Method for preparing electrode altitude difference absorption dielectric paste and laminated ceramic electronic components

A technology of electrode height and electronic components, applied in the direction of fixed capacitor dielectrics, laminated capacitors, printed circuit components, etc., can solve the problems of thickness fluctuation of paste printing, low solubility of ethyl cellulose, etc., to prevent chip erosion , The effect of improving peelability and suppressing wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0108] Embodiments of the present invention have been described above, but the present invention is not limited to the above-described embodiments in any way, and various changes can be made without departing from the gist of the present invention.

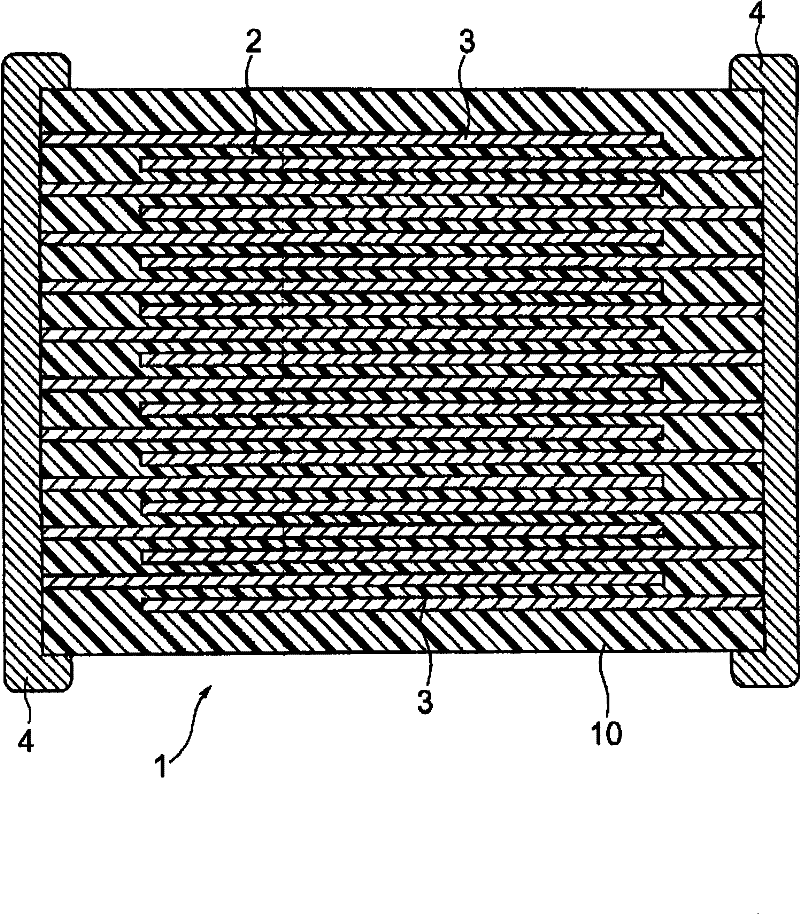

[0109] For example, in the above-mentioned embodiment, the laminated ceramic capacitor was exemplified as the laminated ceramic electronic component of the present invention, but it goes without saying that the laminated ceramic electronic component of the present invention is not limited to the laminated ceramic capacitor, and may be Applicable to multilayer ceramic substrates, etc.

Embodiment 1

[0113] First, a dielectric paste for forming a ceramic green sheet is produced.

[0114] Preparation of Dielectric Paste

[0115] Prepare BaTiO 3Ceramic-like powder, polyvinyl butyral (PVB) as an organic binder, and methanol as a solvent. Next, 10 parts by weight of the organic binder and 150 parts by weight of the solvent were weighed with respect to 100 parts by weight of the ceramic powder, kneaded by a ball mill, and slurried to obtain a dielectric paste.

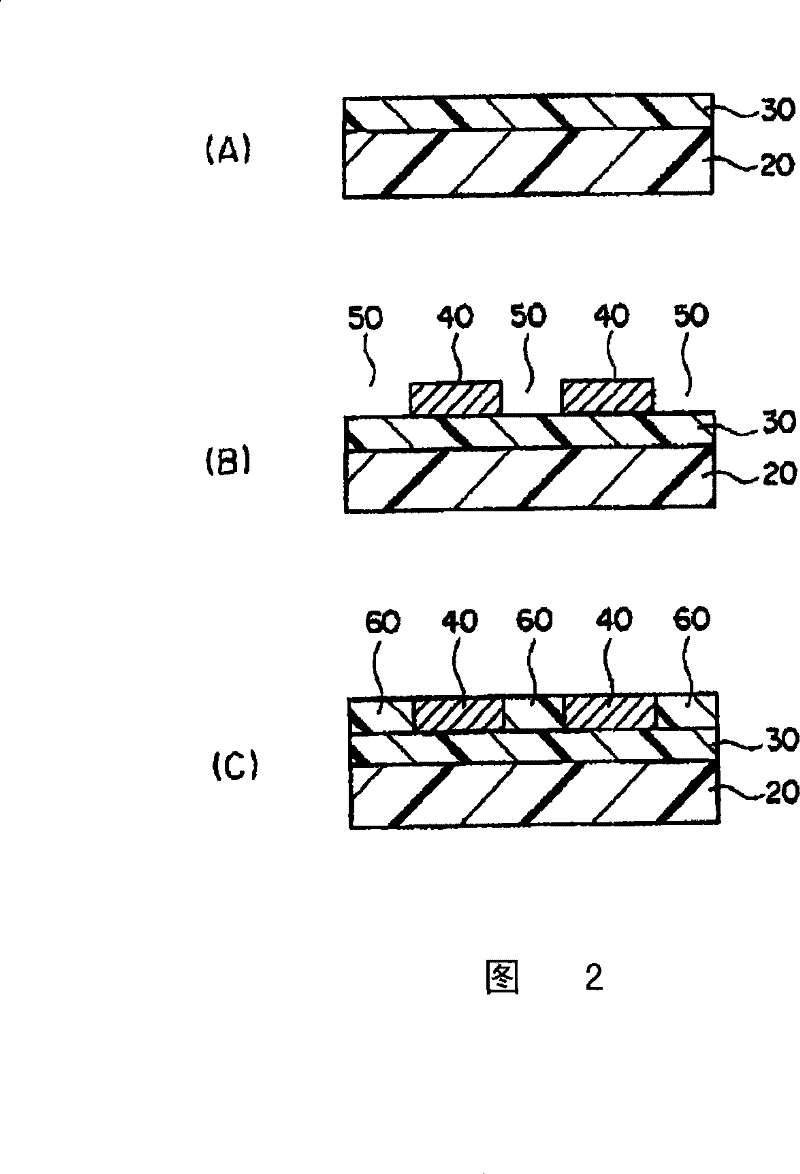

[0116] Production of Ceramic Green Sheets

[0117] The above-mentioned dielectric paste was applied to a predetermined thickness on a PET film by a knife coating method, and dried to form a ceramic green sheet having a thickness of 3 μm after drying.

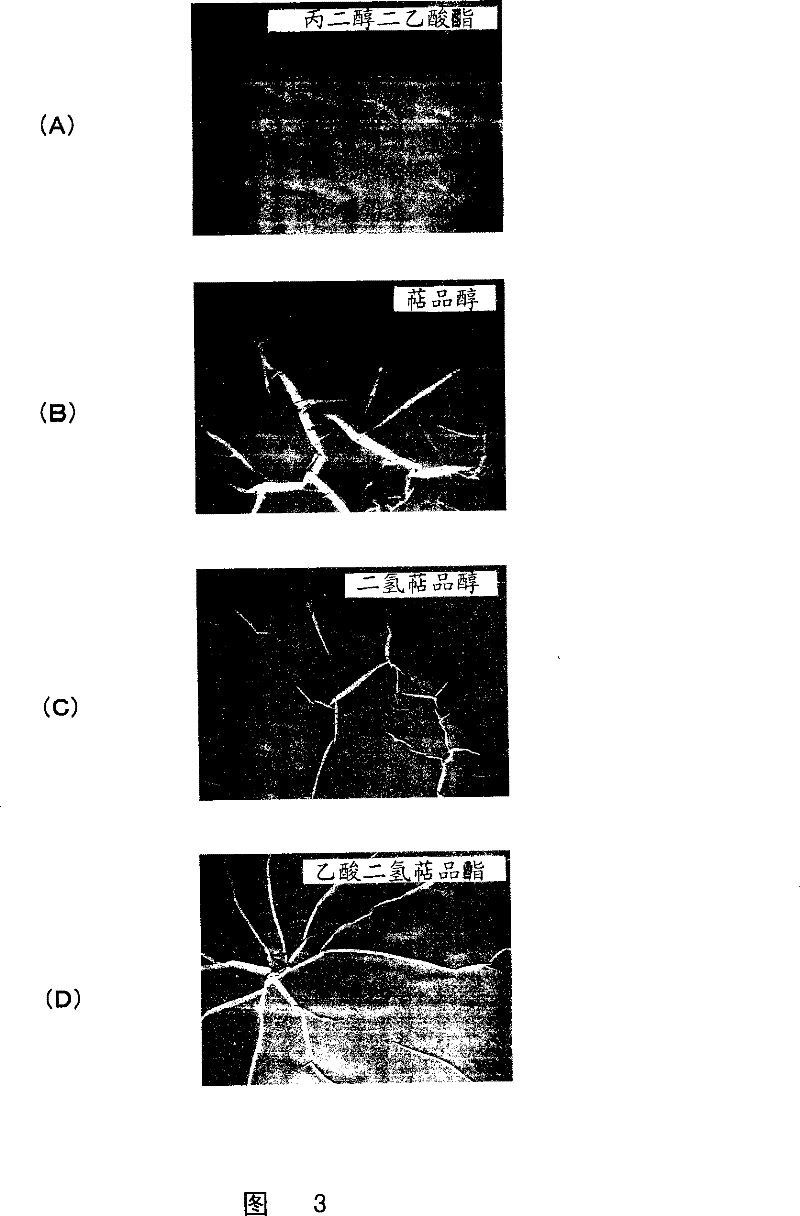

[0118] Compatibility test of solvent and ceramic green sheet (room temperature, dropwise)

[0119] The ceramic green sheet produced above was peeled off from the PET film, and then attached to a glass slide with double-sided adhesive tape. Next, at room tempera...

Embodiment 2

[0136] Production of Organic Carriers

[0137] Prepare ethyl cellulose as an organic binder and the solvents shown in Table 3.

[0138] Next, 10 parts by weight of the organic binder was dissolved in 100 parts by weight of the solvent to prepare an organic vehicle.

[0139] Evaluation of tanδ

[0140] The tan δ (dynamic viscoelasticity) is the tan δ value when a stress of 10 Pa is applied to the obtained organic vehicle measured with a viscosity / viscoelasticity measuring device (Leostress RS1, manufactured by Eiko Seiki Co., Ltd.) at a frequency of 0.628 rad / s. The results are shown in Table 3. The lower the tanδ value, the more elastic and difficult to level. On the other hand, the higher the tanδ value, the less elastic and easier to level. Therefore, it can be considered that the larger the tanδ value, the better the dynamic viscoelasticity, that is, the better the leveling property , the higher the solubility.

[0141] [table 3]

[0142] table 3

[0143] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com