Hydraulic tension device

A tensioning device and hydraulic technology, which is applied to valve devices, transmission devices, engine components, etc., can solve problems such as insufficient tension force, risk of damage, vibration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

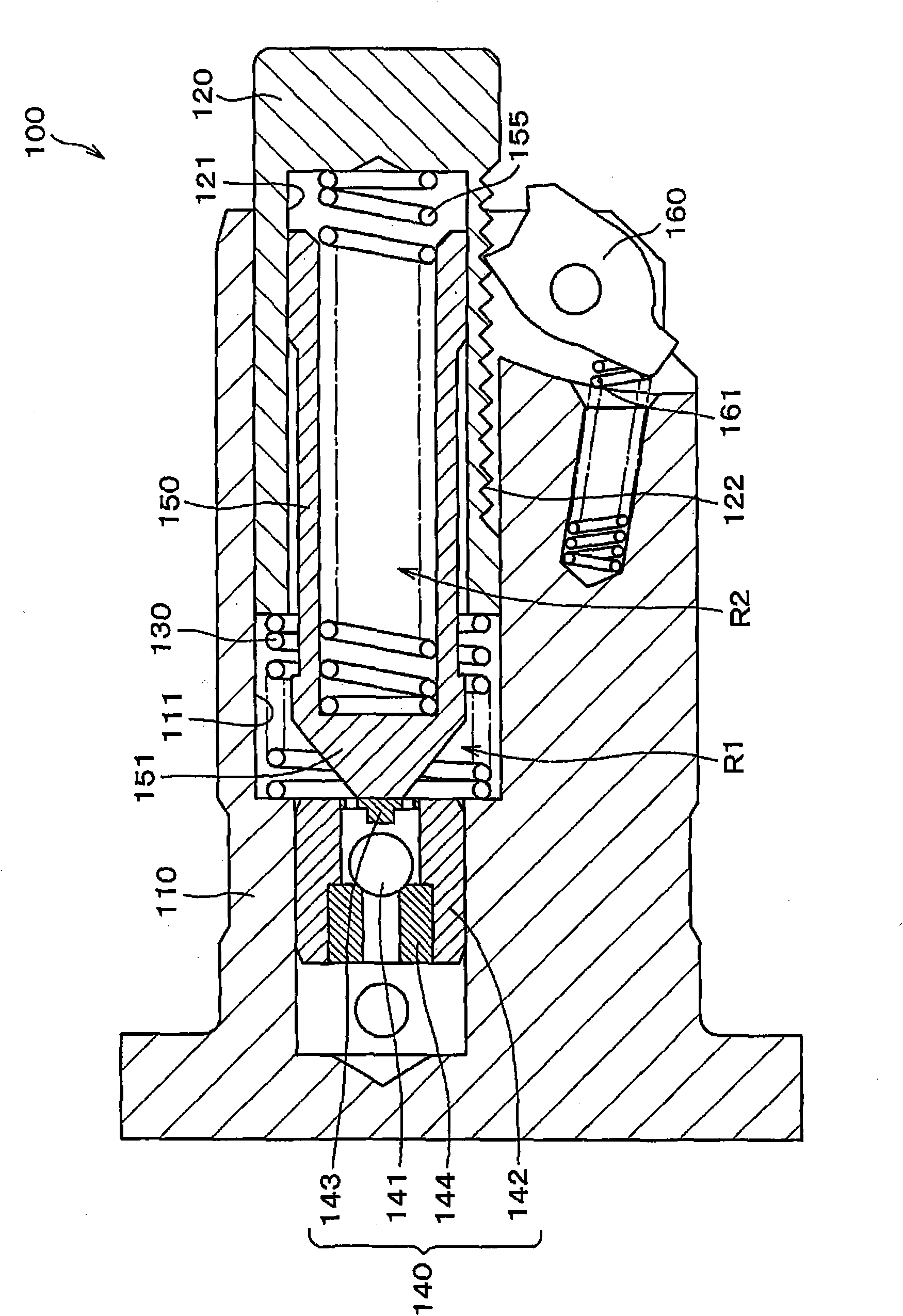

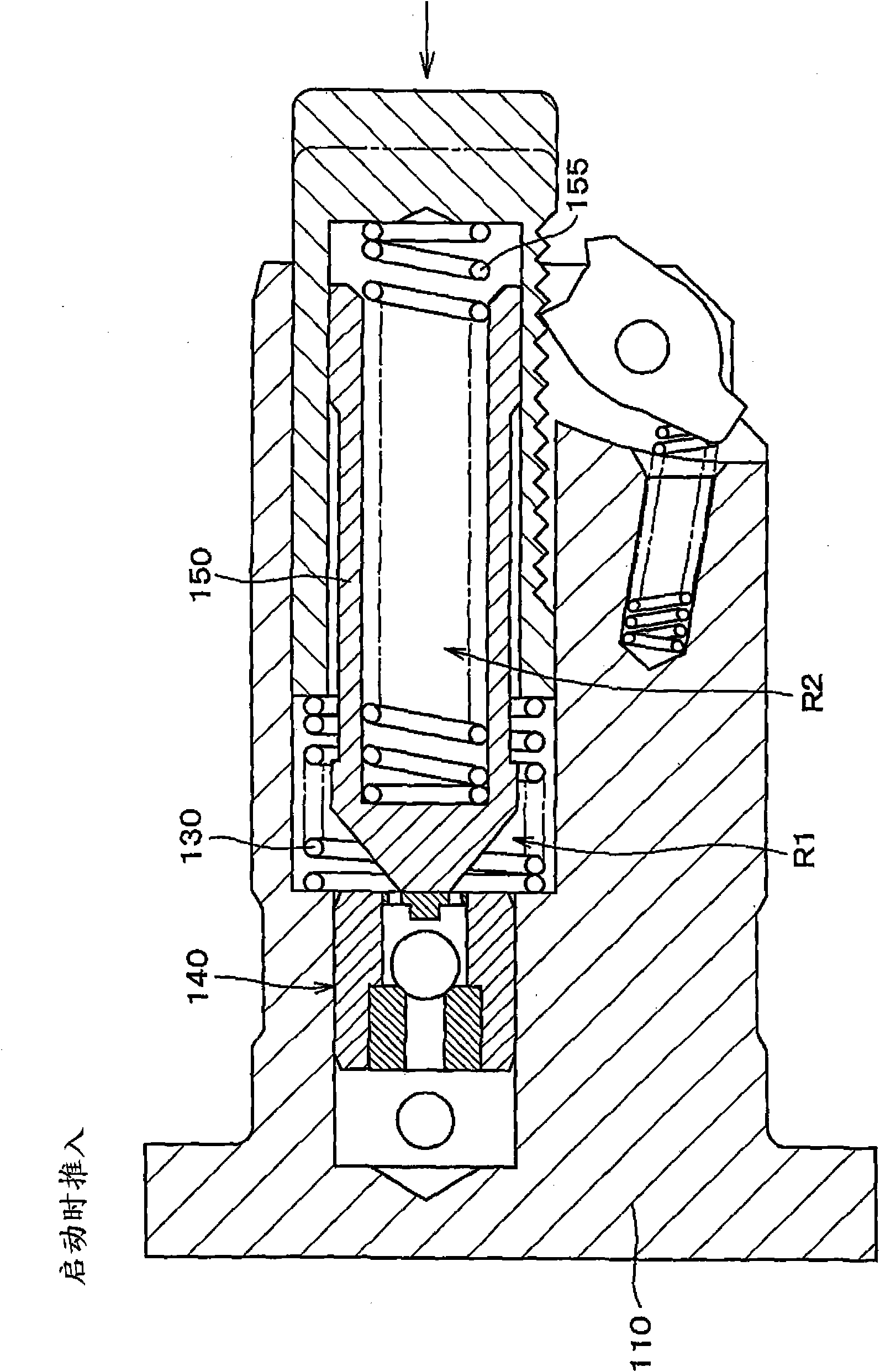

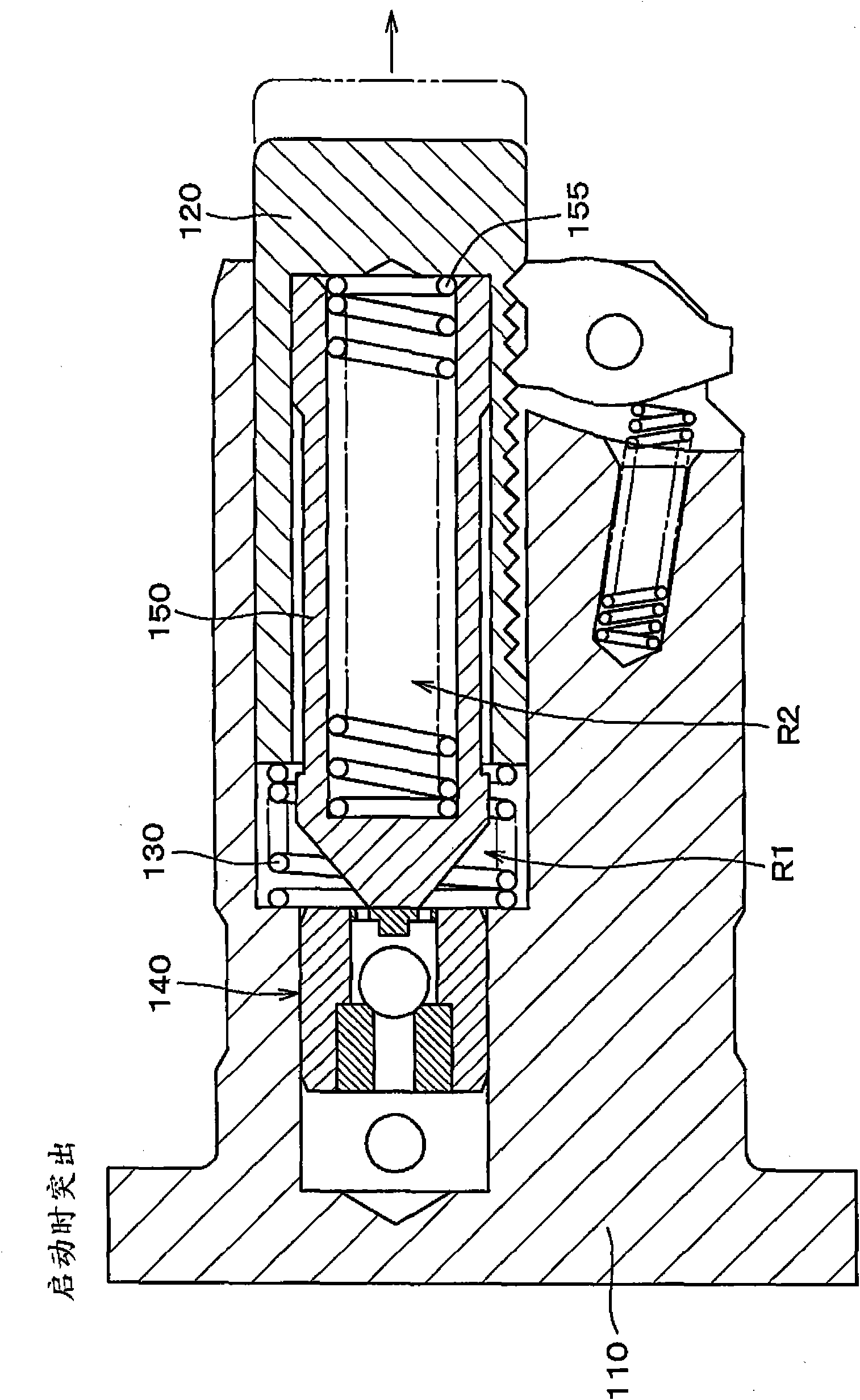

[0050] The hydraulic tensioner of the present invention comprises: a housing main body, a push rod receiving hole provided on the housing main body, a push rod protruding freely slidably from the push rod receiving hole, The high-pressure oil chamber formed between the push rods, the push rod urging spring that is accommodated in the high-pressure oil chamber and urges the push rod in the direction to protrude, is installed in the bottom of the above-mentioned push rod housing hole to stop the high-pressure oil. In the check valve unit for the reverse flow of pressure oil in the chamber, the push rod has an inner sleeve receiving hole on the side of the above-mentioned high-pressure oil chamber, and the inner sleeve receiving hole is slidably accommodated in the above-mentioned high-pressure oil chamber. The inner sleeve, the inner sleeve is biased in the direction of the check valve unit by the inner sleeve urging spring provided at the bottom of the inner sleeve receiving hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com