An agitator for treating organic waste

A technology of agitator and agitating container, which is applied in the removal of solid waste, mixer with rotary stirring device, and treatment of biological organic parts, etc., can solve the problems such as the inability of fermenting microorganisms to function well and the decrease of fermentation rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Preferred embodiments of the present invention are described in detail below. However, this embodiment is illustrative only, and various modifications are possible within the scope and spirit of the invention. In addition, this invention is not limited to this embodiment.

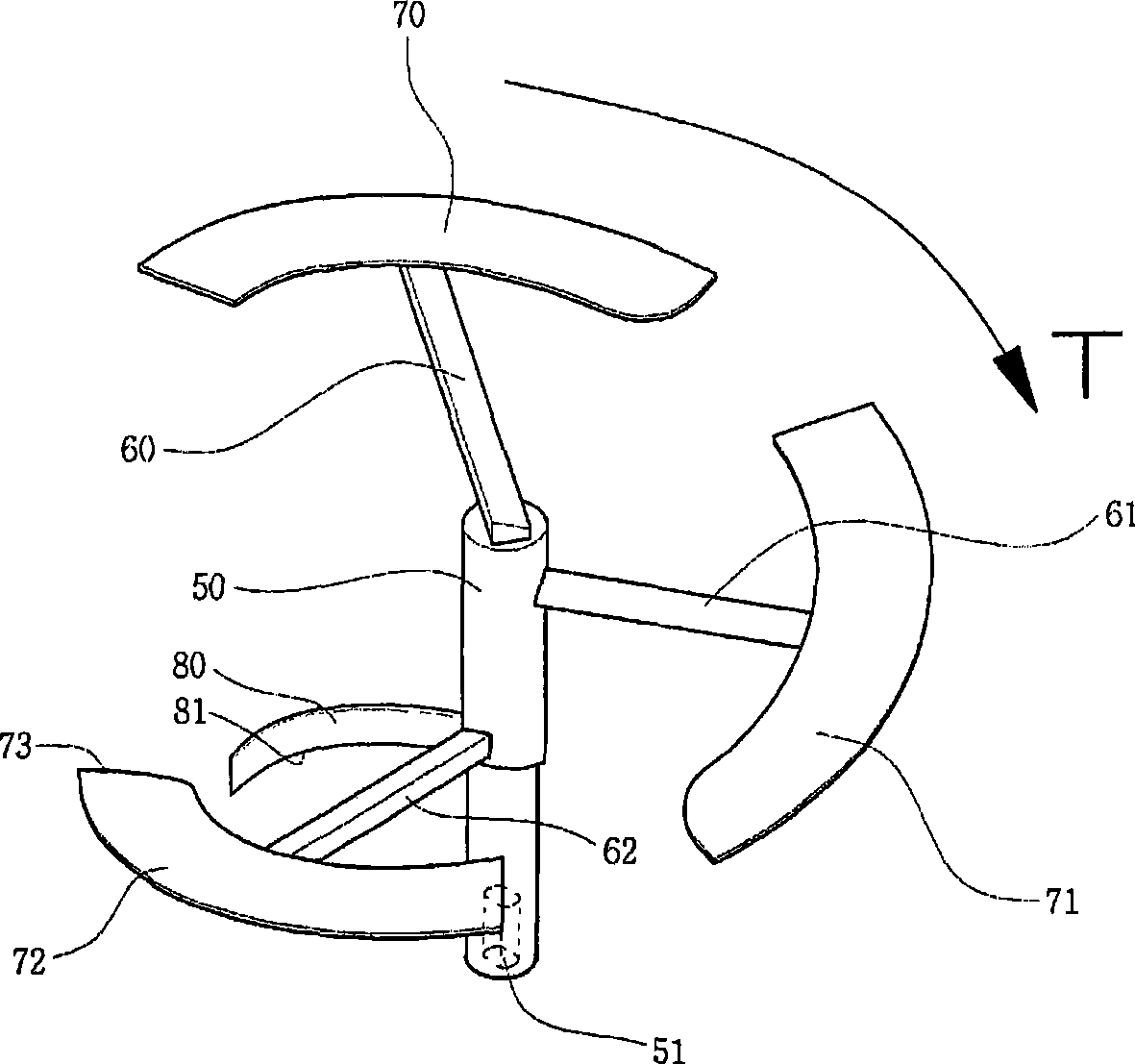

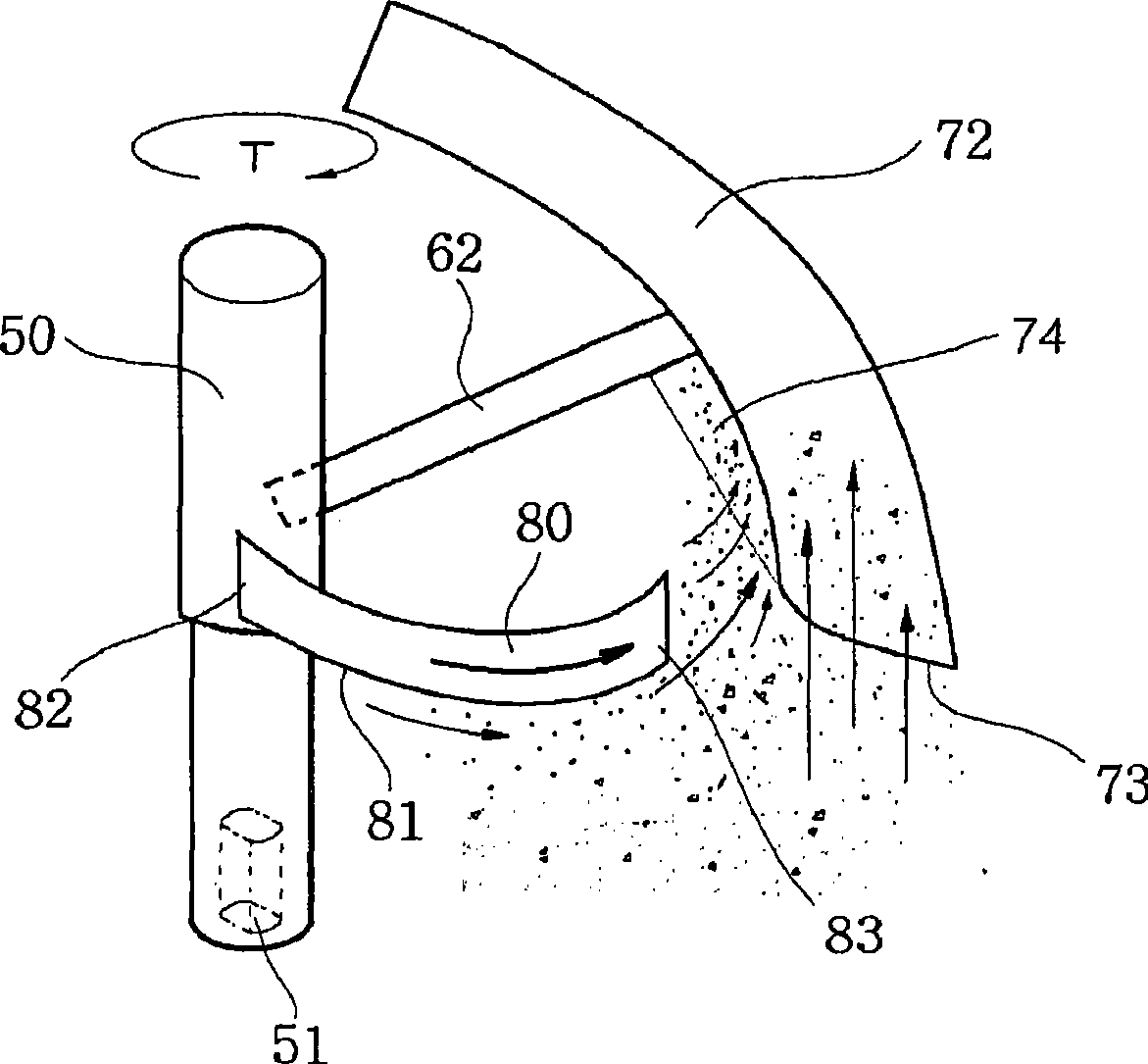

[0031] figure 1 is a perspective view of a stirrer according to an embodiment of the present invention, figure 2 is a diagram showing the movement of the contents while the contents are stirred in the stirrer according to the embodiment of the present invention.

[0032] As shown, an agitator according to an embodiment of the present invention is used for processing food waste. The agitator includes a rotating shaft 50 , connecting members 60 , 61 and 62 , agitating blades 70 , 71 and 72 , and an auxiliary agitating blade 80 .

[0033] The rotating shaft 50 is a rod-shaped member made of stainless steel, and extends in the longitudinal direction. A groove 51 for fitting the shaft of the drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com