Grinding device with detachably mounted grinding element

一种地连接、磨削的技术,应用在连接构件、薄板连接、磨料等方向,能够解决昂贵、粘扣锁合装置磨损、生产总体麻烦等问题,达到工作能力高、好使用可能性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

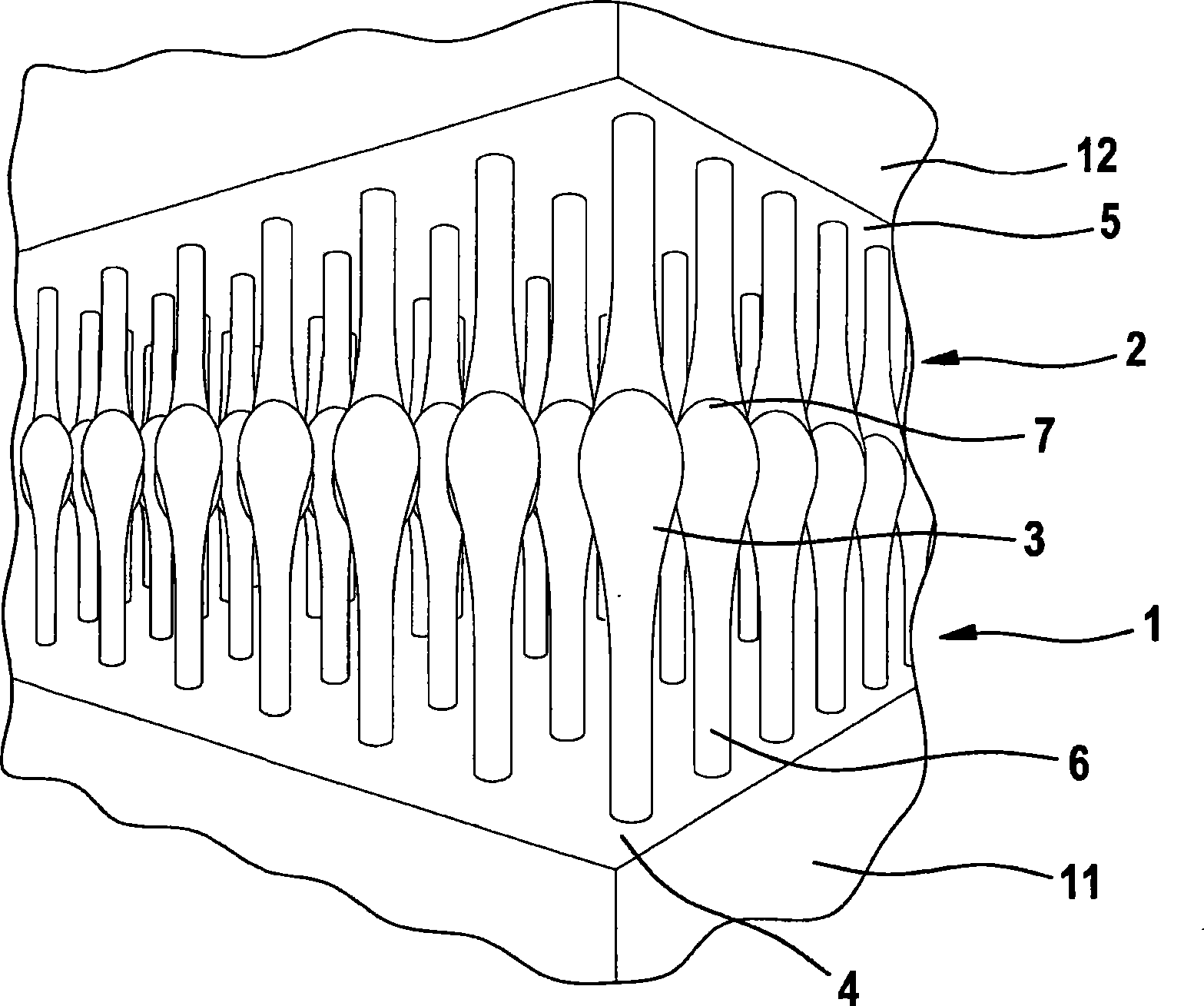

[0019] exist figure 1 In the center, the surface structure of the mating attachment device of the receiver body and of the grinding element can be seen in a strongly enlarged detail. Here, a first attachment device 1 which is connected to the upper side of a receiving body 11 (schematically shown) of the grinding device is connected to an exchangeable grinding element 12, for example a grinding disc (schematically shown). The second attachment device 2 on the back side of the is in engagement. The first attachment means 1 and the second attachment means 2 have a plurality of protrusions 3 of the same shape and size, which project from the bases 4 , 5 of the attachment means 1 , 2 at regular intervals from each other. The protrusions 3 are shaped in the shape of a thickened rod, wherein the cross-section of each protrusion 3 expands substantially continuously from its shank 6 to its free end 7 . The size of the protrusions 3 is only a few tenths of a millimeter. When the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com