Twisted tube heat exchanger and manufacturing method of twisted tube heat exchanger

A heat exchanger and twisted-tube technology, applied in the field of twisted-tube heat exchangers, can solve the problems of content regulation, unpredictable anti-corrosion effect, solder corrosion, etc., and achieve the effect of anti-corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

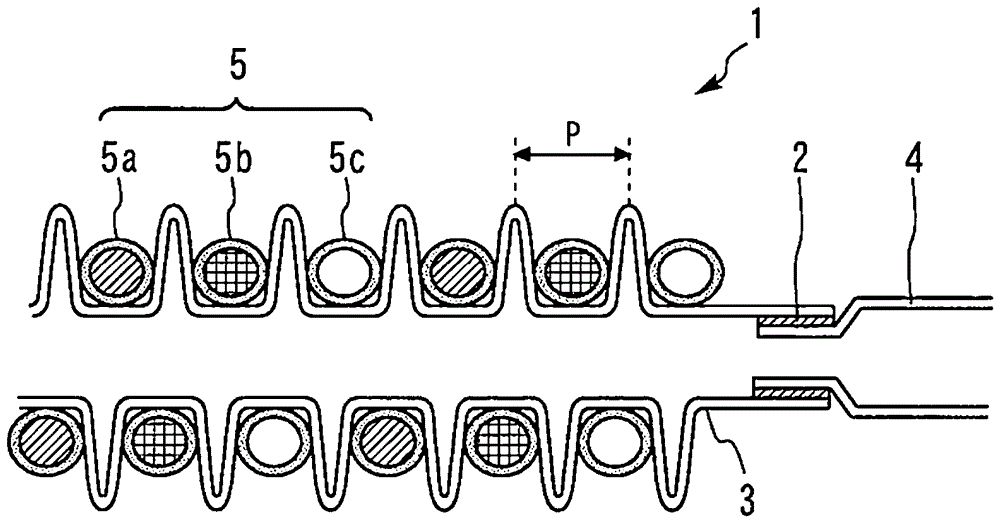

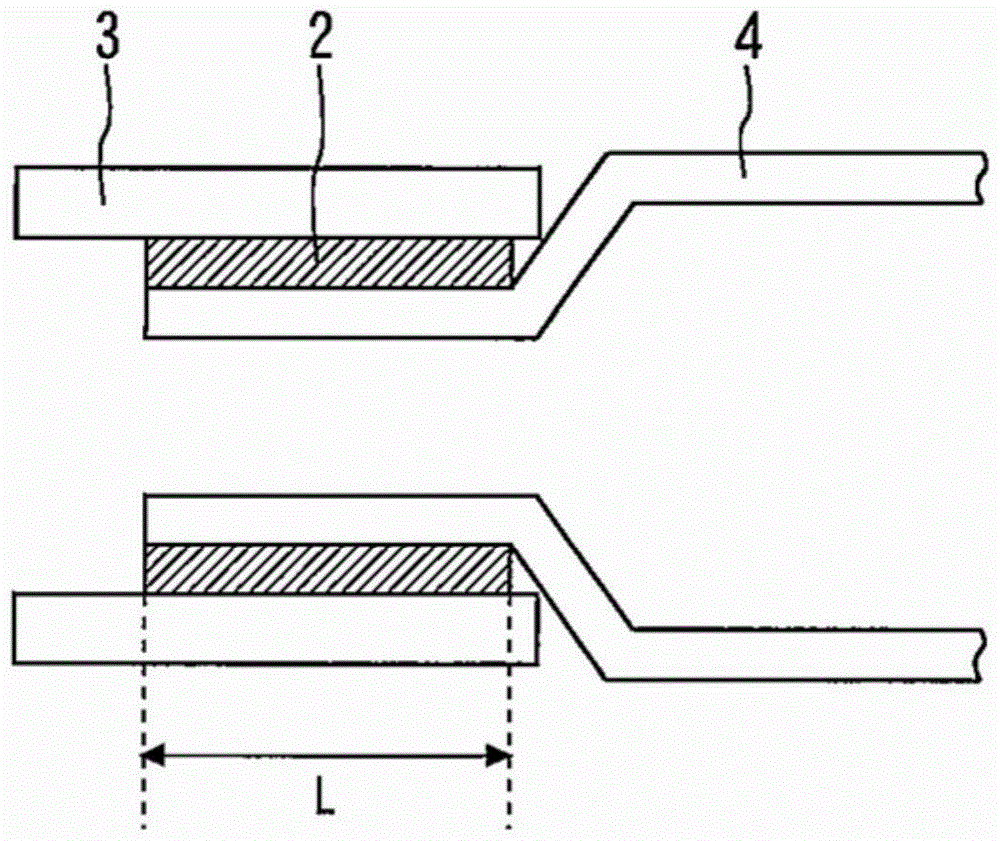

[0018] figure 1 It is a figure which schematically shows the cross section of the twisted-tube heat exchanger in Embodiment 1 of this invention along the water-tube longitudinal direction. Such as figure 1 As shown, for the twisted tube heat exchanger 1 , a twisted tube with a plurality of (for example, 3) valleys provided on the outer periphery and each valley is continuously spirally arranged is used as the water pipe 3 . For the water pipe 3 , both ends of the phosphorus-deoxidized copper smooth pipe were fixed, a mandrel was inserted into the inner diameter side, and the phosphorus-deoxidized copper smooth pipe was continuously twisted to form a plurality of valley bottoms. At this time, by controlling the helical pitch P of the water pipe 3 with high precision, it is possible to stably insert the refrigerant pipe 5 described later.

[0019] On the outer periphery of the water pipe 3, the refrigerant pipe 5 is spirally wound along the shape of the bottom of each valley. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com