Flexible ellipse-like wheel of detection robot

An ellipse-like and robot-like technology, applied in manipulators, manufacturing tools, etc., can solve the problems of the impact of internal parts of the wheel, poor wheel passing performance, affecting the service life and other problems, so as to reduce the impact, reduce the slip phenomenon and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

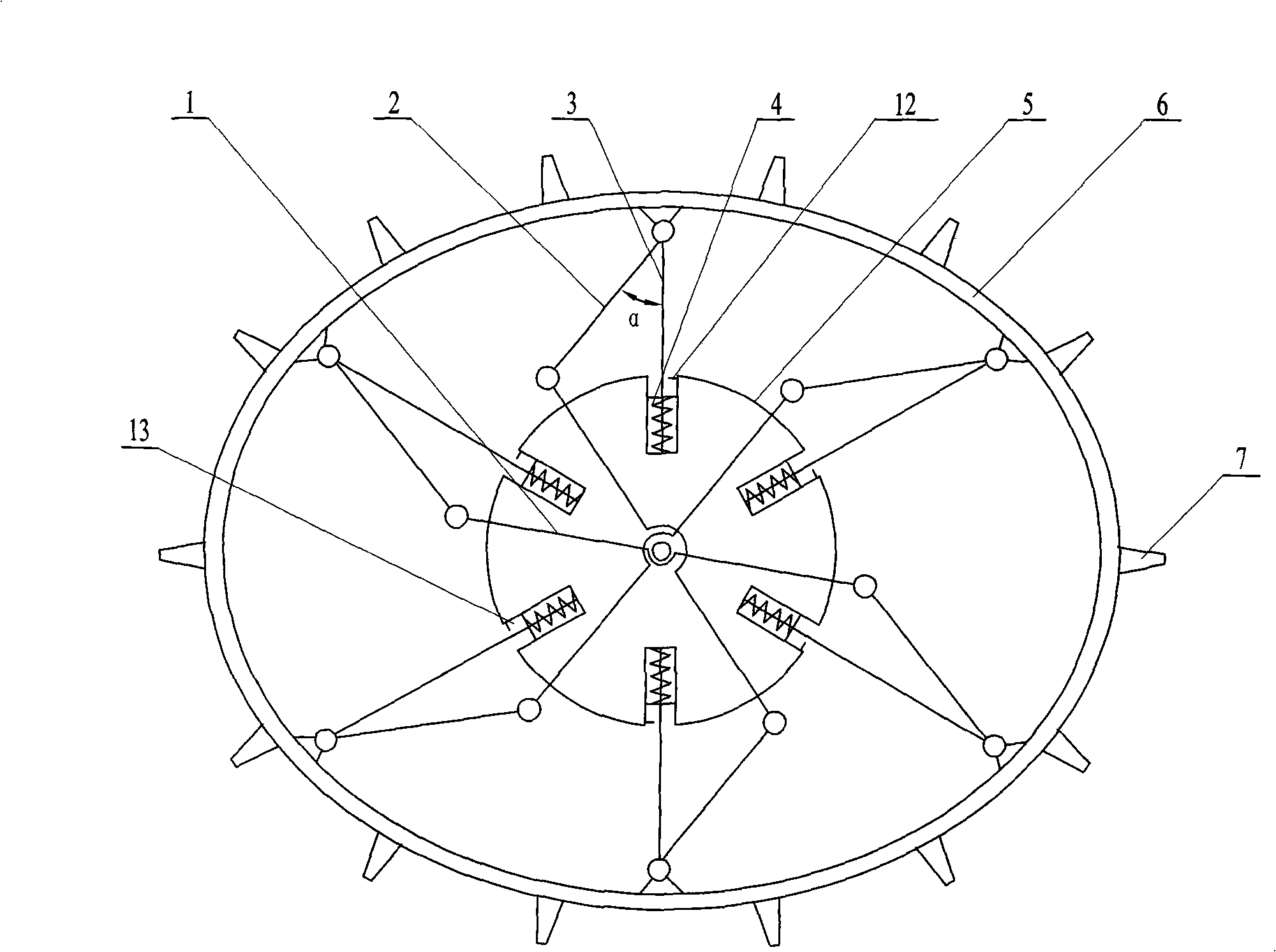

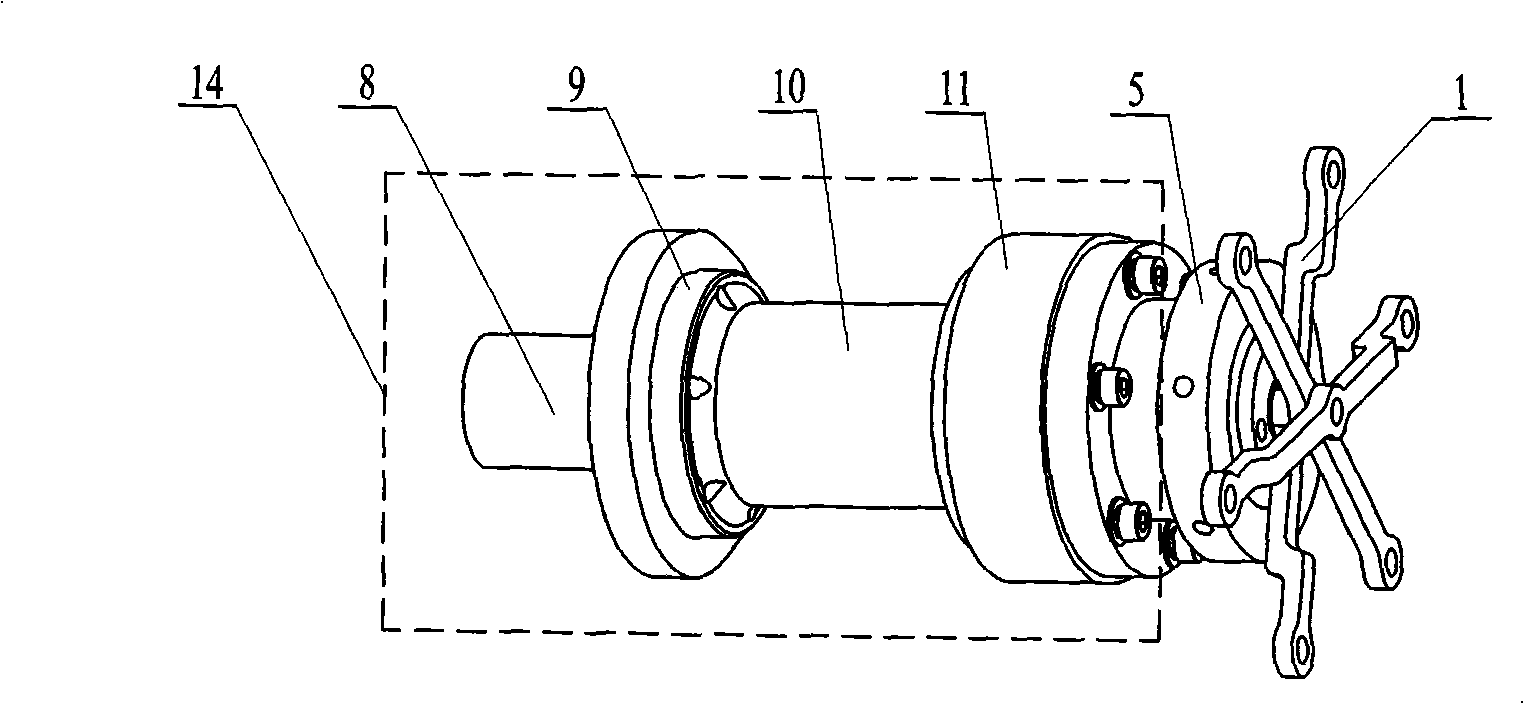

[0007] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, the wheel of this embodiment includes a hub 14 and a drive flange 5; the wheel of this embodiment also includes at least three adjustment rods 1, at least six support rods 2, at least six slide bars 3, and at least six springs 4 , at least six limit blocks 12, a flexible rim 6 and a plurality of tooth pieces 7; at least six grooves 13 are evenly distributed on the circumferential end surface of the drive flange 5, and each groove 13 is equipped with a A spring 4, a limit block 12 is fixed in each groove 13, the drive flange 5 is fixed on the output shaft of the reducer 11 in the hub, and the at least three adjustment rods 1 are fixed along the drive flange. The circumference of the disk 5 is evenly distributed, and the middle part of each adjusting rod 1 is installed on the shaft end of the output shaft of the reducer 11 in the wheel hub and is hinged thereto. Each is provided w...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 To describe this embodiment, a plurality of gear pieces 7 in this embodiment are evenly distributed along the circumference of the outer edge of the flexible rim 6 . Such setting can prevent the wheels from slipping, reduce the ground pressure, and reduce the subsidence of the wheels to the ground. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 2 Describe this embodiment, the wheel hub 14 of this embodiment is made up of drive motor 8, suspension connecting flange 9, motor sleeve 10 and reducer 11; The shaft is connected with the input shaft of the speed reducer 11, and the suspension connection flange 9 is fixedly set on the motor sleeve 10. Such arrangement has a simple structure, and the output shaft of the reducer 11 on the wheel hub drives the flange 5 to rotate. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com