Method for producing waveguide substrate

A manufacturing method and substrate technology, which are applied in the directions of waveguide, semiconductor/solid-state device manufacturing, and waveguide-type devices, etc., can solve the problems of metal film peeling, difficult to reach plating solution, and inability to ensure metal film, and achieve the effect of preventing peeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] [Structure of waveguide substrate]

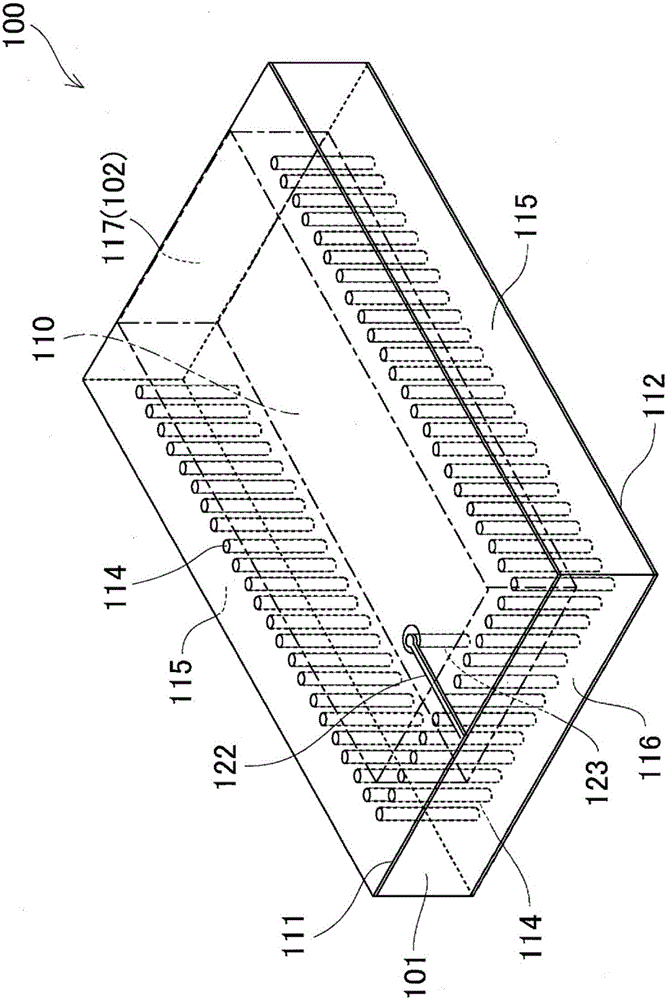

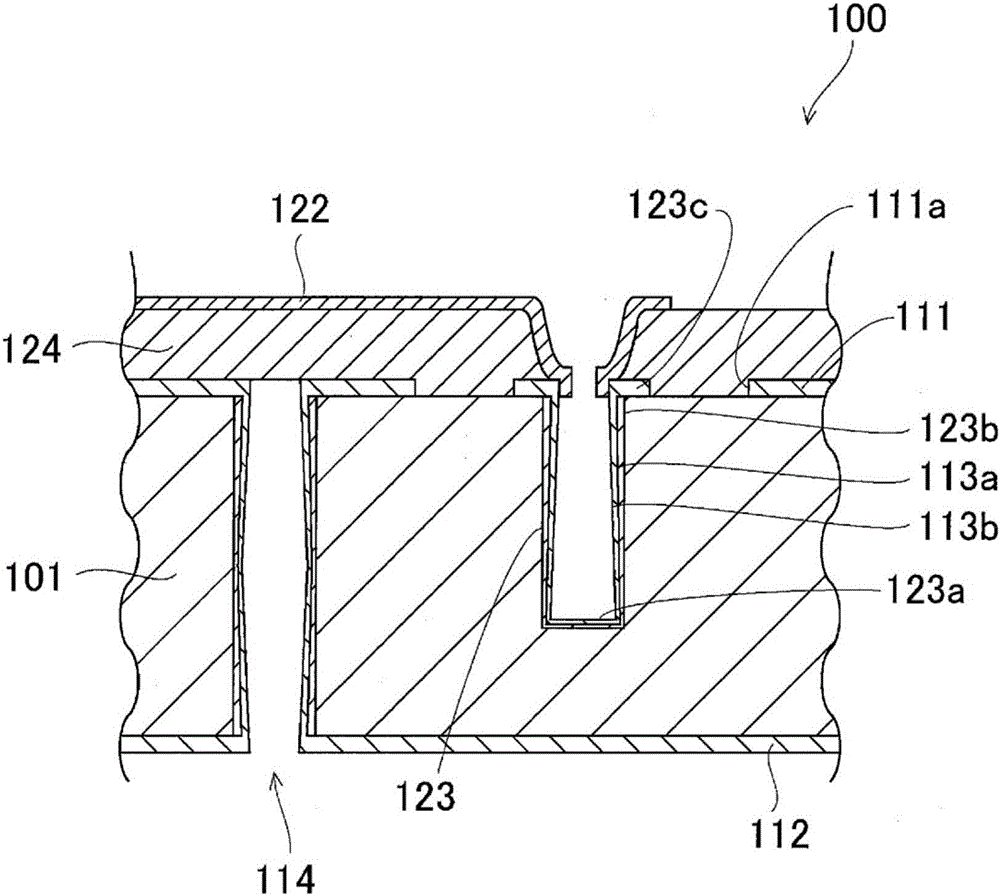

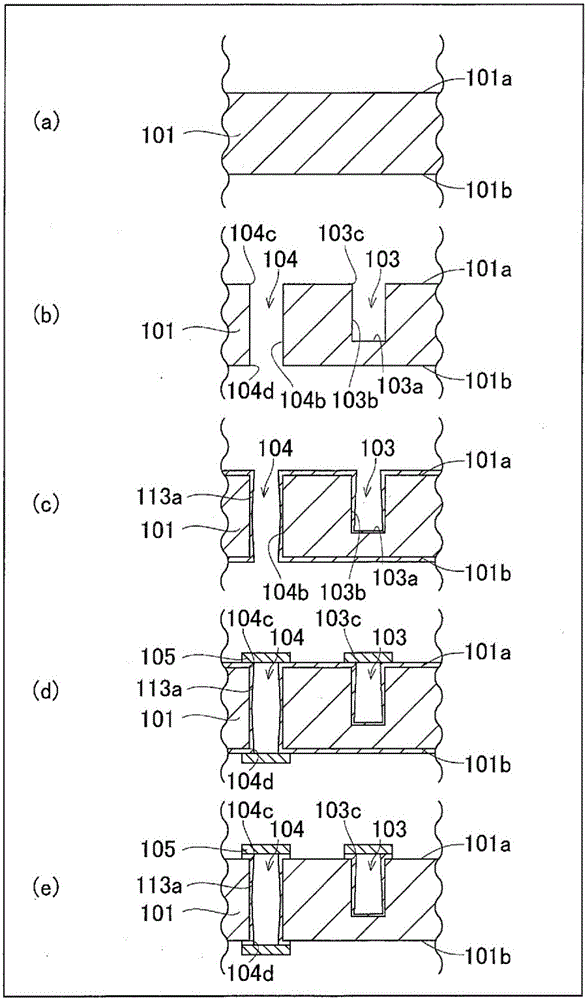

[0020] figure 1 is a perspective view showing the waveguide substrate 100, figure 2 is an end view showing the waveguide substrate 100 . It should be noted that although the conductor column 114 and the transmission path 122 are as figure 1 not present on the same face as shown, but on figure 2 Both are shown in the same end view for ease of presentation.

[0021] Such as figure 1 as well as figure 2 As shown, the waveguide substrate 100 of this embodiment includes: a glass substrate 101, a transmission path (planar circuit) 122 for signal propagation, a conductor pin 123, and a first ground conductor layer 111 and a second ground conductor layer 112 connected to a ground potential. , and waveguide 110 .

[0022] The glass substrate 101 is a glass substrate made of a single material. Instead of the glass substrate, a quartz substrate or a semiconductor substrate may be used.

[0023] The waveguide 110 is composed of a fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com