Mask, mask manufacturing method, pattern forming apparatus, and pattern formation method

A mask and pattern technology, which is applied in the direction of lighting device, pattern surface photolithography process, semiconductor/solid-state device manufacturing, etc., can solve the problem of large deflection, difficulty in silicon mask transportation, silicon mask loading and unloading evaporation method, It is difficult to prevent large-scale silicon masks from bending due to their own weight, and achieve the effect of preventing bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Hereinafter, embodiments of the mask, the method of manufacturing the mask, the film forming apparatus, the light emitting device, and the electronic device of the present invention will be described with reference to the drawings. In addition, in each drawing, in order to make each layer or each member have a recognizable size on the drawing, the scale of each layer or each member is different.

[0040] (mask)

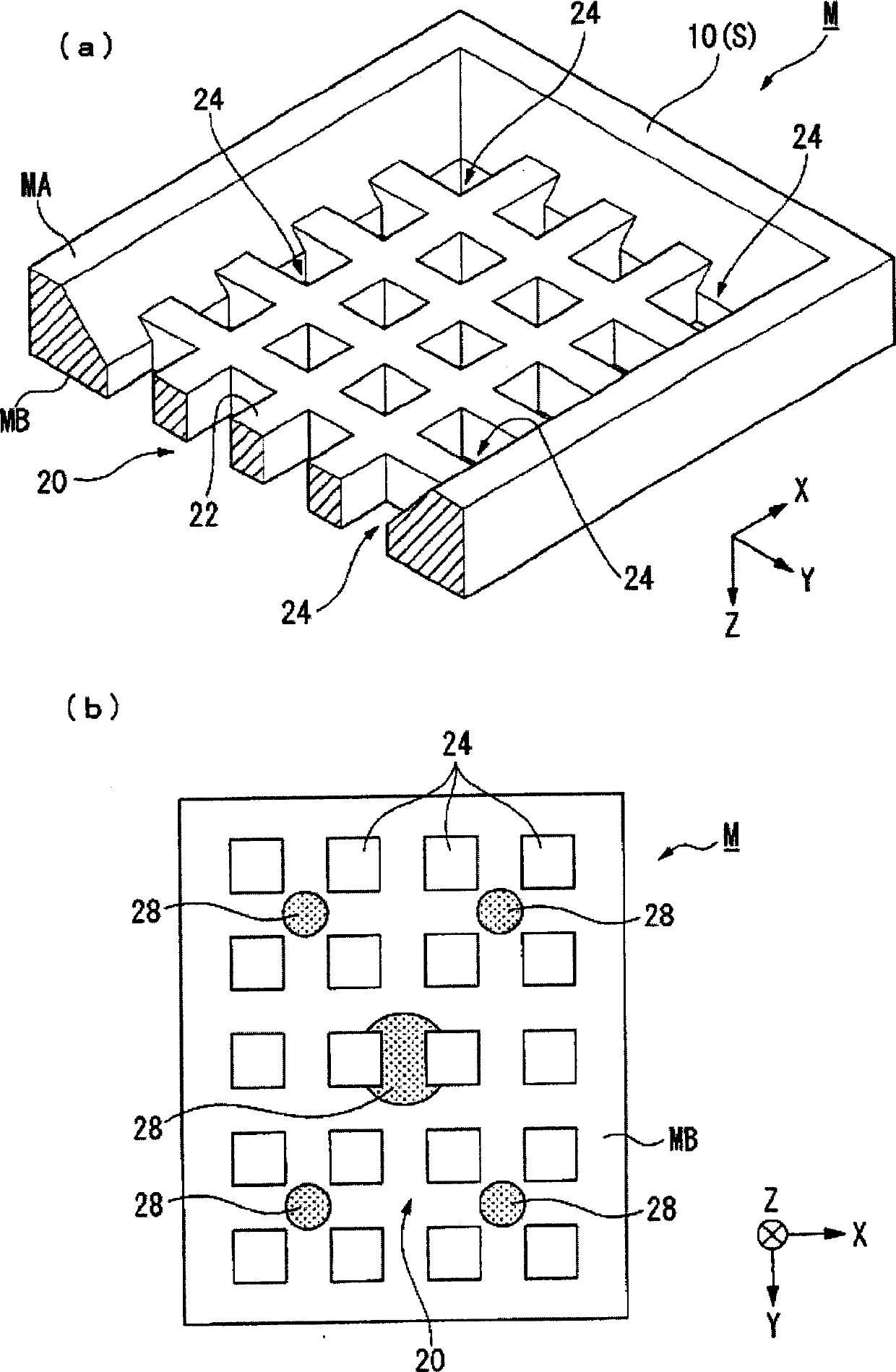

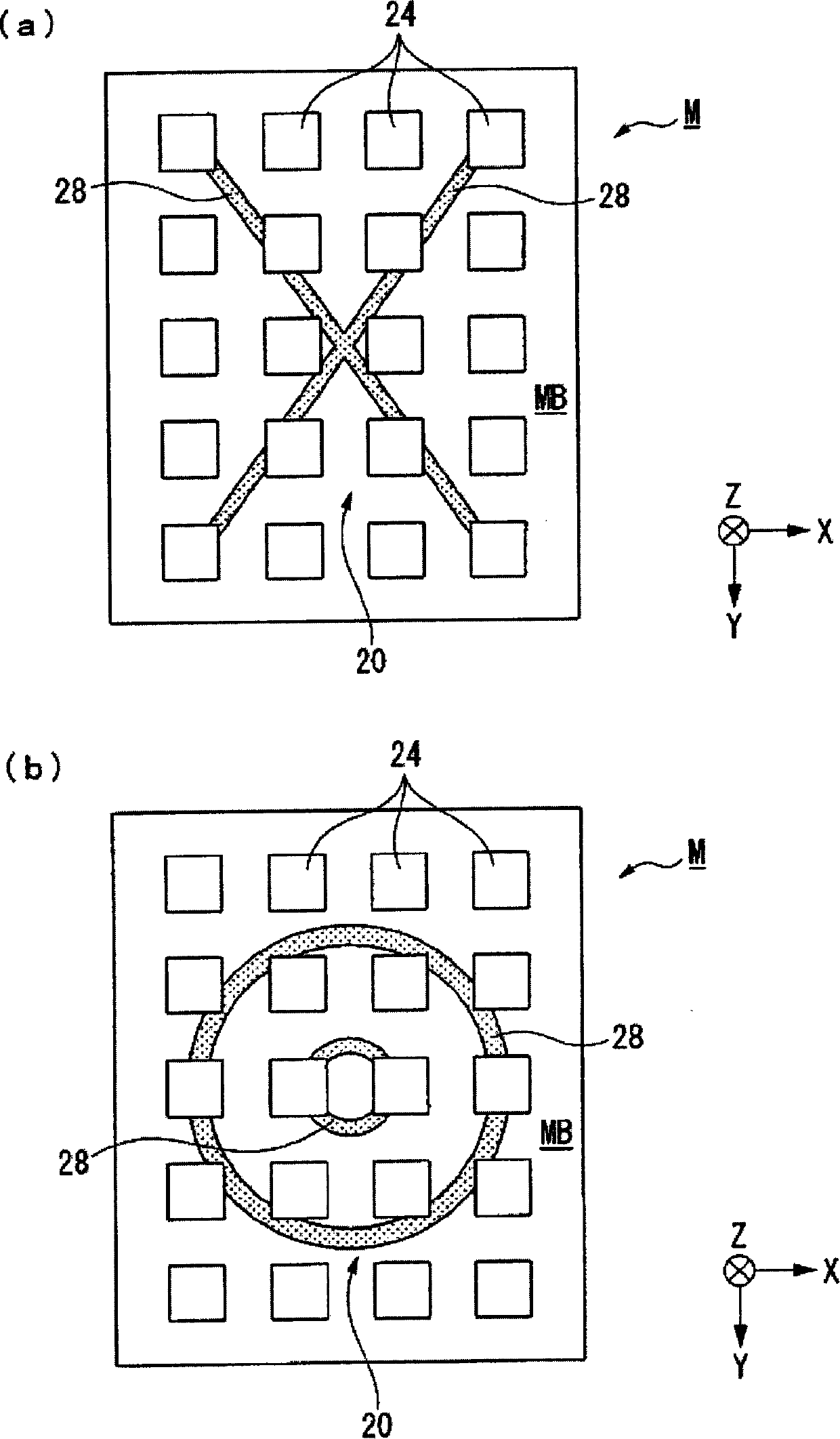

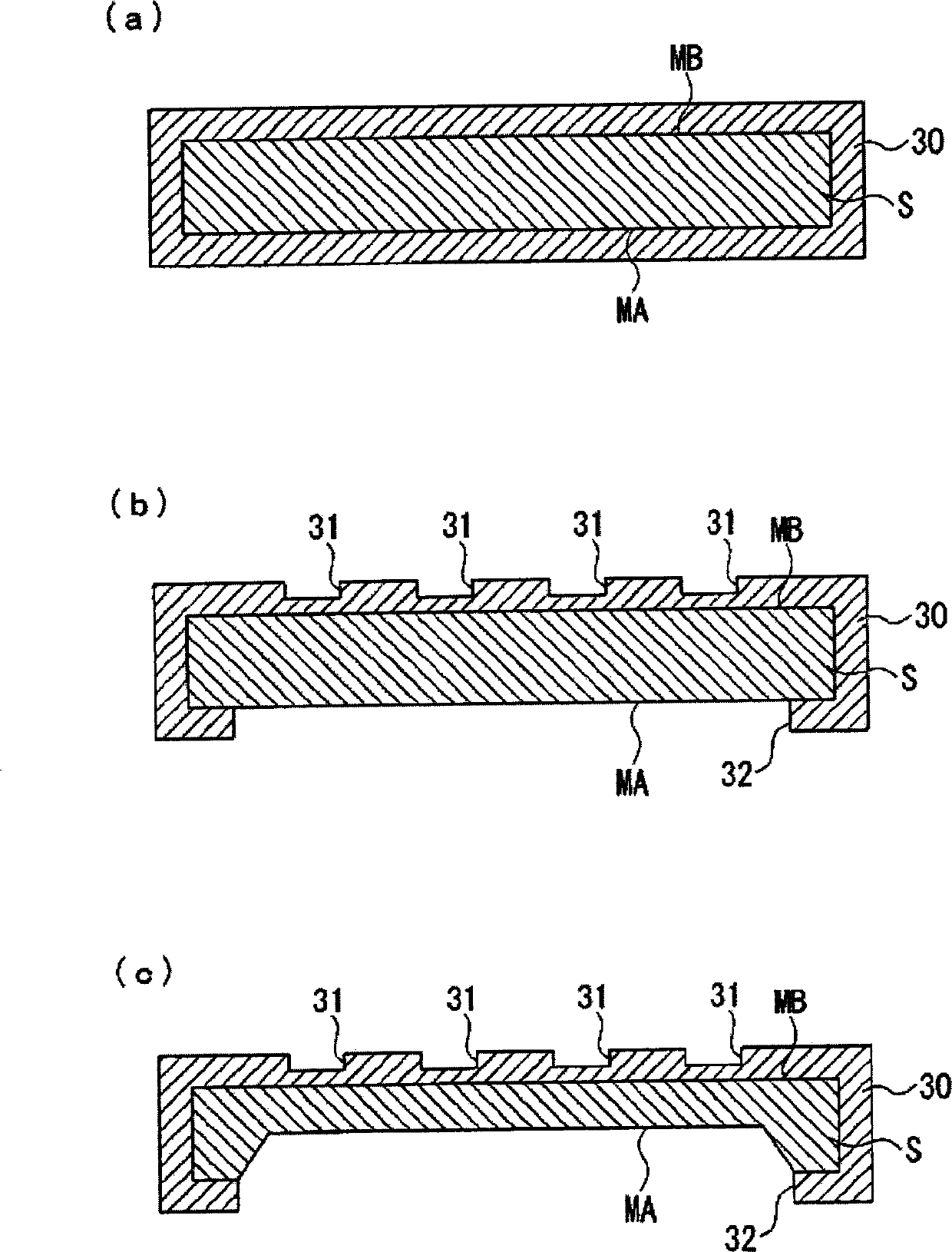

[0041] FIG. 1 is a configuration diagram for explaining a mask of the present invention, FIG. 1( a ) is a cross-sectional perspective view of the mask, and FIG. 1( b ) is a view showing the back surface of the mask.

[0042] The mask M is configured to include: an outer frame portion 10 having an outer shape of the mask M; and a pattern portion 20 having a plurality of mask openings 24 provided inside the outer frame portion 10 . In addition, the outer frame portion 10 is a member formed by directly utilizing the thickness of a silicon wafer.

[0043] The pat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com