A battery pack based on a cylindrical battery pack unit

A technology for battery packs and battery packs, which is applied to battery pack components, electrical components, circuits, etc., and can solve problems such as low versatility, affecting the structural stability of battery packs, and safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

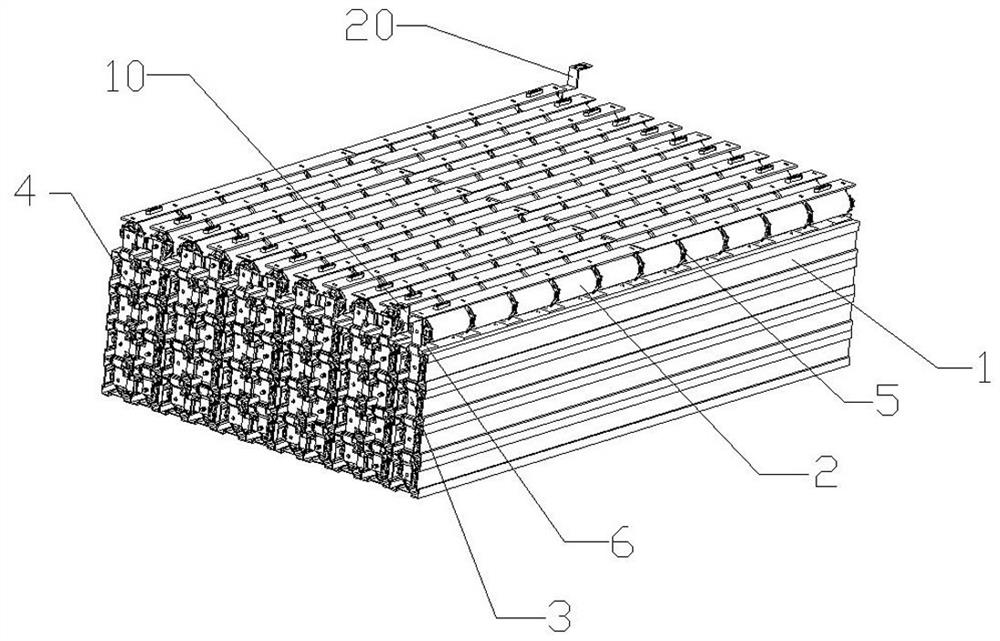

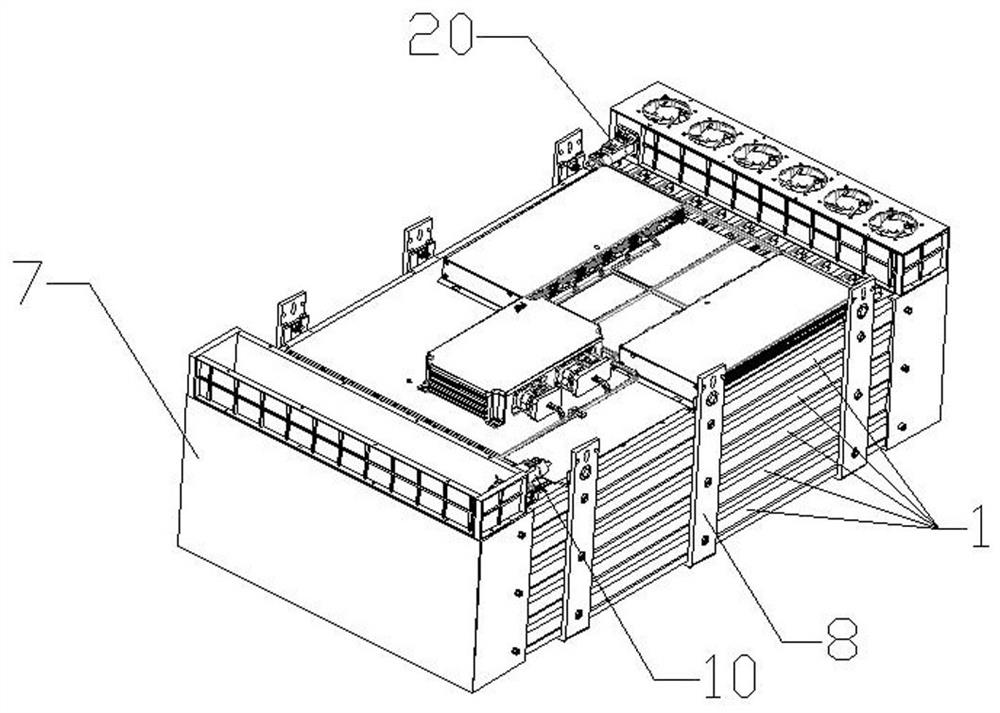

[0028] Such as Figure 1-2 As shown, this embodiment provides a battery pack based on a cylindrical battery unit, including a positive terminal 10 and a negative terminal 20 , front and rear end covers 7 , a fixing bracket 8 and 55 battery packs. The front and rear end caps 7 are made of high flame-retardant polymer materials, and are arranged at the front and rear ends of the battery pack. The fixing bracket 8 is made of high-strength aluminum alloy material, which is evenly arranged in the middle of the battery pack and fixed on three sides. The front and rear end caps 7 and the fixing bracket 8 are all threadedly connected with the battery pack to fix each battery pack.

[0029] Among them, the battery packs are stacked in rows and columns, divided into 5 layers and 11 columns. The battery packs in the same row are connected in parallel synchronously, and the battery packs in adjacent rows are connected in series in S-shaped direction.

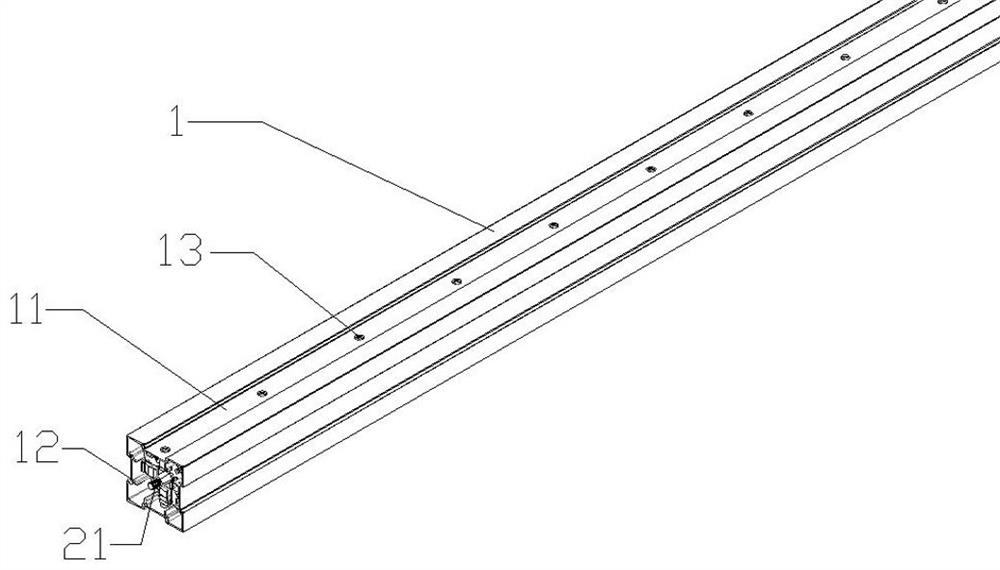

[0030] The battery pack includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com