Molding mold, and manufacturing method for transdermal absorption sheet

A technology of absorbing sheets and shapes, applied in chemical instruments and methods, medical preparations with non-active ingredients, devices introduced into the body, etc., to achieve the effect of preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Next, the molded article, the percutaneous absorbable sheet and the manufacturing method thereof in the embodiment of the present invention will be described.

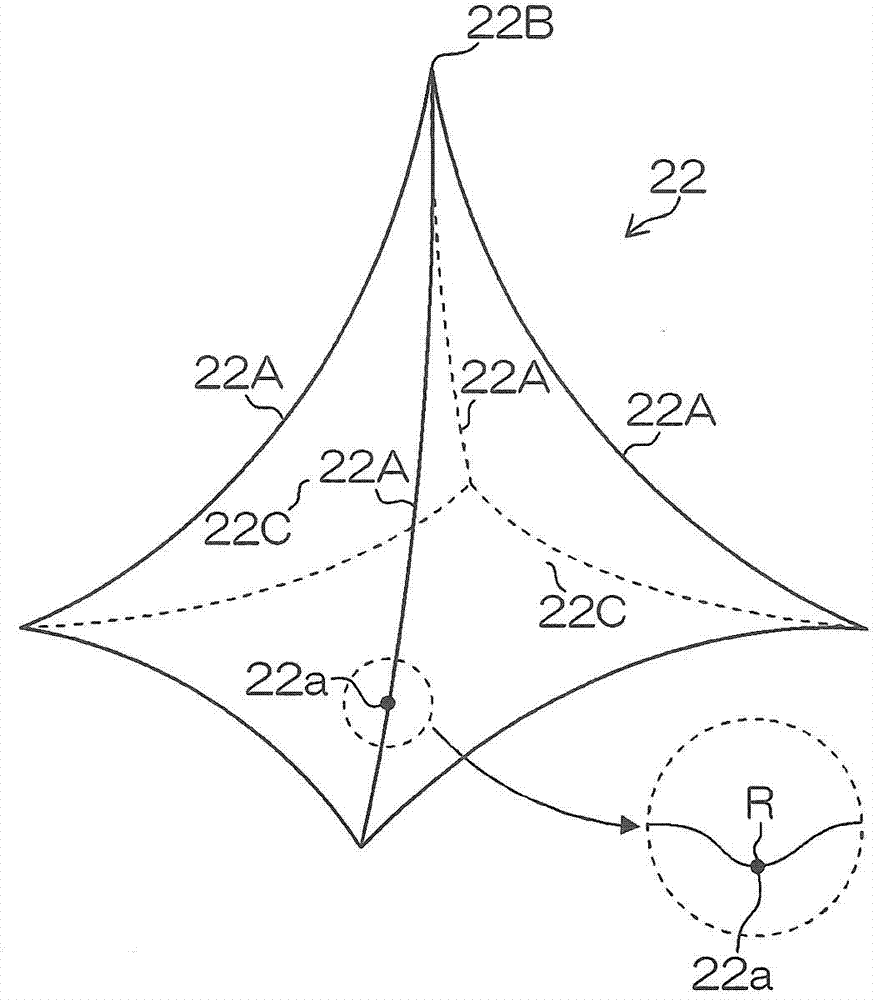

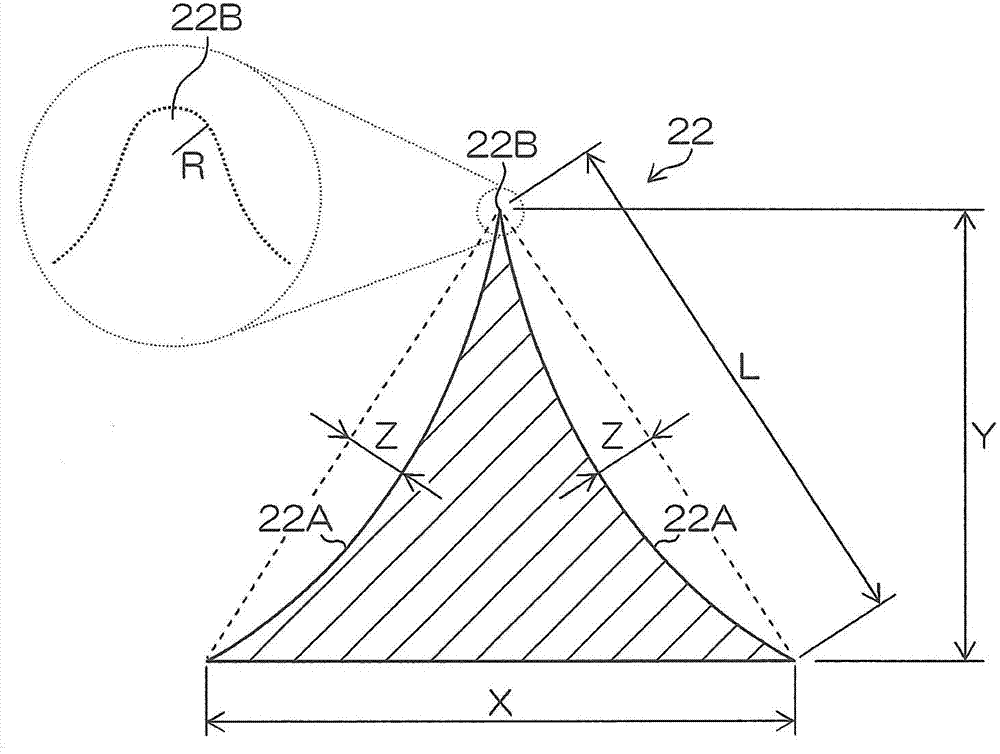

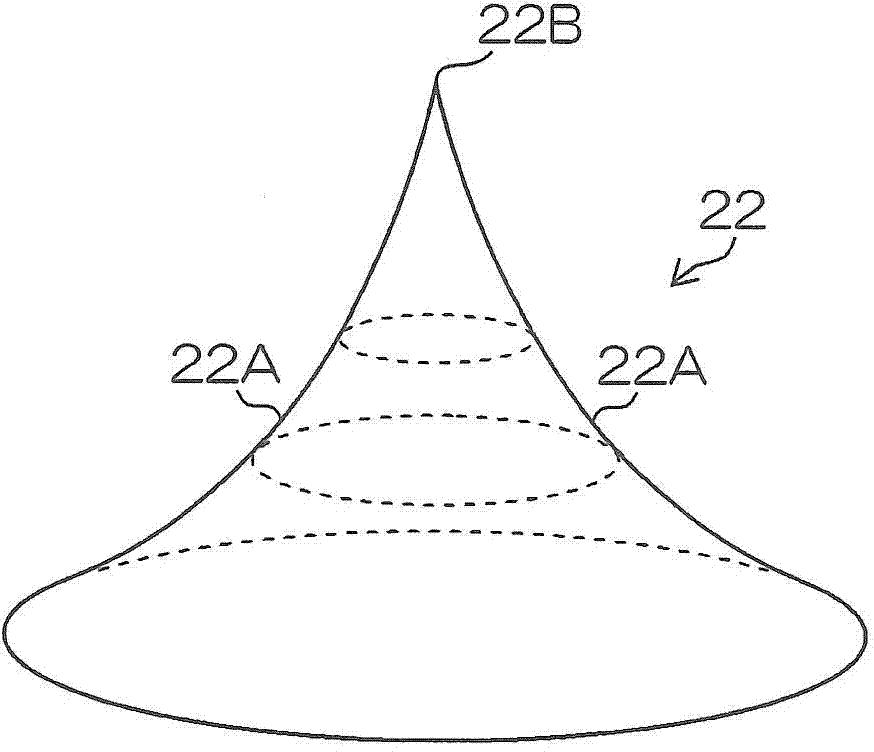

[0036] Figure 1A and 1B A perspective view and a cross-sectional view of the pyramid-shaped microneedles of the percutaneous absorption sheet manufactured by the manufacturing method of the present invention are shown in .

[0037] Such as Figure 1A and Figure 1B As shown, in order for the microneedles 22 to penetrate the skin surface at a depth of several hundred μm, for the shape of the microneedles (fine protrusions) 22 formed on the percutaneous absorption sheet, it is necessary that: (1) the front end be sufficiently sharp, The diameter of the needles entering the skin is also sufficiently thin (high aspect ratio of length / diameter); (2) has sufficient strength (the needles will not bend).

[0038] Therefore, in order to meet the requirements of (1), a thin and pointed shape is required, but this is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com