A high voltage corona grading ring and a high voltage device comprising such ring

A technology of high-voltage corona and high-voltage equipment, which is applied to transformer/inductor components, circuits, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Next, a detailed description of preferred embodiments of the present invention will be given. In this description, the term "high voltage" is used for voltages of 50KV and higher. Today, the upper limit in commercial high voltage installations is 800KV, but even higher voltages, such as 1000KV or higher, are also established or envisioned in the near future.

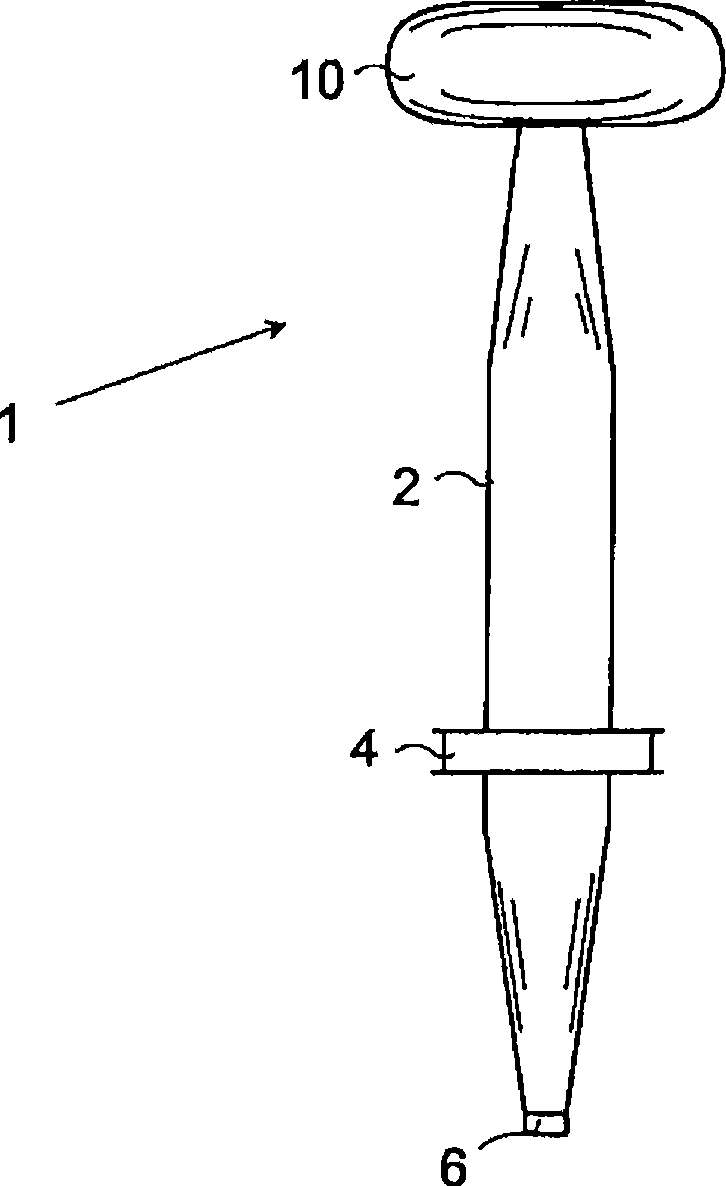

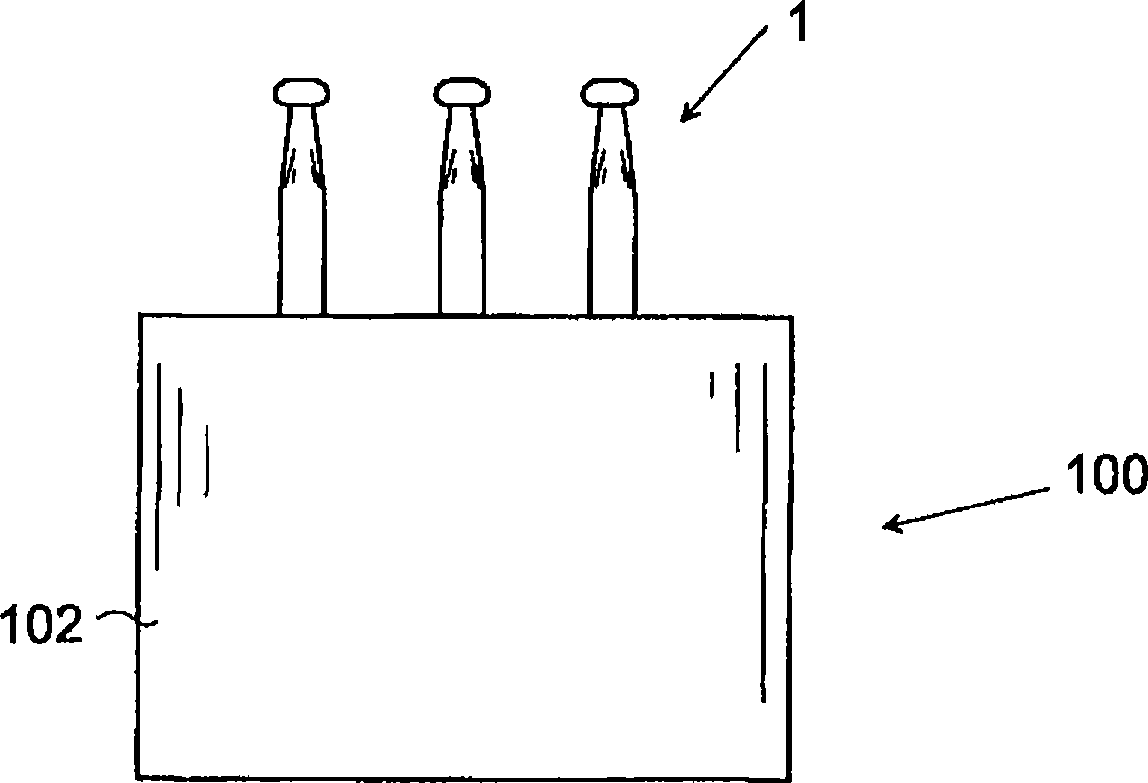

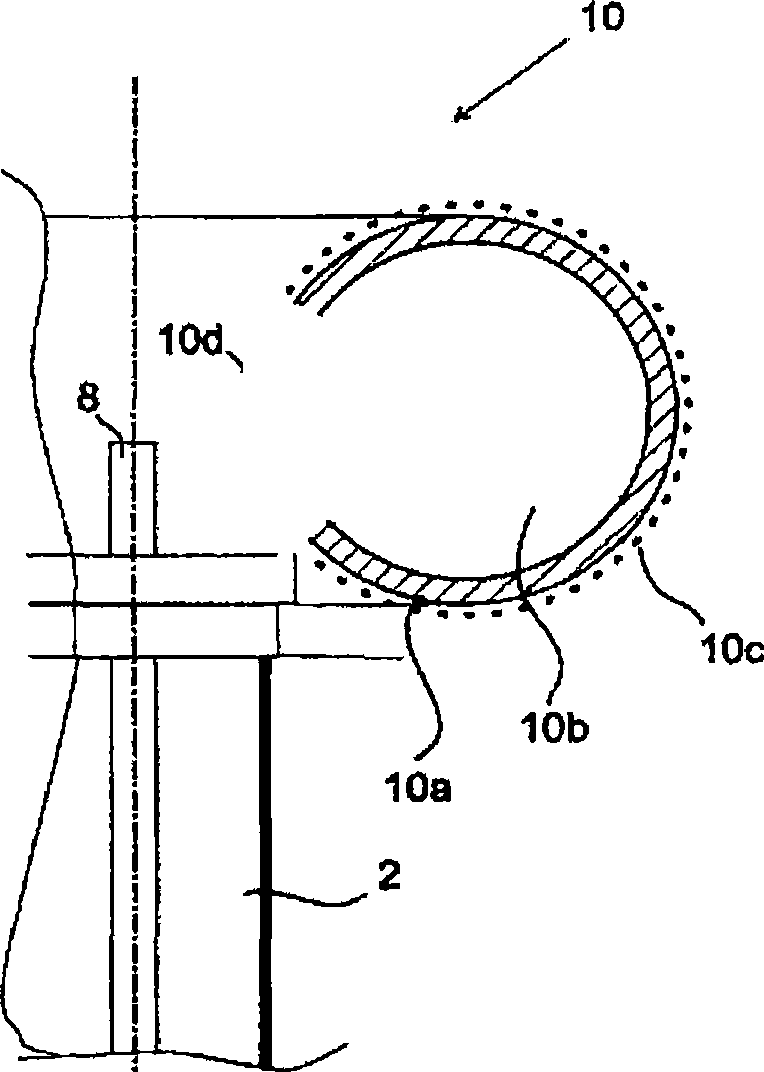

[0023] The present invention can be applied to reference figure 1 and figure 2 A general description of the high-voltage bushing arrangement given in the Background section, reference will be made to these figures below. However, first refer to the attached image 3 , image 3 A schematic cross-sectional view of an embodiment of a corona grading ring according to the invention is shown, wherein together with a part of the corona grading ring 10 a part of the hollow bushing insulator 2 and the upper external terminal 8 are shown. The corona grading ring is cylindrical or annular, like the corona grading rings...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com