Monitor element and magneto-resistance effect element substrate, and method of manufacturing monitor element

A technology of magnetoresistance effect element and manufacturing method, which is applied in the direction of manufacturing magnetic head surface, magnetic flux-sensitive magnetic head, magnetic recording head, etc., can solve the problems of shape deformation, difficult separation process and peeling of the opposite surface of the medium, and achieve the purpose of preventing short circuit Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

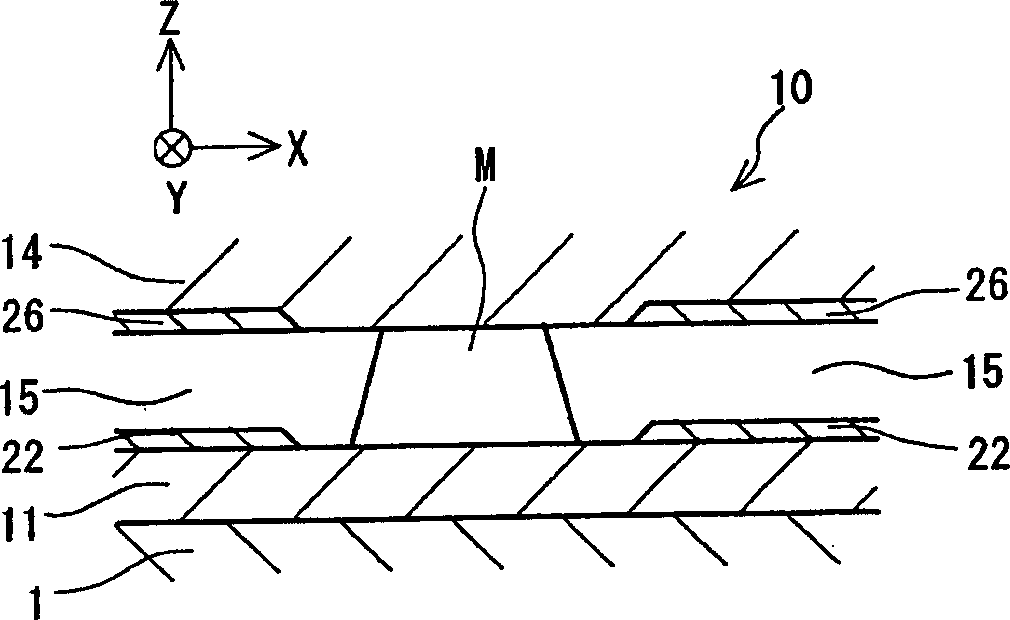

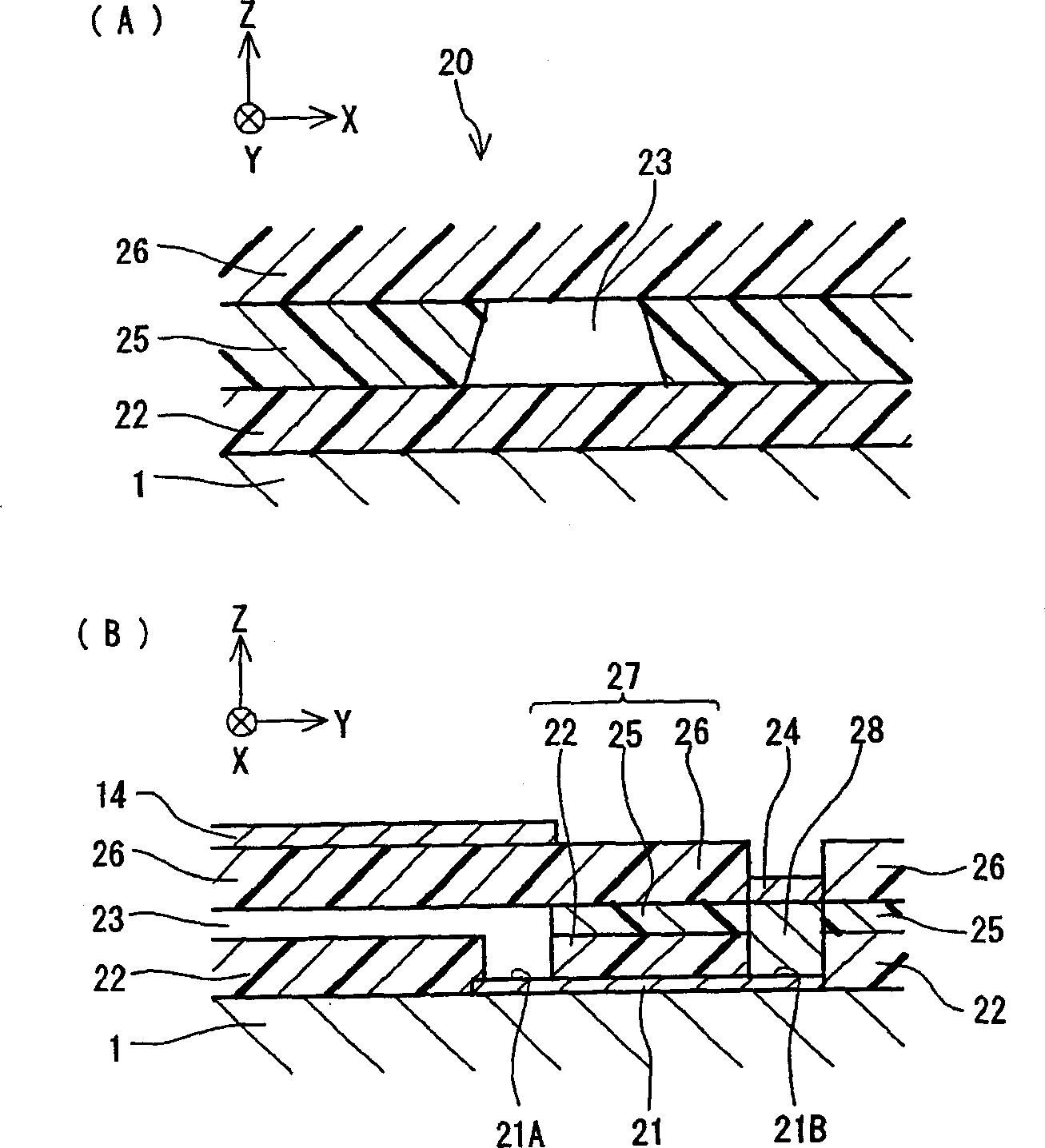

[0032] The present invention is illustrated below with reference to the accompanying drawings. In each figure, the X direction is the width direction of the track (track), the Y direction is the element height direction (the leakage field direction from the recording medium), and the Z direction is the moving direction of the recording medium and each layer constituting the magnetoresistance effect element. Stacking direction.

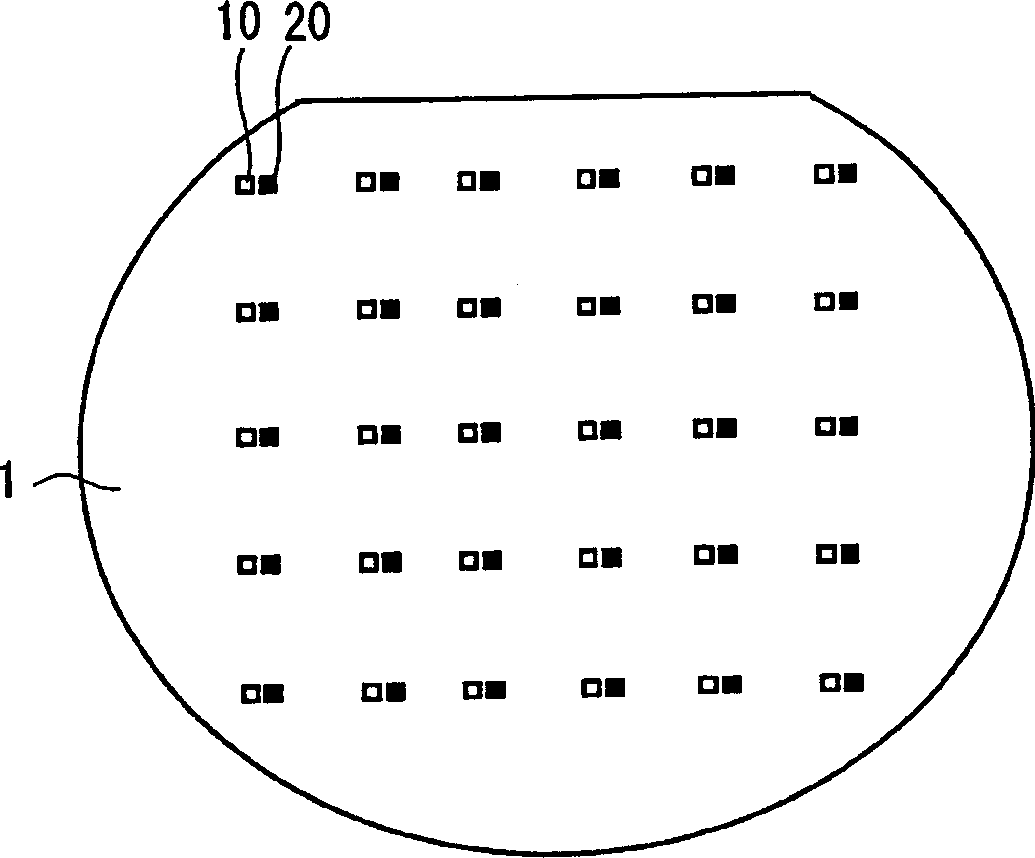

[0033] figure 1 It is a schematic diagram showing a wafer according to one embodiment of the present invention. A plurality of CPP-type magnetoresistance effect elements 10 are formed in parallel on a wafer 1, and monitoring elements 20 that are located near each CPP-type magnetoresistance effect element 10 and paired with the CPP-type magnetoresistance effect elements 10 are respectively formed. . exist figure 1 In , the CPP type magnetoresistive effect element 10 is indicated by □, and the monitor element 20 is indicated by ■.

[0034] CPP type ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com