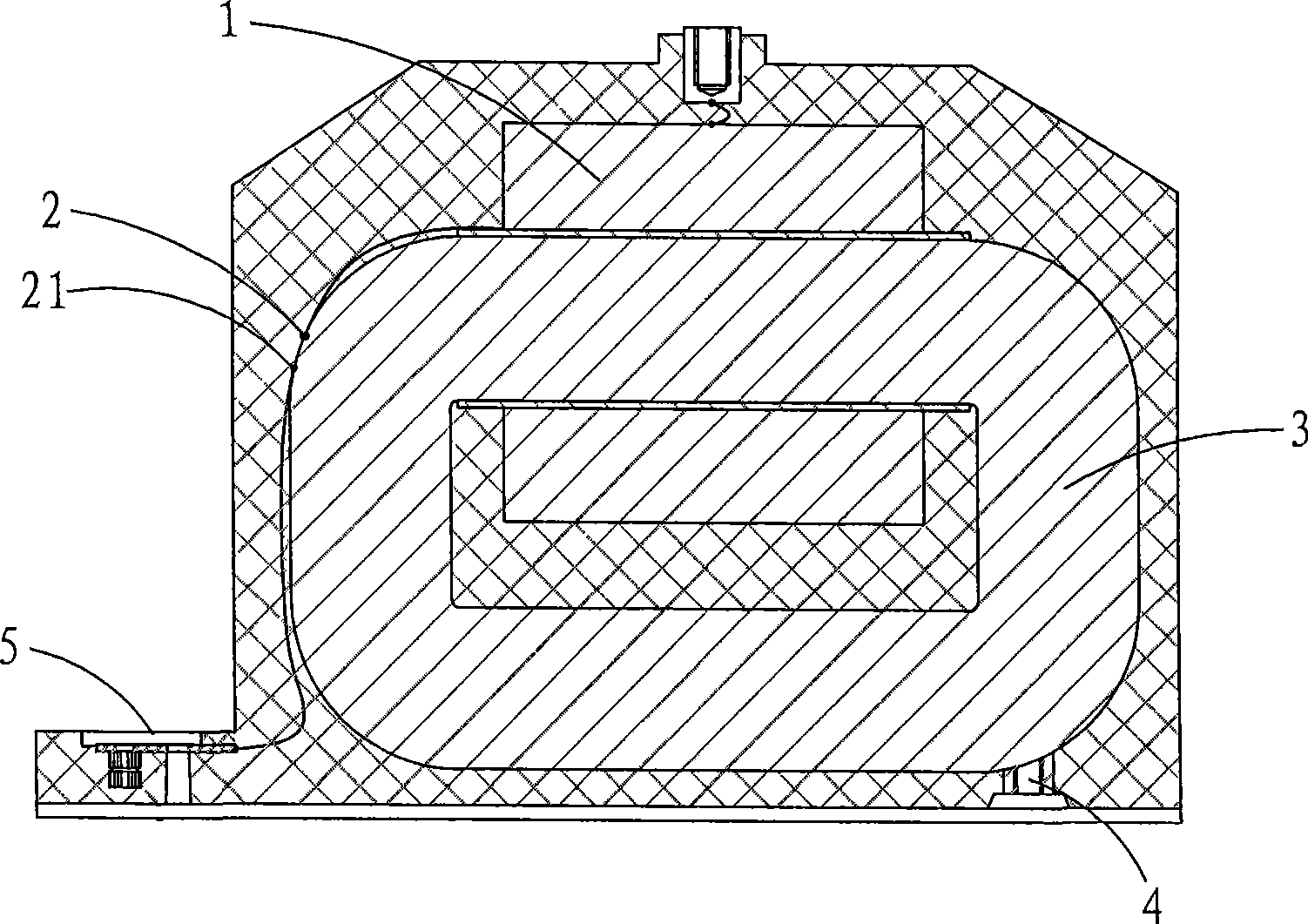

[0015] Such as image 3 Shown is a preferred embodiment of the present invention.

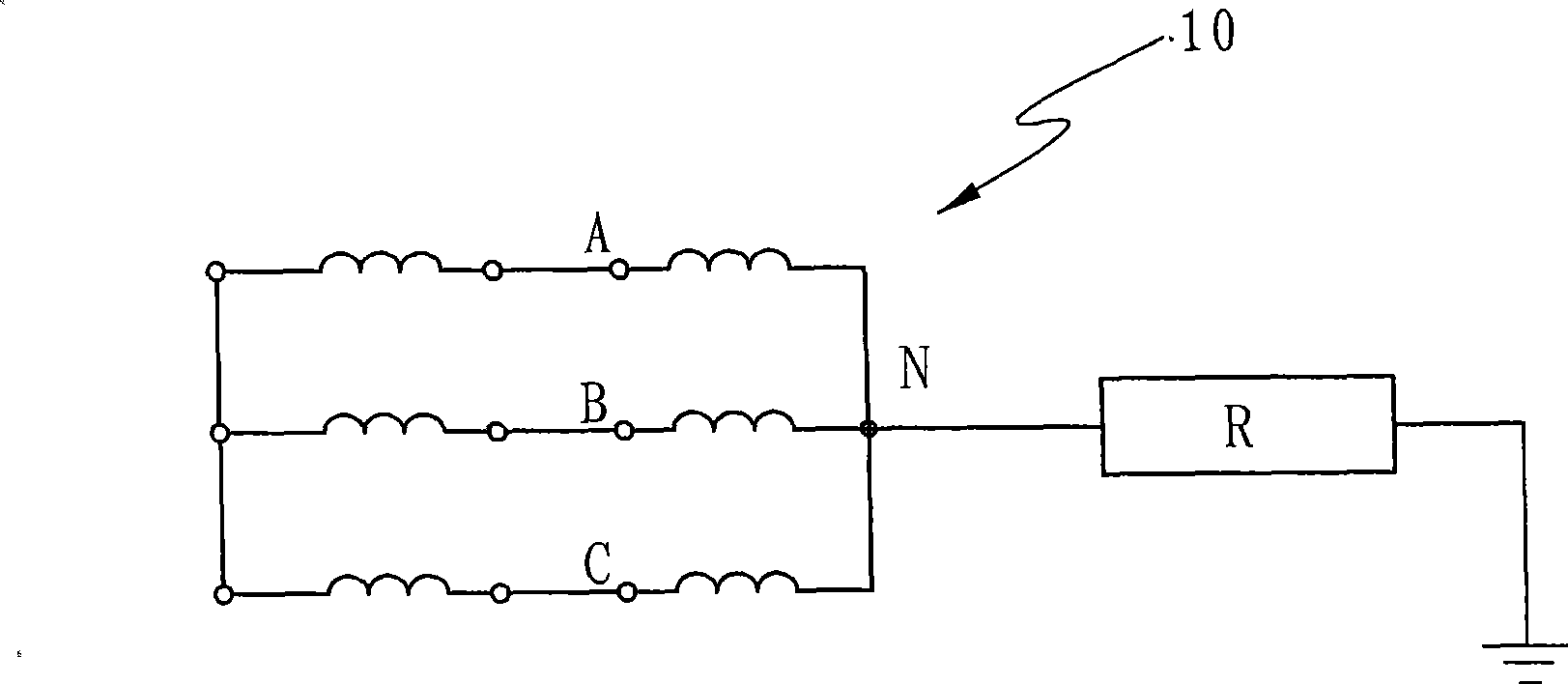

[0016] The invention discloses a method for grounding the N terminal of the primary coil of a relatively semi-insulated electromagnetic voltage transformer and the iron core. To lead out the N-terminal 21, specifically, the connection point between the N-terminal 2 of the primary coil 1 and the core 3 and the point where the N-terminal 21 is drawn out from the core 3 coincide, or as image 3 As shown, the connection point between the N-terminal 2 of the primary coil 1 and the core 3 is separated from the point where the N-terminal 21 is drawn from the core 3, and then the N-terminal 21 and the connecting piece 5 are grounded, and the N-terminal 21 It can be effectively grounded or grounded through a large resistance (such as figure 2 shown). The core 3 is still connected to the mounting base insert 4 .

[0017] Compared with the prior art, the present invention directly connects the N term...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com