Semiconductor device and manufacturing method of the same

A manufacturing method and semiconductor technology, applied in the direction of semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve problems such as easy cracking, and achieve the effect of suppressing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] 0028

[0067] use below Figure 1 to Figure 9 , the semiconductor device and the manufacturing method of the semiconductor device of the present invention will be described.

[0068] 0029

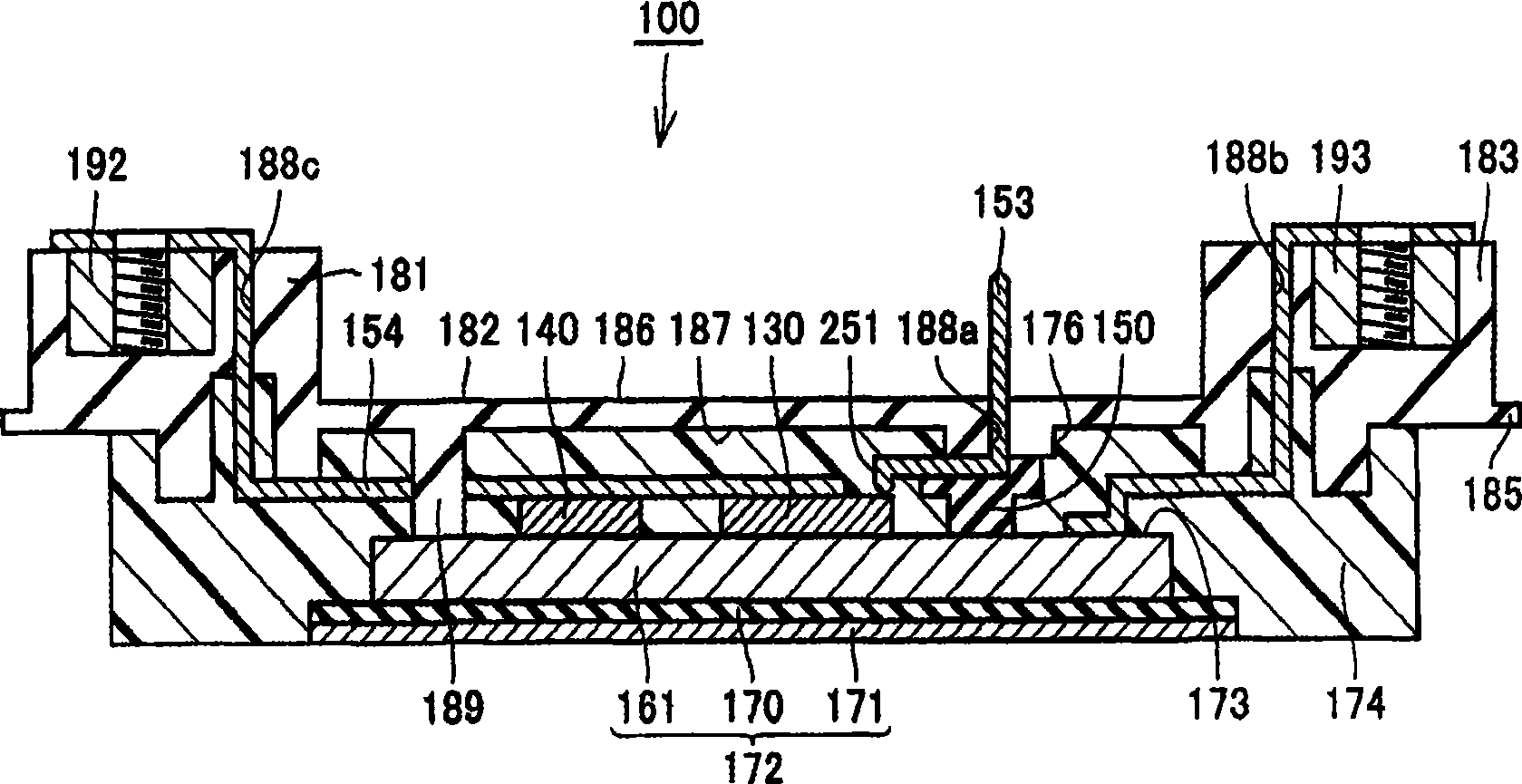

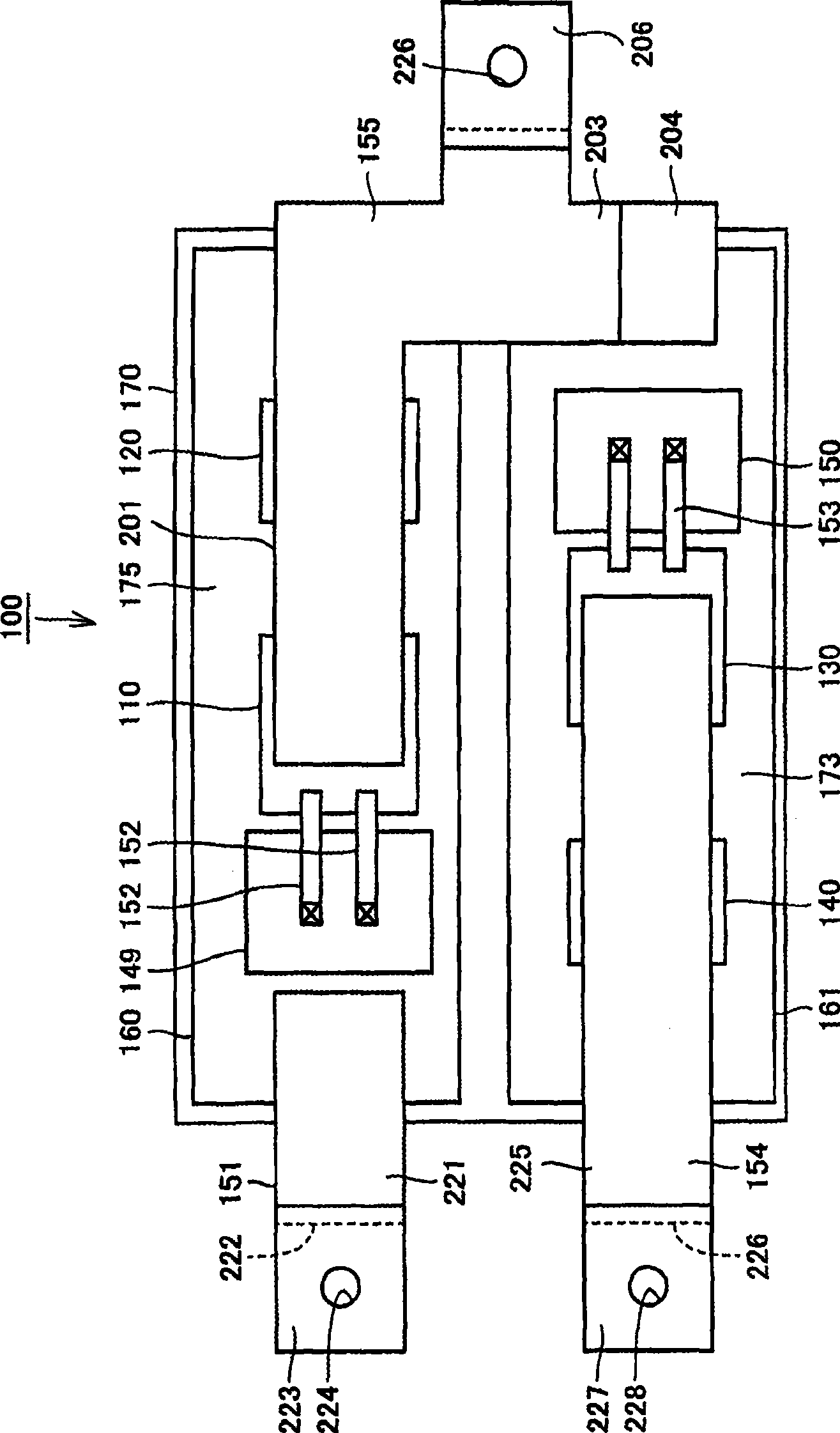

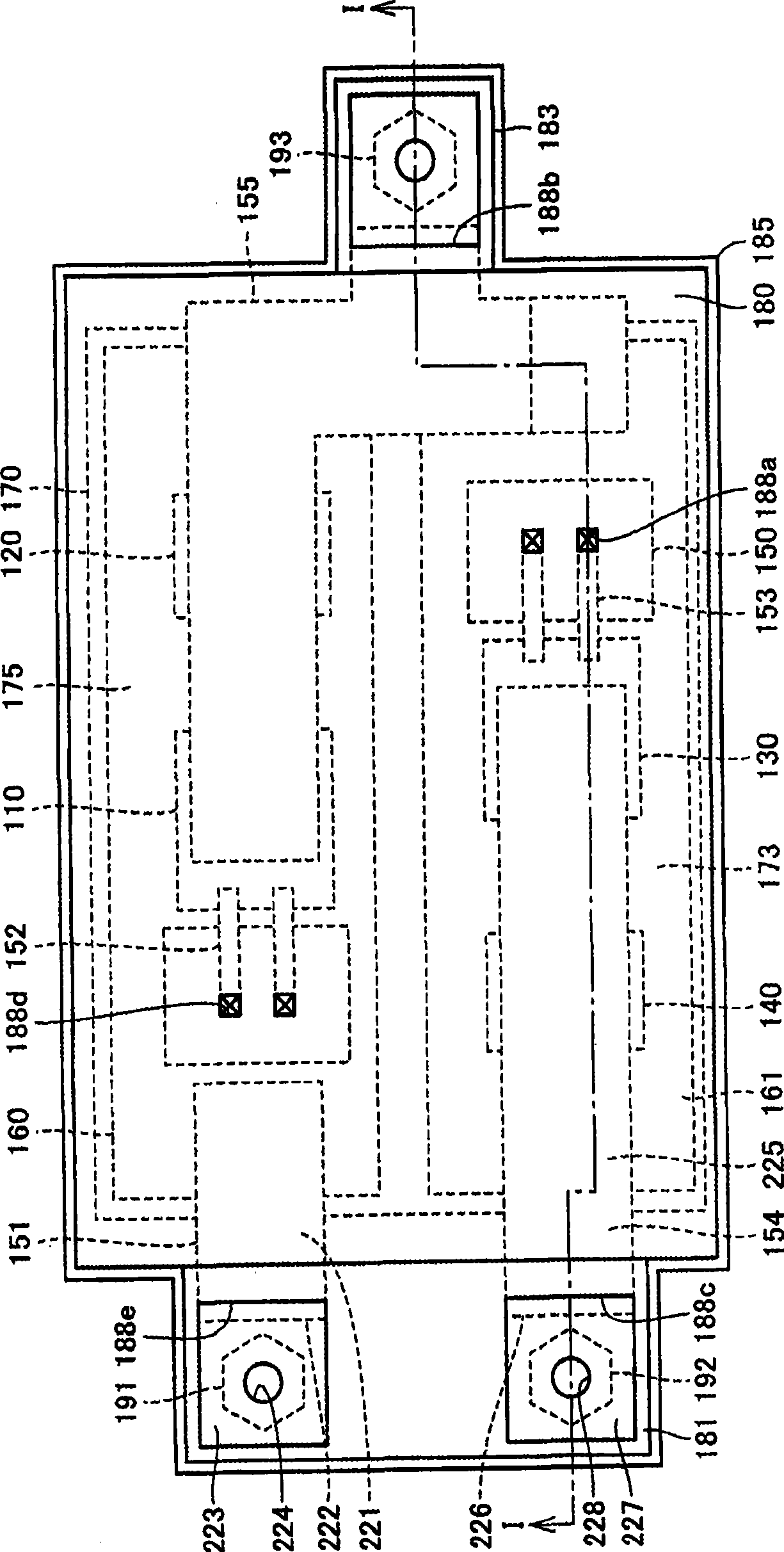

[0069] figure 1 It is a cross-sectional view of the semiconductor device 100 according to the embodiment of the present invention. figure 2 yes figure 1 A plan view of semiconductor device 100 is shown. image 3 It is a plan view of semiconductor device 100 omitting terminal block 182 and molding resin 174 .

[0070] 0030

[0071] exist figure 1 , figure 2 and image 3 In the illustrated example, the semiconductor device 100 is provided with a substrate 172 having a main surface 173; a plurality of elements 110, 120, 130, 140 disposed on the main surface 173 of the substrate 172; 130 , 140 formed on the molding resin 174 ; and the terminal block 182 covering the upper surface of the molding resin 174 .

[0072] 0031

[0073] The elements 110 , 120 , 130 , and 140 are, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com