Film withdrawing device and manufacturing method of flexible printed circuit board

A take-out device, flexible printing technology, applied in the direction of printed circuit manufacturing, printed circuits, electrical components, etc., can solve the problems of forming fold lines, bending copper foil, manufacturing flexible printed circuit boards and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

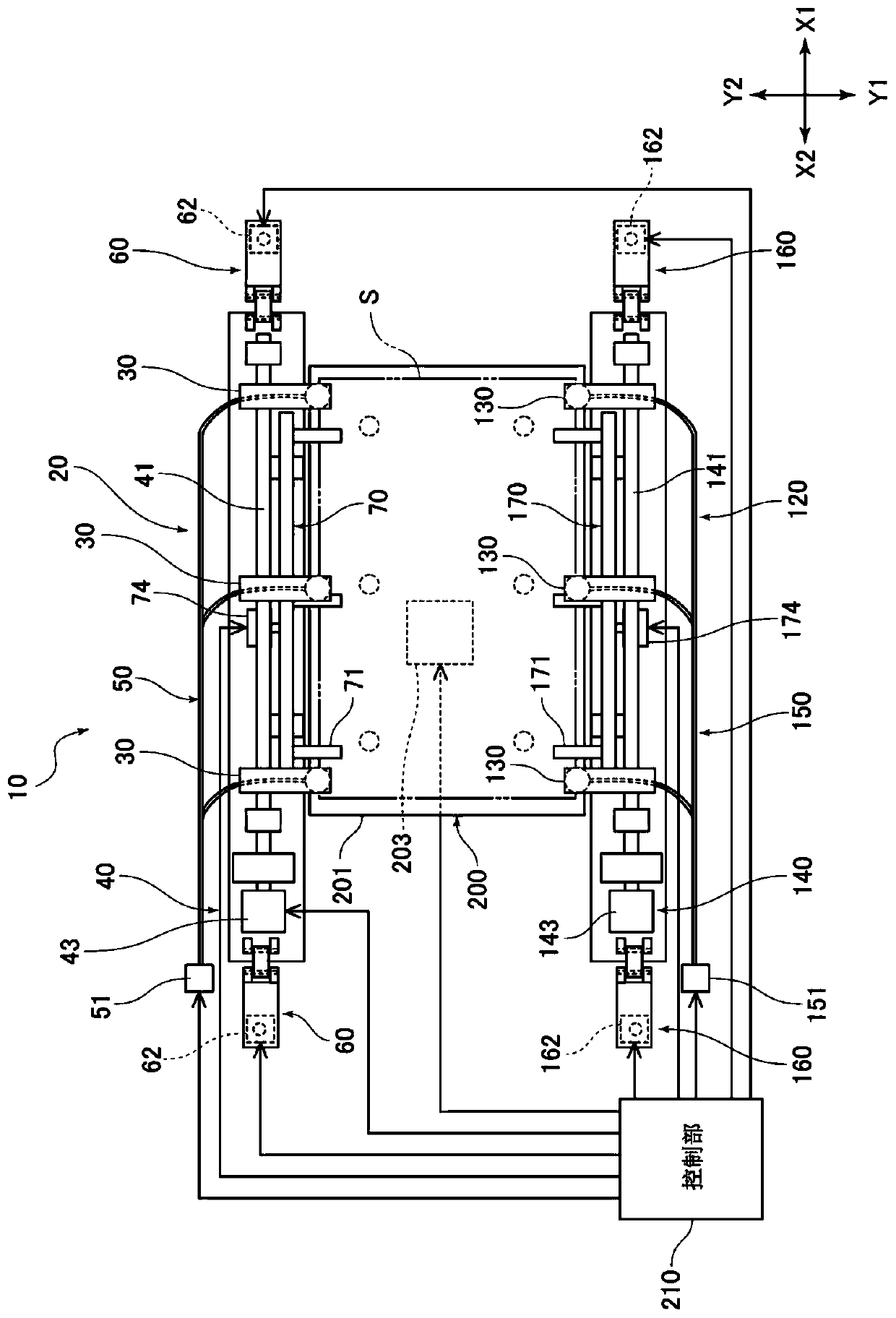

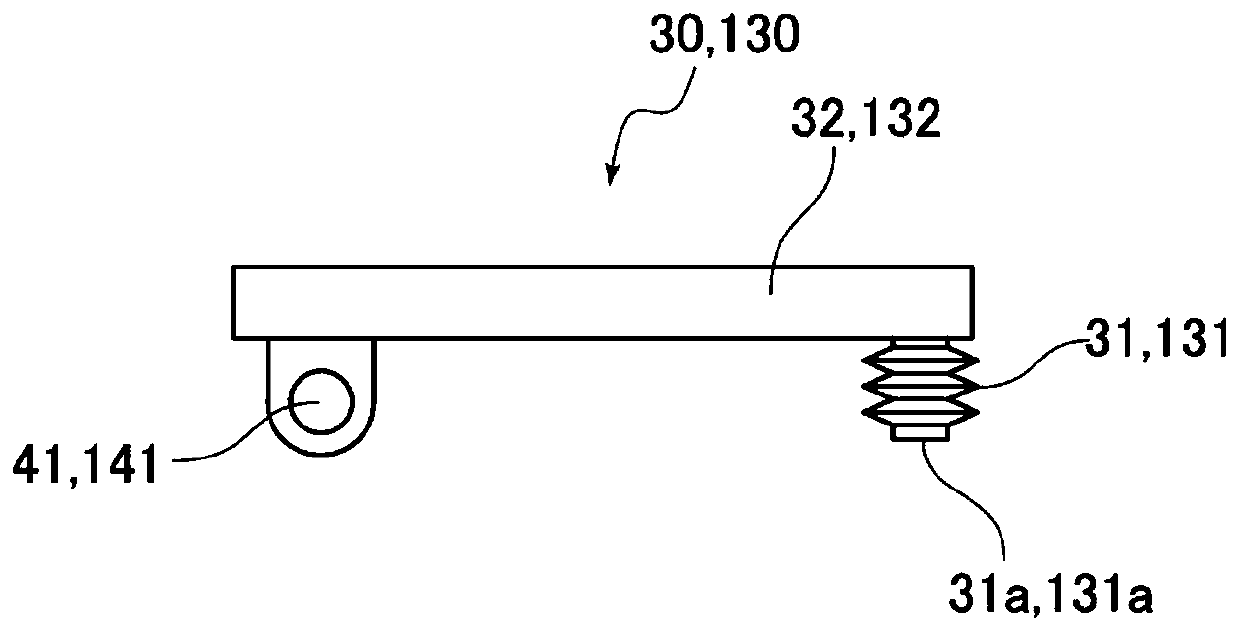

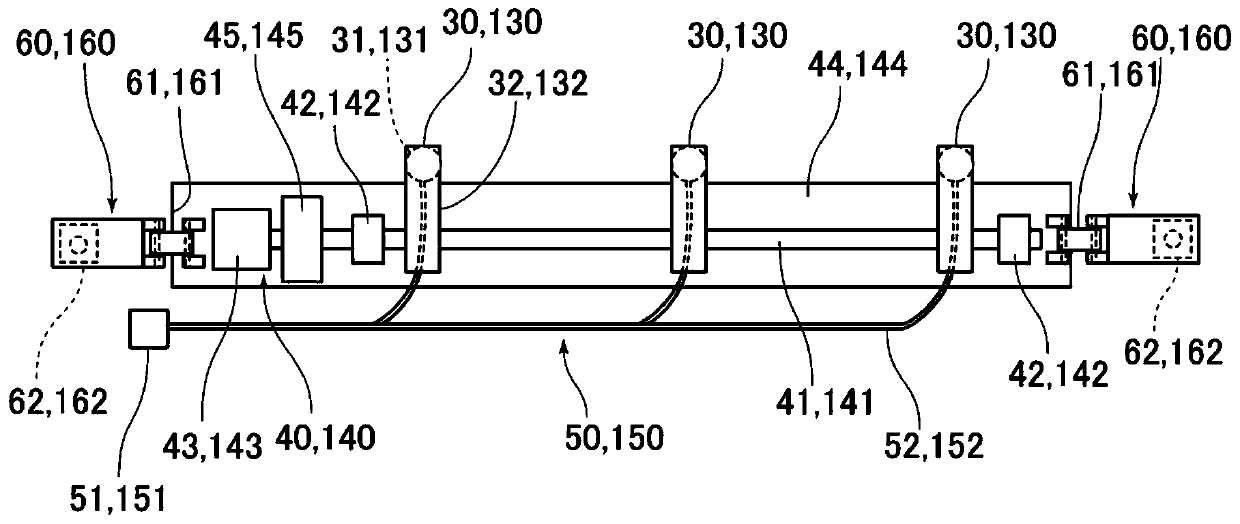

[0044] Hereinafter, the film take-out device 10 according to one embodiment of the present invention will be described. In the following description, the longitudinal direction of the support shaft 41 is referred to as the X direction, and the X1 side is figure 1 The right side of the paper in the X2 side is figure 1 on the left side of the paper. In addition, let the direction connecting the first adsorption unit 20 and the second adsorption unit 120 be the Y direction, and the Y1 side be figure 1 The front side of the paper in the Y2 side is figure 1 Backside of paper in . Additionally, connect Figure 5 The direction (up and down) of the suction base 220 and the stage unit 200 in the diagram is taken as the Z direction, and the Z1 side is Figure 5 The rear side (upper side) of the paper in , and the Z2 side is Figure 5 The front side (lower side) of the paper in the middle.

[0045] (About the configuration of the film take-out device)

[0046] figure 1 It is a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com