Patents

Literature

39results about How to "Avoid preparation method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

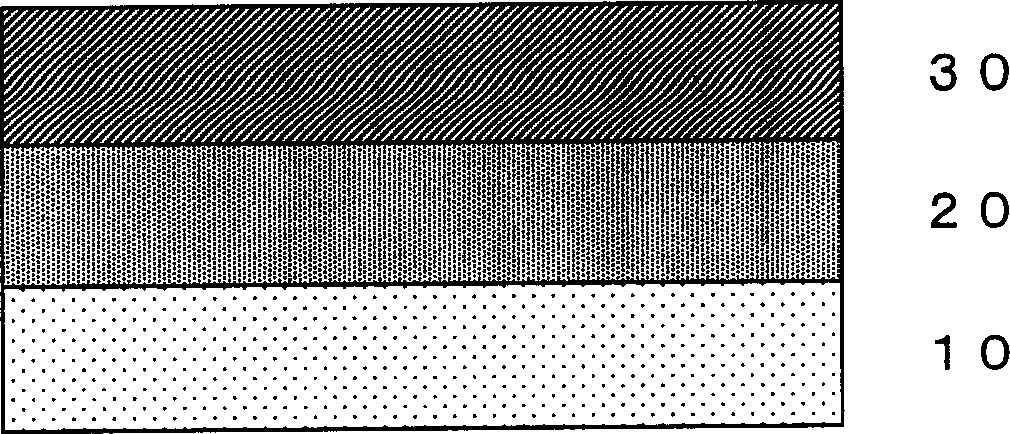

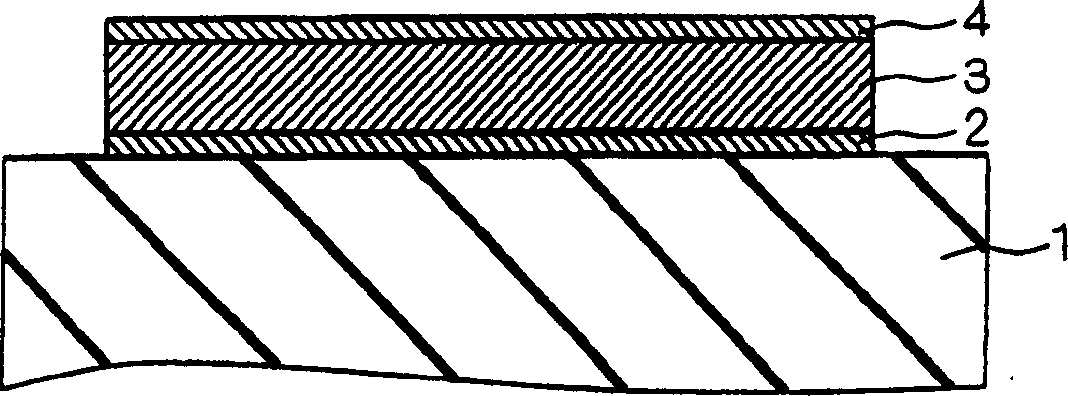

Near-infrared absorbing film, process for producing the same, near-infrared absorbing film roll, process for producing the same and near-infrared absorbing filter

InactiveCN1836176AAvoid preparation methodHigh absorption capacityColor measuring devicesSynthetic resin layered productsTransmittanceHigh luminance

The near-infrared ray absorption film of the present invention is a near-infrared ray absorption film in which a near-infrared ray absorption layer comprising a composition containing a near-infrared ray absorbing dye having maximum absorption at a wavelength of 800 to 1200 nm, and a resin is provided on a transparent substrate film, and is characterized that a surfactant having HLB of 2 to 12 is contained in the composition at 0.01 to 2.0% by mass. There can be provided a near-infrared ray absorption film excellent in coated film appearance which has the wide absorbing ability in the near-infrared ray absorbing region, has a high light transmittance in the visible light region, has little change in optical properties with time, and can respond to a higher luminance of a display, and higher-definition and higher image quality by Hi-Vision broadcasting in recent years.

Owner:TOYO TOYOBO CO LTD

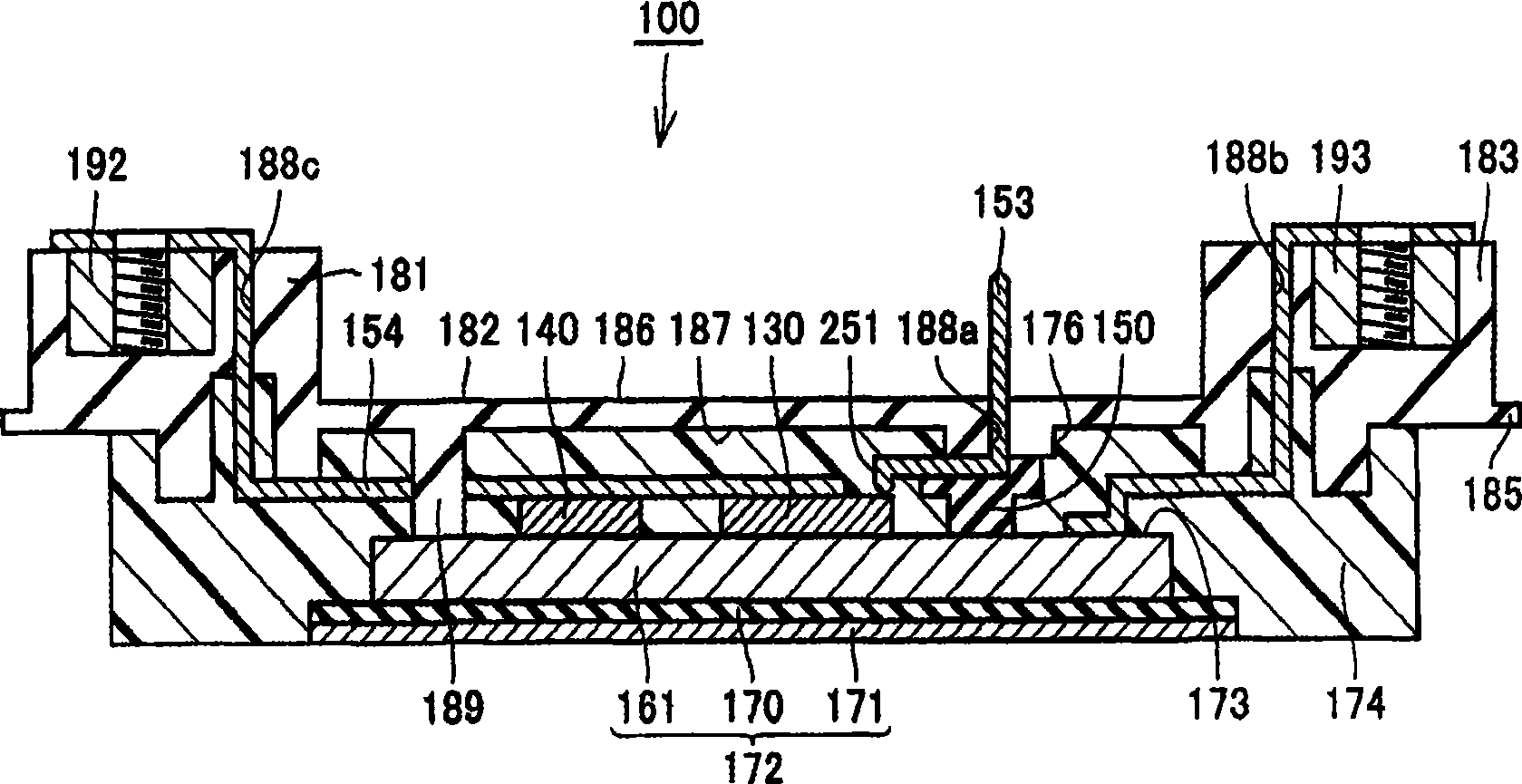

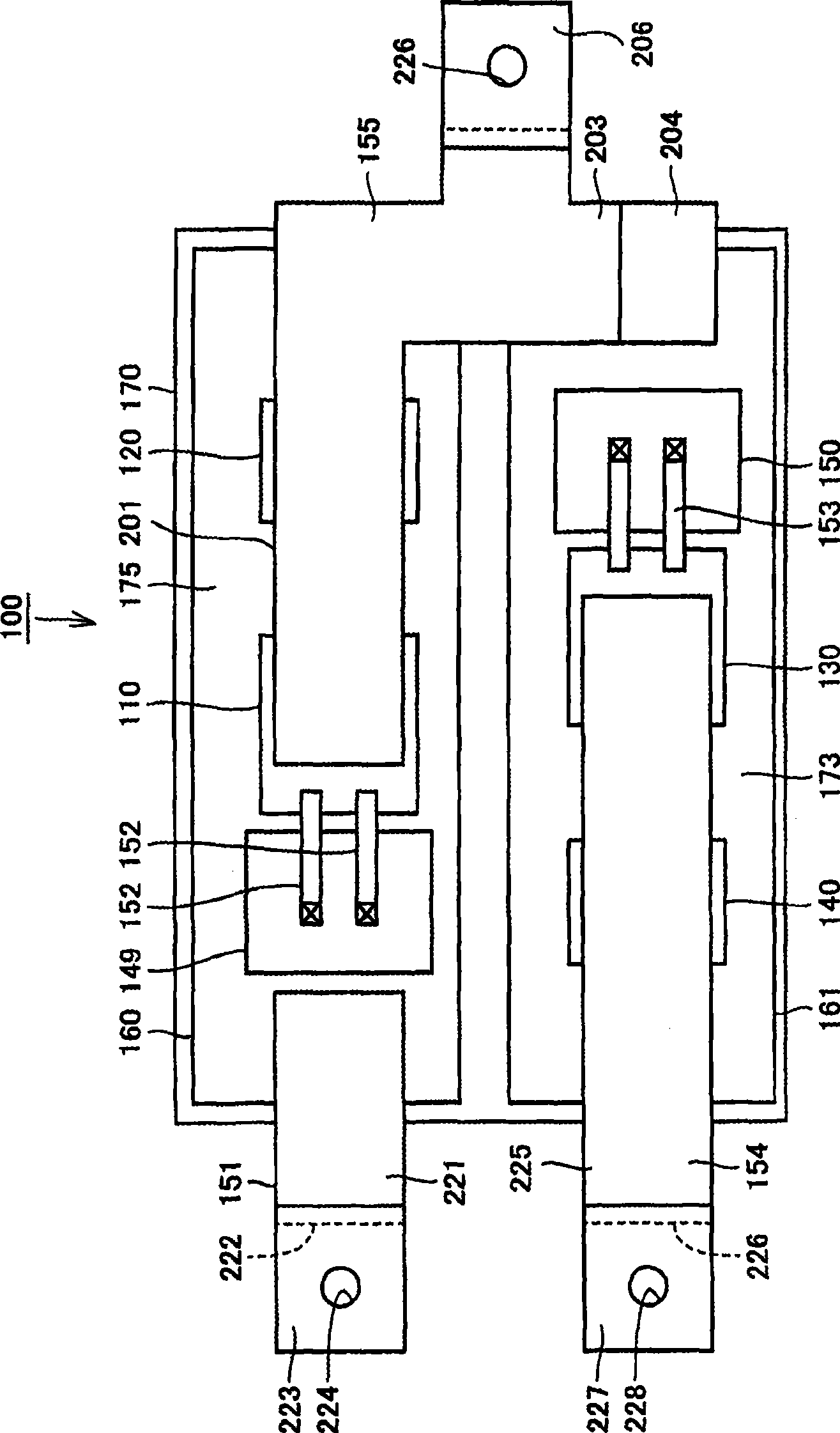

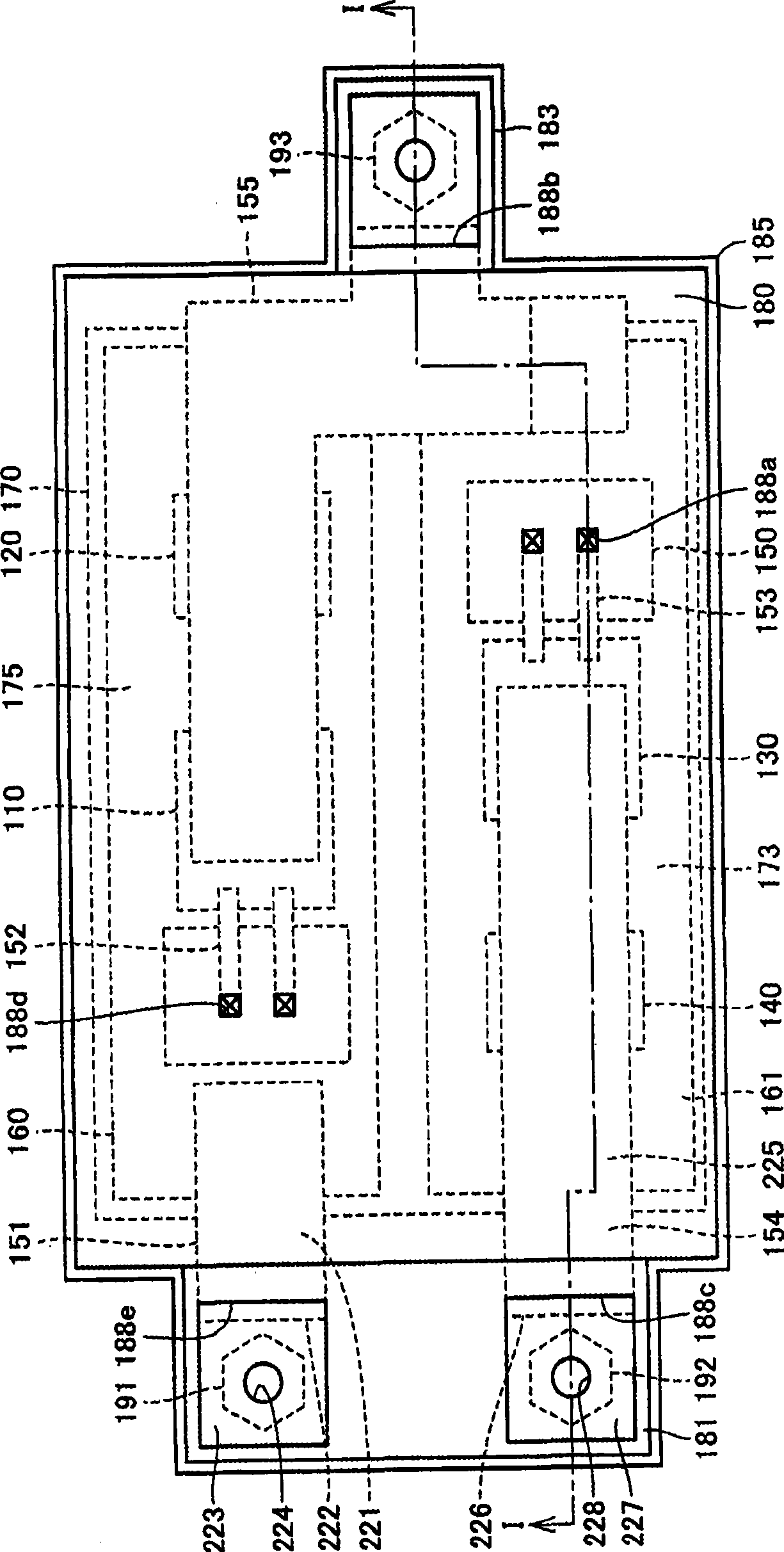

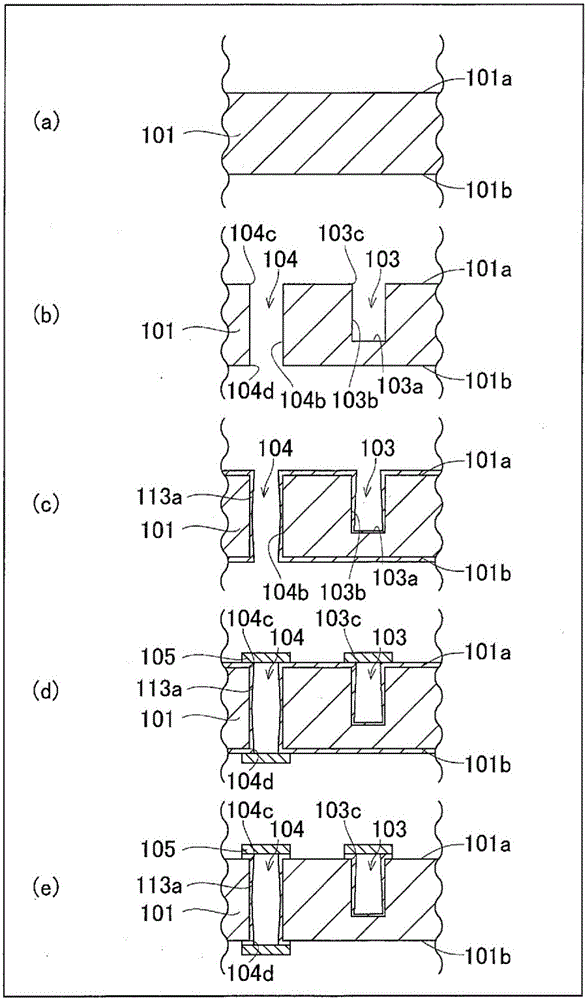

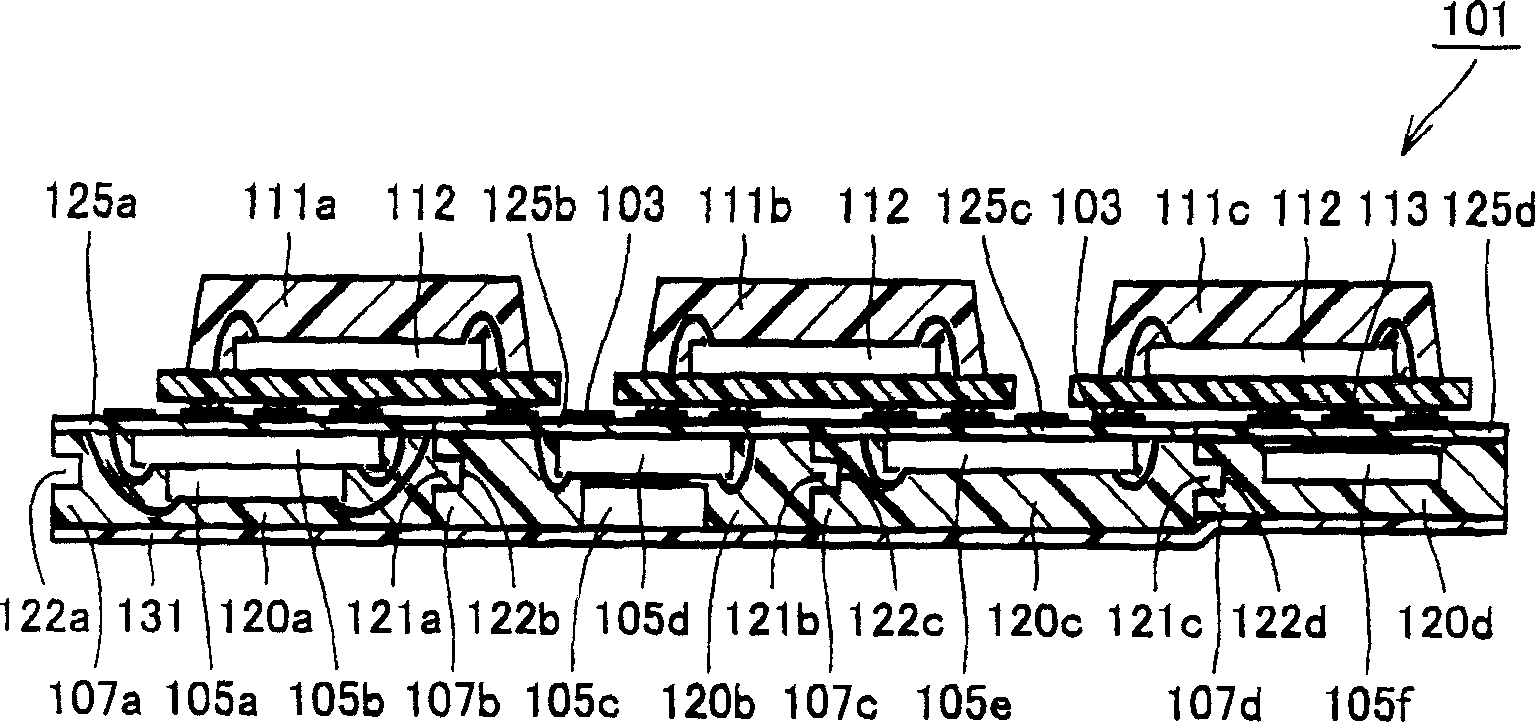

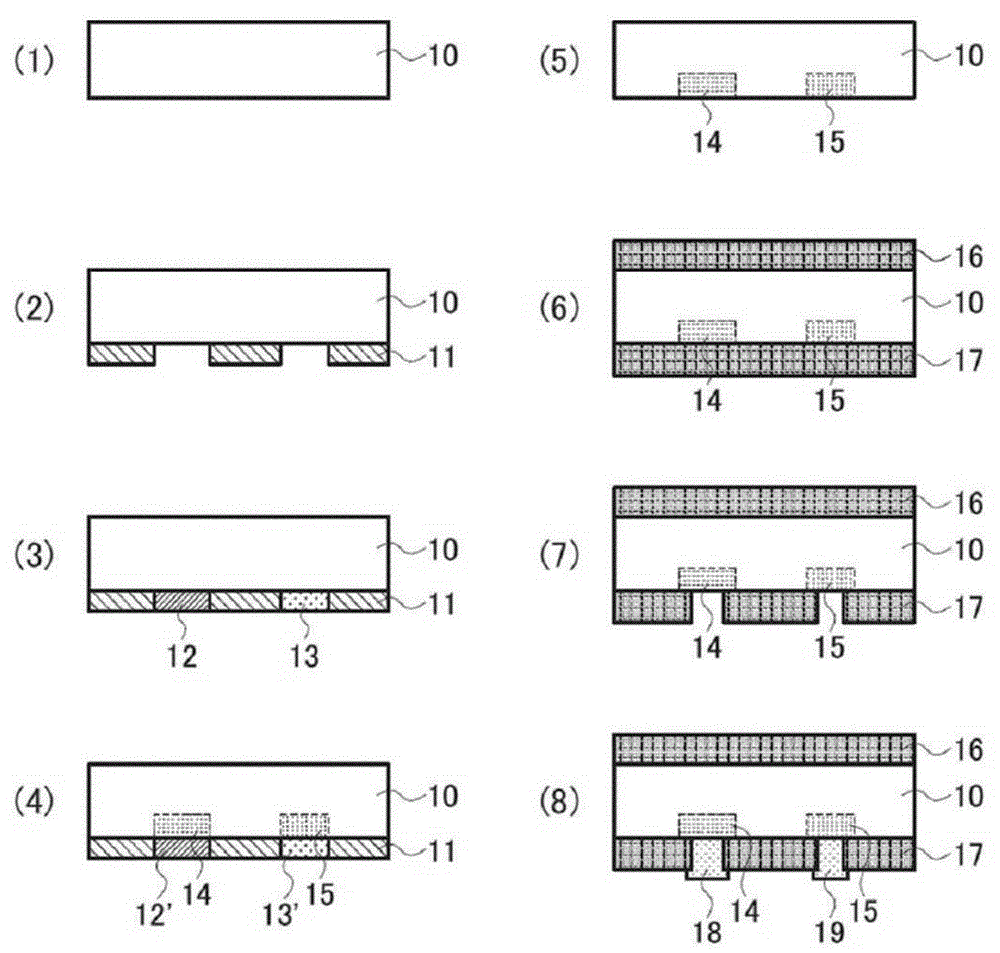

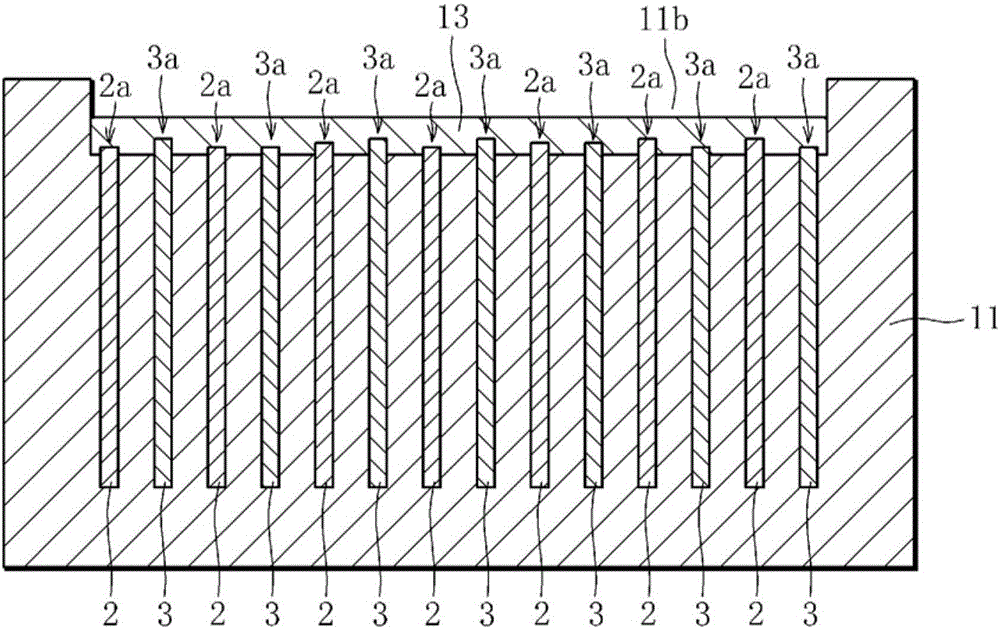

Semiconductor device and manufacturing method of the same

InactiveCN101521167AAvoid preparation methodAvoid damageSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

The present invention provides a semiconductor device and manufacturing method of the same, the method includes steps of: preparing a substrate (172), a clintheriform terminal stand (182) arranged in interval with the substrate (172) to form through holes from a side to the other, and a control terminal (153) built in the through holes and projecting from the terminal stand (182); preparing a first and second metal moulds, the former forming a first concave section of the first metal mould for containing the substrate (172), and the latter forming a second concave section of the second metal mould for containing the terminal stand (182) and a third concave section of the second metal mould for containing the control terminal (153) projecting from the terminal stand (182); configuring the substrate (172) in the first concave section; configuring the terminal stand (182) in the second concave section and configuring the control terminal (153) in the third concave section, and sealing opening of the second concave section of the stand (182); filling resin between the substrate (172) and the terminal stand (182) to form mould resin (174) on the substrate (172) in state that the first and second metal moulds clamping the periphery of the terminal stand (182).

Owner:MITSUBISHI ELECTRIC CORP

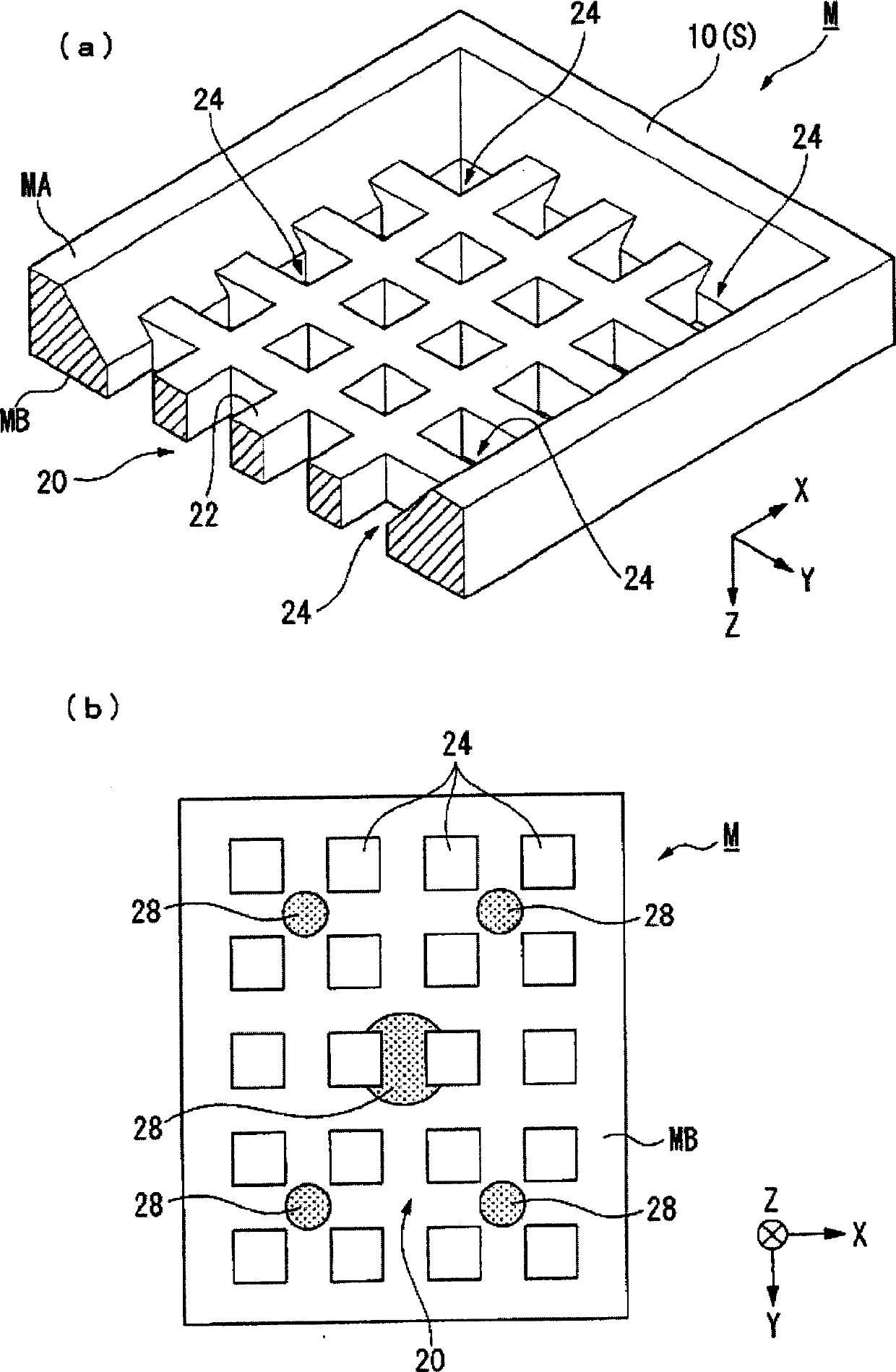

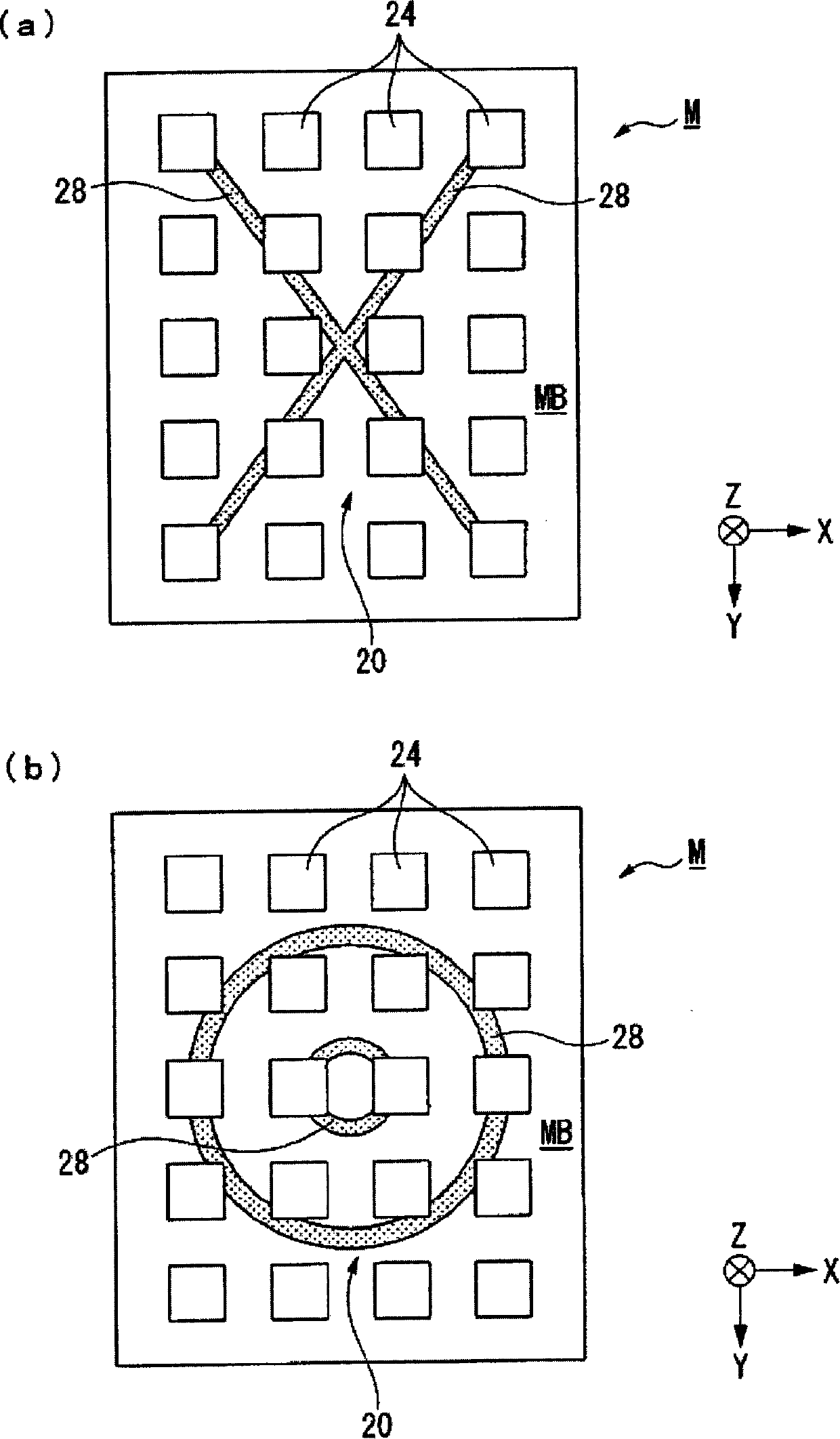

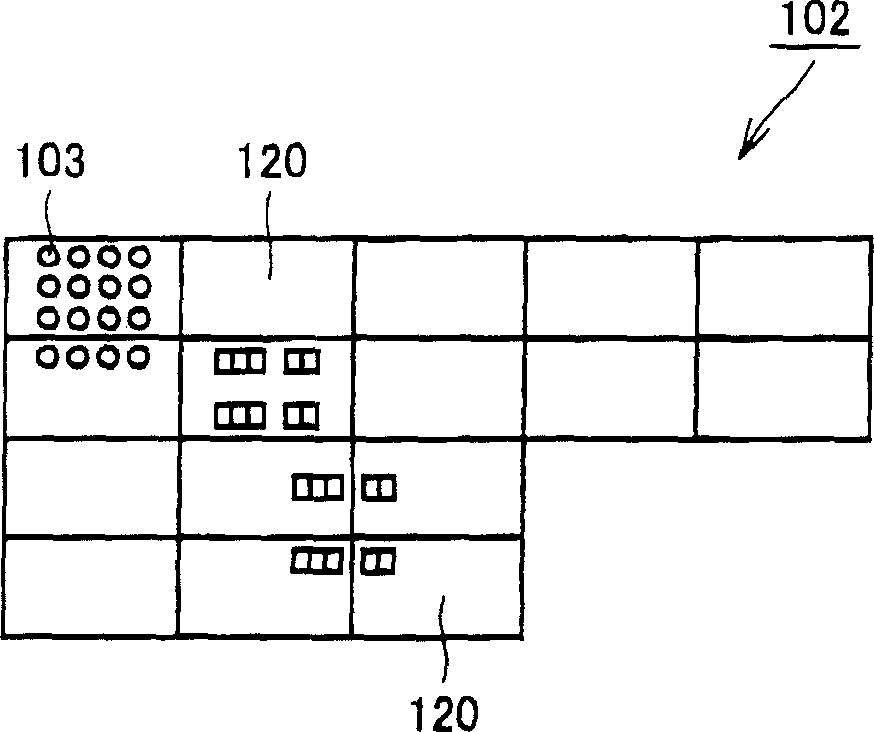

Mask, mask manufacturing method, pattern forming apparatus, and pattern formation method

InactiveCN1824826AAvoid preparation methodElectroluminescent light sourcesSolid-state devicesOptoelectronicsPhysics

Owner:SEIKO EPSON CORP

Manufacturing method for sparkling black glass

InactiveCN1583618APrevent color impurityMethod for making crystal black glass to prevent color impurityGlass furnace apparatusColoring agentsBlack glass

A black sparkling glass comprises: Fe2O3 0.13-0.20, NiO 0.15-0.19, CoO 0.014-0.019. It is produced by: melting stably at 1560-1570deg.c, removing carbon powder and having sal mirabile content<4%, and stirring mechanically. The method can be used to eliminate black strips and bubbles.

Owner:JINGNIU GLASS CERAMICS GROUP

Fabricating method for flat display device

InactiveCN1888953AAvoid preparation methodNanotechStatic indicating devicesDisplay deviceEngineering

Owner:LG DISPLAY CO LTD

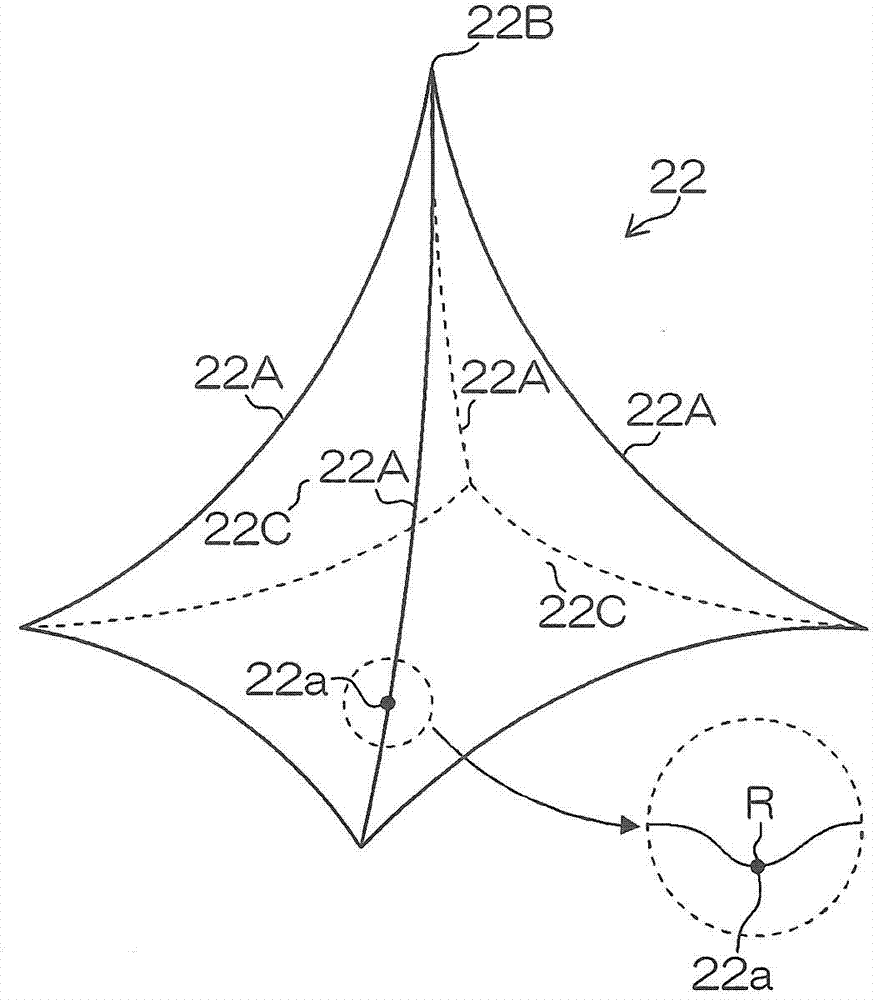

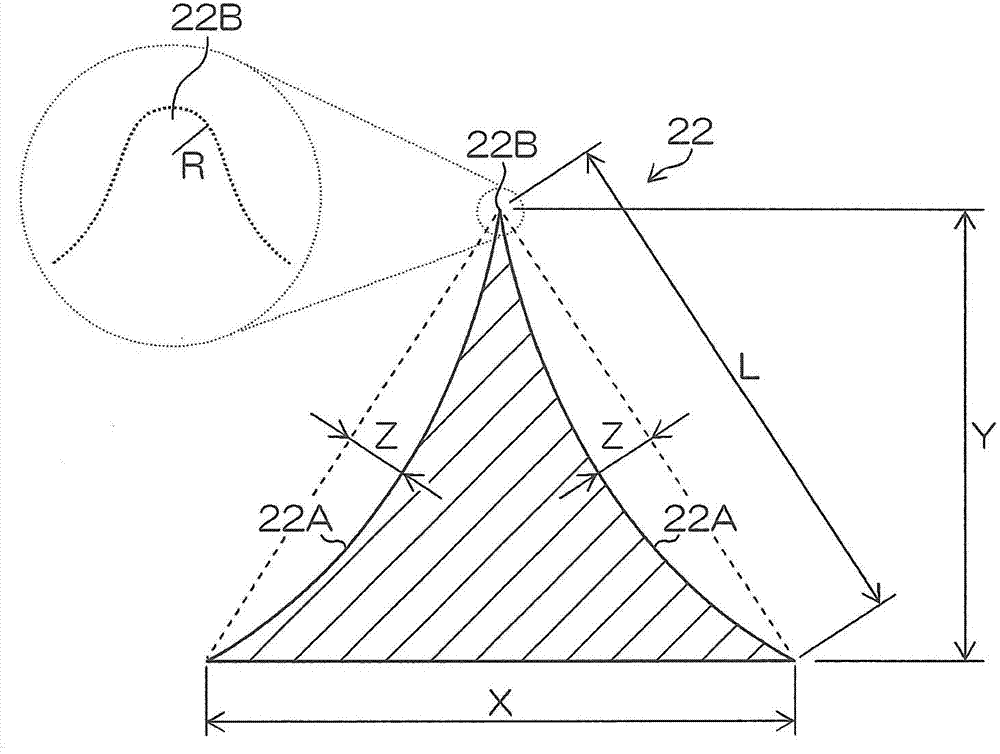

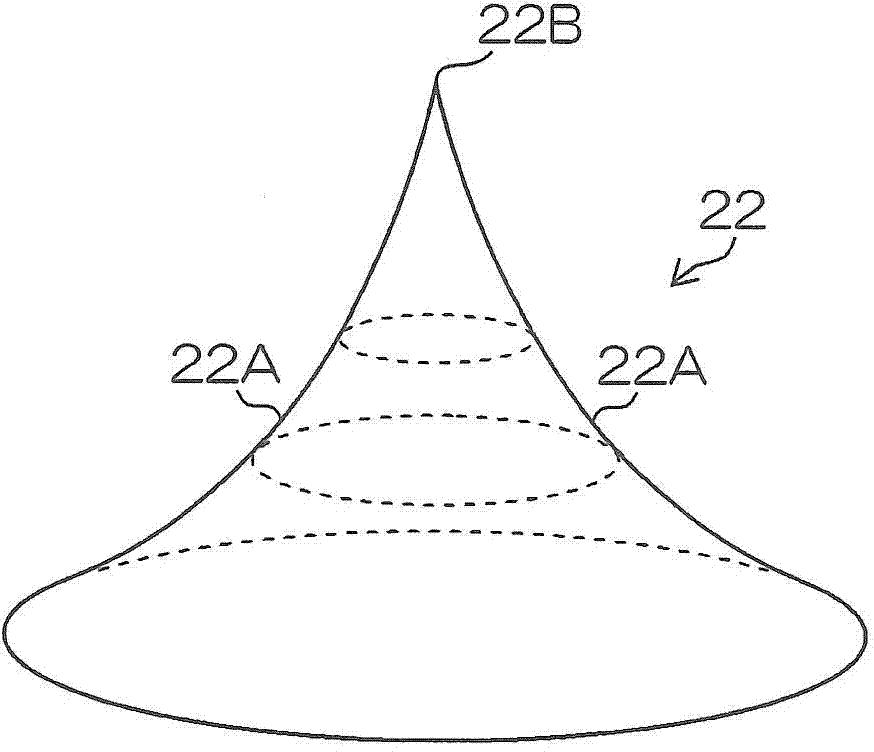

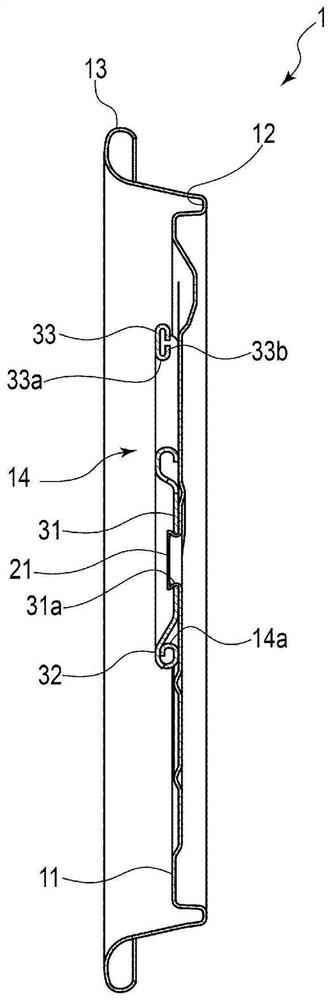

Molding mold, and manufacturing method for transdermal absorption sheet

InactiveCN104780966AAvoid preparation methodSynthetic resin layered productsMicroneedlesShell moldingMoisture

A molding mold for forming a transdermal absorption sheet having needle-shaped protrusion parts arrayed thereupon. The molding mold is formed by laminating: a first member, the surface of which has needle-shaped recesses that are the inverse of the needle-shaped protrusions; a second member that is disposed on the rear surface of the first member and comprises waterproof, moisture-permeable materials; and a third member that is disposed on the rear surface of the second member and comprises a rigid body. Thus provided is a molding mold that can prevent the leakage of a medicine-containing liquid that is filled into the needle-shaped recesses, and a transdermal absorption sheet manufacturing method using the molding mold.

Owner:FUJIFILM CORP

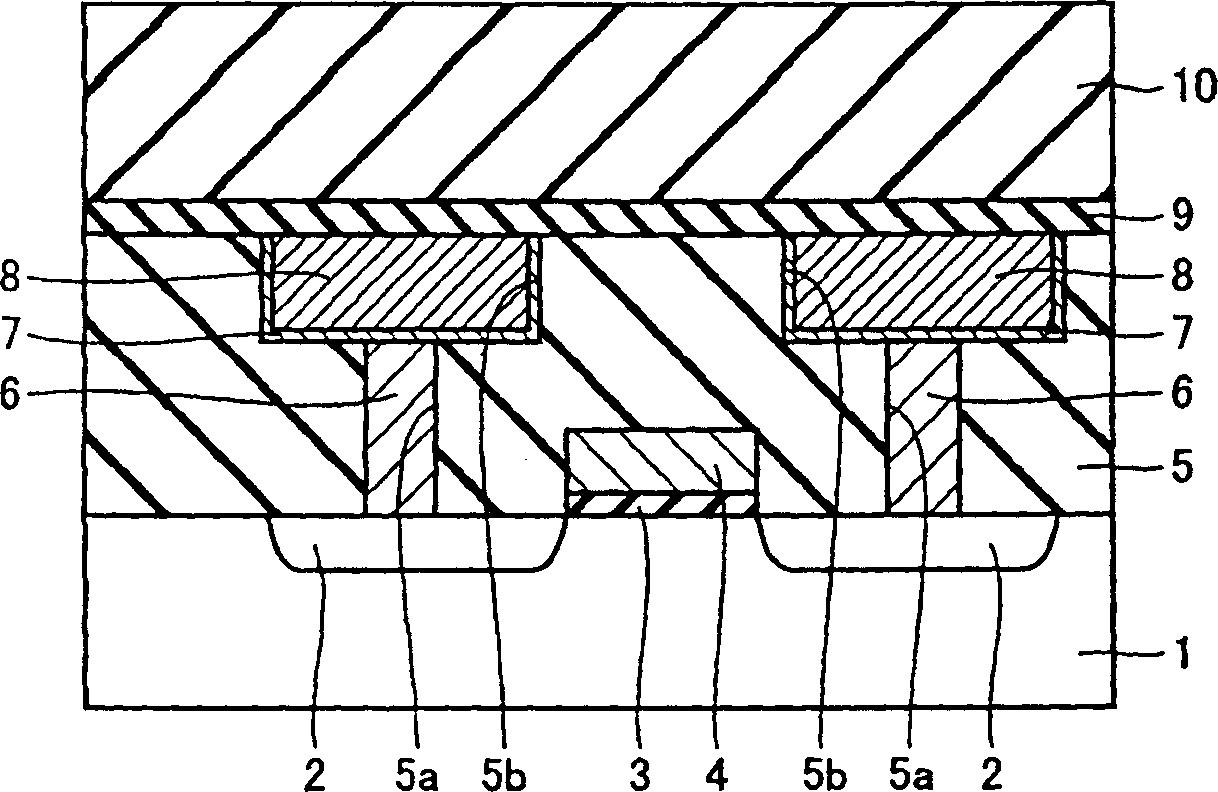

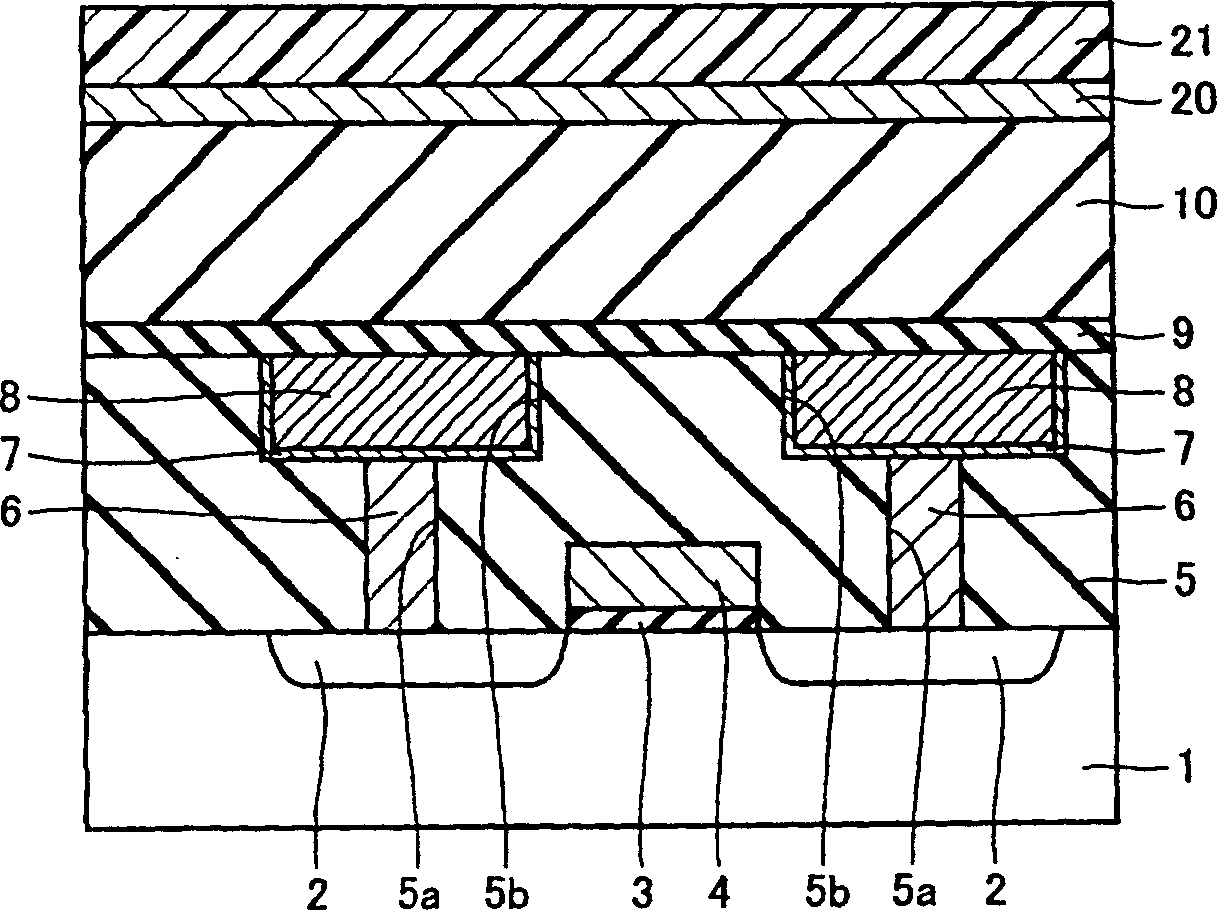

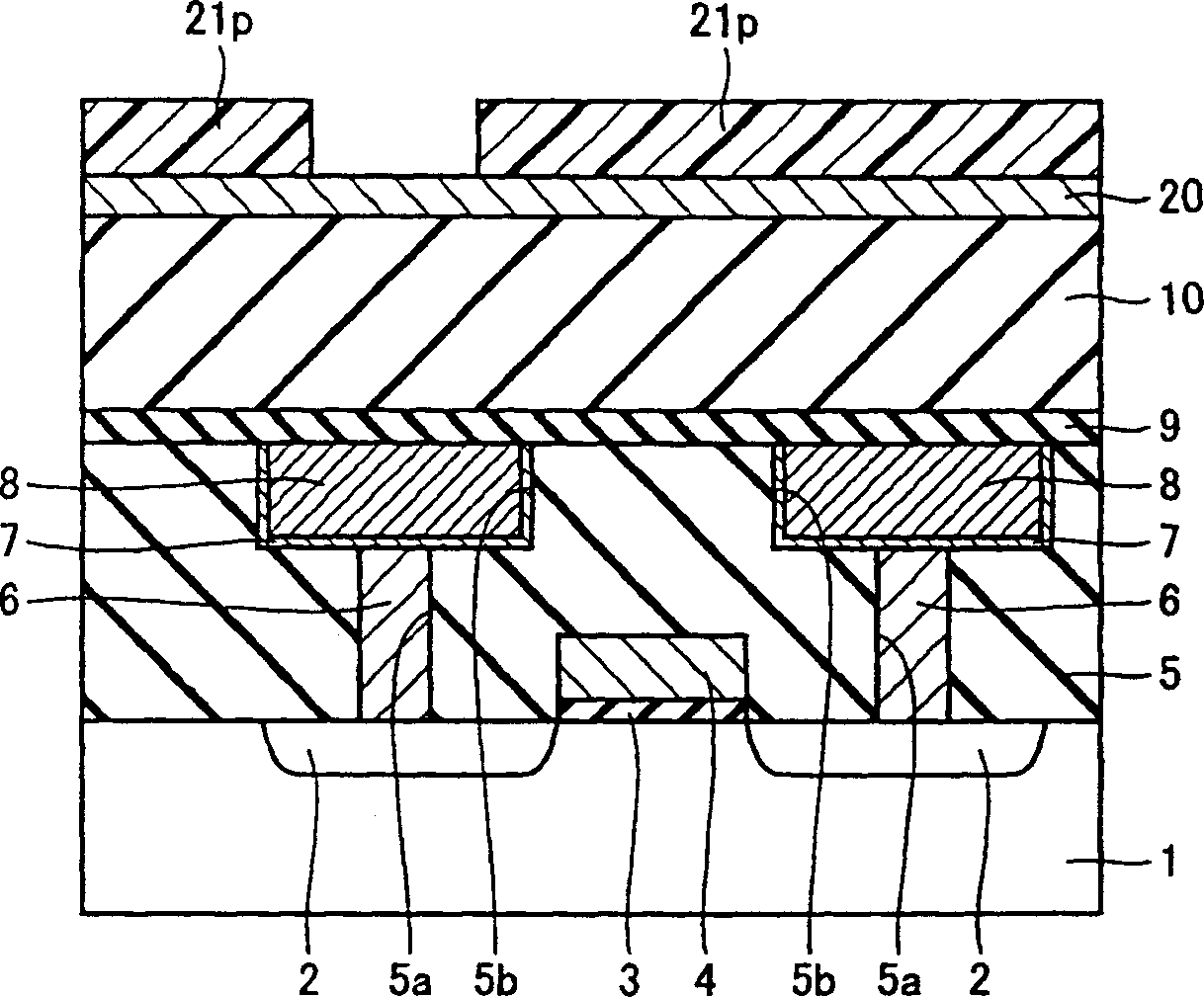

Mfg. method of semiconductor device with opening portion

InactiveCN1447414AAvoid preparation methodLow reliabilitySemiconductor/solid-state device manufacturingResistEngineering

When an antireflection film is used when forming the two-stage stepped opening on the interlayer insulating film, it is possible to obtain a semiconductor device manufacturing method capable of preventing a decrease in reliability. The manufacturing method of this semiconductor device comprises the steps of forming a first resist pattern on a predetermined region on an antireflective film, using the first resist pattern as a mask to form a first opening in an interlayer insulating film, leaving After removing the first anti-corrosion pattern on the anti-reflection film, in the predetermined area on the anti-reflection film, the process of forming the second anti-corrosion pattern, using the second anti-corrosion pattern as a mask, at least on the top of the first opening, A step of forming a second opening having a larger opening area than the first opening.

Owner:SANYO ELECTRIC CO LTD

Method for producing waveguide substrate

InactiveCN106410360APrevent peelingGuaranteed film thicknessSemiconductor/solid-state device detailsSemiconductor/solid-state device manufacturingChemistryComposite material

To allow a metal film to have a sufficient thickness around a bottom surface of a non-through hole and prevent the metal film from being peeled from a substrate surface, a method for producing a waveguide substrate includes forming a first metal film on (i) a first main surface of a substrate, at which first main surface a non-through hole opens, and on (ii) an inner wall of the non-through hole, forming resist on a first main surface side of the substrate in such a manner that the resist blocks the opening of the non-through hole, removing a first portion of the first metal film which first portion is on the first main surface, removing the resist, and forming a second metal film on the first main surface of the substrate in a state where the first metal film is present on the inner wall of the non-through hole.

Owner:FUJIKURA LTD

Method of mfg. electronic device with wiring connection structure

InactiveCN1519911AAvoid preparation methodSemiconductor/solid-state device manufacturingHydrofluoric acidCompound (substance)

To obtain a method for manufacturing an electronic device having a wiring connection structure which can avoid improper contact between a via plug and a metal wiring. In an etching step for forming a via hole 8, mixture gas of C4H8, O2, and Ar is used an etching gas. This enables the surface of the side wall of the via hole 8 to be smooth without fine irregularity at least in the upper part of the side wall 8. Thus, a barrier metal film 9 and the side wall of the via hole 8 can be tightly contacted with each other without causing a gap therebetween caused by the fine irregularity. As a result, in a cleaning step using a hydrofluoric acid after a CMP (chemical mechanical polishing) step, a cleaning solution can be avoid from passing through the gap between the film 9 and the side wall of the via hole 8 and being impregnated into the film 3.

Owner:RENESAS TECH CORP

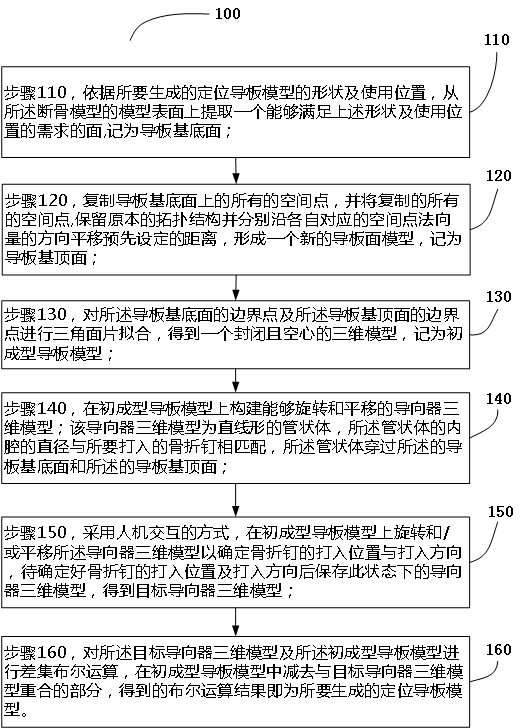

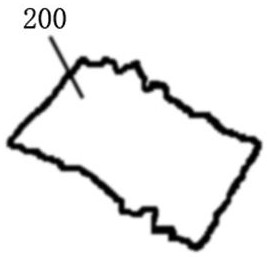

Positioning guide plate and manufacturing method thereof, and positioning guide plate model generation method and system

InactiveCN111956318ABreak the limitAvoid preparation methodOsteosynthesis devicesEngineeringHuman–robot interaction

The invention provides a positioning guide plate, a manufacturing method thereof, a positioning guide plate model generation method and a positioning guide plate model generation system. The positioning guide plate model generation method and system are all based on a broken bone model after virtual reduction of a fractured bone of a fracture nail to be driven into a patient, and the method comprises the following steps: extracting a guide plate base surface from the model surface of the broken bone model; copying all the space points on the guide plate base surface and translating all the copied space points for a preset distance by keeping the original topological structure to form a guide plate base top surface; carrying out triangular patch fitting on the boundary points of the guide plate base surface and the boundary points of the guide plate base top surface to obtain an initially-formed guide plate model; constructing a guider three-dimensional model; rotating and / or translating the guider three-dimensional model on the initially-formed guide plate model by adopting a human-computer interaction mode to obtain a target guider three-dimensional model; and carrying out difference set Boolean operation on the target guider three-dimensional model and the initially-formed guide plate model to obtain a Boolean operation result, namely the positioning guide plate model to be generated. The method and system are used for assisting surgical positioning of the fracture nail.

Owner:UNIV OF JINAN

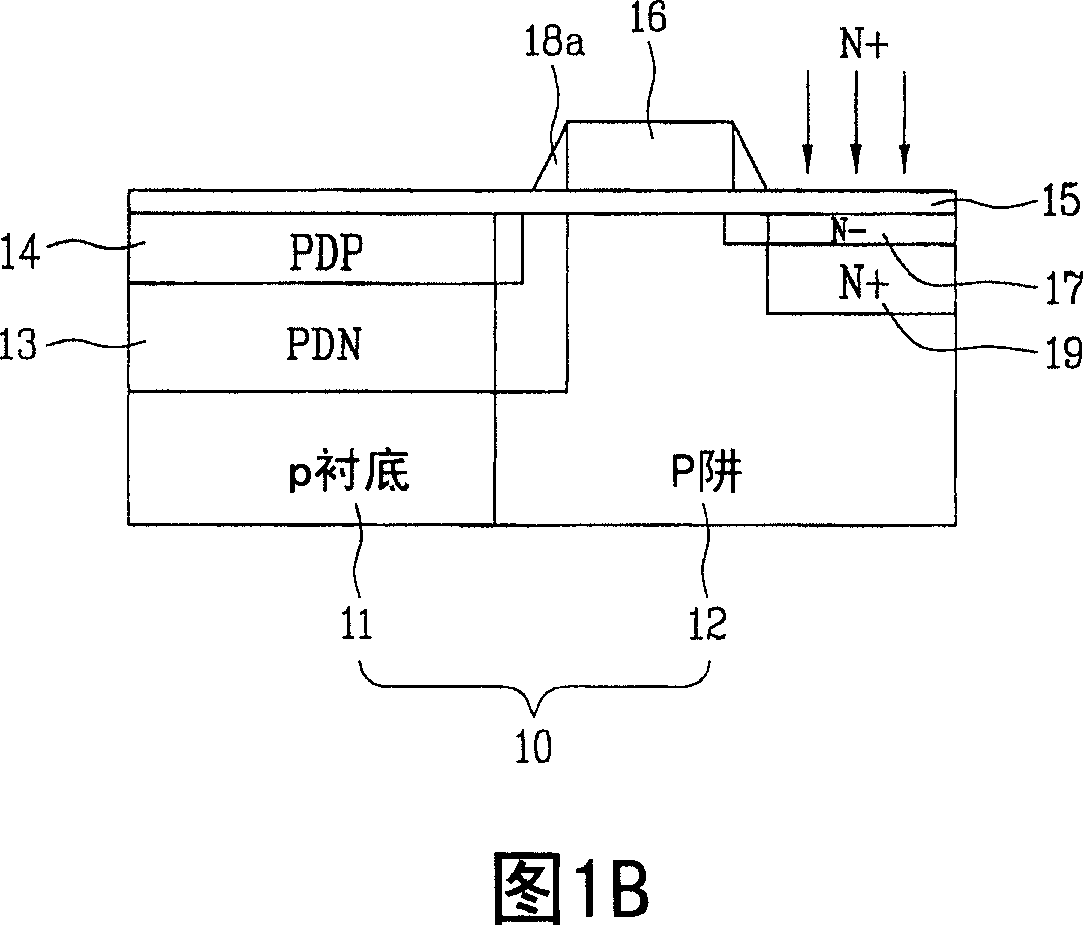

Method for manufacturing cmos image sensor

InactiveCN1992215AProtect manufacturing methodProtect a method of manufacture that sufficiently avoidsSolid-state devicesSemiconductor/solid-state device manufacturingSalicideCMOS

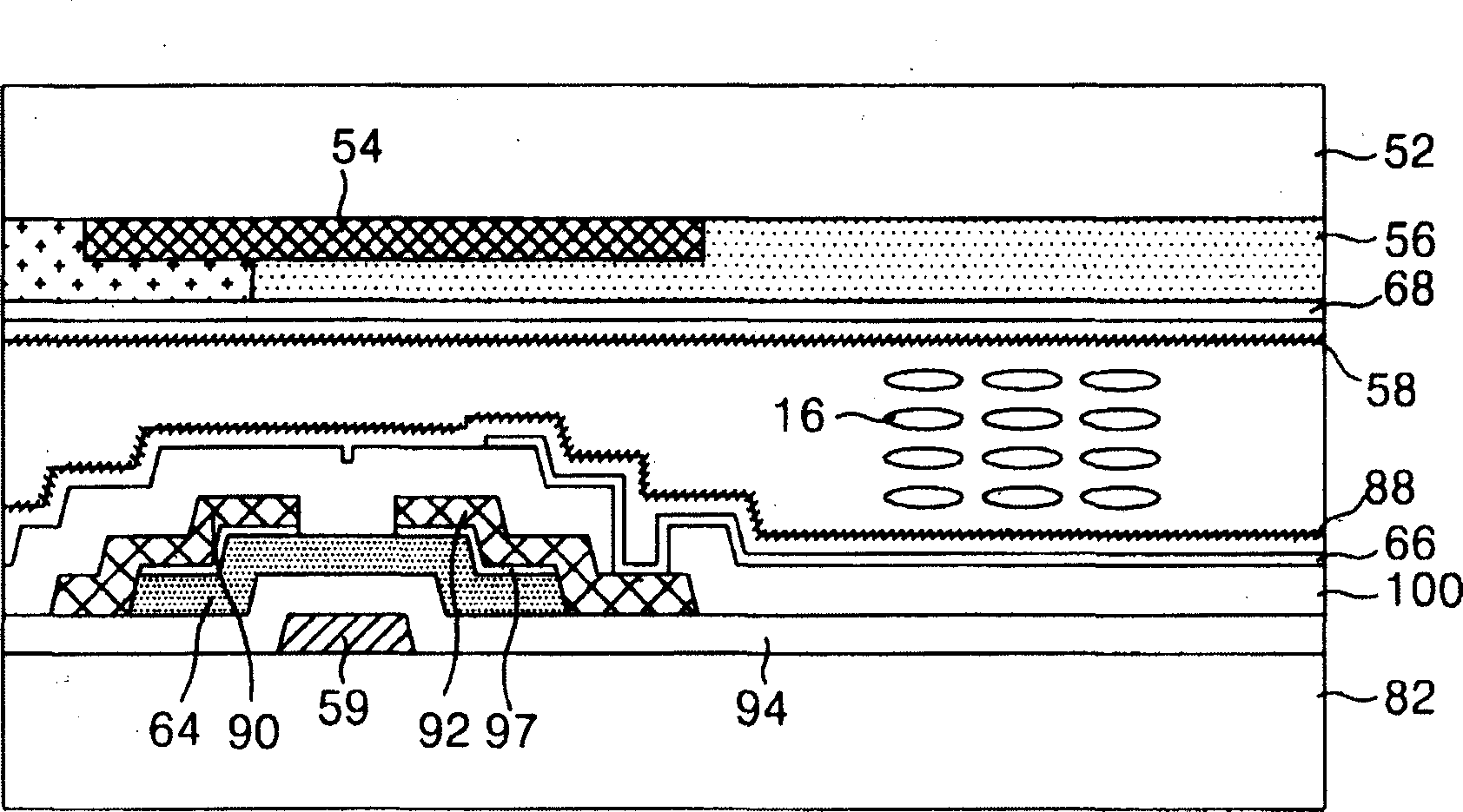

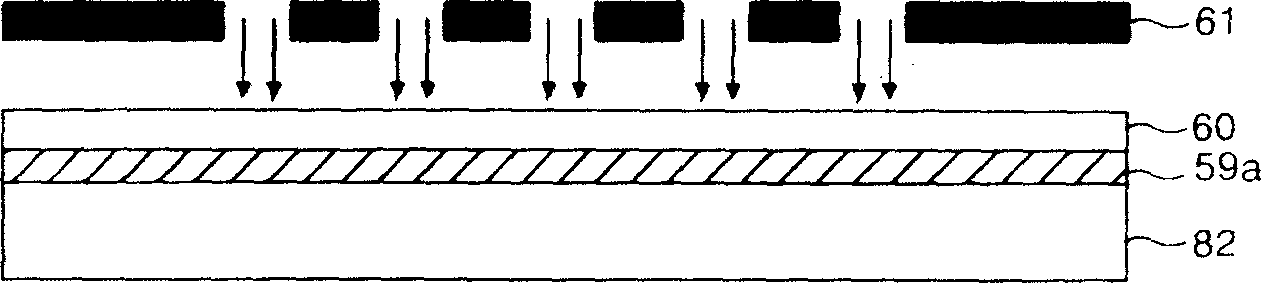

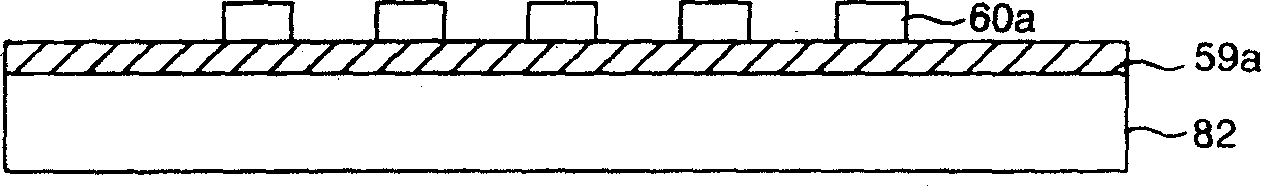

The invention provides a method for manufacturing a CIS, wherein a process has been improved in order to reduce or prevent a dark current of a photodiode region. In the method, a plurality of gates are formed on a semiconductor substrate, and impurities are implanted in side portions of a predetermined gate to form a photodiode region. Subsequently, a spacer nitride layer is formed and then etched to form a first spacer pattern covering the photodiode region and a second spacer pattern on sidewalls of the rest of the gates. After that, impurities are implanted using the first and second spacer patterns as a mask to form source / drain regions in portions of the semiconductor substrate that are exposed at the side portions of the gate(s). Subsequently, a salicide is formed on the gate and in the exposed portion of the semiconductor substrate.

Owner:DONGBU ELECTRONICS CO LTD

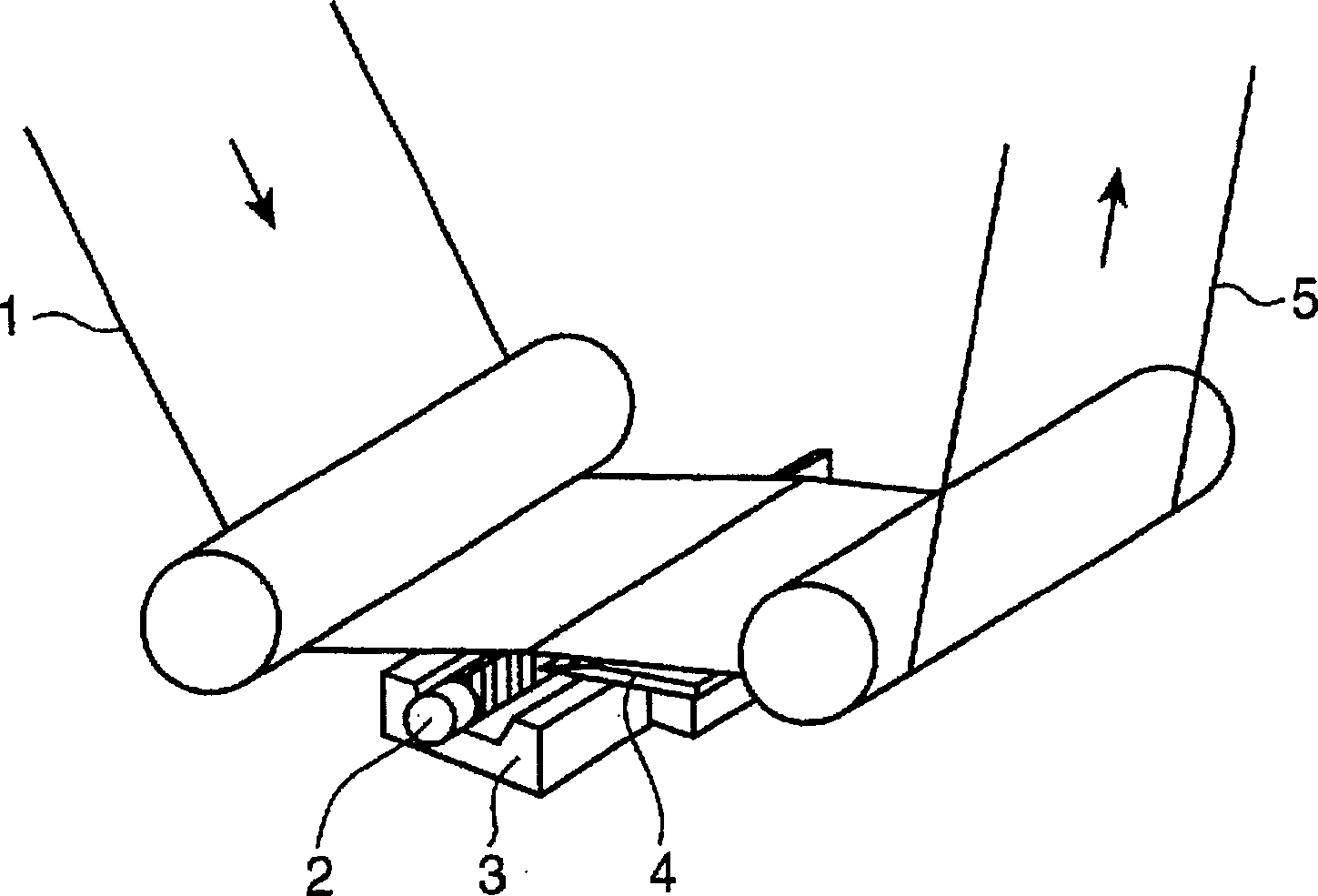

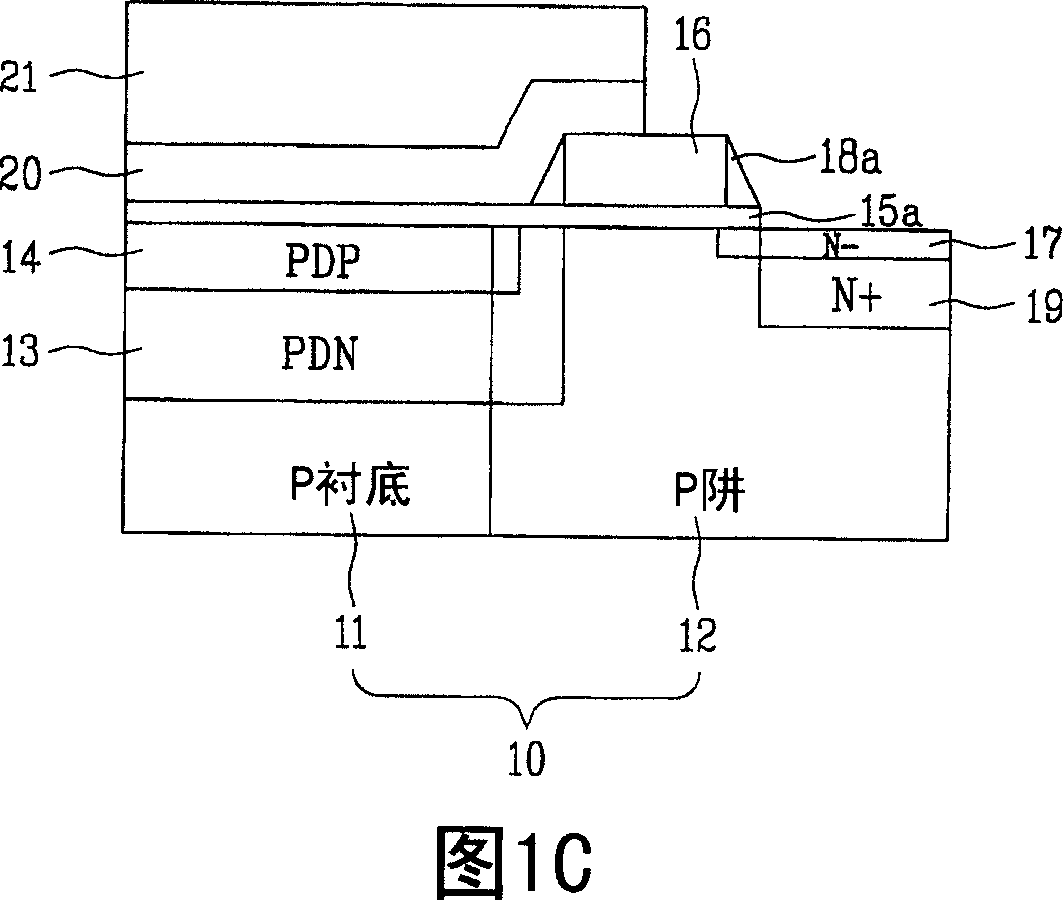

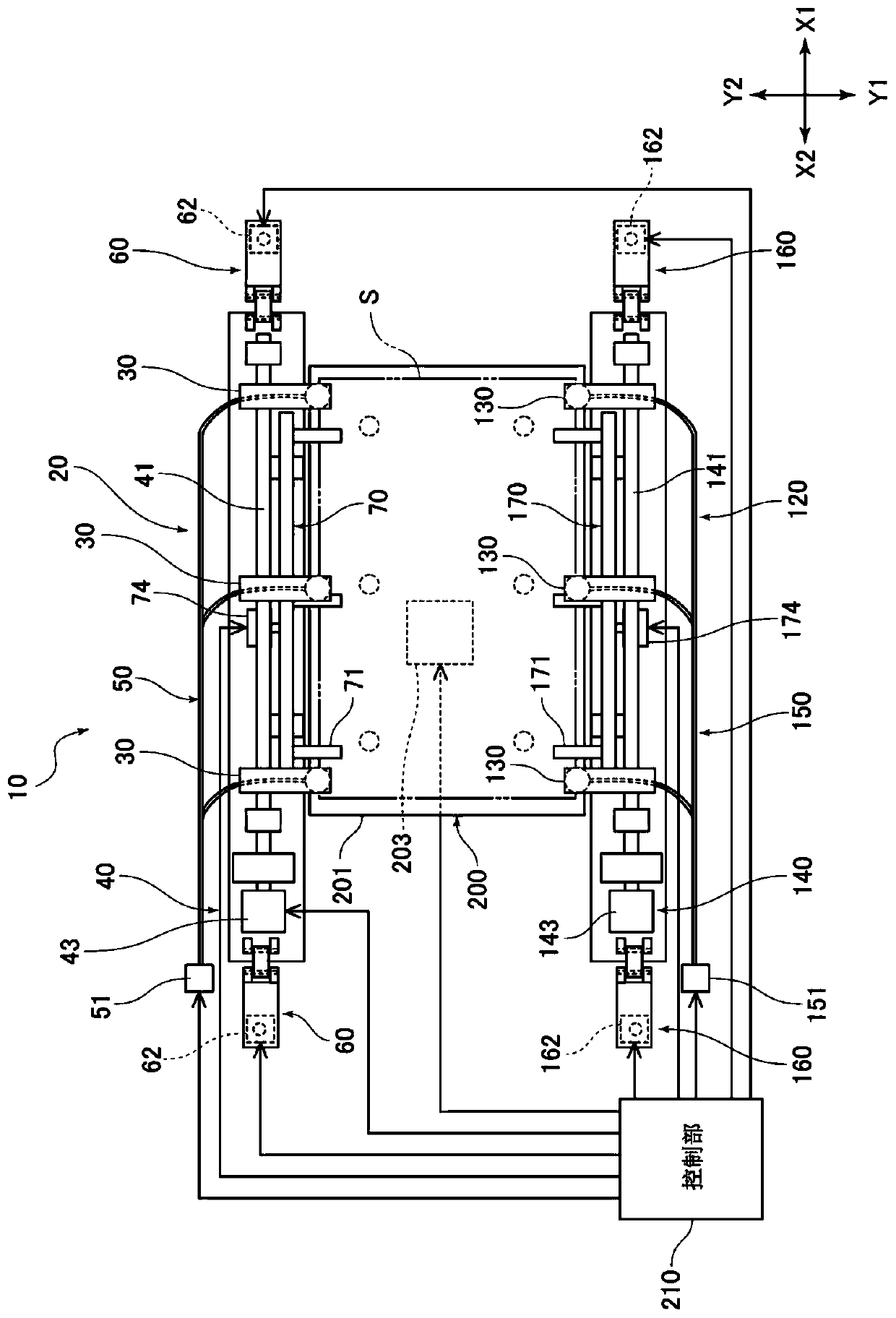

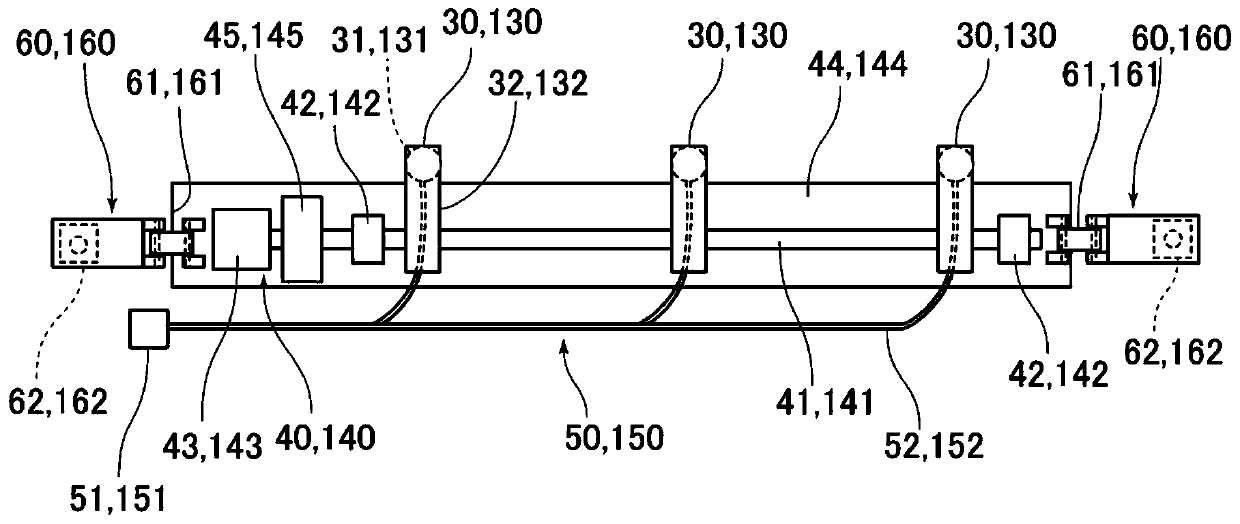

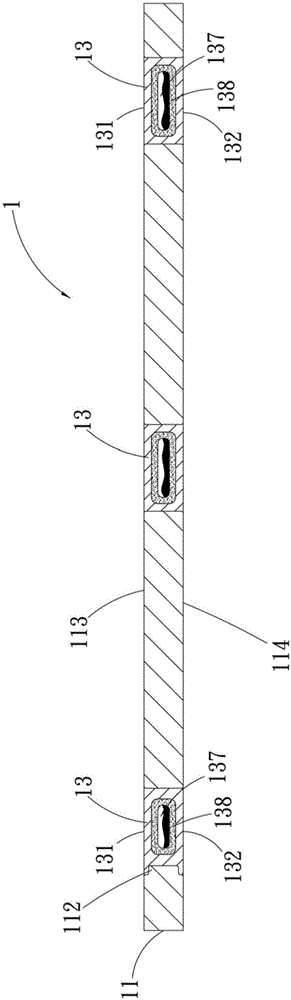

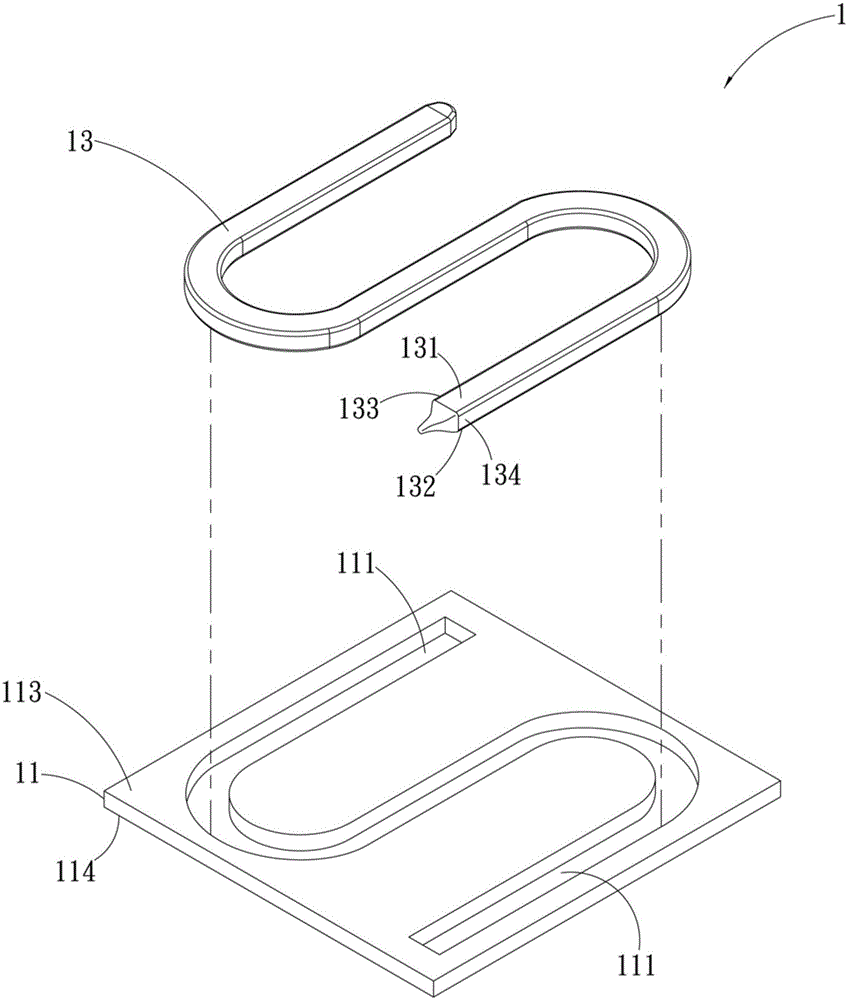

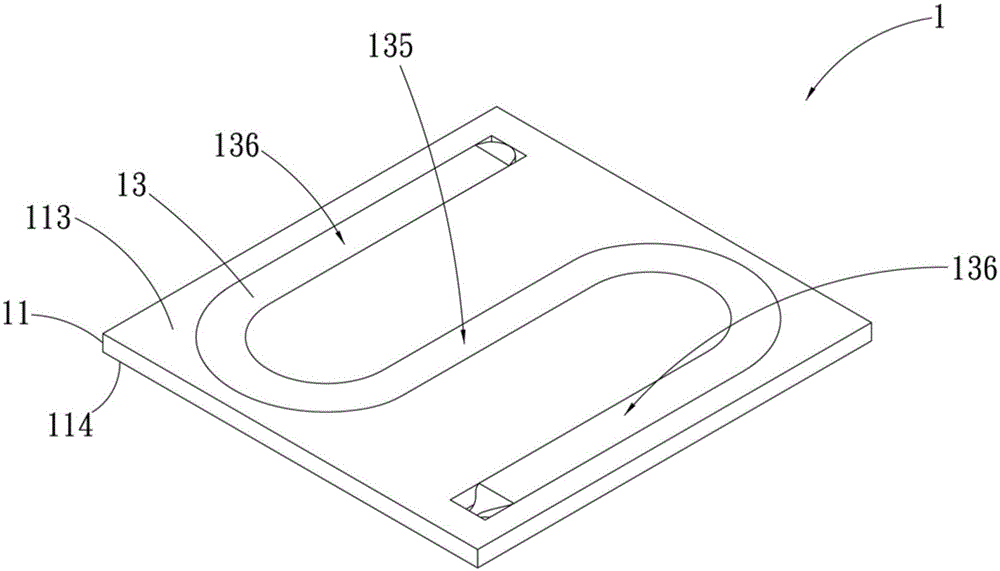

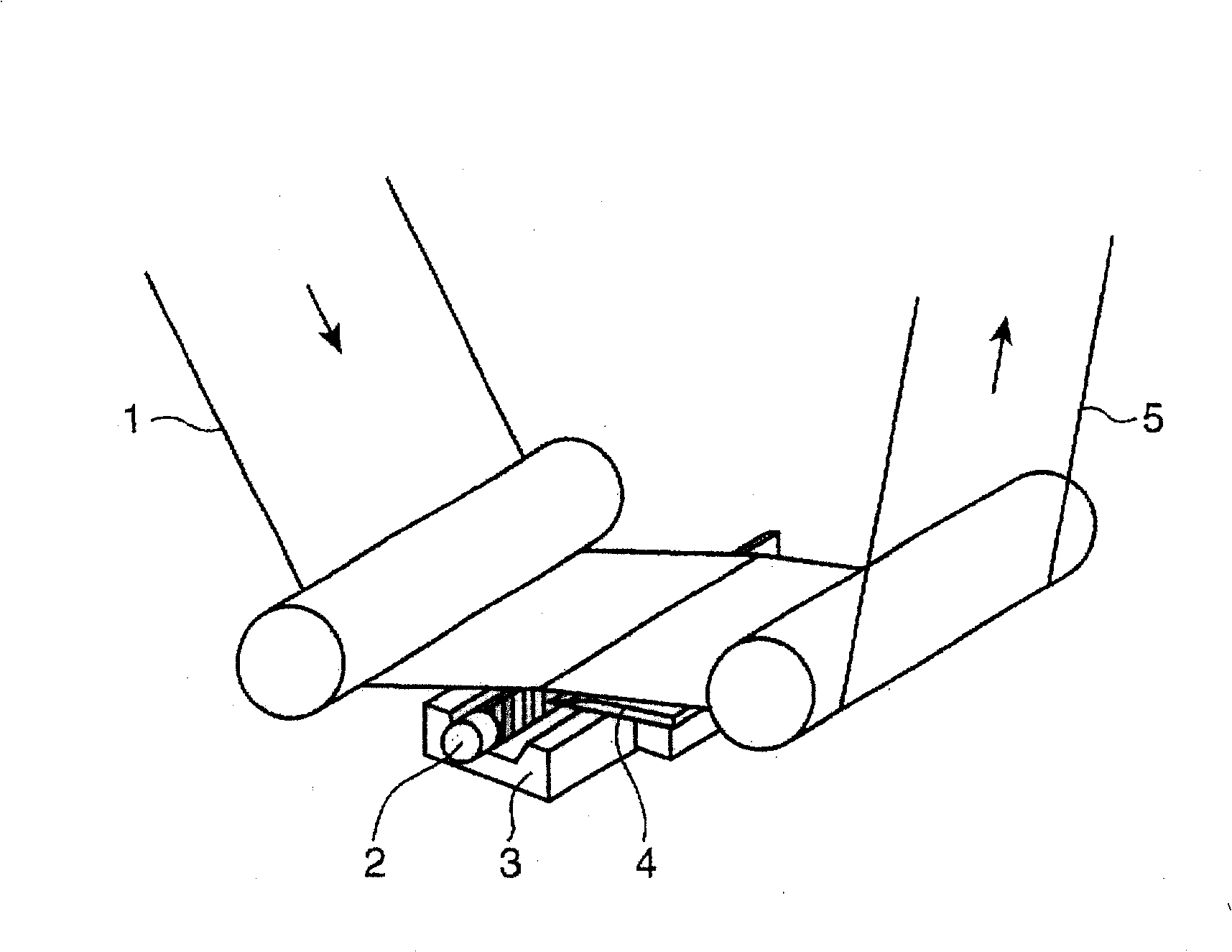

Film withdrawing device and manufacturing method of flexible printed circuit board

ActiveCN110790046AAvoid preparation methodPrinted circuit manufactureArticle separationThin membraneEngineering

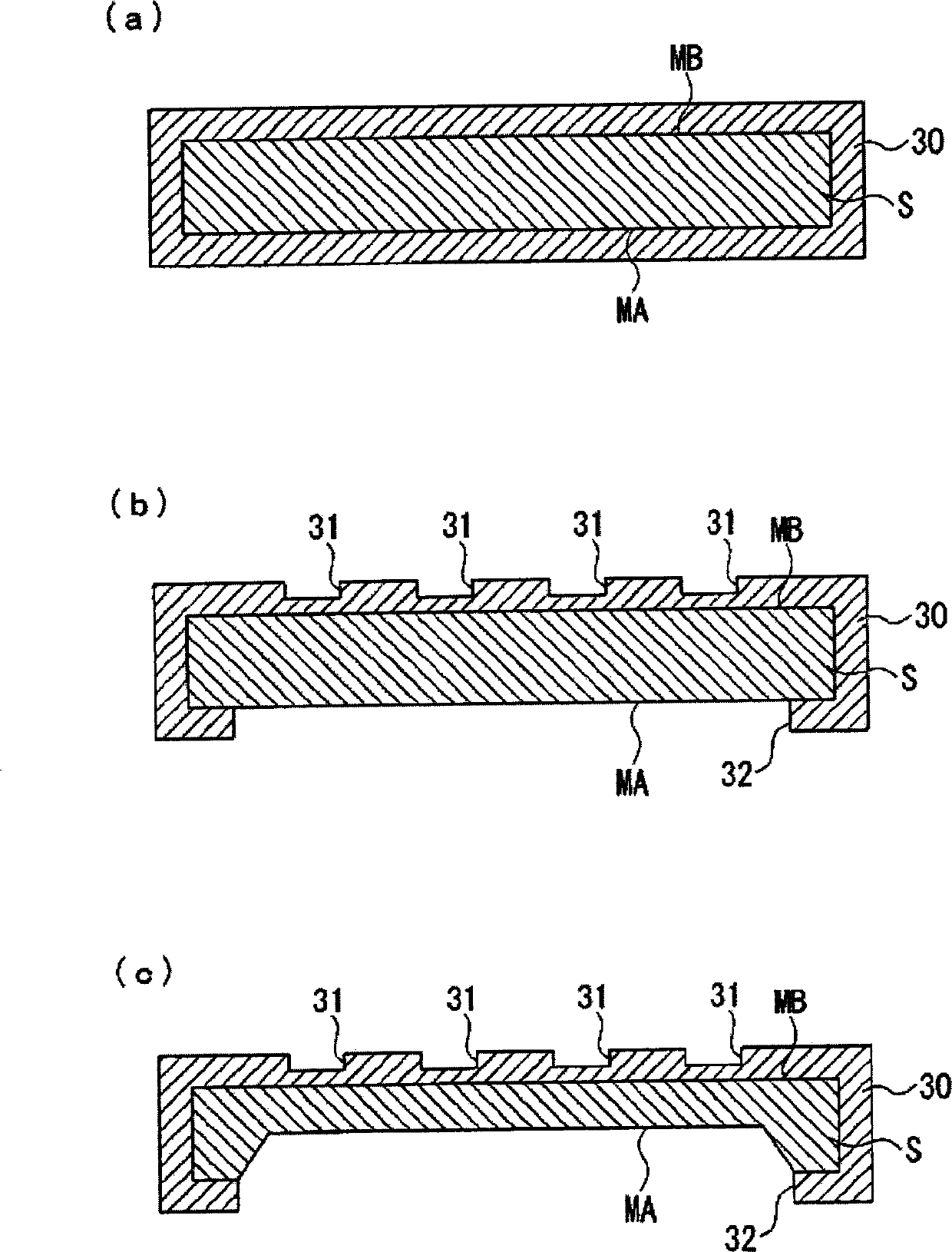

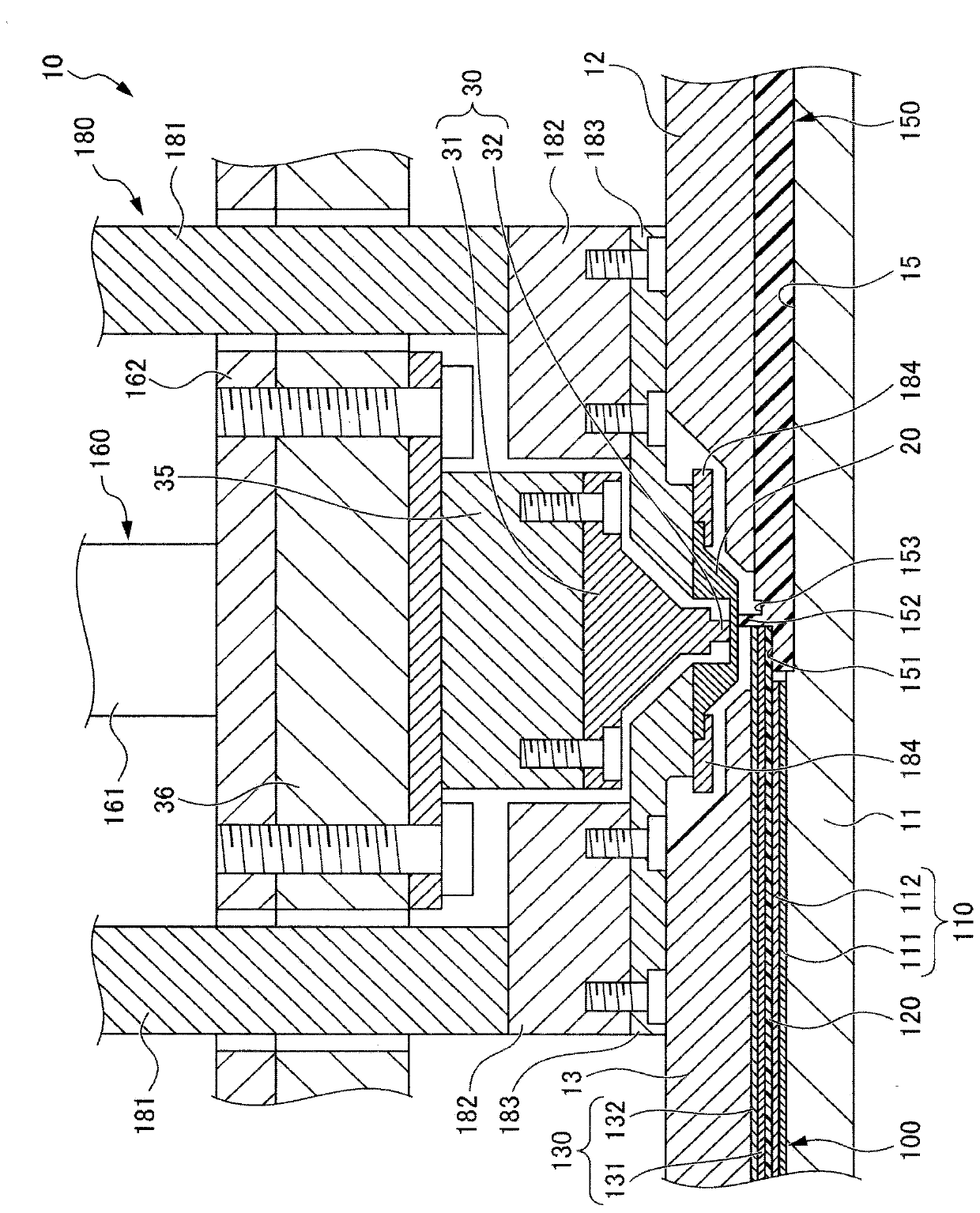

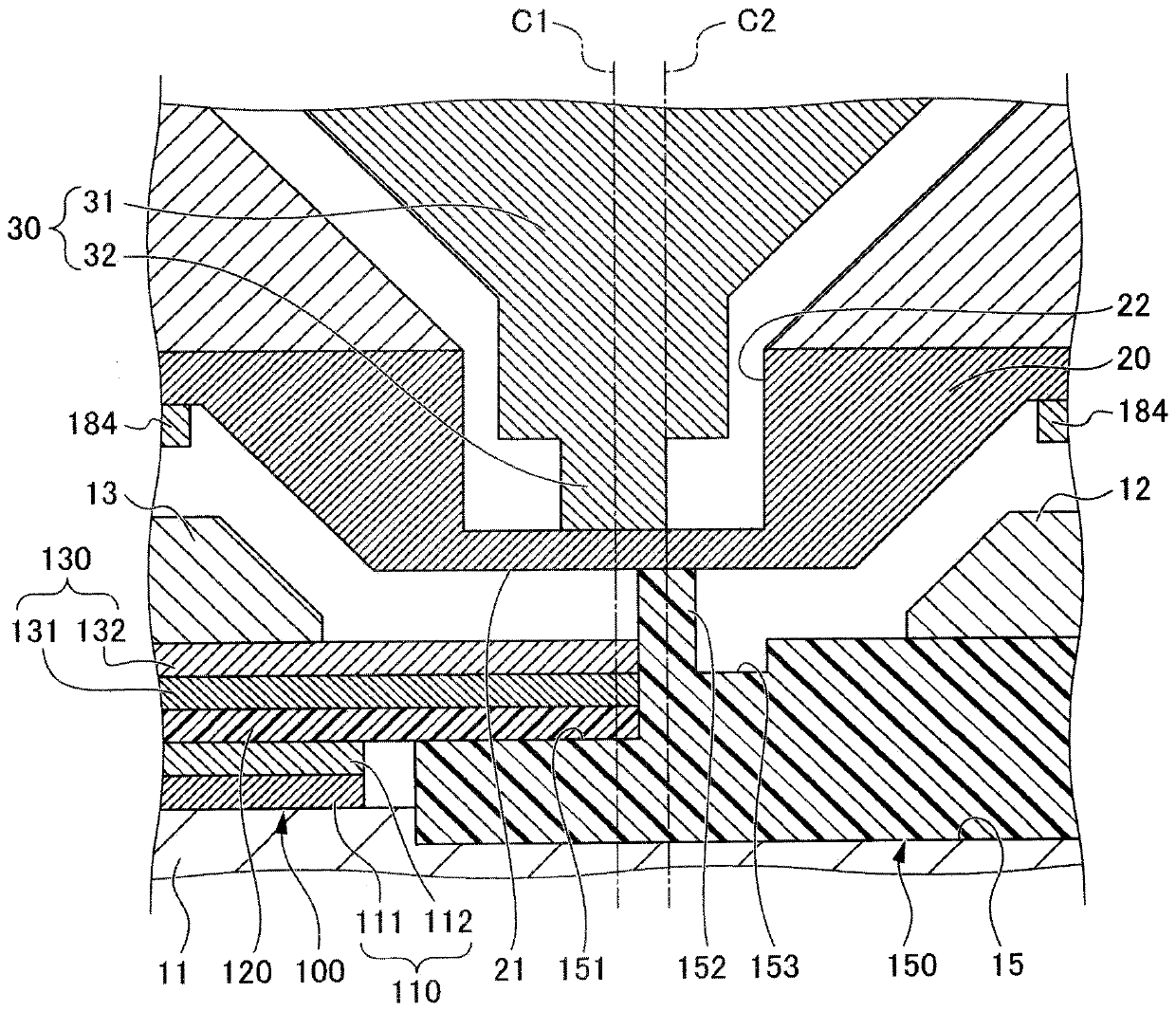

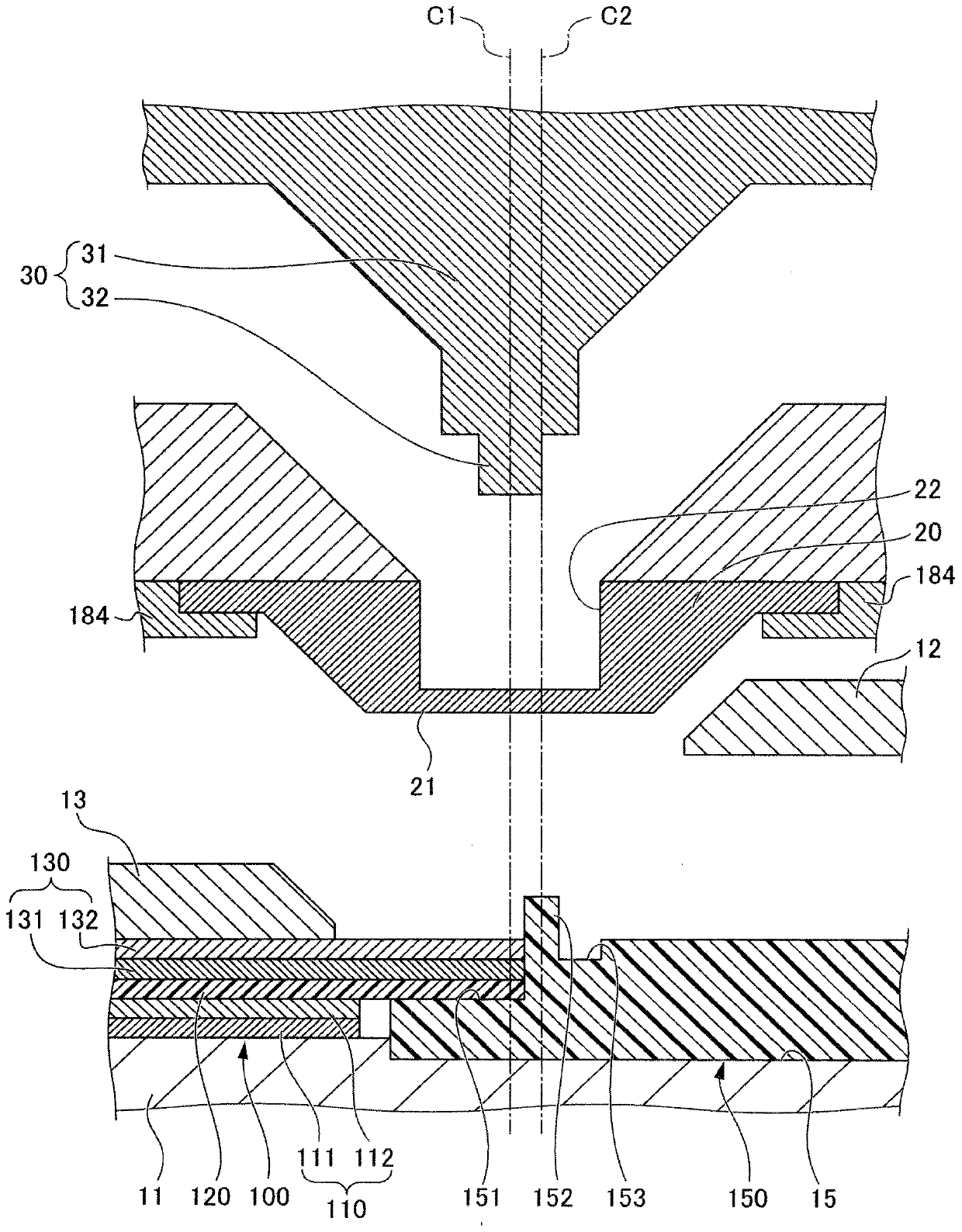

The invention provides a film withdrawing device and a manufacturing method of a flexible printed circuit board. The provided film withdrawing device can take out a plurality of film like members at the same time without generating any deformation on the film like members. The film withdrawing device (10) comprises a first attracting member (30) that can attract and hold one edge of a film like member (S); a second attracting member (130) that can attract and hold the other edge of the film like member (S); a first elevating member (60) that can lift or lower the first attracting member (30);a second elevating member (160) that can lift or lower the second attracting member (130); and a control part (210) that controls the movement of the first attracting member (30) and the second attracting member (130). The control part (210) controls the first attracting member (30) and the second attracting member (130) to attract and hold the uppermost film like member (S1) of a laminate (PS) and then makes any one of the first attracting member (30) and the second attracting member (130) go up or down relative to the other.

Owner:NIPPON MEKTRON LTD

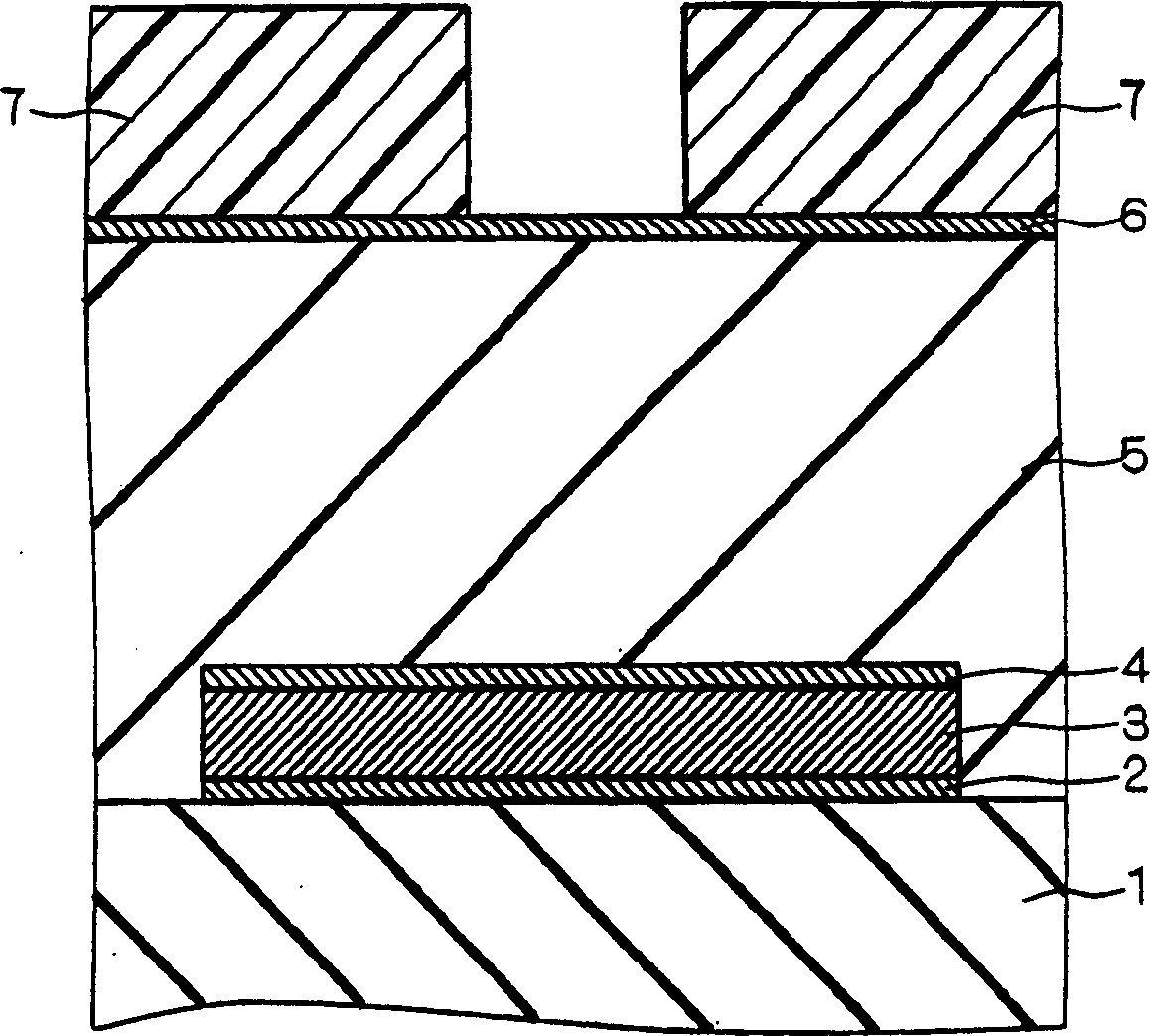

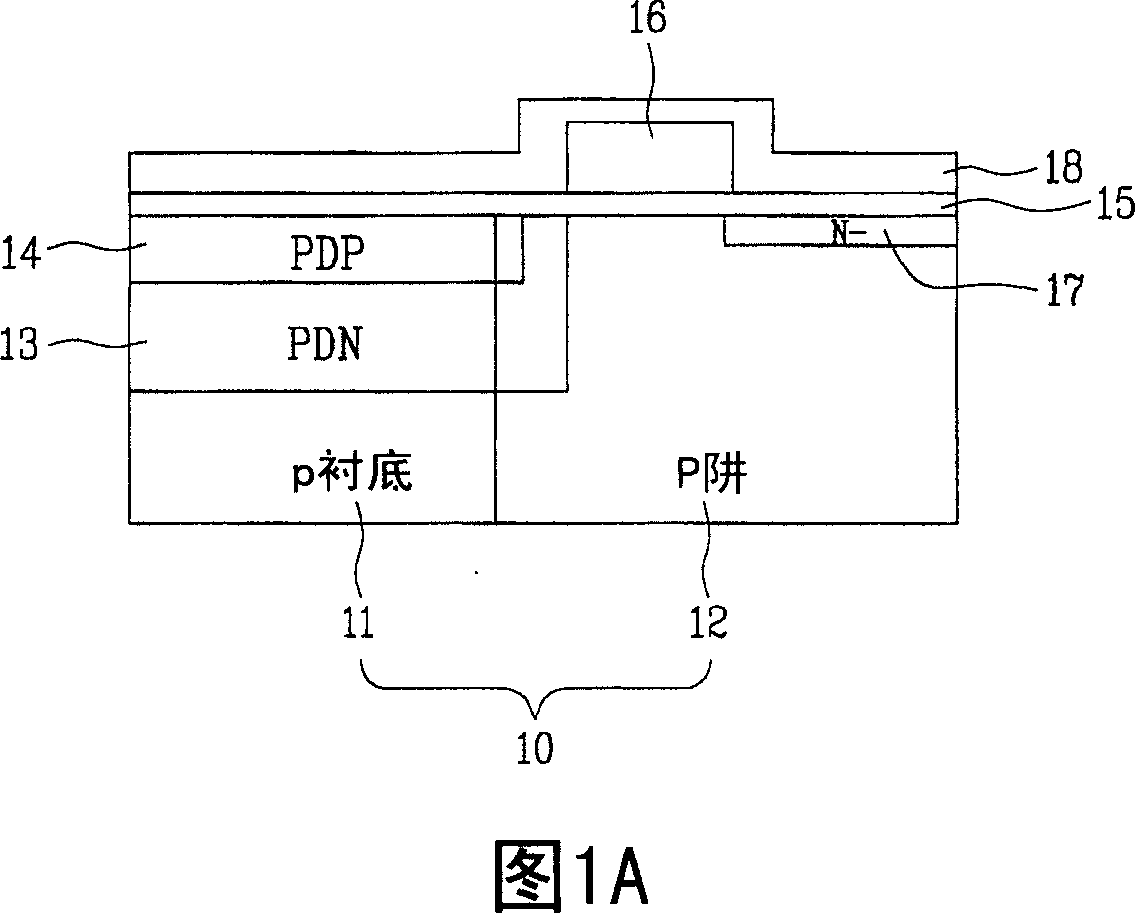

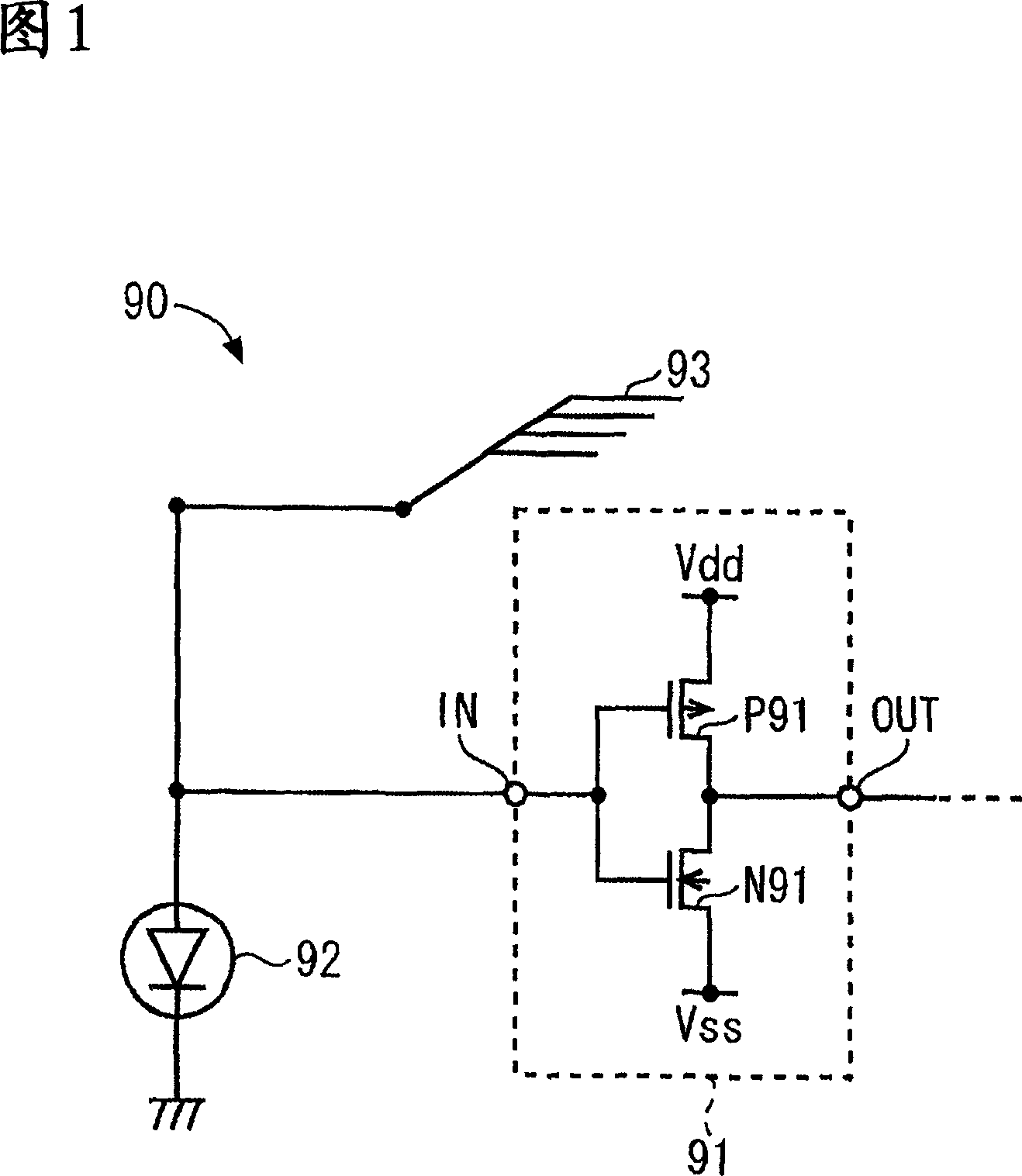

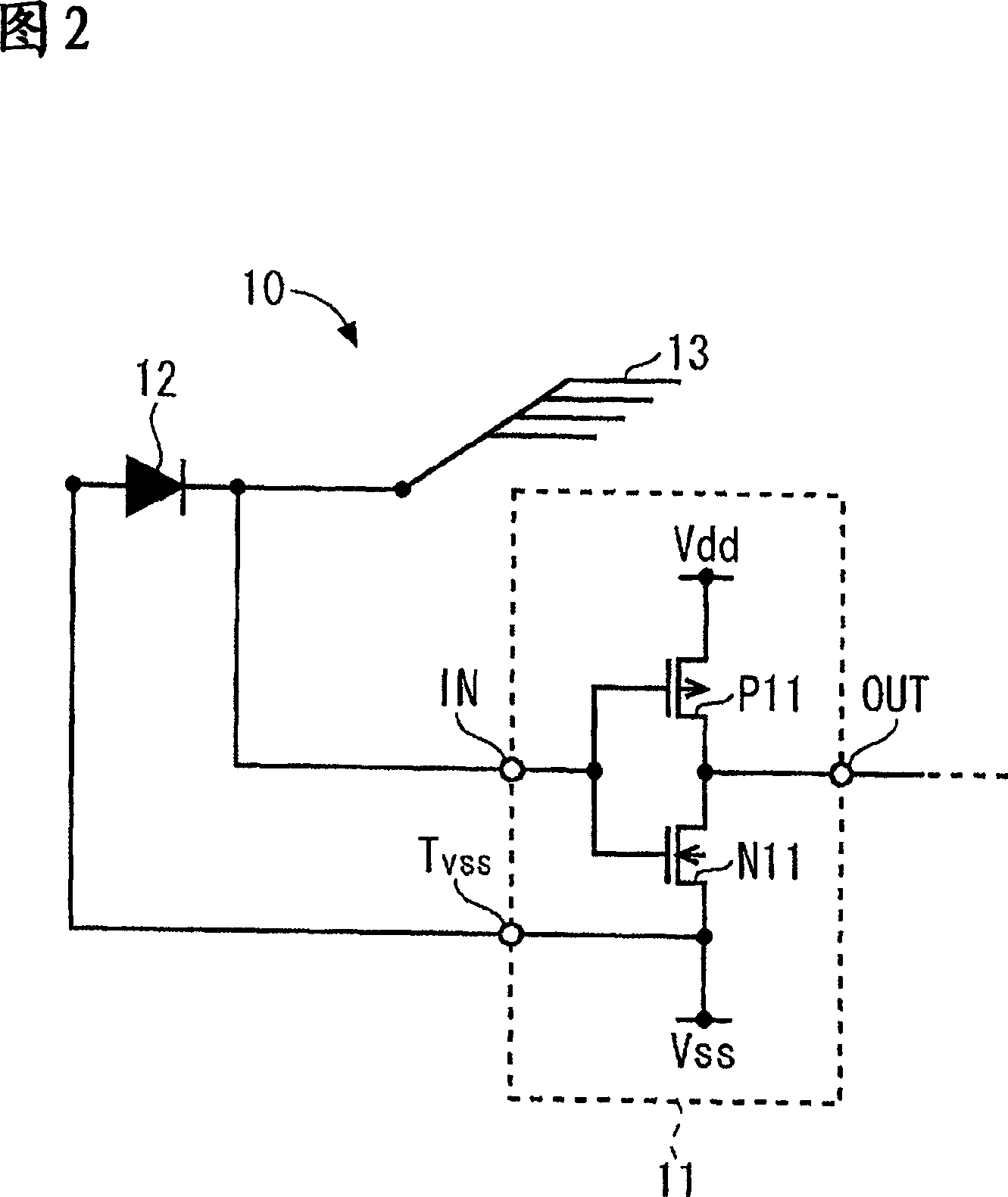

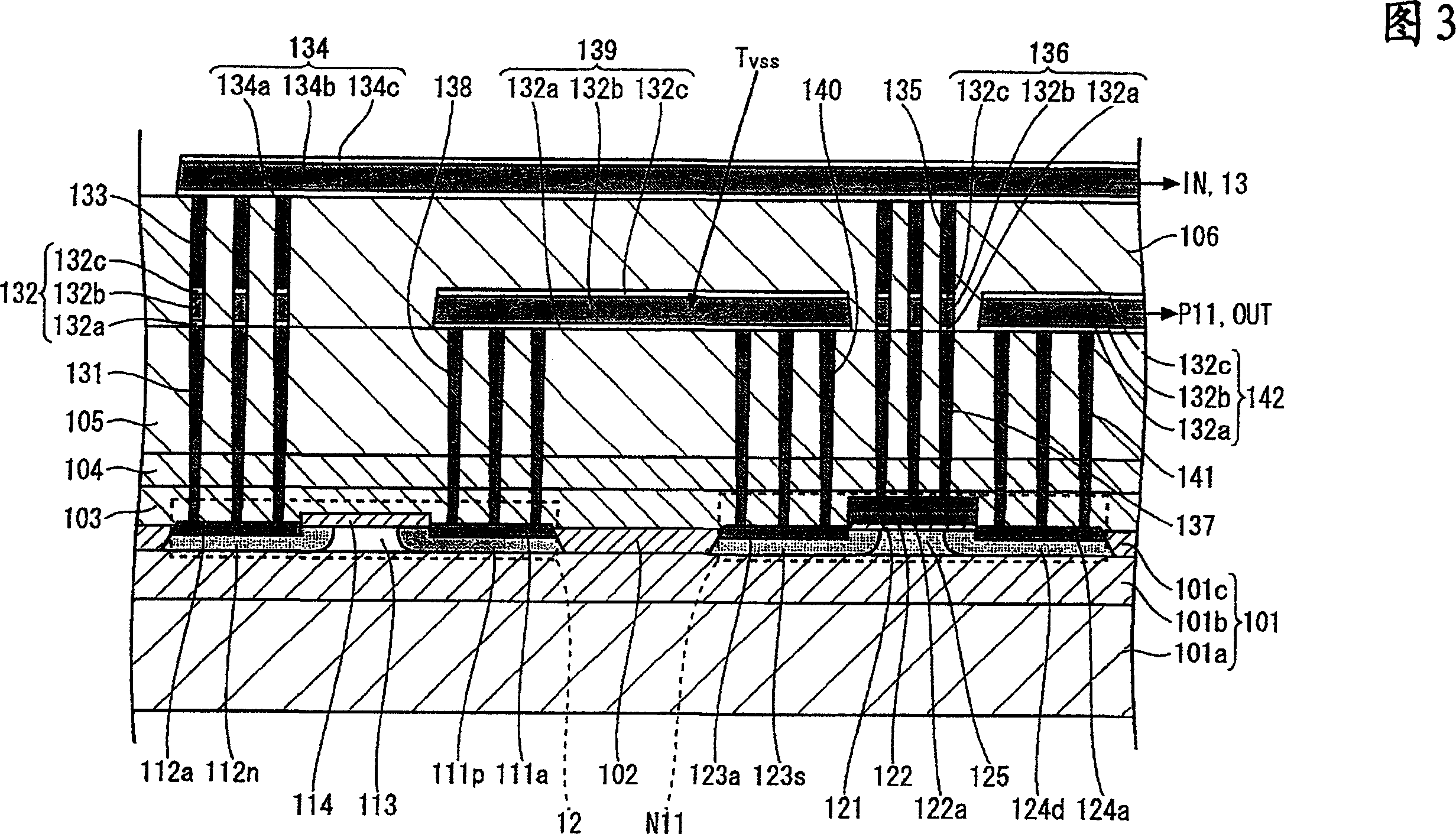

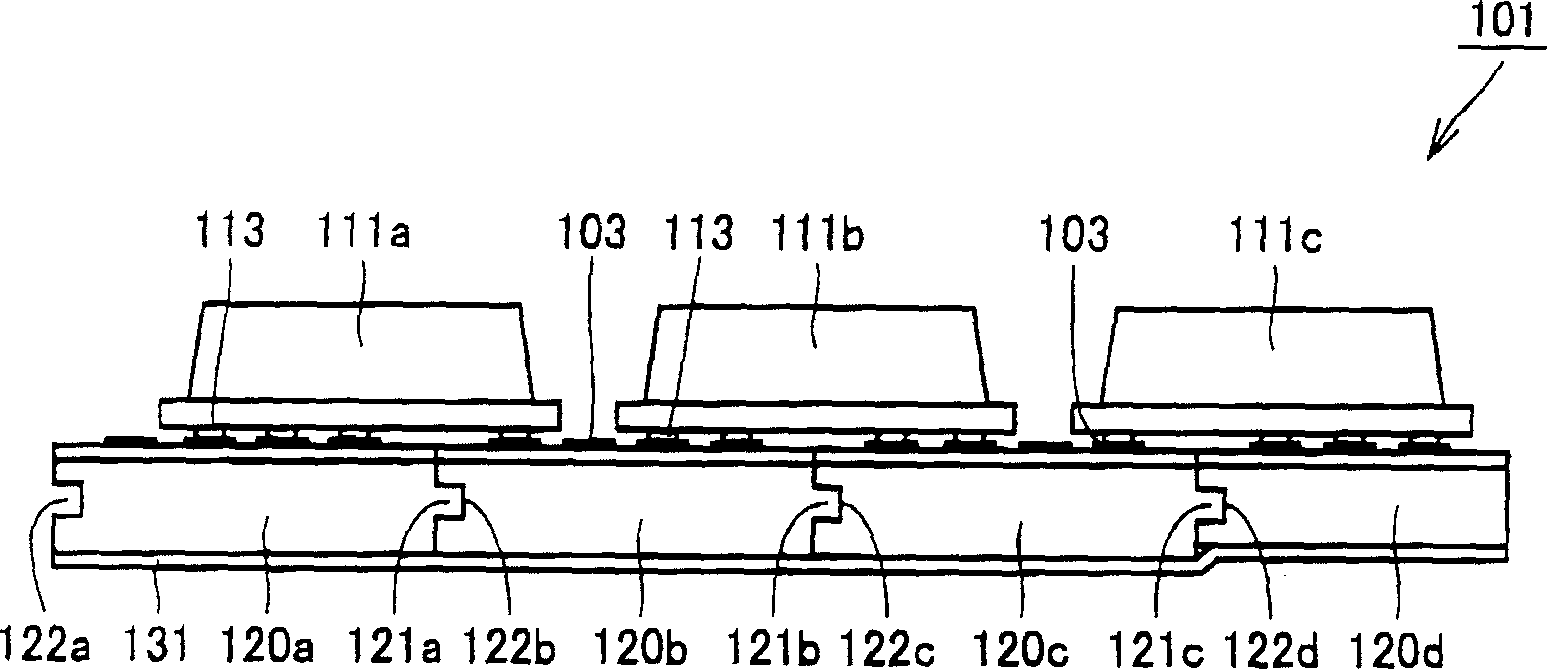

Semiconductor device and method for manufacturing the same

InactiveCN1945843AAvoid destructionAvoid preparation methodSolid-state devicesSemiconductor/solid-state device manufacturingPlasma currentSoi substrate

Provided is a semiconductor device which can be prevented from breaking by plasma current in a manufacturing process, and keep a breakdown voltage of diode from rising simultaneously; and to provide a manufacturing method of the semiconductor device. A semiconductor device 10 comprises an SOI substrate 101 having a silicon substrate 101a a supporting substrate, an oxide film 101b on the silicon substrate 101a, and a silicon thin film 101c on the oxide film 101b; an input terminal IN (a second upper layer interconnect line 134) formed on the silicon thin film 101c; a Vss terminal Tvss (a first upper layer interconnect line 139) formed on the silicon thin film 101c; a semiconductor device formed on the silicon thin film 101c, which is connected to the input terminal IN and Vssterminal Tvss (e.g. the inverter 11); and a protection diode 12, formed on the silicon thin film 101c, which is connected in a forward direction from the Vss terminal Tvss to the input terminal IN.

Owner:LAPIS SEMICON CO LTD

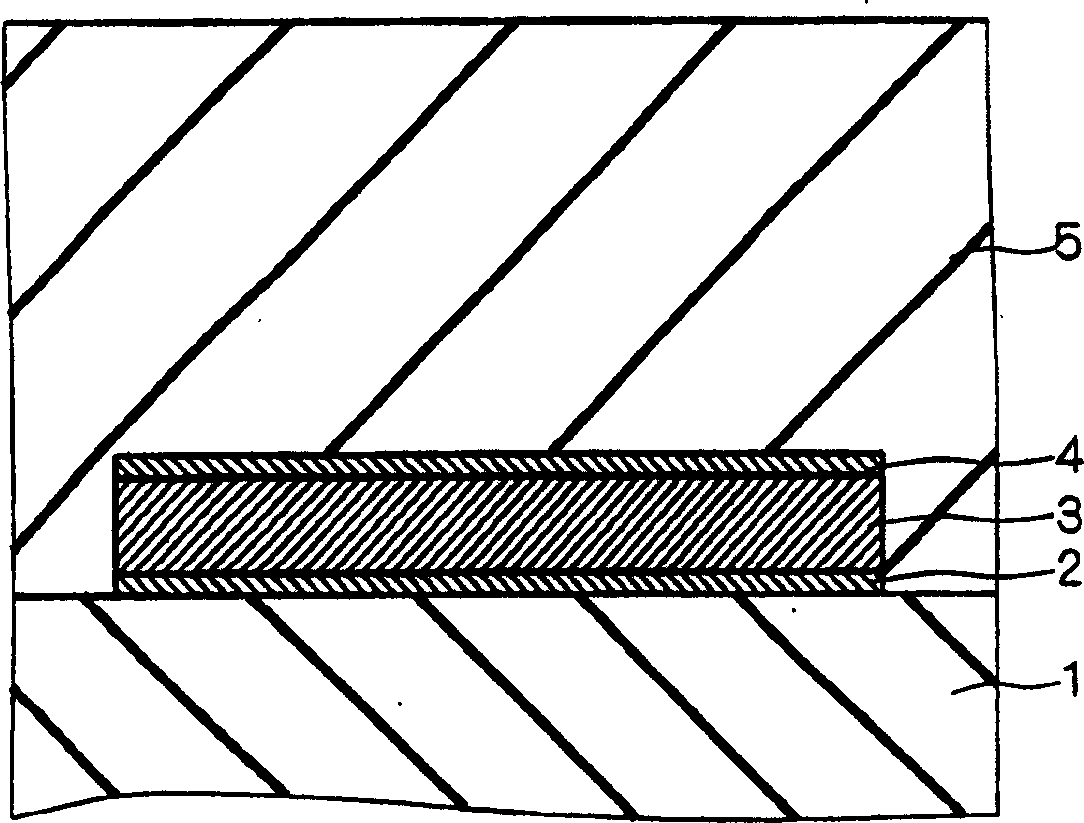

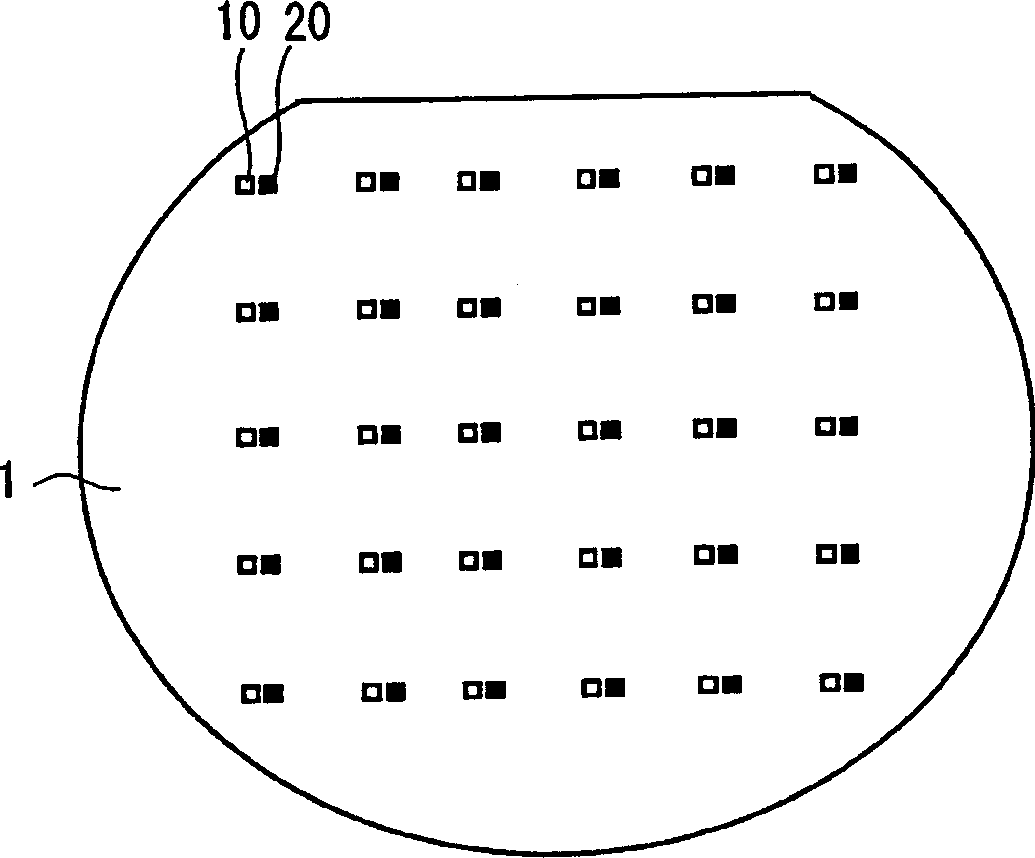

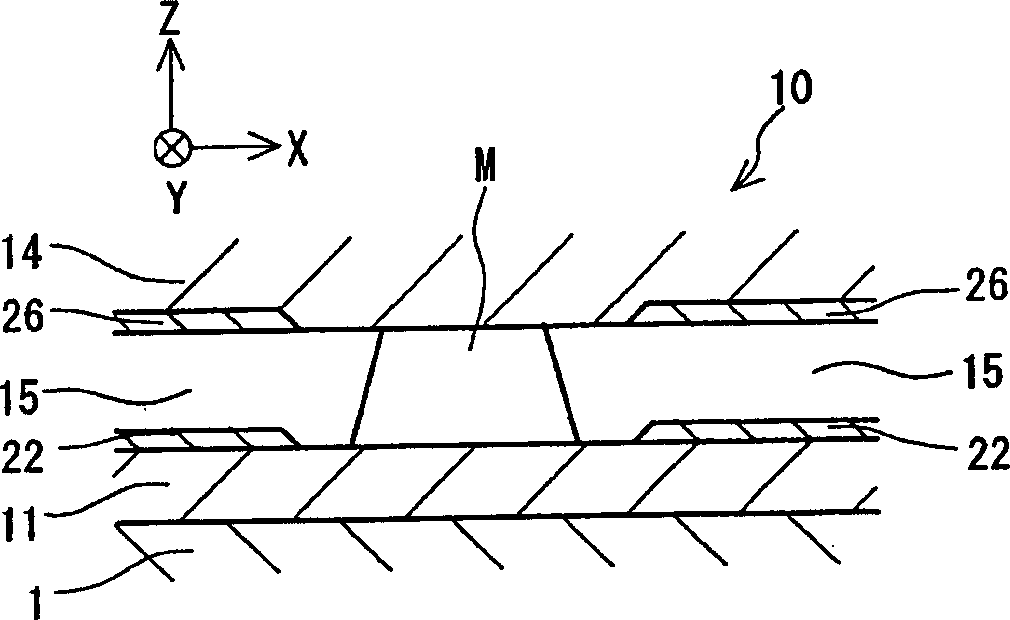

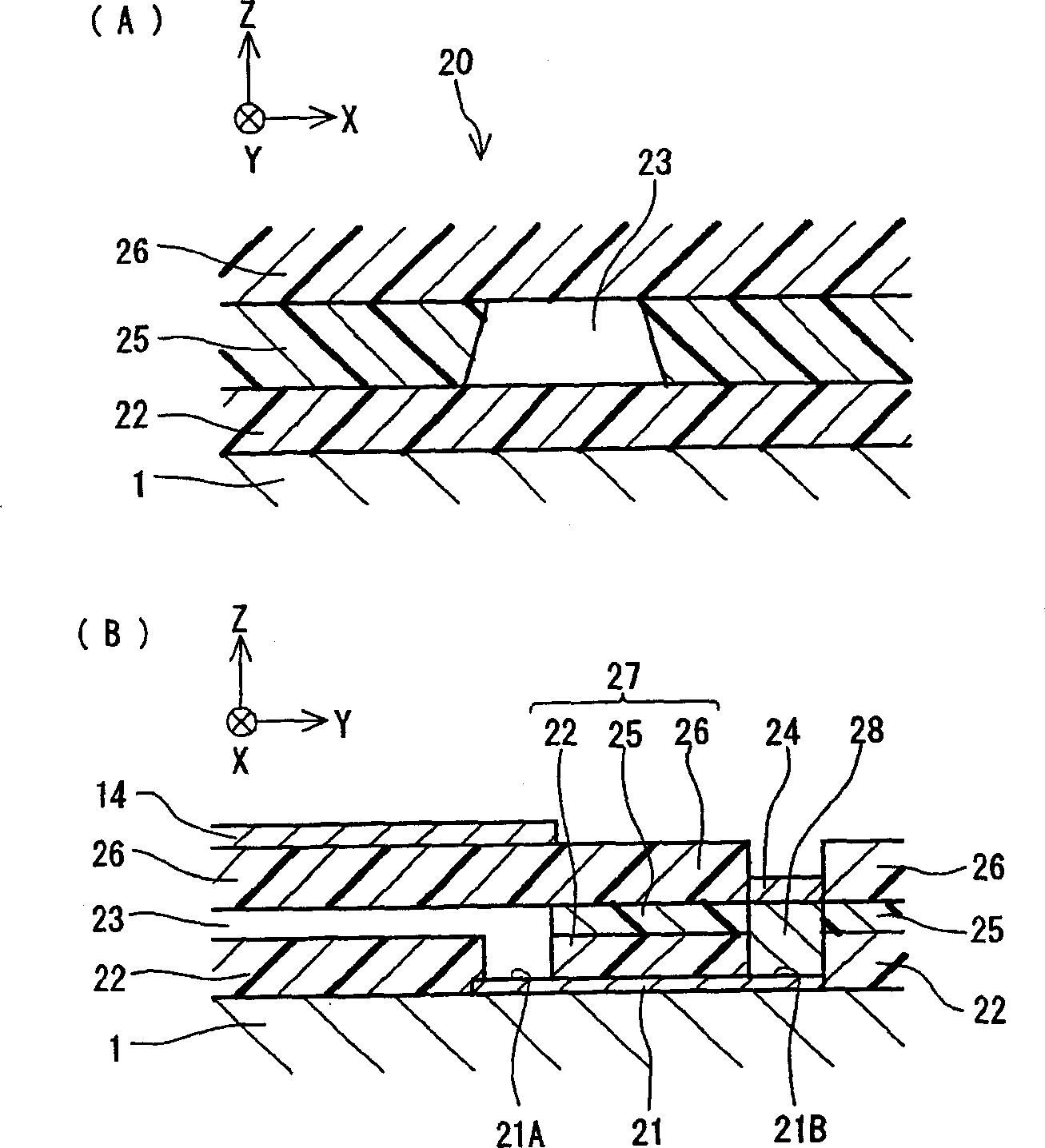

Monitor element and magneto-resistance effect element substrate, and method of manufacturing monitor element

InactiveCN1831946AAvoid short circuitAvoid preparation methodManufacture head surfaceManufacture of flux-sensitive headsEngineeringProtection layer

The objective of the invention is to provide a monitor element and a magneto-resistance effect element substrate which can be prevented from short circuits, and also to provide a method of manufacturing the monitor element. The monitor element is used as an element resistance monitor for a magneto-resistance effect element during a polishing process for forming the medium facing surface of the magneto-resistance effect element which is applied with sensing current in a direction perpendicular to a film surface by upper and lower shield layers. The monitor element comprises a multilayer film having the same film structure as a magneto-resistance effect film of the magneto-resistance effect element, and an electrode layer which applies current in parallel to the film surface of the multilayer film. The electrode layer is formed at the same height as the lower shield layer, and is covered with an insulating protection layer except for an electrode connecting portion with the multilayer film and an electrode extractor.

Owner:TDK CORPARATION

Semiconductor device, semiconductor module and method of manufacturing semiconductor device

InactiveCN1591863AAvoid preparation methodGuaranteed softnessSemiconductor/solid-state device detailsSolid-state devicesCouplingSemiconductor chip

A semiconductor device containing a semiconductor chip is provided with a coupling portion allowing coupling to a neighboring semiconductor device. The coupling portions couple the plurality of semiconductor devices to form a substrate, and a semiconductor package is arranged on the substrate via an electrode arranged on a surface of the substrate. This structure can improve a packaging density.

Owner:RENESAS TECH CORP

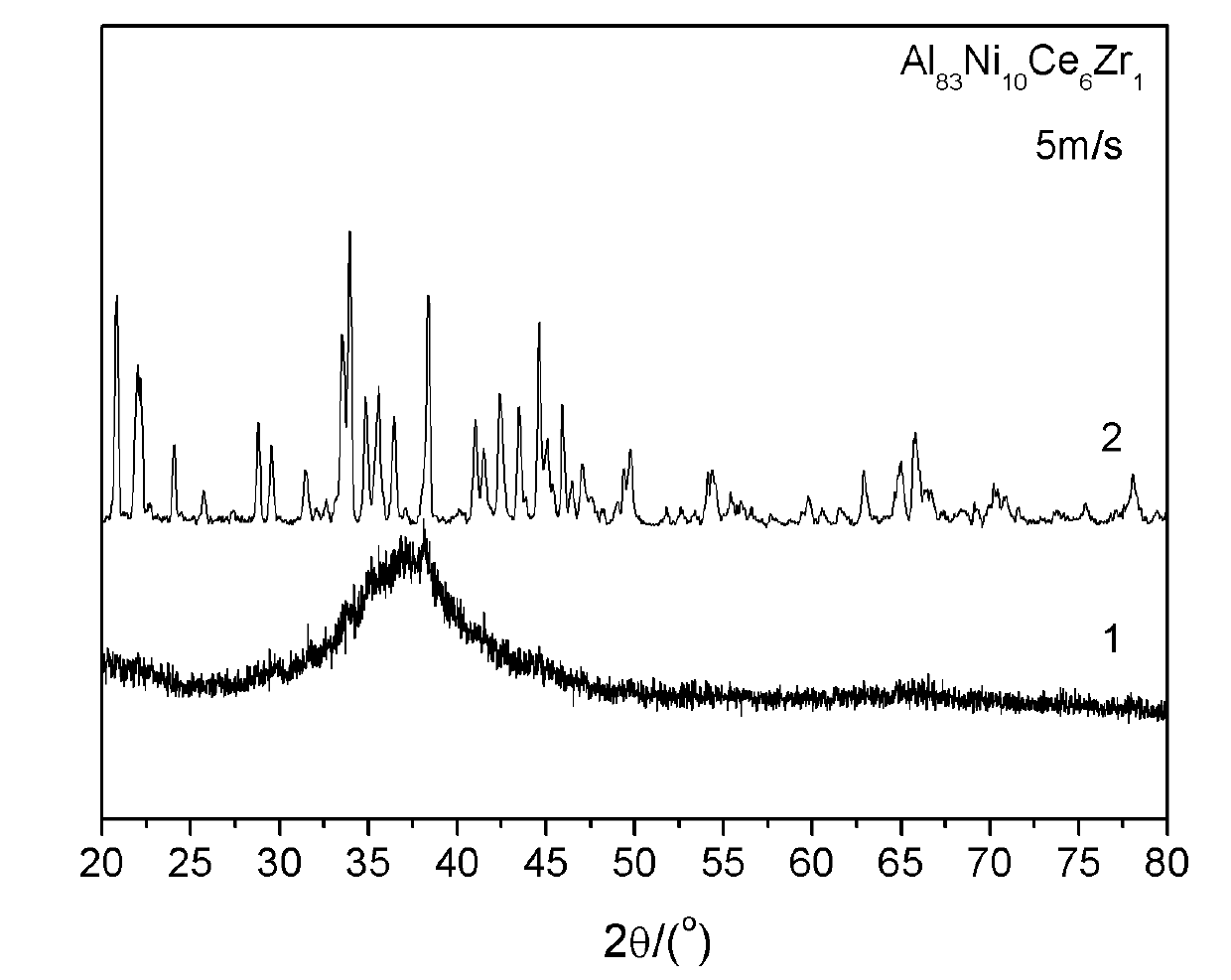

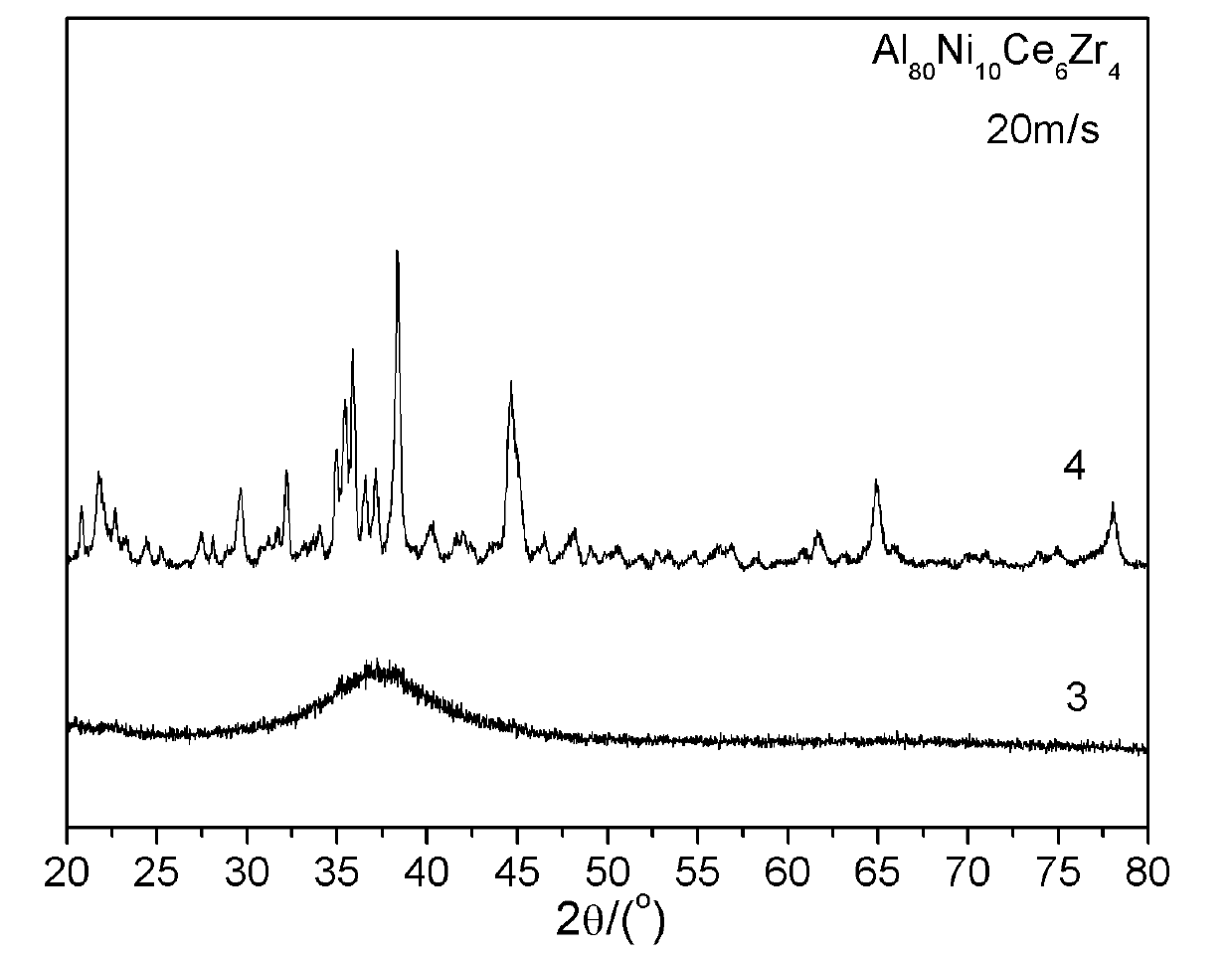

Method for preparing amorphous/crystal composite structure aluminium-based alloy

InactiveCN102168231AChange the manufacturing processEvenly distributedUltimate tensile strengthMaterials science

The invention discloses a method for preparing amorphous / crystal composite structure aluminium-based alloy. The composition is as follows: Al(84-x)Ni10Ce6Prx (in percentage by weight), or Al(84-x)Ni10Ce6Zrx (in percentage by weight), wherein x is equal to 1 to 4. The method for preparing the amorphous / crystal composite structure aluminium-based alloy comprises the following steps: during the processes of fast solidifying aluminium-based alloy melt and preparing the amorphous alloy, applying stable and constant magnetic field action on a melt solidification process; and controlling the forming of the solidified tissue structure of the alloy, thus obtaining amorphous / crystal composite structure materials. The intensity of the applied stable and constant magnetic field ranges from 900Gs to 1,200Gs; the selected alloy is alloy capable of forming complete amorphous tissues, parent alloy is prepared through vacuum arc melting or vacuum induction melting according to composition distribution, then the stable and constant magnetic field is applied on the melt solidifying process, and the amorphous / crystal composite structure materials are prepared according to the preparation technique of fast solidifying alloy melt and preparing the amorphous alloy. The invention provides a method for directly preparing the amorphous / crystal composite structure tissues, the phase distribution of crystals in the prepared amorphous / crystal composite structure is uniform, the preparation process ensures that the original preparation technique is not changed, and the technique process is simple.

Owner:CENT SOUTH UNIV

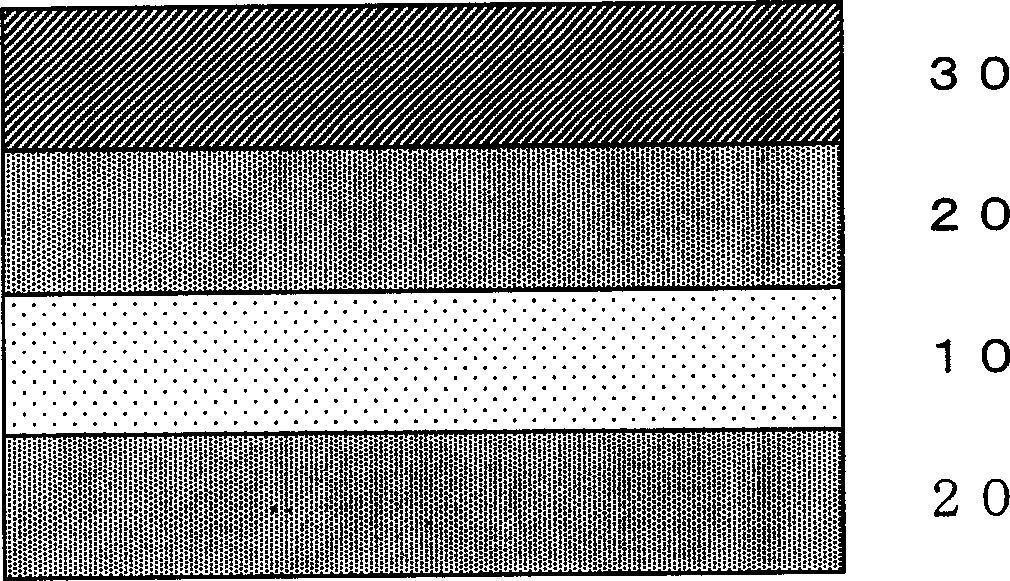

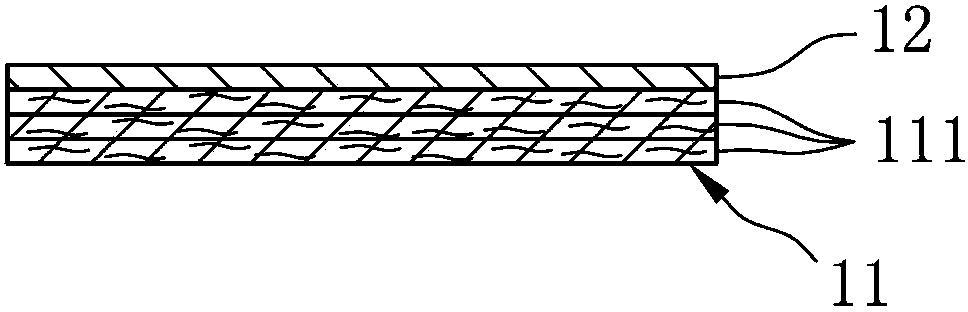

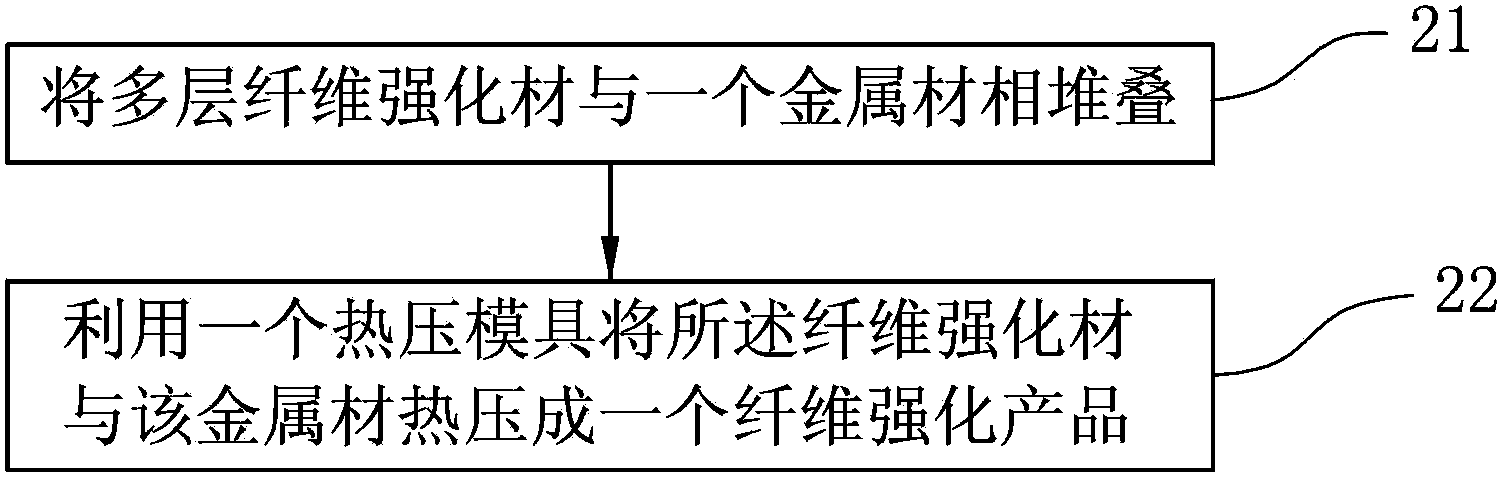

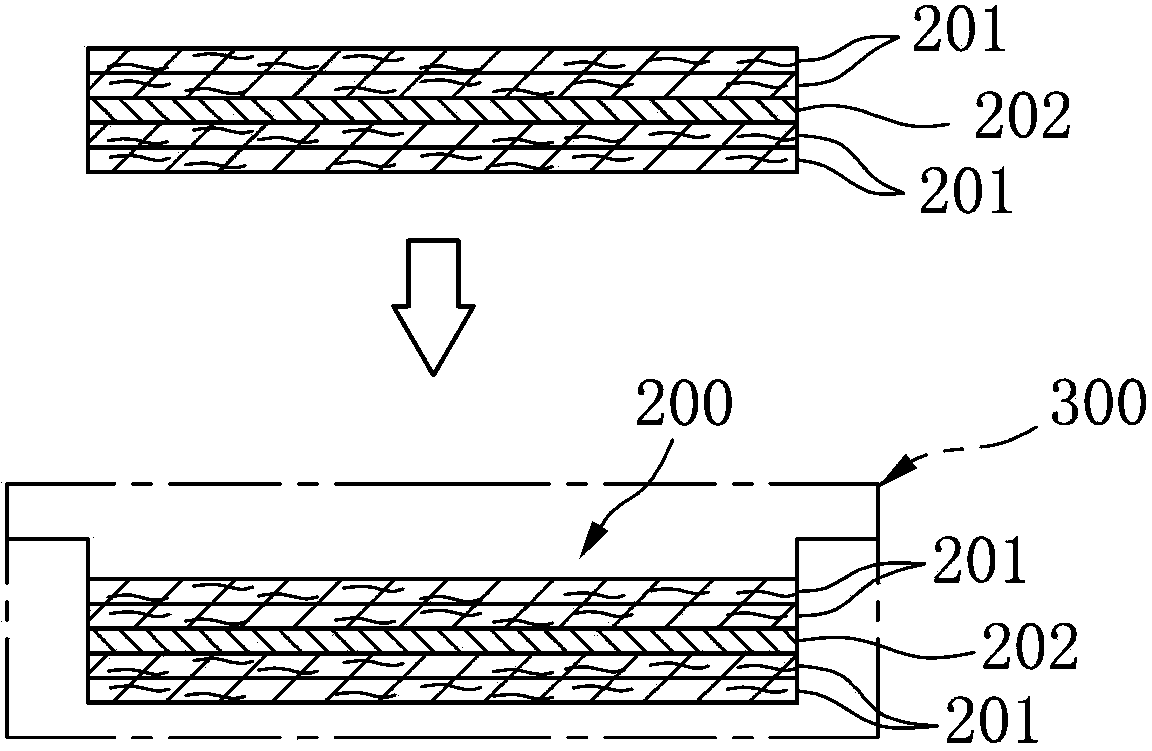

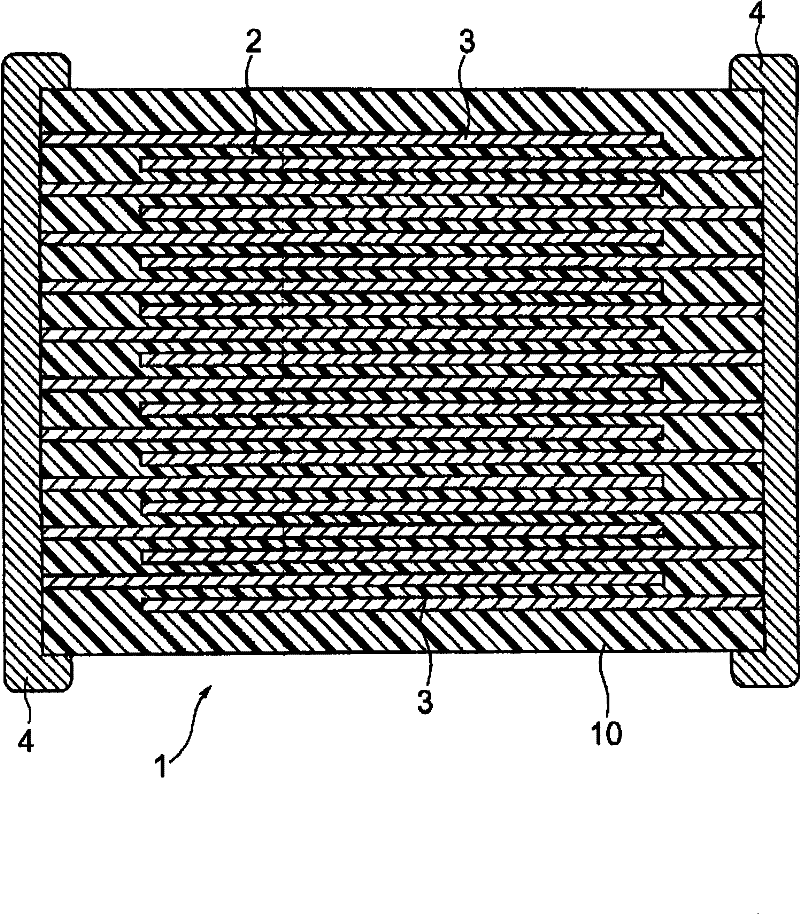

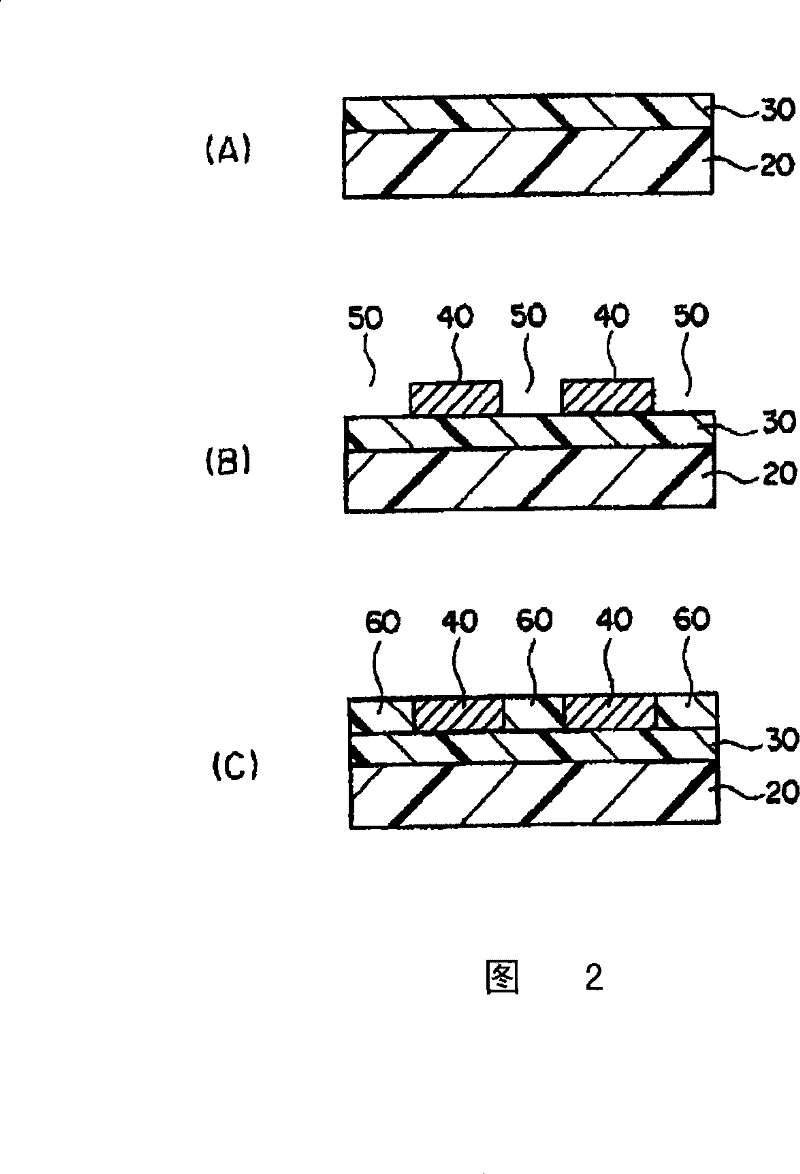

Production method of fiber reinforced product capable of preventing electromagnetic wave interference

InactiveCN103481590AControl thicknessReduce operating proceduresSynthetic resin layered productsLaminationFiberElectromagnetic interference

A Production method of a fiber reinforced product capable of preventing electromagnetic wave interference comprises the following steps: (A) mutually stacking multi layers of a fiber reinforced material and a metal material; and (B) hot pressing the multi layers of the fiber reinforced material and the metal material into a fiber reinforced product by using a hot press die. Through mutual stacking and one-body hot pressing molding of the metal material and the fiber reinforced material, not only the operating procedure and work time can be effectively reduced so as to reduce the production cost and time, also the thickness of the metal material can be effectively controlled, so that the overall electromagnetic shielding effect is consistent.

Owner:ADVANCED INT MULTITECH CO LTD

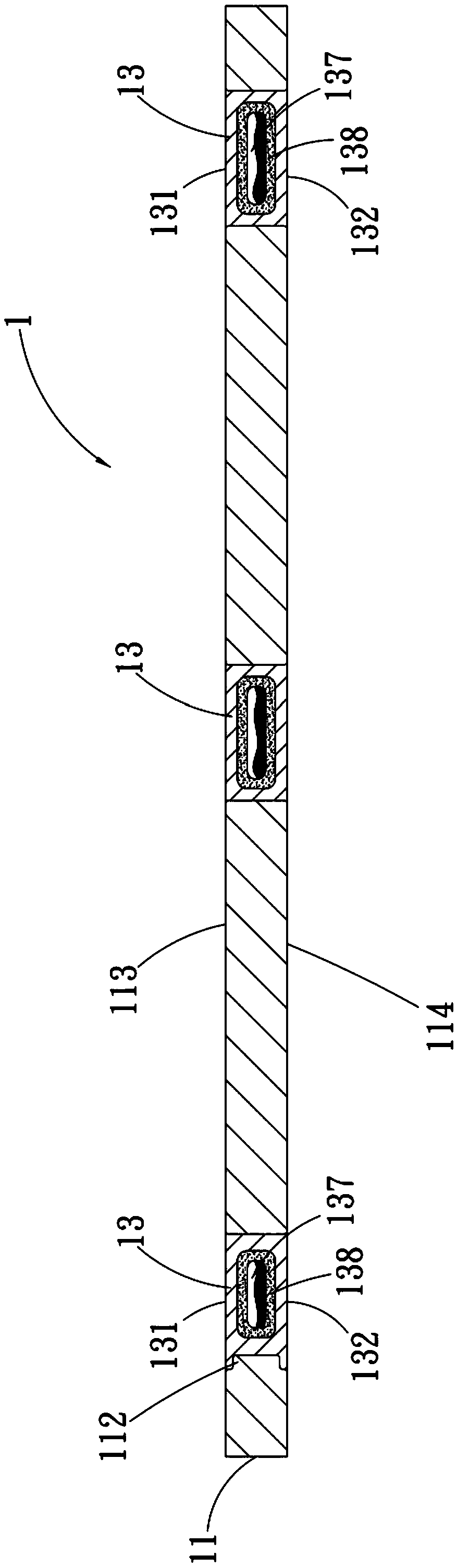

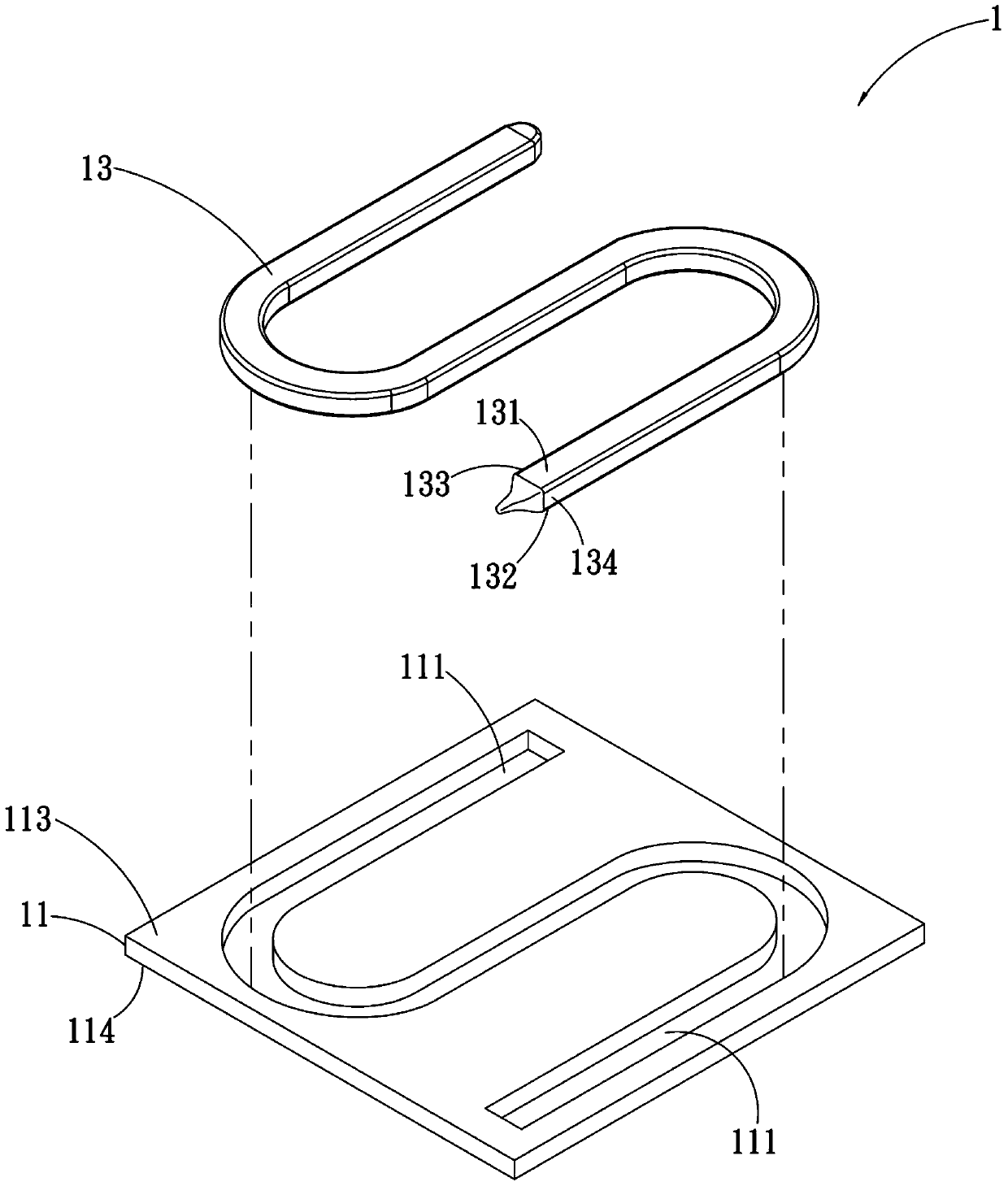

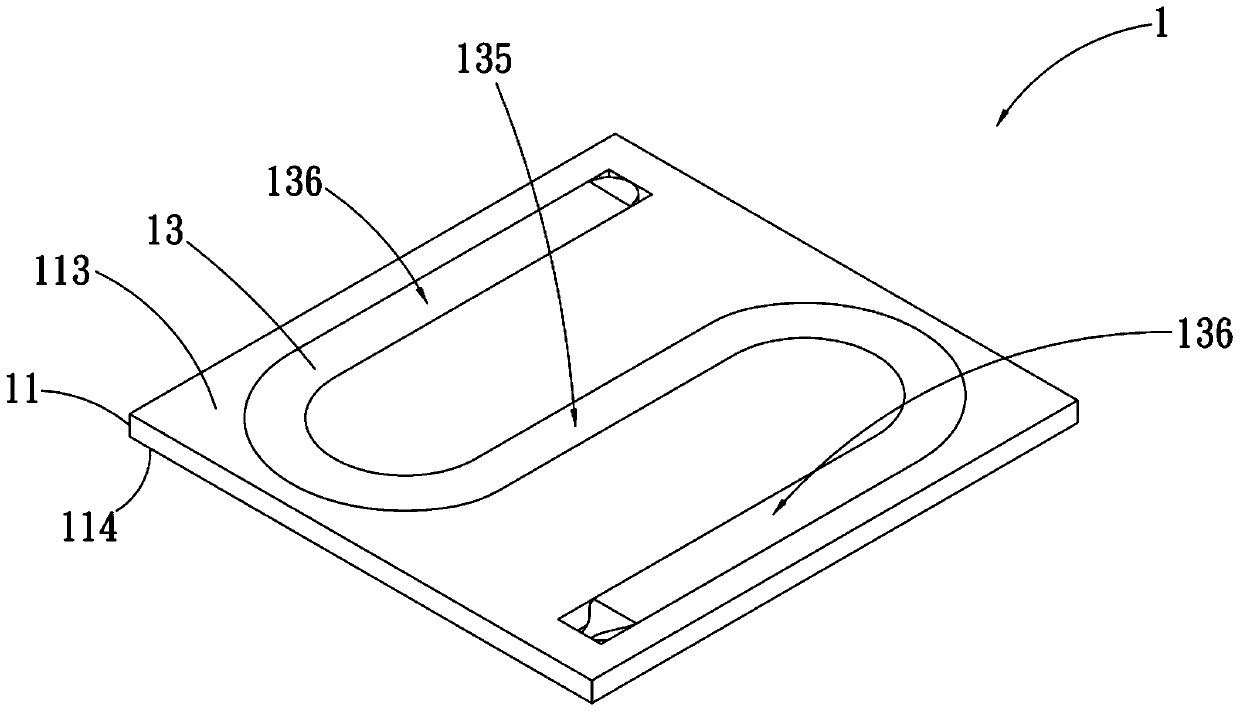

Heat dissipation device and manufacturing method thereof

ActiveCN106486434AImprove flatnessAchieve uniform temperature effectSemiconductor/solid-state device detailsSolid-state devicesWhole bodyEngineering

The invention relates to a heat dissipation device and a manufacturing method thereof. The heat dissipation device comprises a substrate and at least one heat pipe which is arranged in a containing hole of the substrate. Two sides of the heat pipe are pressed and deformed to be close to the two opposite inner walls in the containing hole, thus the substrate and the heat pipe are closely combined to be a whole body, the problem that a known hole needs secondary processing and the back side flatness is poor due to processing are solved, and the effects of cost saving and uniform temperature can be achieved at the same time.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

Mask forming composition, production method for solar cell substrate, and production method for solar cell element

InactiveCN104067395AAvoid preparation methodSemiconductor/solid-state device manufacturingPhotovoltaic energy generationSolar cellMetal

A mask forming composition including: a silicon compound; a metal compound including an alkaline earth metal or an alkaline metal; and a dispersion medium.

Owner:HITACHI CHEM CO LTD

Heat sink and manufacturing method thereof

ActiveCN106486434BImprove flatnessAchieve uniform temperature effectSemiconductor/solid-state device detailsSolid-state devicesWhole bodyMechanical engineering

The invention relates to a heat dissipation device and a manufacturing method thereof. The heat dissipation device comprises a substrate and at least one heat pipe which is arranged in a containing hole of the substrate. Two sides of the heat pipe are pressed and deformed to be close to the two opposite inner walls in the containing hole, thus the substrate and the heat pipe are closely combined to be a whole body, the problem that a known hole needs secondary processing and the back side flatness is poor due to processing are solved, and the effects of cost saving and uniform temperature can be achieved at the same time.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

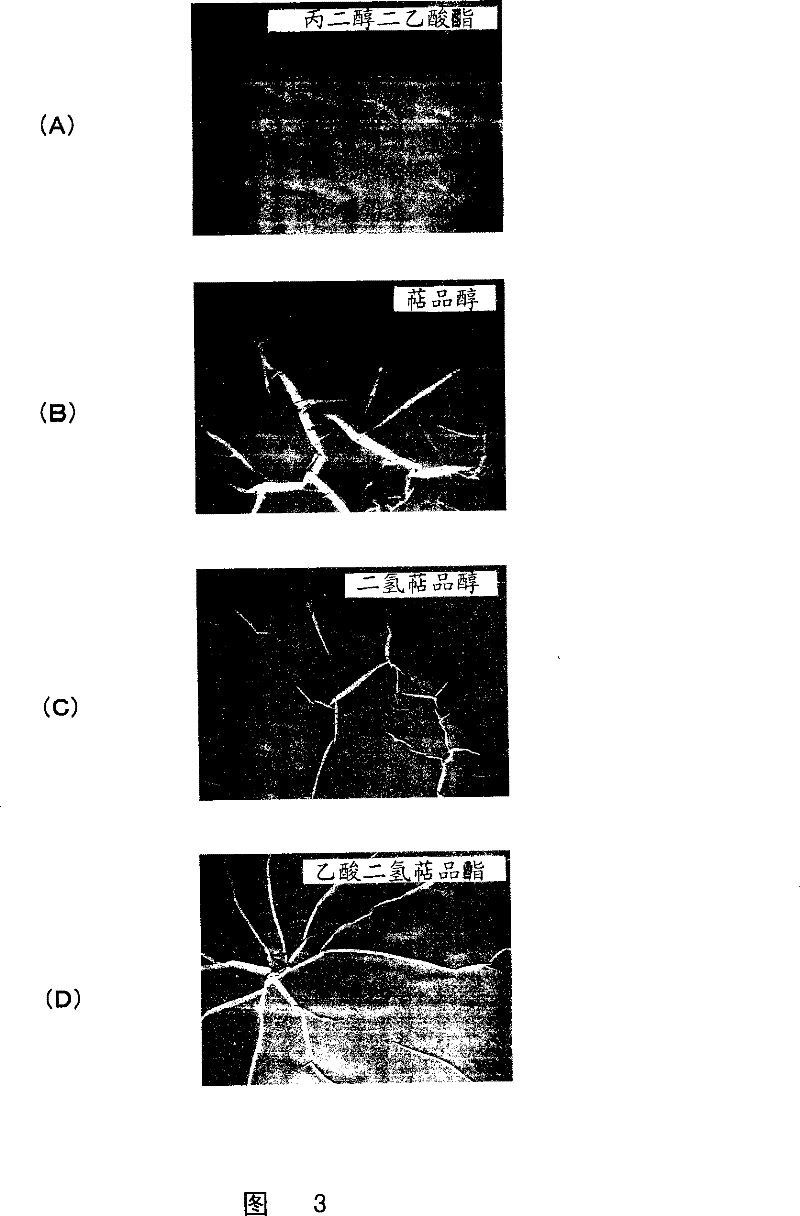

Method for preparing electrode altitude difference absorption dielectric paste and laminated ceramic electronic components

InactiveCN101150012BPrevent corrosionGood peeling effectFixed capacitor electrodesFixed capacitor dielectricElectricityDielectric

The printing past used for absorption of electrode height difference for making laminated ceramic electronic part, the characteristic of which is that it contains ceramic powder and organic carrier and is used combinedly with ceramic young tablet containing butyral resin whose thickness is below 5 micrometer. The main composition of solvent in the organic carrier is 1, 2-propylene glycol diacetate. Even the ceramic young tablet is thinned, tablet etching can be prevented effectively by using the printing past used for absorption of electrode height difference of the invention.

Owner:TDK CORPARATION

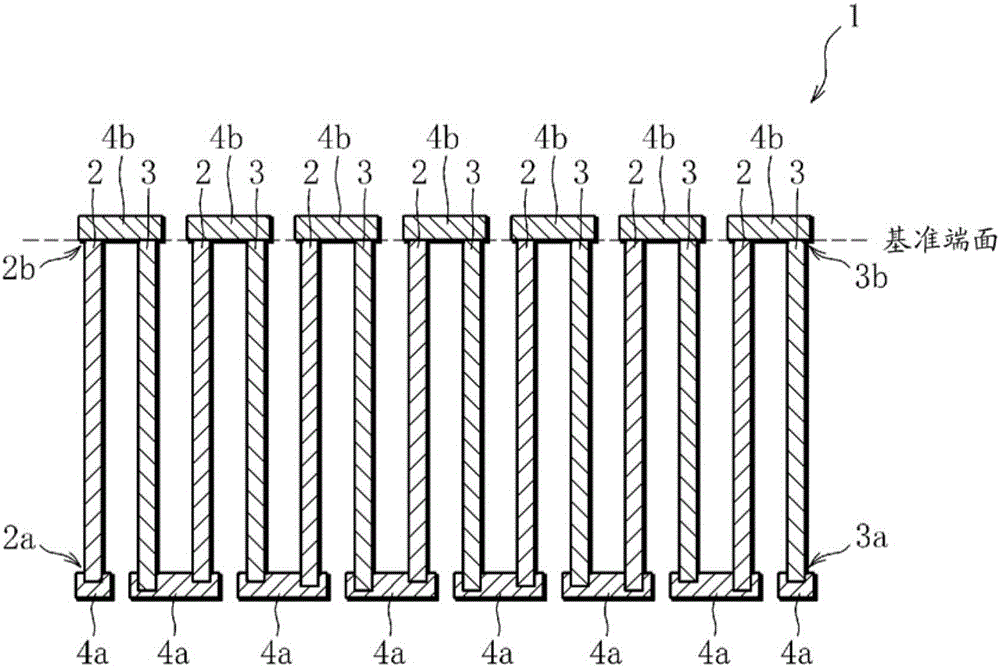

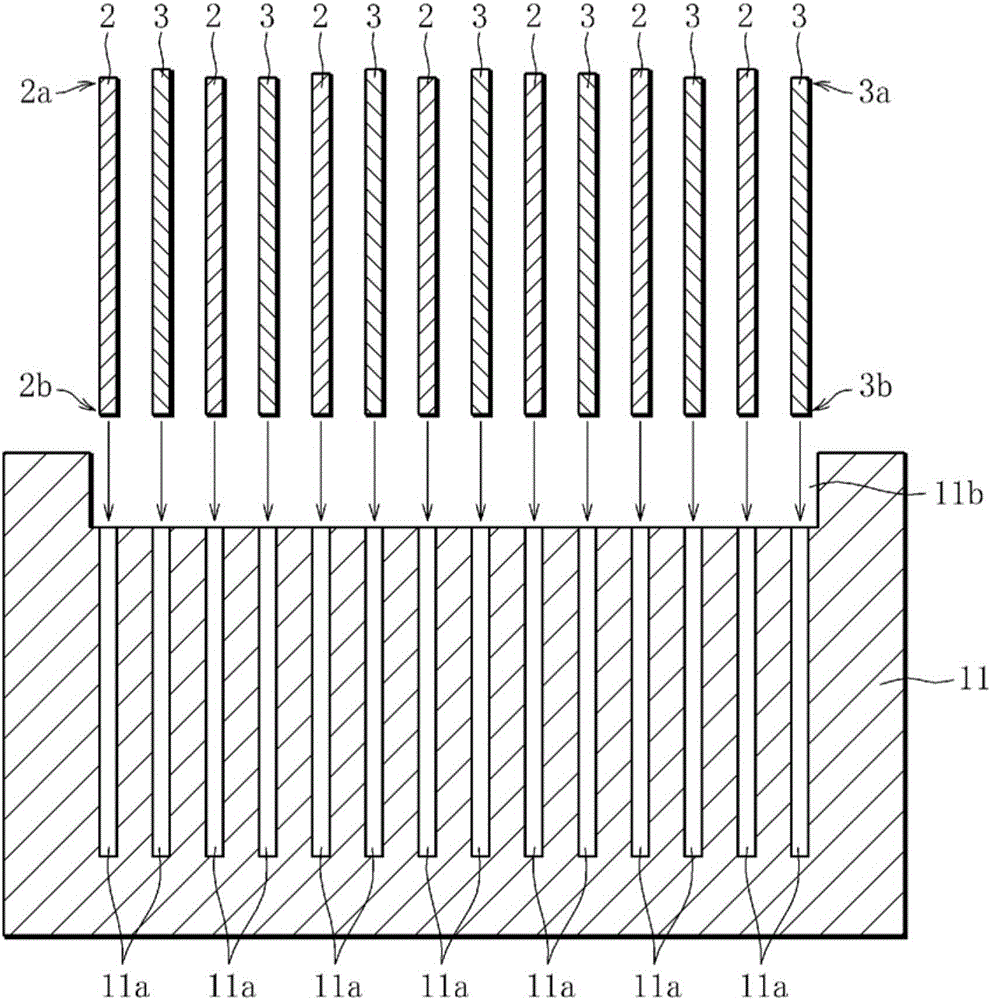

Method for manufacturing thermoelectric conversion element, and thermoelectric conversion element

ActiveCN105960716AAvoid preparation methodReduced thermoelectric propertiesThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentMetallurgyMetal powder

A method for manufacturing a thermoelectric conversion element includes: a holding step of holding at least one thermoelectric conversion member (2, 3) while at least one end of the thermoelectric conversion member is exposed; a coating step of coating the exposed end of the thermoelectric conversion member with metal powder (13); and an electrode forming step of forming an electrode (4a) at the end of the thermoelectric conversion member by sintering the metal powder.

Owner:ATSUMITEC CO LTD

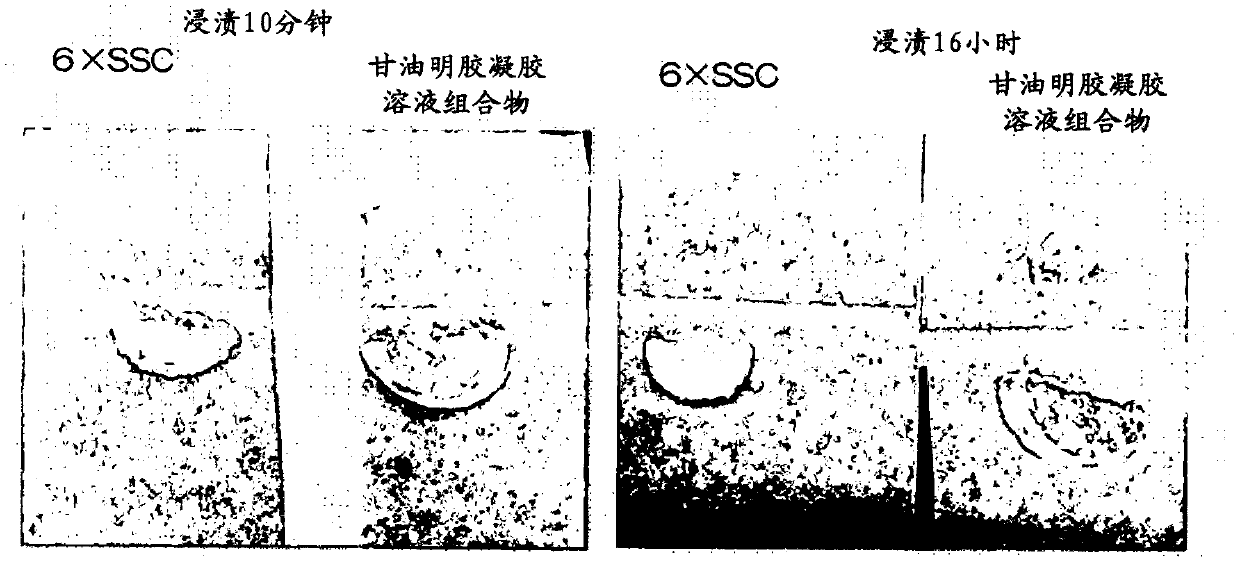

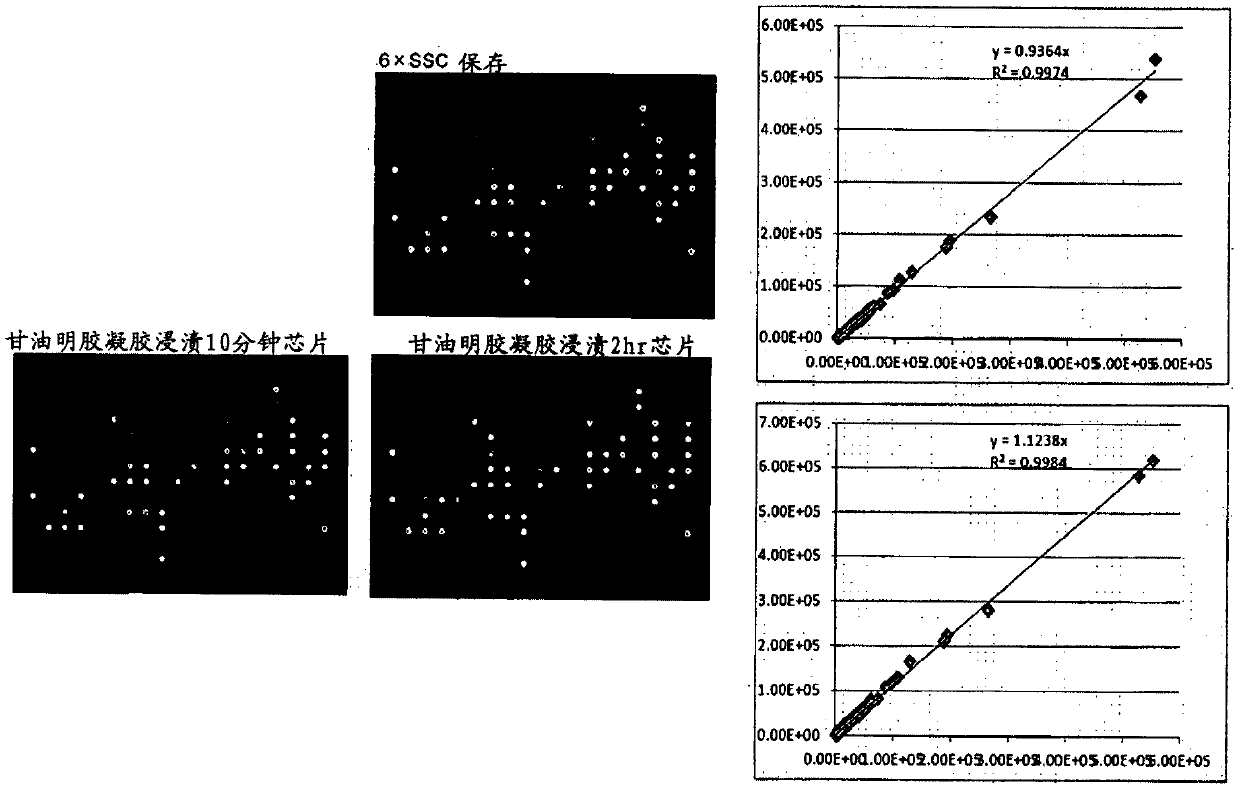

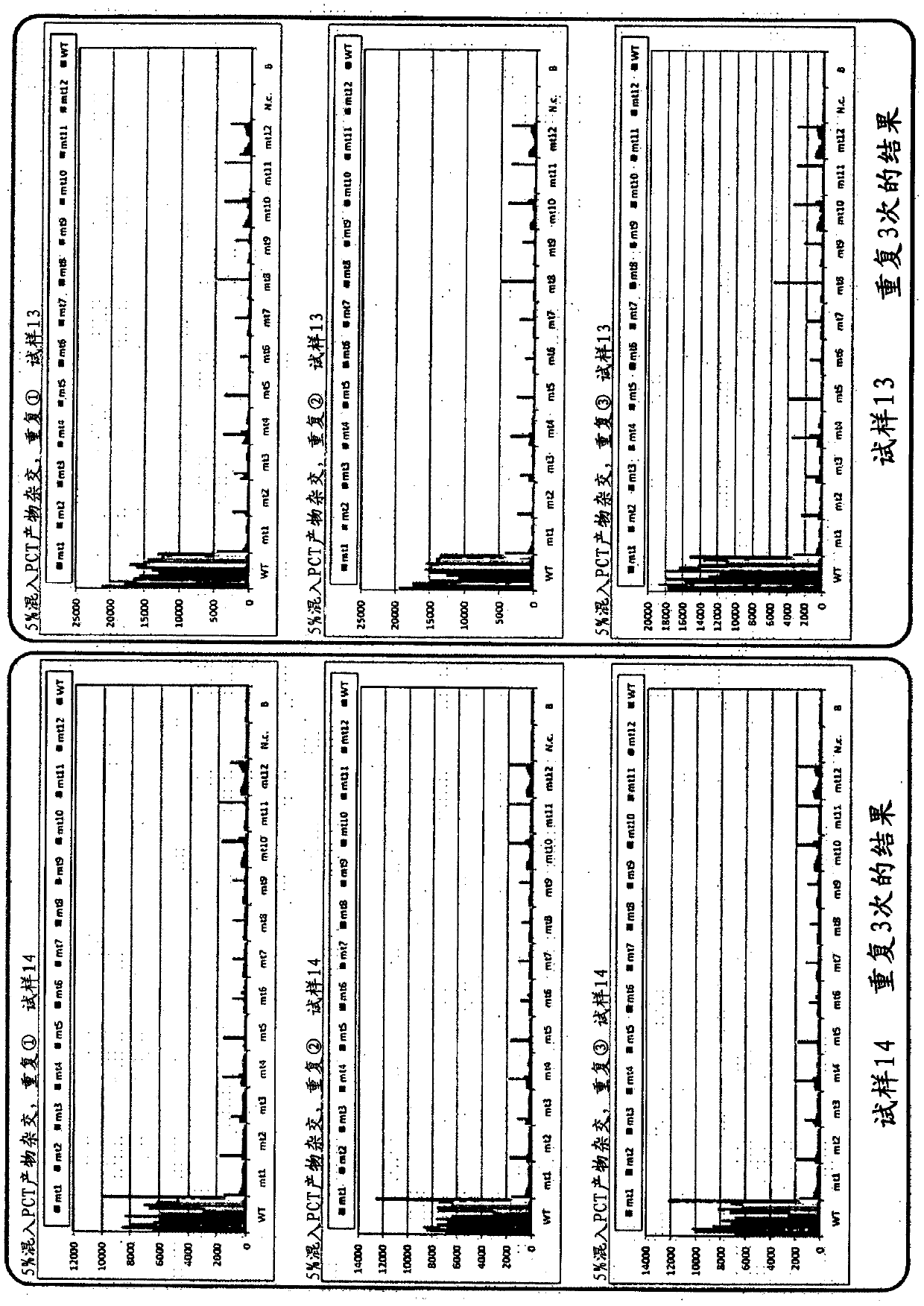

Composition for preventing drying of gel, gel composite and DNA chip containing said composite, and method for producing said composition, composite, and chip

InactiveCN109563502AAvoid preparation methodBioreactor/fermenter combinationsBiological substance pretreatmentsCarrageenanAlcohol

The invention provides: a composition for preventing the drying of gel with which it is possible to prevent the drying of gel more easily than in the past; a gel complex and a DNA chip containing saidcomposite; and a method for producing said composition, composite, and chip. This problem can be overcome by a composition for preventing the drying of gel that includes a polyhydric alcohol and at least one selected from gelatin, collagen, carrageenan, pectin, and agar.

Owner:MITSUBISHI CHEM CORP

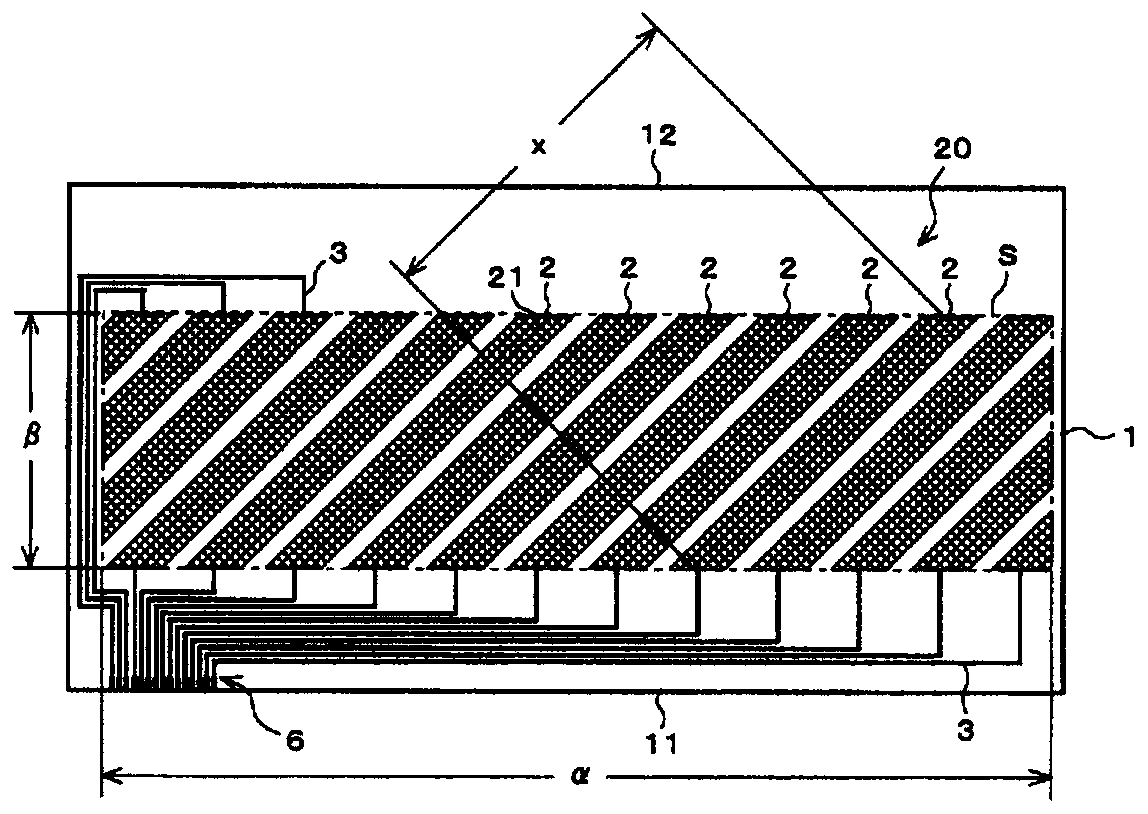

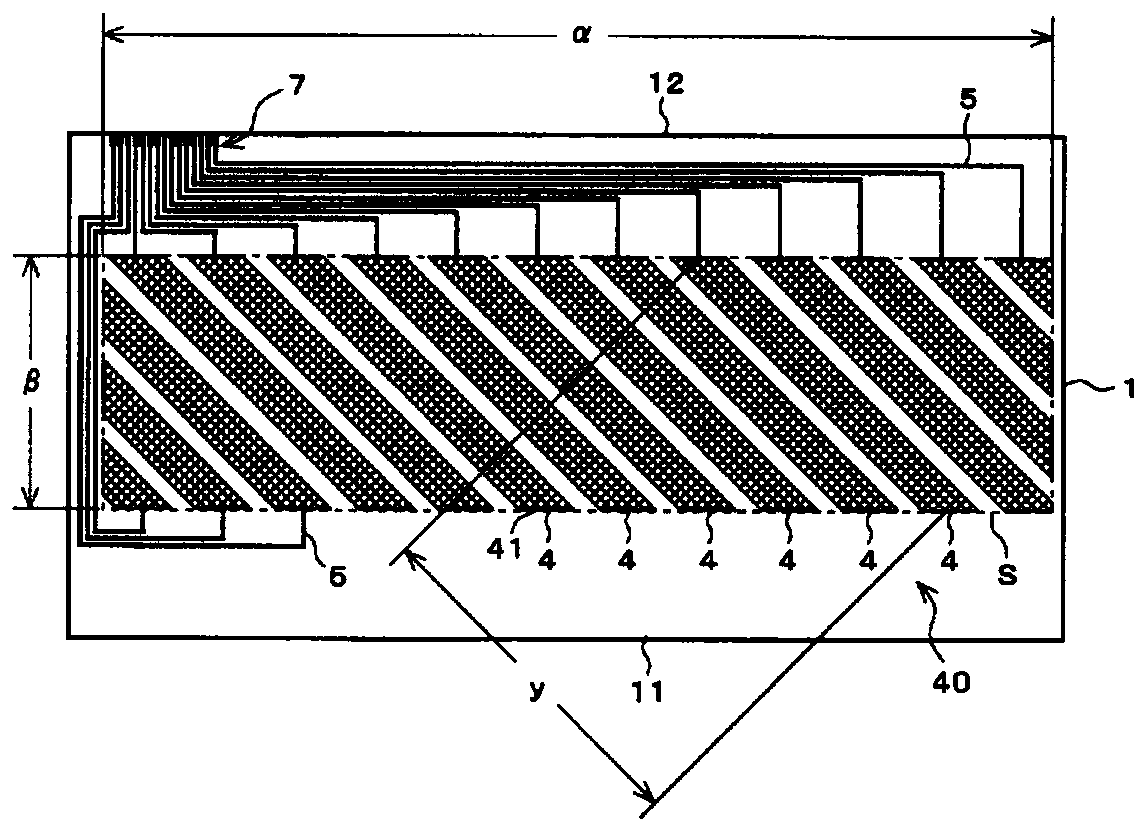

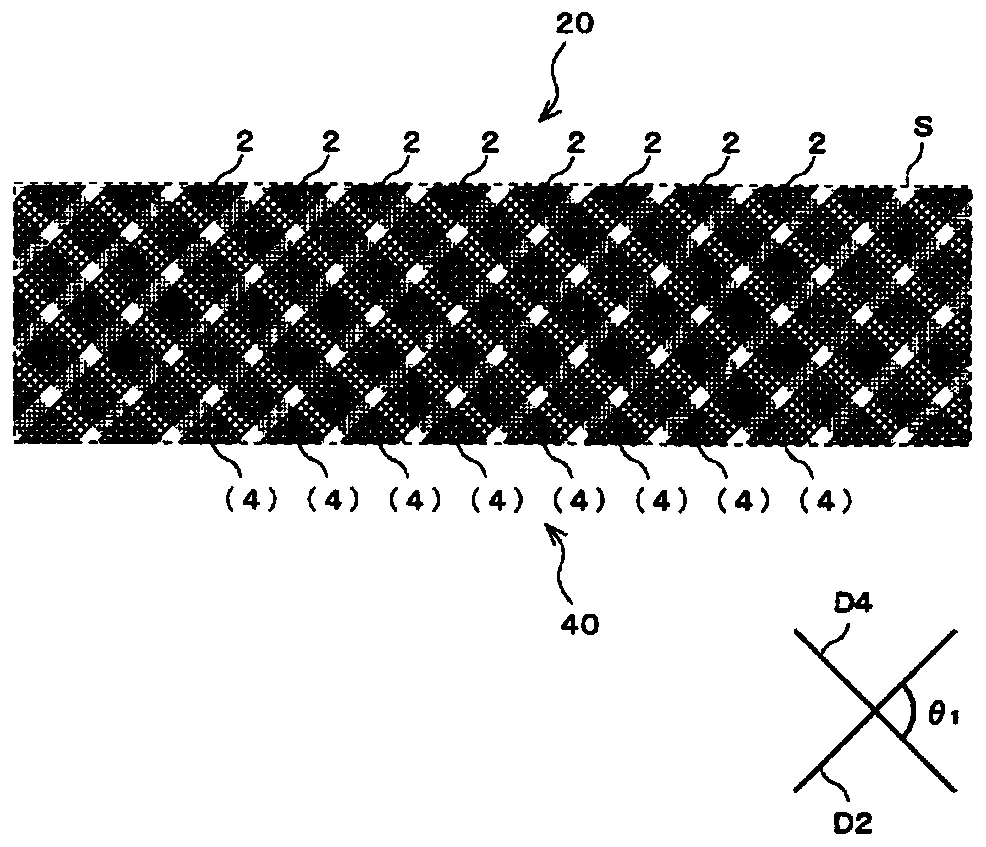

Touch panel sensor and method of manufacture of touch panel sensor

PendingCN111133405AAvoid preparation methodPrevent touch sensitivity lossInput/output processes for data processingComputer scienceMechanical engineering

The present invention addresses the problem of providing a touch panel sensor and a method of manufacture thereof capable of preventing touch sensitivity reduction due to elongation of a touch sensoreffective region, and also capable of avoiding inserting a region that does not contribute to touch detection into the touch sensor effective region. The problem is solved by a touch panel sensor thathas, provided on one surface of a substrate thereof, a first sensor group (20) comprising a plurality of sensor channels (2), and that also has, provided on the opposite surface of the substrate, a second sensor group (40) comprising a plurality of sensor channels (4), wherein: the plurality of sensor channels (2) and the plurality of sensor channels (4) are disposed to extend in directions to intersect each other; the first sensor group (20 and the second sensor group (40) form a rectangular touch sensor effective region (S); and the equation x <= y < alfa is satisfied, where x is the sensorlength of the longest of the plurality of sensor channels (2), y is the sensor length of the longest of the plurality of sensor channels (4), and alfa is the length of the long sides of the touch sensor effective region (S).

Owner:KONICA MINOLTA INC

Near-infrared absorbing film, process for producing the same, near-infrared absorbing film roll, process for producing the same and near-infrared absorbing filter

InactiveCN100442087CAvoid preparation methodHigh absorption capacityColor measuring devicesSynthetic resin layered productsDisplay deviceInfrared wavelength

The near-infrared-absorbing film of the present invention is a near-infrared-absorbing film in which a near-infrared-absorbing layer composed of a composition containing a near-infrared-absorbing dye and a resin having a maximum absorption at a wavelength of 800 nm to 1,200 nm is provided on a transparent base film. The film, wherein the composition contains 0.01 to 2.0% by mass of a surfactant having an HLB of 2 to 12. Therefore, it is possible to provide a high-fidelity television based on a wide range of absorbing power in the near-infrared region, a high light transmittance in the visible region, a small change in optical characteristics over time, and suitable for higher brightness of displays in recent years. A near-infrared absorbing film with excellent appearance for high-definition or high-quality coatings for broadcasting.

Owner:TOYOBO CO LTD

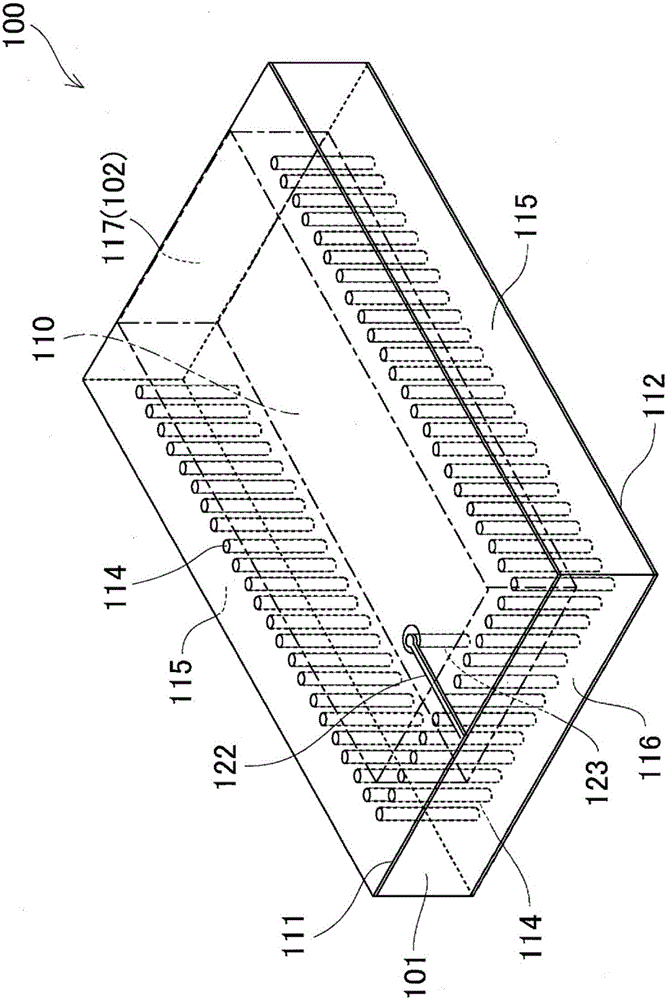

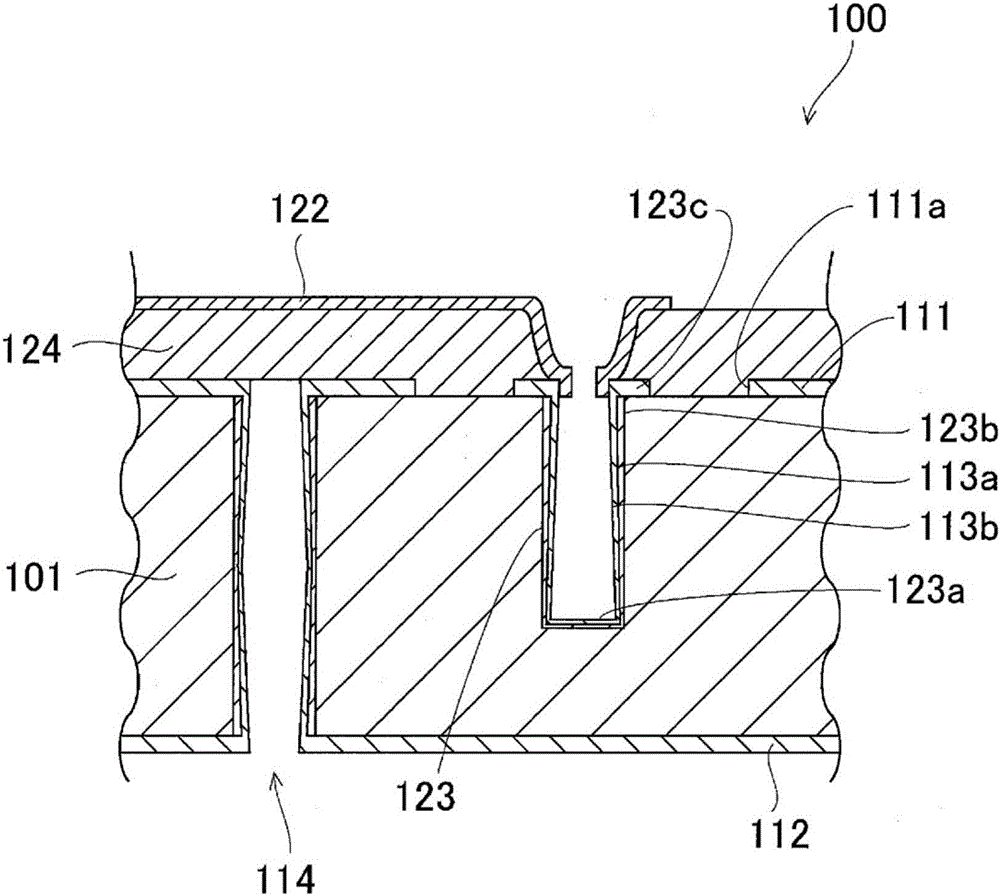

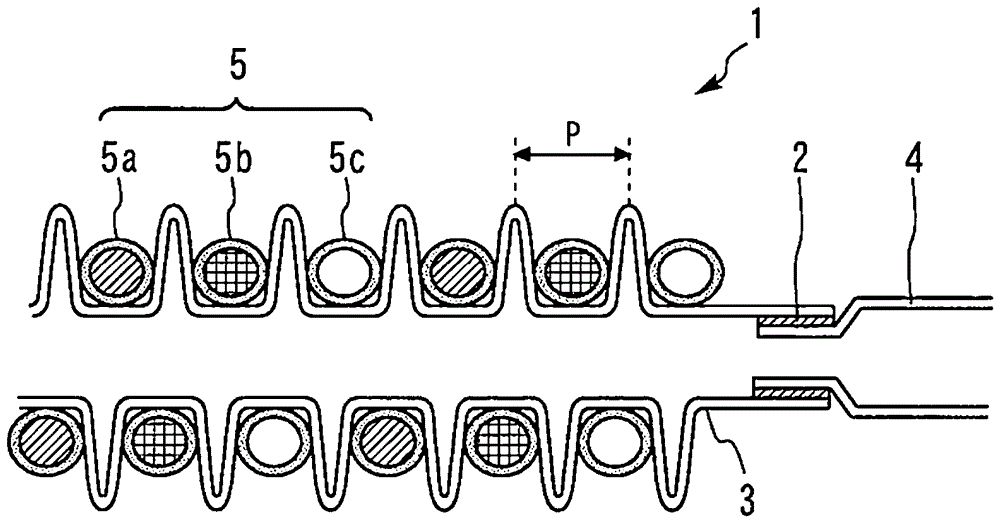

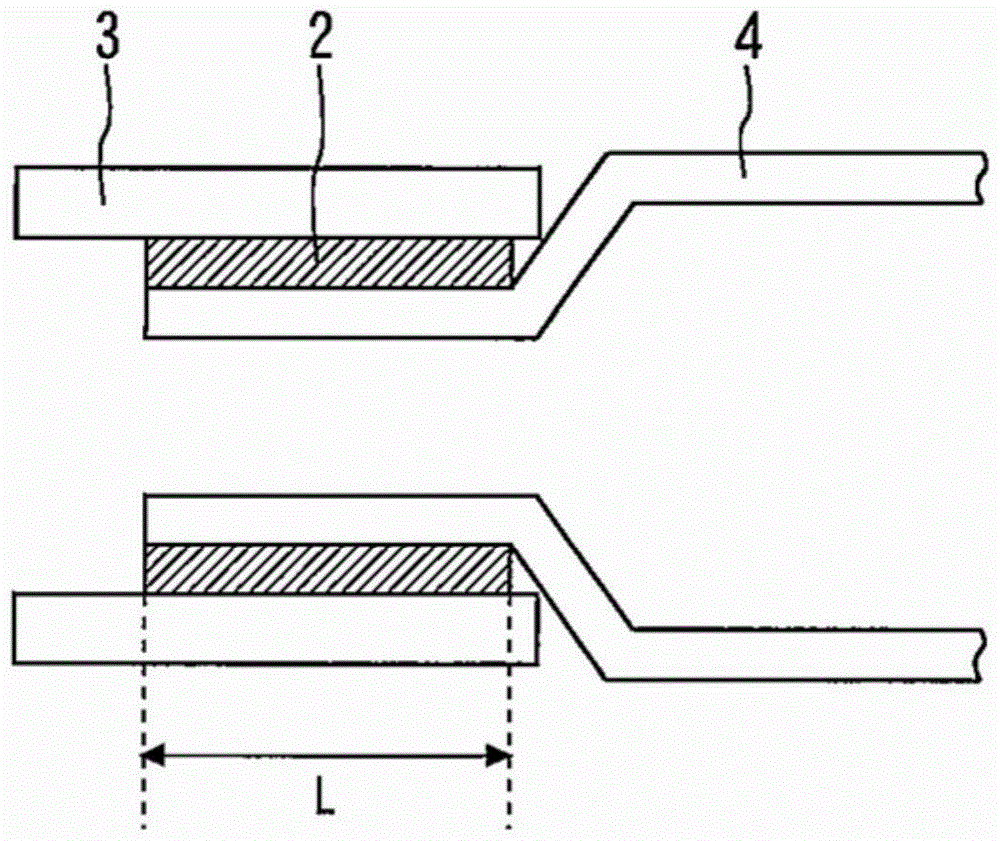

Twisted tube heat exchanger and manufacturing method of twisted tube heat exchanger

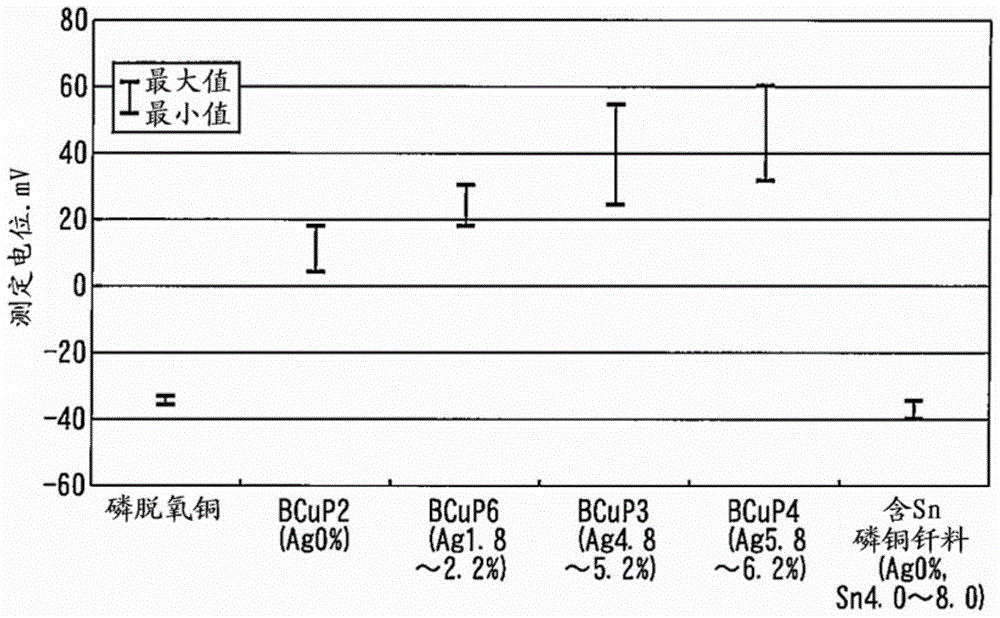

InactiveCN104236339BAvoid corrosionAvoid preparation methodStationary tubular conduit assembliesWelding/cutting media/materialsEngineeringCopper

A twisted tube heat exchanger which can prevent corrosion of a brazed joined part of water tubing is provided. A twisted tube heat exchanger 1, comprises: water tubing 3 which is made of phosphorus deoxidized copper, and which is provided with plural rows of crests and valley bottoms on the circumference thereof in a continuous and spiral form for each row; refrigerant tubing 5 which is spirally wound up and secured along the shape of the crest and valley bottom on the circumference of the water tubing 3; and joint tubing 4 which is made of phosphorus deoxidized copper, and which is connected to an end of the water tubing 3, wherein a joined part between the water tubing 3 and the joint tubing 4 is brazed with a brazing material 2 of phosphorus copper filler metal containing 4.0 to 8.0 weight% of tin, and 6.8 to 8.0 weight% of phosphorus, but containing no silver.

Owner:MITSUBISHI ELECTRIC CORP

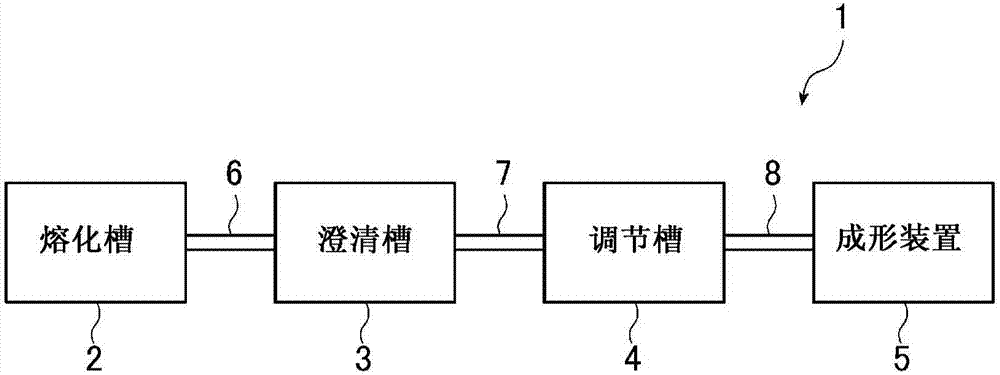

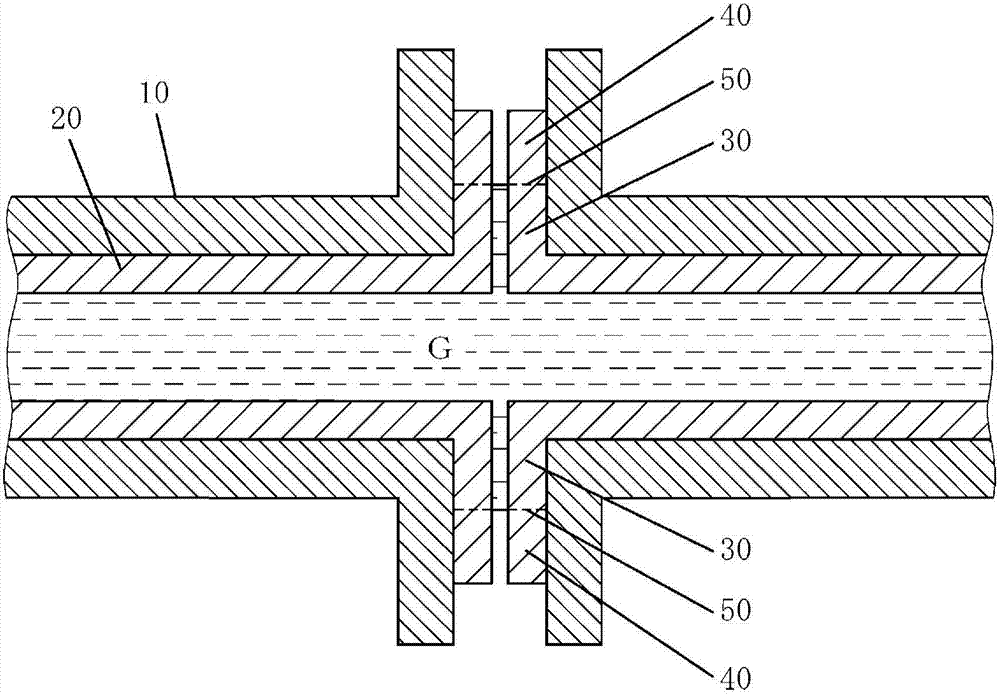

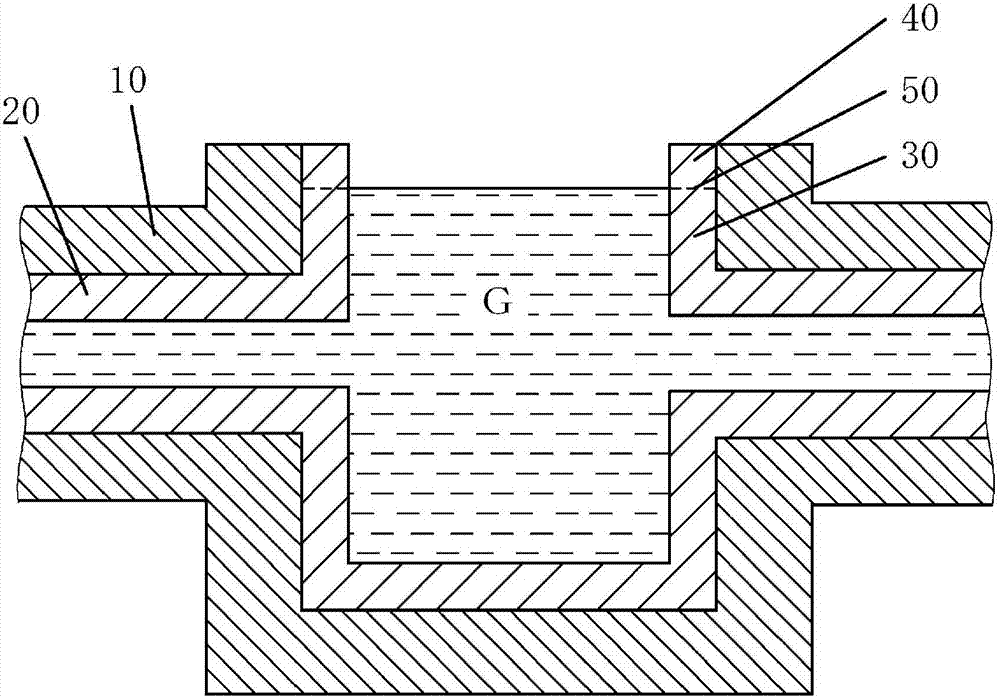

Conduit for molten glass, container for molten glass, manufacturing method thereof, glass article manufacturing apparatus, and glass article manufacturing method

ActiveCN105683099BAvoid it happening againAvoid preparation methodMolten spray coatingGlass furnace apparatusIridiumThermal spraying

The present invention pertains to a method for producing a conduit for a glass melt or a container for a glass melt by forming, on at least a portion of the inner surface of a platinum or platinum alloy hollow tube, a coating obtained by thermal spraying and satisfying conditions (1)-(4) below, and subsequently exposing the coating to an oxygen-containing atmosphere at 1300-1800°C. (1) The average film thickness of the coating is 0.1-0.5 mm; (2) A starting material containing a platinum alloy and at least one element selected from the group consisting of zirconium (Zr) and yttrium (Y) is used in the formation of the coating; (3) The platinum alloy in (2) is an alloy of platinum (Pt) and at least one element selected from the group consisting of rhodium (Rh), iridium (Ir), gold (Au), palladium (Pd), and ruthenium (Ru), and the total content of the element(s) other than platinum is 5-40 mass% relative to the total mass of the platinum alloy; (4) In the starting material in (2), the total content of the element(s) other than the platinum alloy relative to the total mass of the platinum alloy is 0.05-3 mass%.

Owner:ASAHI GLASS CO LTD

Manufacturing method of fuel cell assembly

ActiveCN107017418BPrevent the case that becomes the cause of flashingAvoid preparation methodFinal product manufactureDomestic articlesFuel cellsMechanical engineering

A method for manufacturing a fuel cell assembly includes: arranging an end face of a gas diffusion layer on a placement jig in a state abutting an end face of a resin frame; melting a part of the frame member and causing to penetrate into the gas diffusion layer by pressurizing the projecting part by way of a heat-transfer member, and heating the projecting part via the heat-transfer member by abutting a heating member against of the heat-transfer member; and solidifying the part of the resin frame having penetrated into the gas diffusion layer, in which an abutting position of the heating member relative to the heat transfer member is set in the melting step so that a central axis of the heating member is positioned more to a side of the gas diffusion layer than the central axis of the projecting part.

Owner:HONDA MOTOR CO LTD

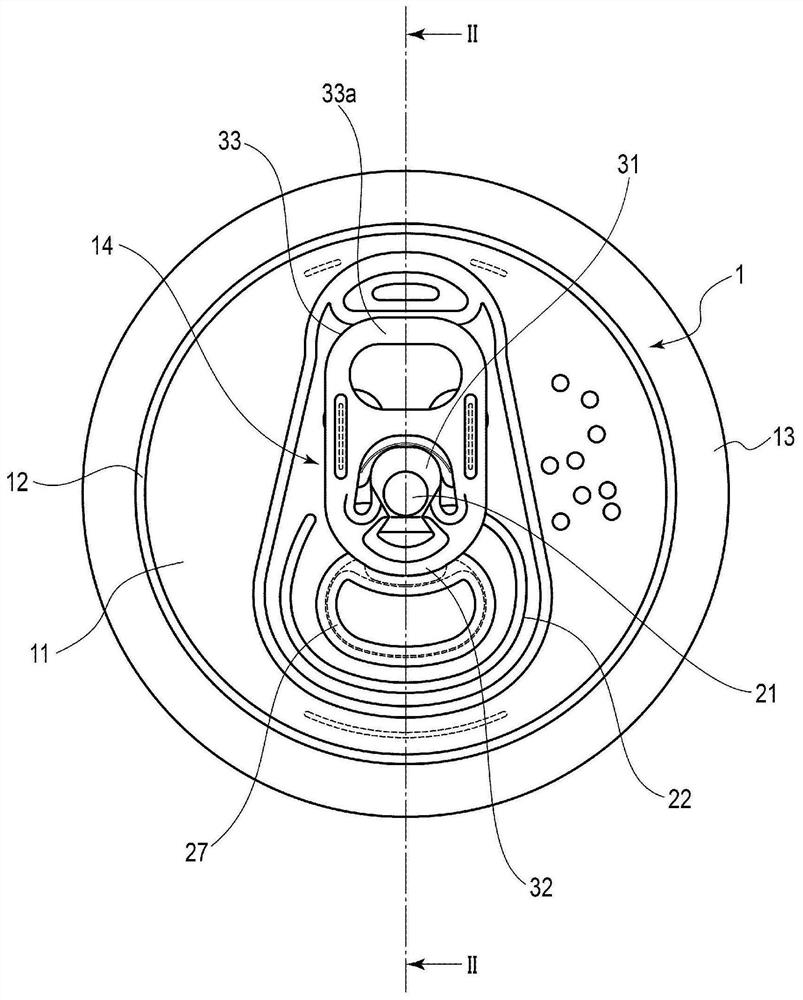

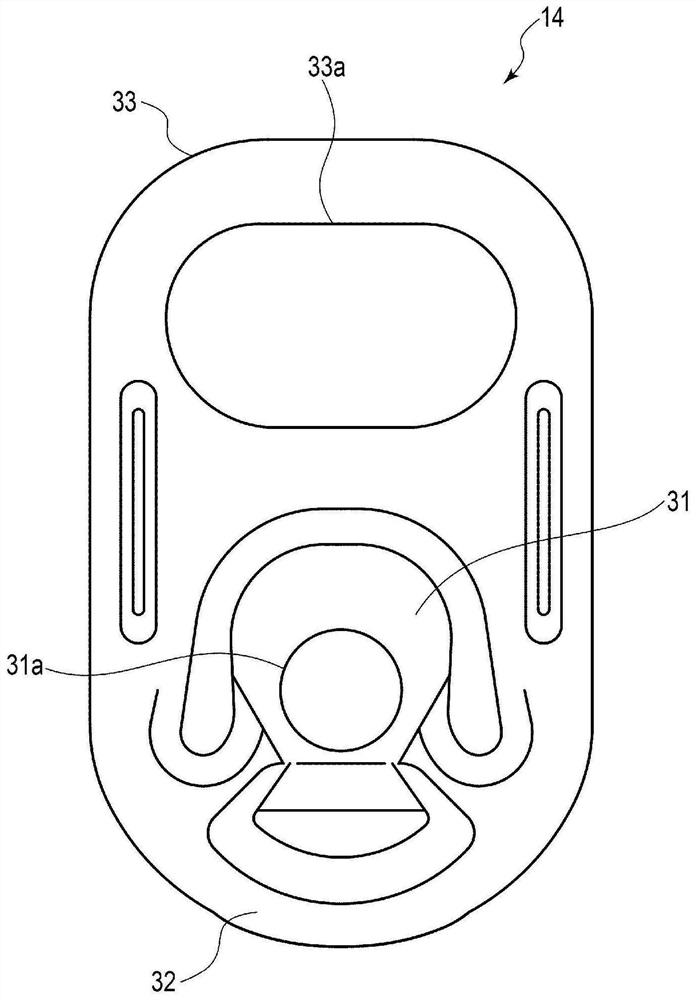

Tab, can lid, and method for manufacturing can lid

ActiveCN112041235AAvoid preparation methodSimple structureOther printing apparatusRigid containersMetallic materialsEngineering

This tab (14) used on a can lid (1) is formed of a metal plate (56) obtained by stacking a resin film (52) on at least one main surface of a base material (51) formed of a metal material, the metal plate comprising: an affixation part (31) including a rivet hole (31a) into which a rivet (21) formed in a panel section (11) of the can lid (1) is inserted; a pressing part (32) that is formed integrally with the affixation part (31) and presses the region inside a score line (22) formed in the panel section (11); and a hook part (33) formed integrally with the pressing part (32).

Owner:DAIWA CAN

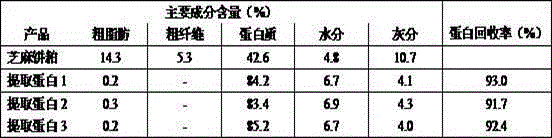

Method for preparing sesame-seed cake meal protein isolate

InactiveCN104522288AAvoid preparation methodProtein composition from vegetable seedsProtein isolateProtein

The invention provides a method for preparing sesame-seed cake meal protein isolate. The sesame-seed cake meal protein isolate is prepared from low-temperature sesame-seed cake meal and 10-20 parts of pure water in an extraction manner. The method for preparing the sesame-seed cake meal protein isolate comprises the following steps: preparing 40-80-mesh low-temperature sesame-seed cake meal and pure water into a 5-10% solution, adding an alkali liquid, adjusting the pH value to be 7.0-10.0, performing centrifugal separation, recycling the liquid phase, adding hydrochloric acid into the obtained liquid phase to adjust the pH to be 4.0-4.6, adding pure water into the obtained solid phase for washing, uniformly stirring, adding the alkali liquid to neutralize until the pH value is 6.0-9.0, and performing spray drying, thereby obtaining sesame-seed cake meal protein isolate. The recycling rate of protein is greater than 90%, and the content of protein of a product is greater than 80%.

Owner:CHONGQING DOUHAO BIOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com