Method for preparing amorphous/crystal composite structure aluminium-based alloy

An aluminum-based alloy and composite structure technology, applied in the field of metal materials, can solve problems such as low strength and reduced material properties, and achieve the effects of easy alloy structure, uniform size and distribution, and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

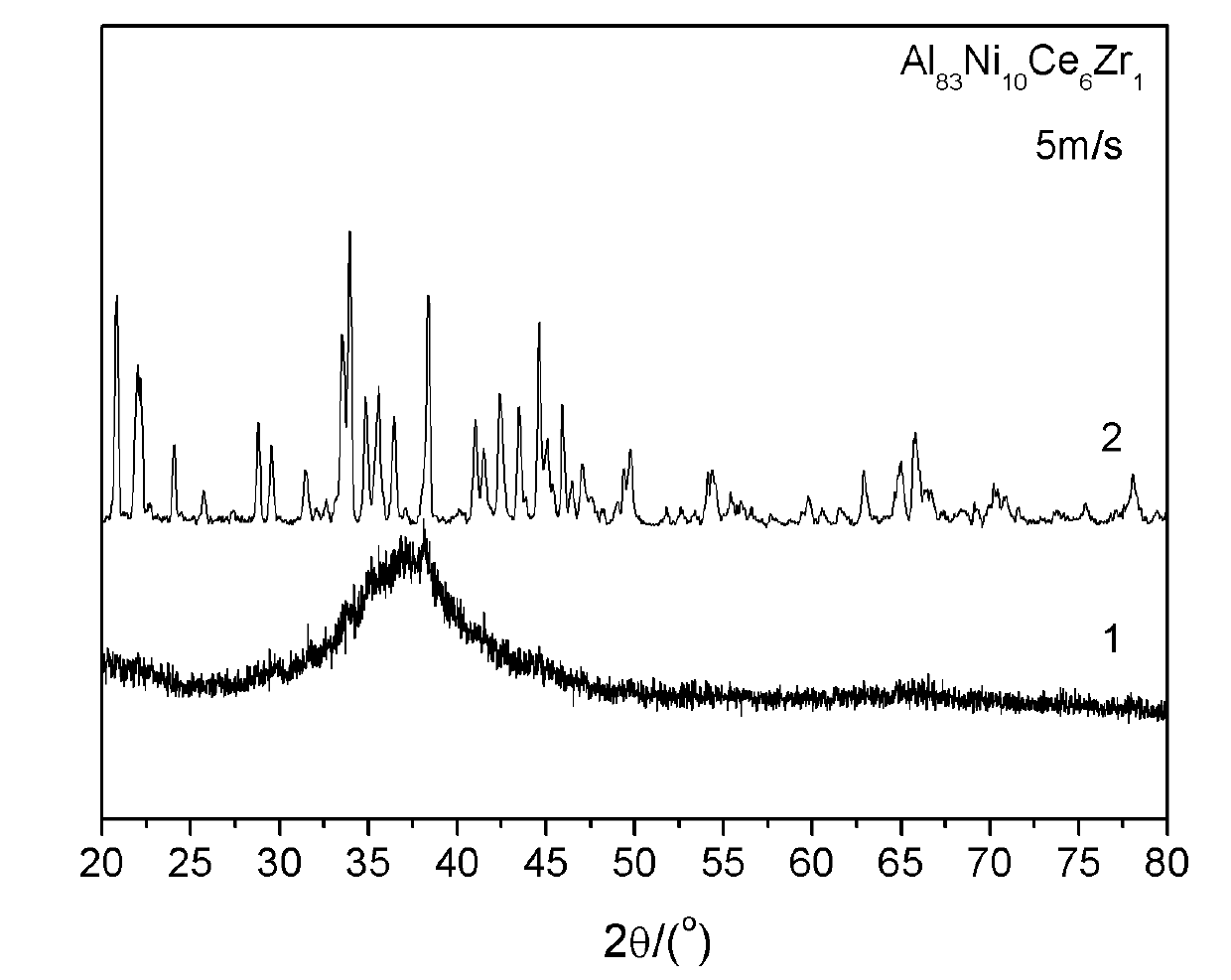

[0043] Example 1: Al 83 Ni 10 Ce 6 Zr 1 (at.%) Amorphous / crystalline composite structure material

[0044] Step 1: Ingredients

[0045] Select industrial pure metal, according to the composition Al 83 Ni 10 Ce 6 Zr 1 (at.%) Ingredients. When batching, it should be mechanically polished to remove the pollution layer on the surface of pure metal raw materials, and then cleaned with a mixed solution of alcohol and acetone and air-dried;

[0046] Step 2: Preparation of master alloy

[0047] Melt the alloy raw material prepared in the first step in a vacuum electric arc furnace to obtain a uniformly smelted master alloy;

[0048] The third step: throwing the tape to prepare the amorphous tape

[0049] The master alloy prepared in the second step is divided into two parts. After the surface is mechanically polished and cleaned, one part is heated and remelted in the quartz tube at the lower end of the grinding port. After the master alloy is completely melted, the master ...

Embodiment 2

[0052] Example 2: Al 80 Ni 10 Ce 6 Zr 4 (at.%) Amorphous / crystalline composite structure material

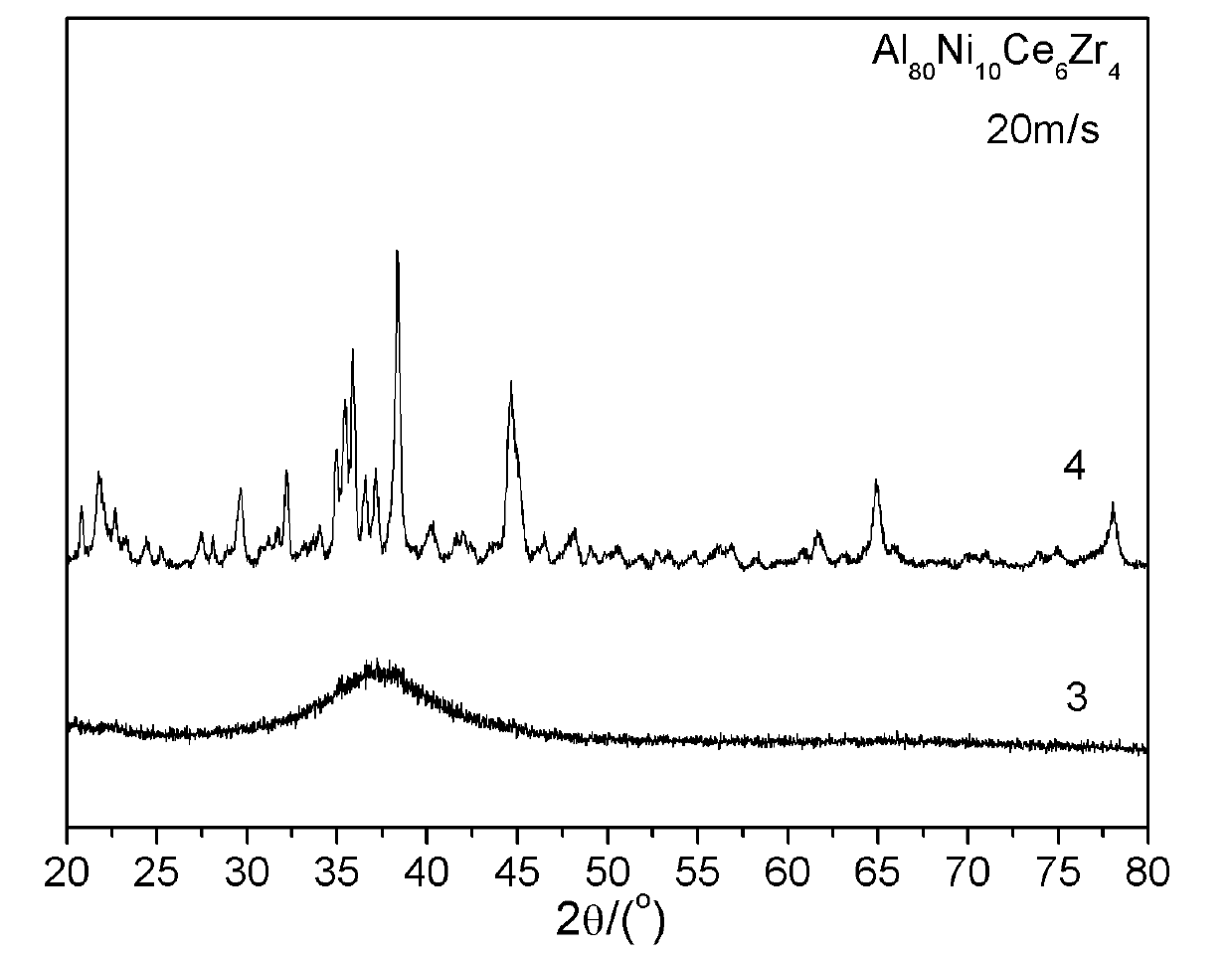

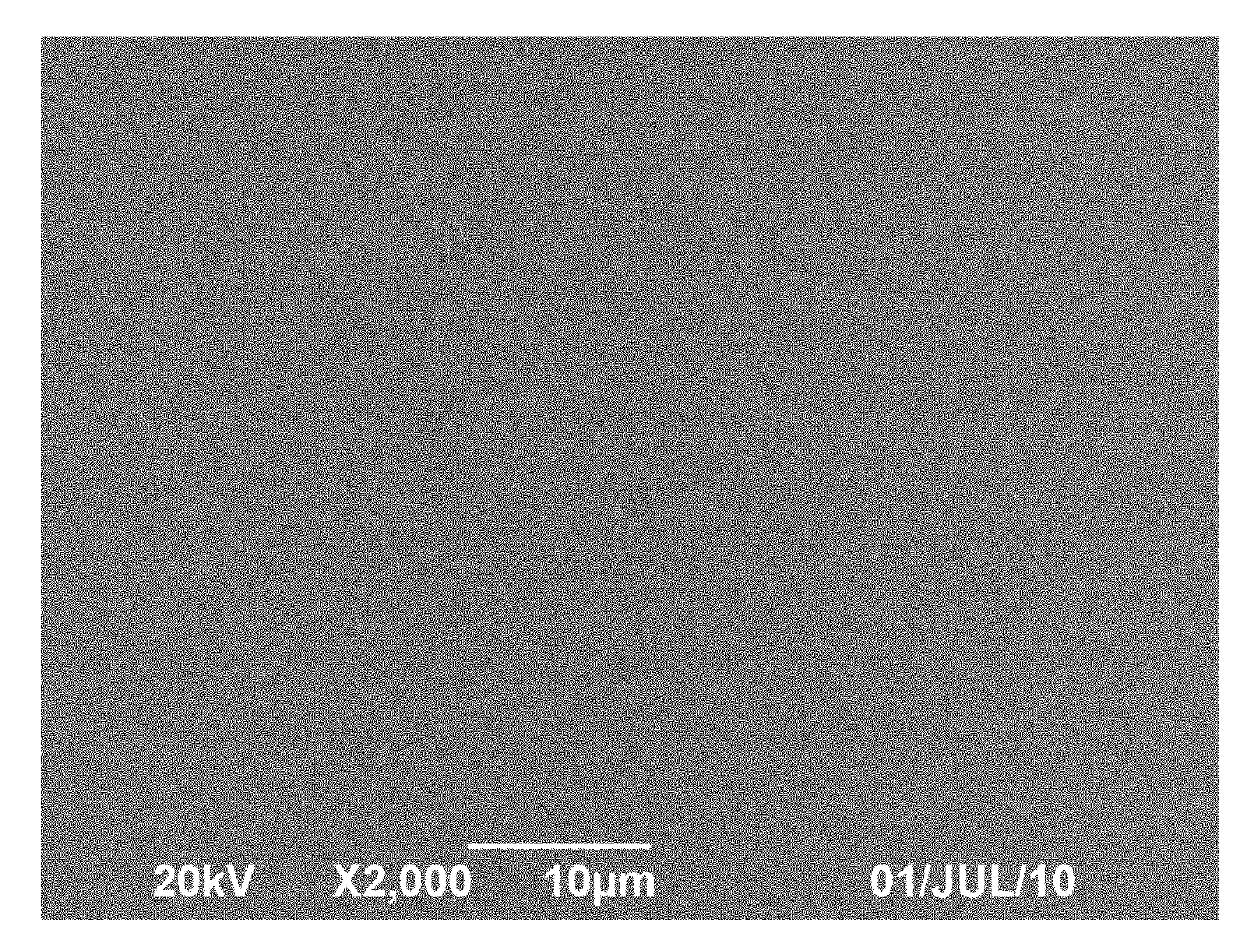

[0053] The nominal composition Al 80 Ni 10 Ce 6 Zr 4 (at.%) alloy, according to the method and step of example 1, under the constant magnetic field effect of 900Gs in magnetic field intensity, prepare the D sample that applies strong magnetic field effect and the non-enhanced magnetic field effect in the solidification process with 20m / s linear speed The C sample; Utilize X-ray diffractometer (XRD) to carry out phase analysis, the result shows that C sample is amorphous structure ( figure 2 Curve 3), D sample contains crystallized phase ( figure 2 Curve 4); Utilize scanning electron microscope to observe respectively to C, D sample, the result shows: C sample does not observe crystallization phase ( image 3 ), sample D is an amorphous / crystalline composite structure with uniform distribution of crystallized phases in the amorphous matrix ( Figure 4 ).

Embodiment 3

[0054] Example 3: Al 83 Ni 10 Ce 6 PR 1 (at.%) Amorphous / crystalline composite structure material

[0055] The nominal composition Al 83 Ni 10 Ce 6 PR 1 (at.%) alloy, according to the method and step of example 1, under the constant magnetic field effect of 1000Gs in magnetic field strength, prepare the F sample that applies strong magnetic field effect and the non-enhanced magnetic field effect in the solidification process with 10m / s linear speed The E sample; Utilize X-ray diffractometer (XRD) to carry out phase analysis, the result shows that the strip material of E sample is amorphous structure, and F sample contains crystallized phase; Utilize scanning electron microscope to the observation of E, F sample respectively, result It shows that no crystalline phase is observed in the prepared E sample, and the F sample is an amorphous / crystalline composite structure with uniformly distributed crystal phases on the amorphous matrix.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com