Method for manufacturing thermoelectric conversion element, and thermoelectric conversion element

A technology of thermoelectric conversion and manufacturing method, which is applied in the manufacture/processing of thermoelectric devices, thermoelectric device parts, thermoelectric device junction lead wire materials, etc. The effect of size deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (Structure of thermoelectric conversion element)

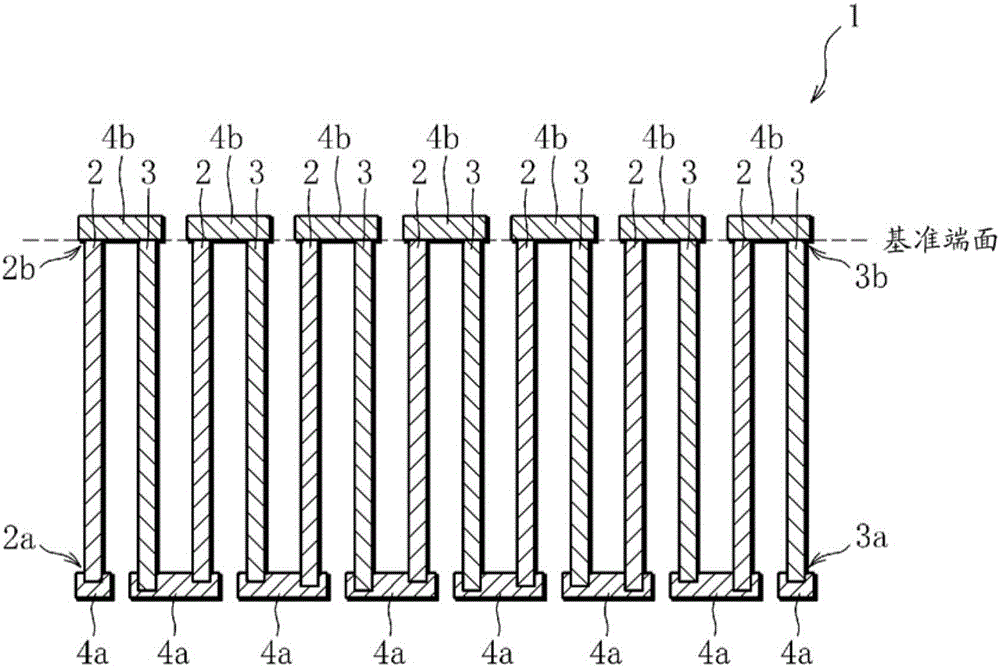

[0054] Below, refer to figure 1 The structure of the thermoelectric conversion element of Example 1 of the present invention will be described. figure 1 It is a cross-sectional view schematically showing the thermoelectric conversion element of Example 1. FIG. in addition, figure 1 is a cross-sectional view along the extending direction of the thermoelectric conversion member constituting the thermoelectric conversion element.

[0055] Such as figure 1As shown, the thermoelectric conversion element 1 of Example 1 has a first thermoelectric conversion component 2 made of N-type semiconductor material, a second thermoelectric conversion component 3 made of N-type semiconductor material, and the first thermoelectric conversion component 2 and the second thermoelectric Electrodes 4a, 4b joined to both ends of the conversion member 3 . In this embodiment, the first thermoelectric conversion component 2 and the secon...

Embodiment 2

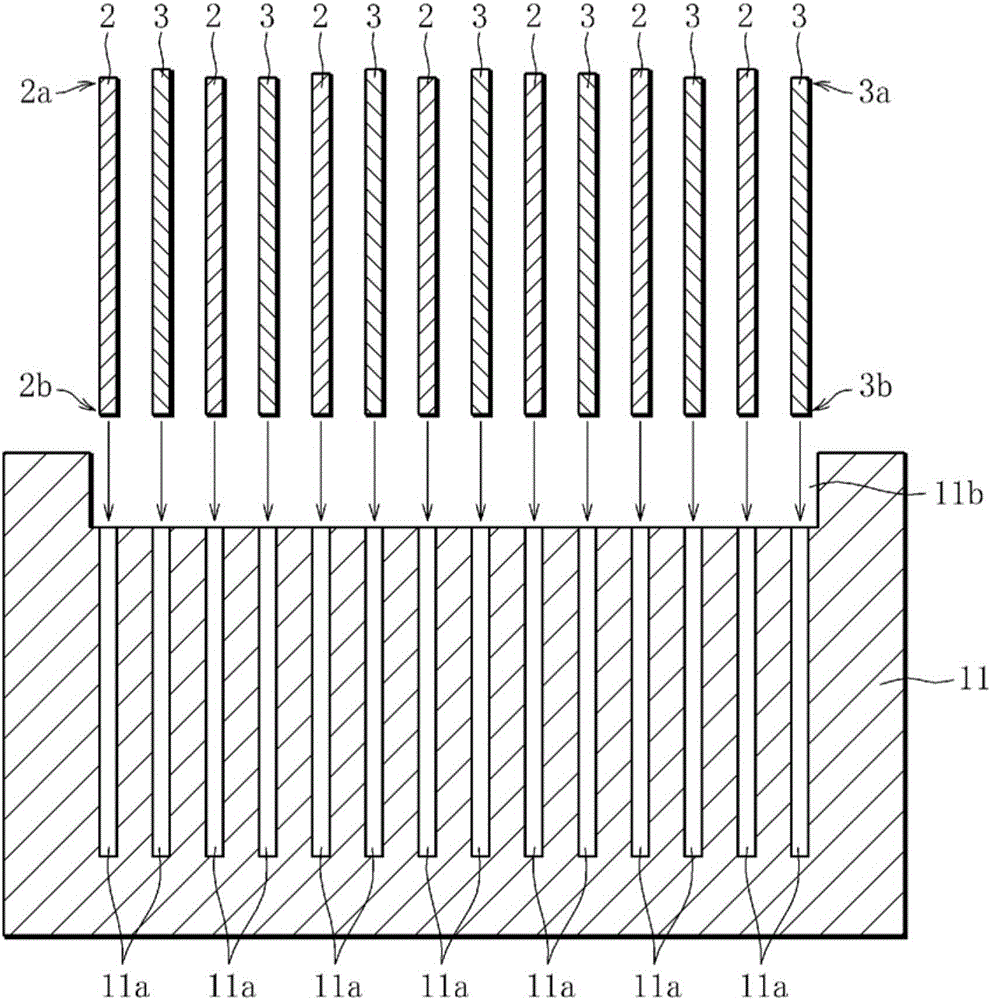

[0076] In the first embodiment described above, the second end portion 2b of the first thermoelectric conversion element 2 and the second end portion 3b of the second thermoelectric conversion element 3 are brought into contact with the bottom surface of the holding part 11 of the manufacturing apparatus 10, whereby , align the second ends 2b, 3b on the same plane, but it is also possible to use Figure 7 The method shown aligns the second ends 2b, 3b on the same plane. Figure 7 With figure 1 A schematic cross-sectional view in the manufacturing process of the thermoelectric conversion element 1 is shown similarly. In addition, except for the process of holding the first thermoelectric conversion member 2 and the second thermoelectric conversion member 3 by the manufacturing apparatus, it is the same as the above-mentioned Example 1, and therefore descriptions other than the holding process are omitted.

[0077] Such as Figure 7 As shown, the holding part 21 of the manuf...

Embodiment 3

[0083] The thermoelectric conversion element of the present invention is not limited to the thermoelectric conversion element 1 of Embodiment 1 and Embodiment 2 described above, and may be formed by covering the ends of the thermoelectric conversion member with all the electrodes positioned at both ends of the thermoelectric conversion member. That is, all the electrodes may be formed of metal powder. Hereinafter, the thermoelectric conversion element 101 having such a structure will be referred to as Embodiment 3, referring to Figure 8 ~ Figure 14 Its structure and manufacturing method will be described.

[0084] (Structure of thermoelectric conversion element)

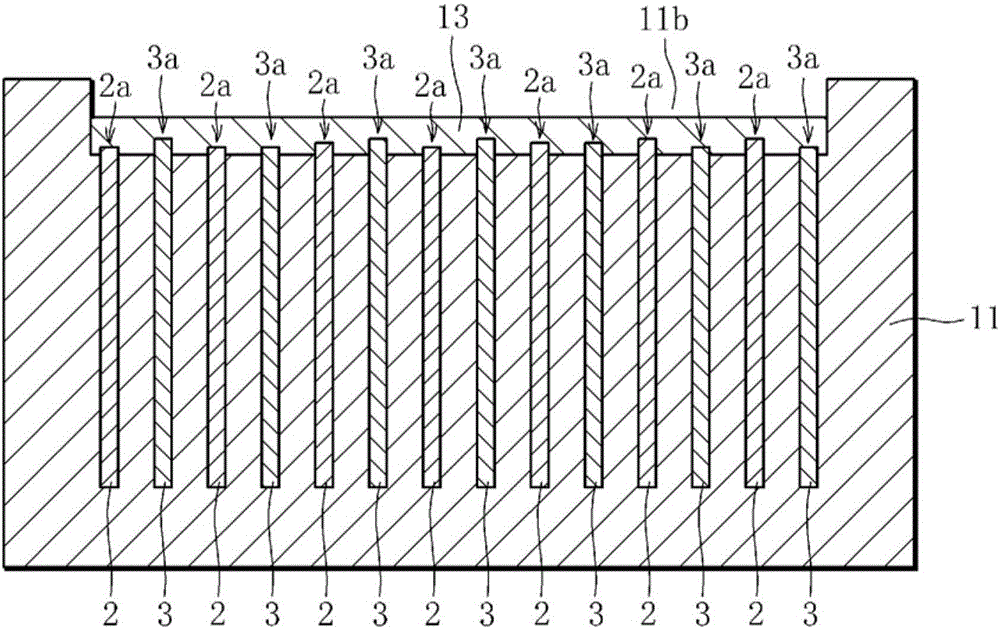

[0085] First, refer to Figure 8 The structure of the thermoelectric conversion element 101 according to Example 3 of the present invention will be described. Figure 8 It is a cross-sectional view schematically showing the thermoelectric conversion element of Example 3. FIG. in addition, Figure 8 It is a cros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com