Hydraulic-control mold filling device of low-pressure casting lift tube

A technology of low-pressure casting and riser tubes, which is applied in the field of low-pressure casting riser tube mold filling devices, can solve problems such as shrinkage cavities, poor steady-state characteristics, and high prices of products, so as to reduce equipment use costs, improve efficiency, and reduce The effect of equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

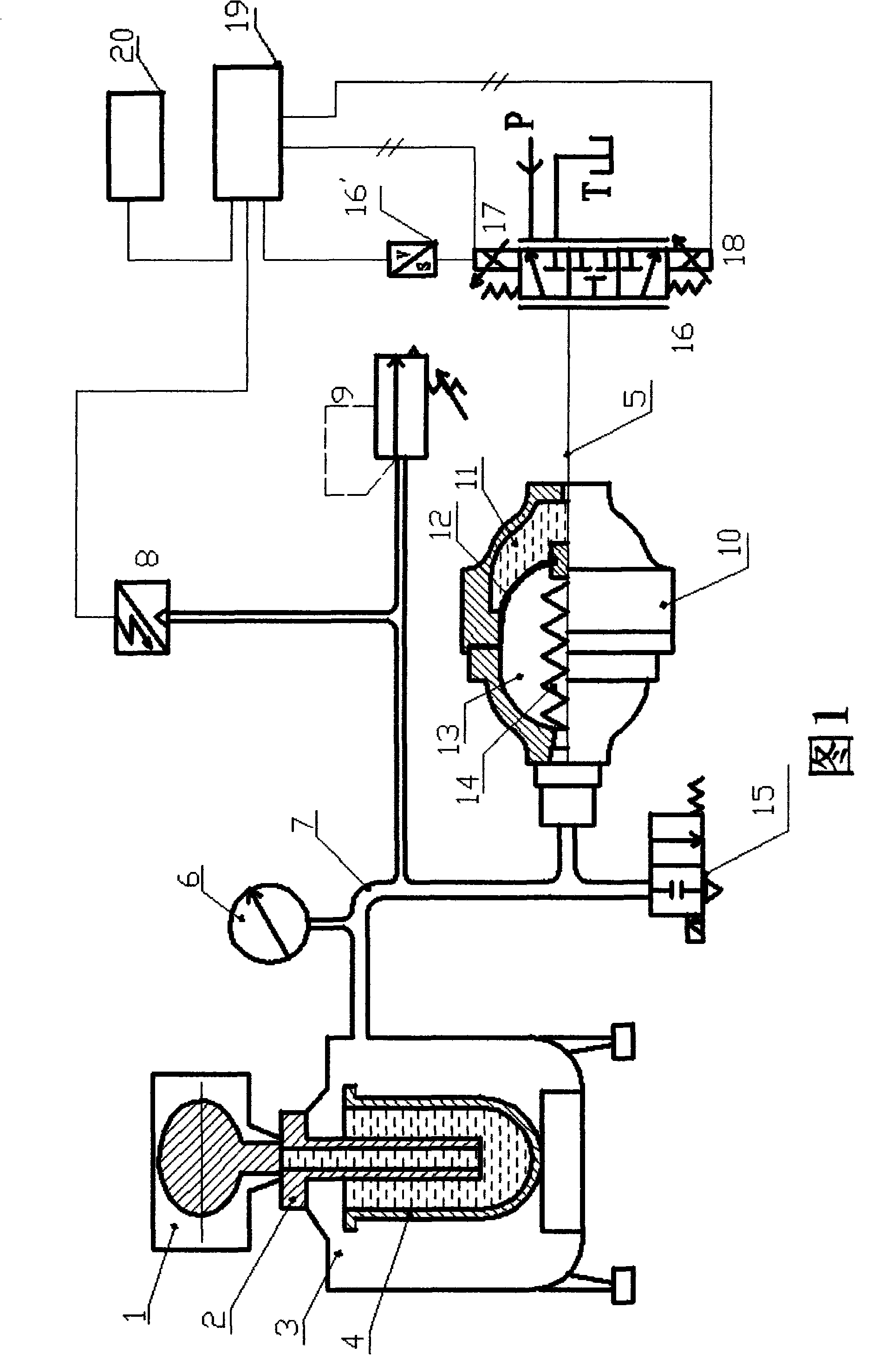

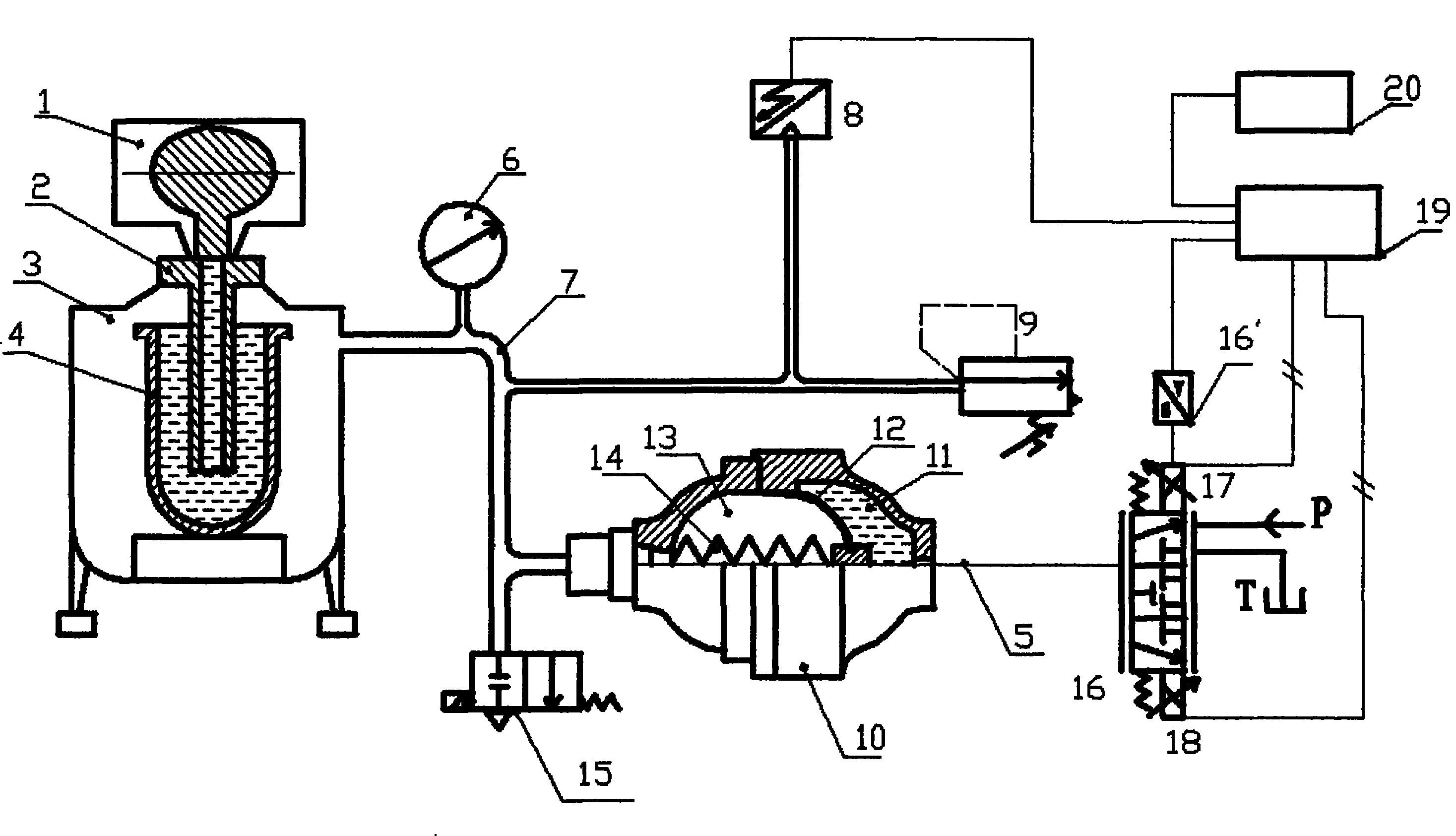

[0014] The invention will be further described below in conjunction with the accompanying drawings, and the present invention is relatively clear to those skilled in the art.

[0015] Prepare the air pressure-time program according to the required process, the program is stored by the PLC controller 20, the PLC controller 20 sends instructions to the power amplifier 19 with feedback signal to drive the proportional electromagnet 17, and the proportional electromagnet 17 drives the three-position electro-hydraulic proportional The spool of the valve 16 moves, so that the single oil port on the left side of the three-position electro-hydraulic proportional valve 16 communicates with the high-pressure hydraulic oil inlet P connected to the one port on the right side of the three-position electro-hydraulic proportional valve 16, and the hydraulic oil in the high-pressure state passes through the seal. The oil pressure tube 5 is filled into the hydraulic cavity 11, and pushes the is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com