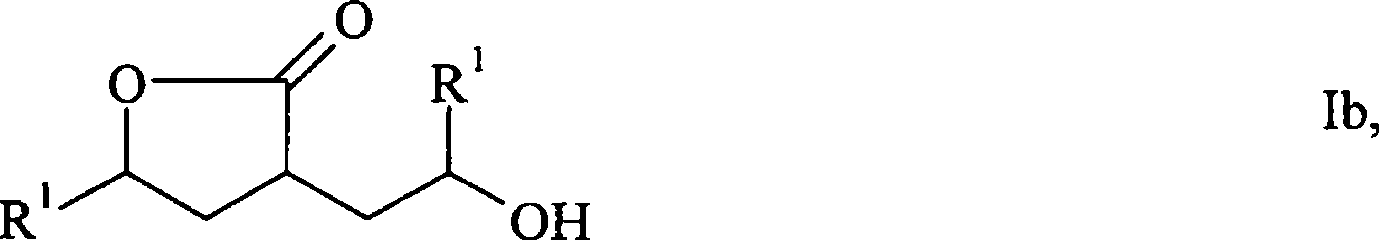

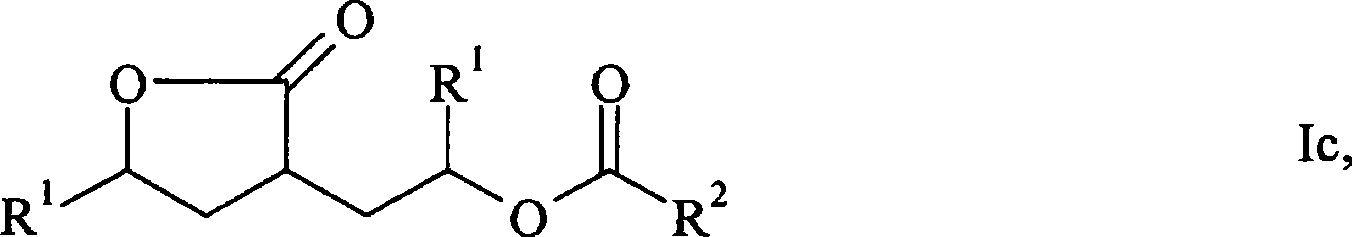

Process for the preparation of gamma-butyrolactones

A kind of alkyl, selected technology, applied in the field of preparation of γ-butyrolactone, can solve problems such as long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Methyl acetoacetate ( MAA, 46.7 g, 0.40 mol) in methanol (MeOH, 144.0 g). The reaction mixture was heated to 40° C. within 0.5 hours and maintained at this temperature for 4.5 hours. Quantitative GC analysis showed that 53.7% of MAA was converted to α-acetylbutyrolactone (ABL) with a selectivity of 75.2%.

Embodiment 2

[0079] A solution of MAA (46.9 g 0.40 mol) in MeOH (144.0 g) was treated sequentially with EO (25.0 g, 1.4 eq.) and triethylamine (TEA, 40.7 g, 1.0 eq.) at 5°C. The reaction mixture was heated to 60° C. within 0.5 hours and maintained at this temperature for 2.5 hours. Quantitative GC analysis showed that 50.8% of MAA was converted to ABL with 72.9% selectivity.

Embodiment 3

[0081] MAA was treated sequentially with EO (17.8 g, 1.0 eq.) and 1,8-diazabicyclo[5.4.0]-7-undecene (DBU) (62.5 g, 1.0 eq.) at 5 °C (46.9 g 0.40 mol) in MeOH (144.0 g). The reaction mixture was heated to 60° C. within 0.5 hours and maintained at this temperature for 2.5 hours. Quantitative GC analysis showed that 59.3% of MAA was converted to ABL with 82.2% selectivity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com