Compressed air supply equipment and method for determining parameters of the equipment

一种压缩空气、设备的技术,应用在泵/压缩机的布置、空气处理装置、运输和包装等方向,能够解决参数化等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

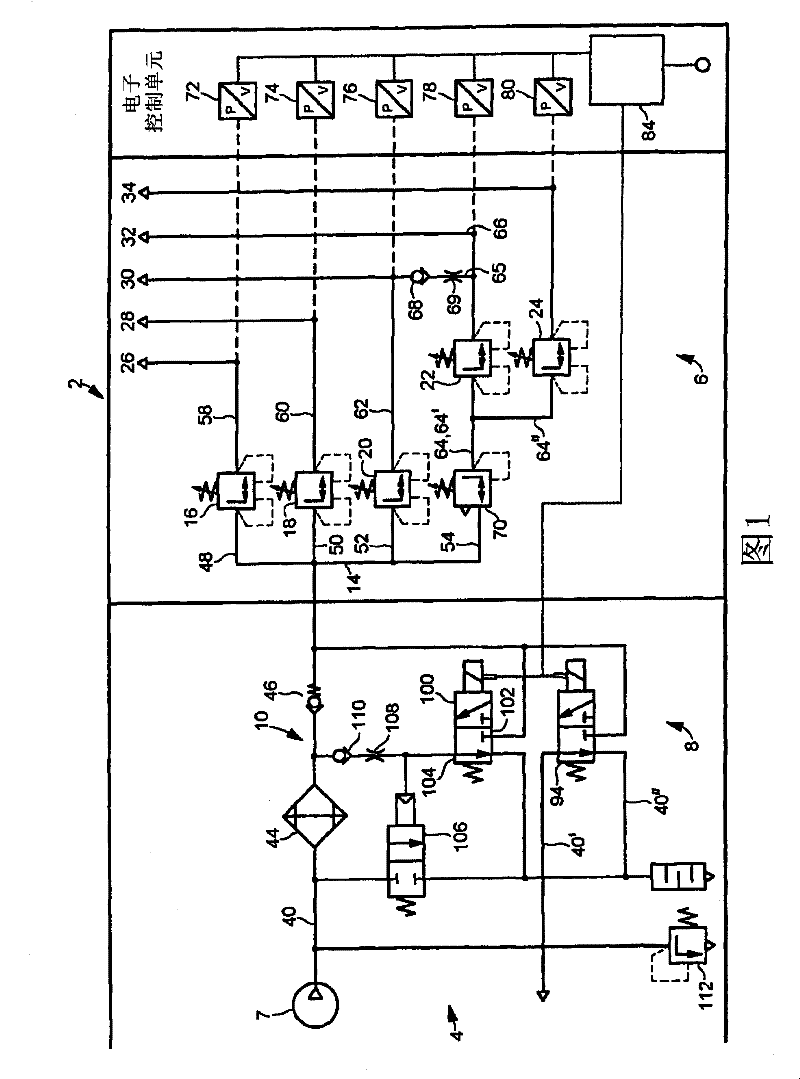

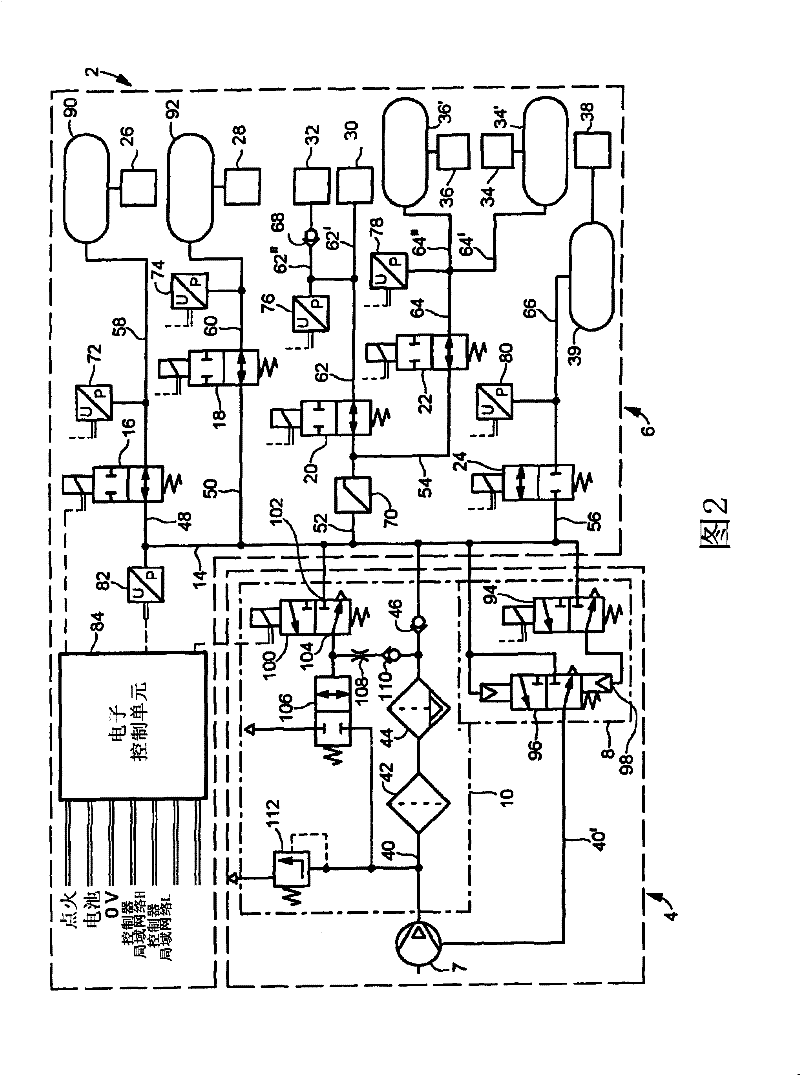

[0023] Attached is figure 1 shows a compressed air preparation device 2 with a compressed air supply 4 and a consumer part 6 . The compressed air supply section 4 includes a compressor 7 , a compressor control device 8 and an air dryer section 10 .

[0024] The consumer part 6 has a compressed air distribution line 14 branching off into a plurality of valves 16 , 18 , 20 , 22 , 24 and a plurality of consumer circuits 26 , 28 , 30 , 32 , 34 supplied with compressed air via the valves.

[0025] A compressed air supply line 40 leads from the compressor 7 via an air dryer scroll 44 (to which a filter (not shown) may be preceded) and a non-return valve 46 to the distribution line 14 , the lines 48 , 50 , 52 , 54 leading to the valves branch off from the distribution line 14 . Compressed air lines 58 , 60 , 62 , 64 lead from the valves to consumer circuits. Line 64 branches into lines 64 ′, 64 ″ leading to circuits 32 and 34 , wherein line 64 ′ branches into lines 65 , 66 leading...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com