Fabricating method for flat display device

一种平板显示器件、制造方法的技术,应用在半导体/固态器件制造、静态指示器、电固体器件等方向,能够解决显影溶液过度损耗、工艺复杂、昂贵设备等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

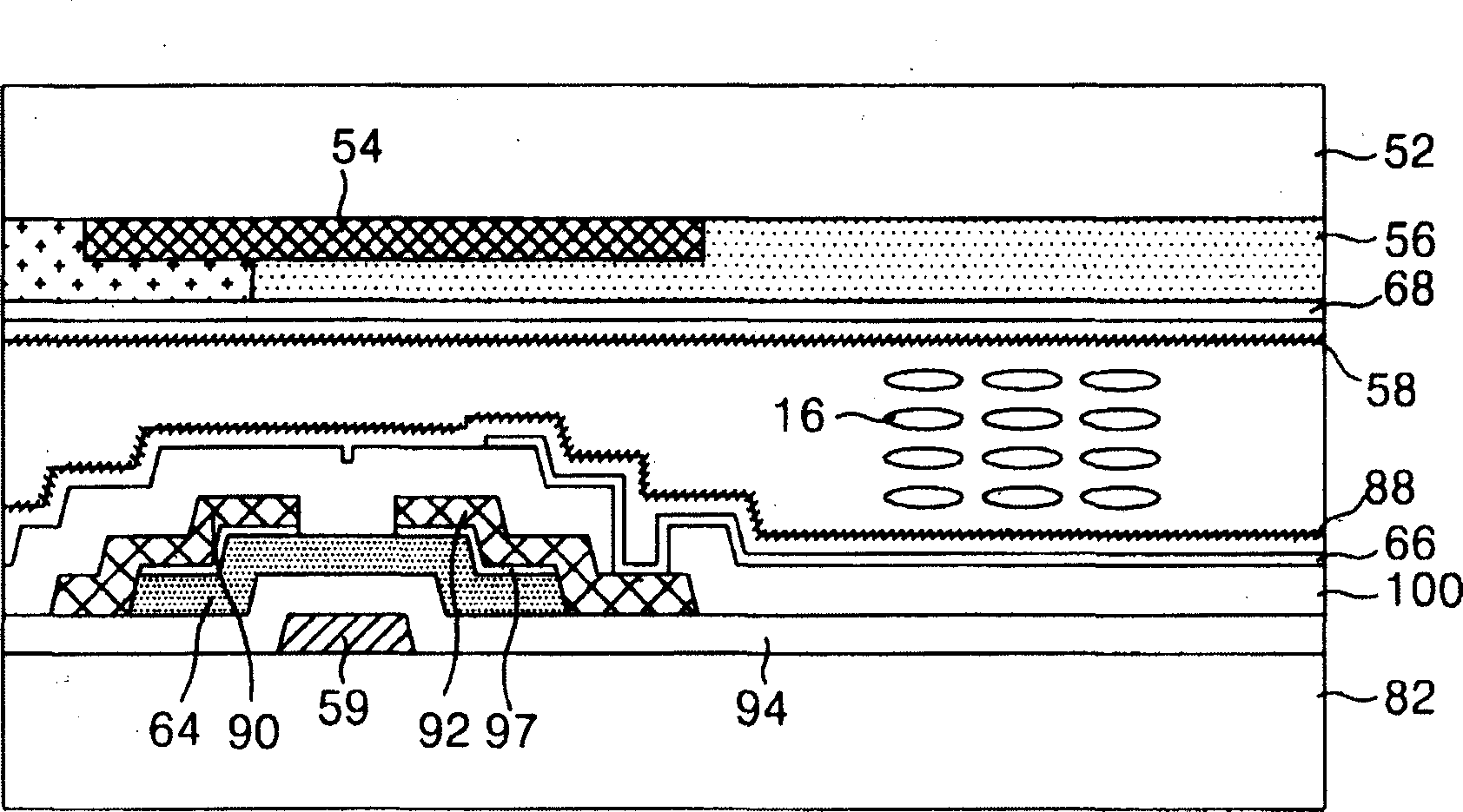

[0031] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0032] refer to Figures 3A to 8 , exemplary embodiments of the present invention are described below.

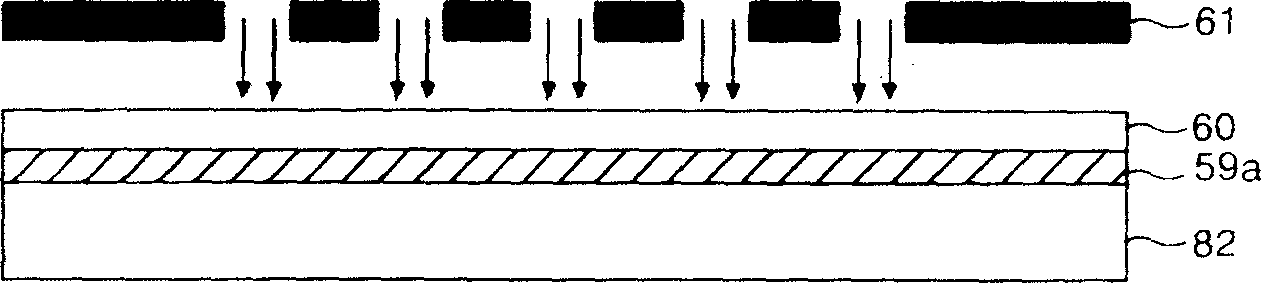

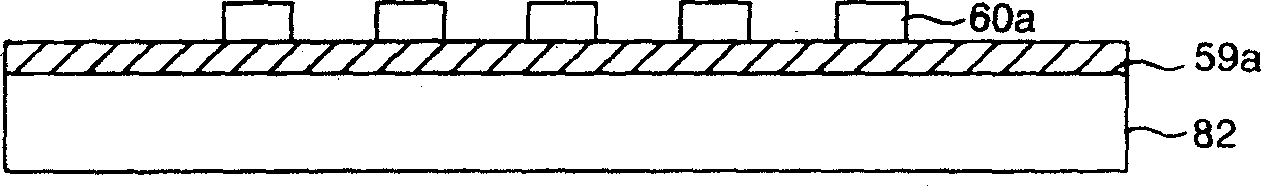

[0033] Figures 3A to 3D Shown is a cross-sectional view of a gate gradually formed according to an exemplary embodiment of the present invention.

[0034] refer to Figure 3A , the nano powder gate material 159a is coated on the entire surface of the lower substrate 182 . The nano-gate material 159a may be a gate material such as aluminum (Al), copper (Cu), chromium (Cr), molybdenum (Mo), aluminum / neodymium (Al / Nd) or alloys thereof. The nanopowder gate material 159a may be dissolved to a nanometer (nm) size. The nanopowder gate material 159a may be dissolved in a solution.

[0035] refer to Figure 3B , the soft mold 170 is positioned on the nano-powder gate material 159a, and the soft mold 170 has a protruding portion 170b. The pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com