Scroll compressor

A scroll compressor and scroll technology, which is used in rotary piston machinery, rotary piston pumps, mechanical equipment, etc., can solve the problems of reduced compressor efficiency, increased power consumption of the compressor, and seizure of the front end of the wall.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

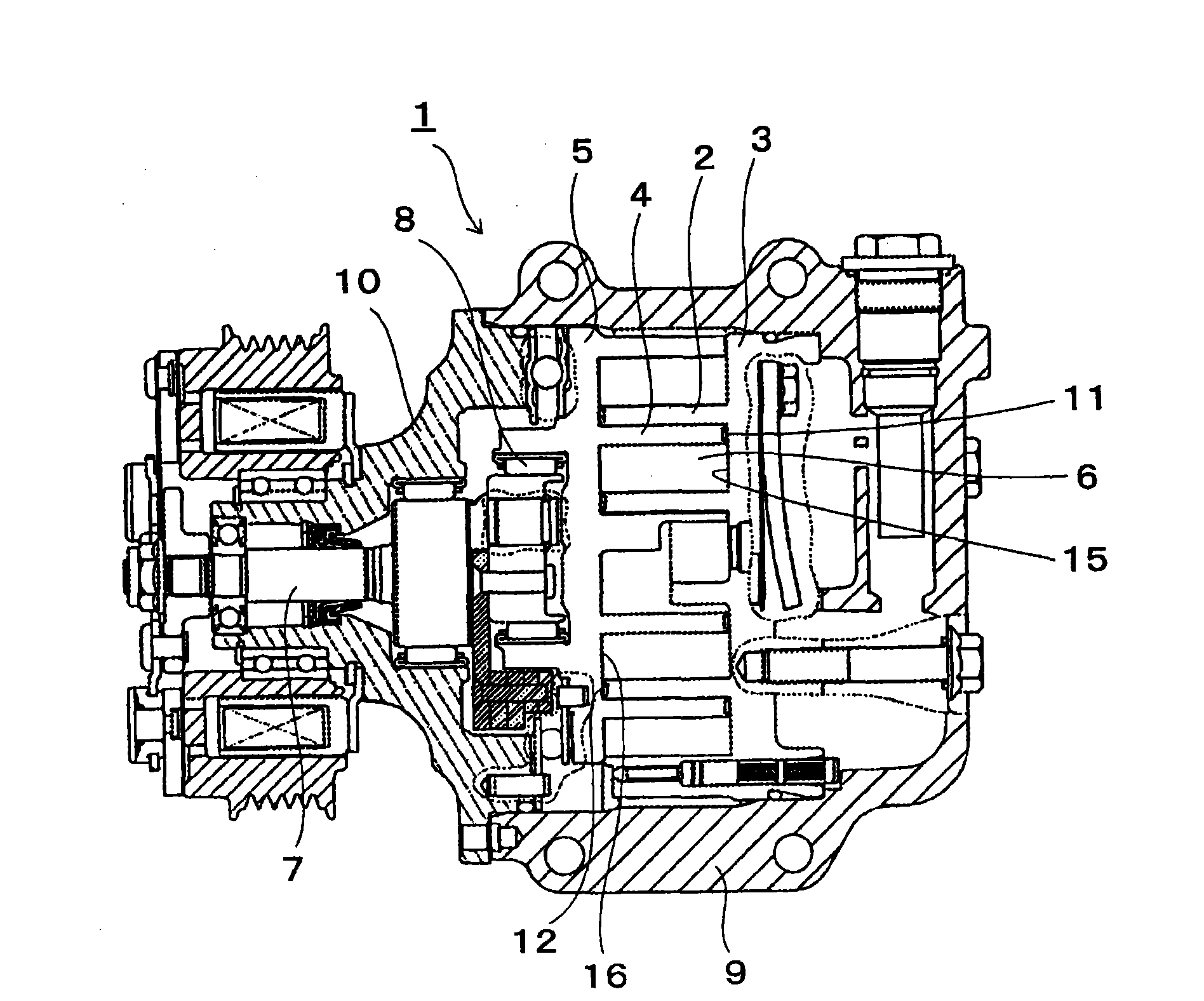

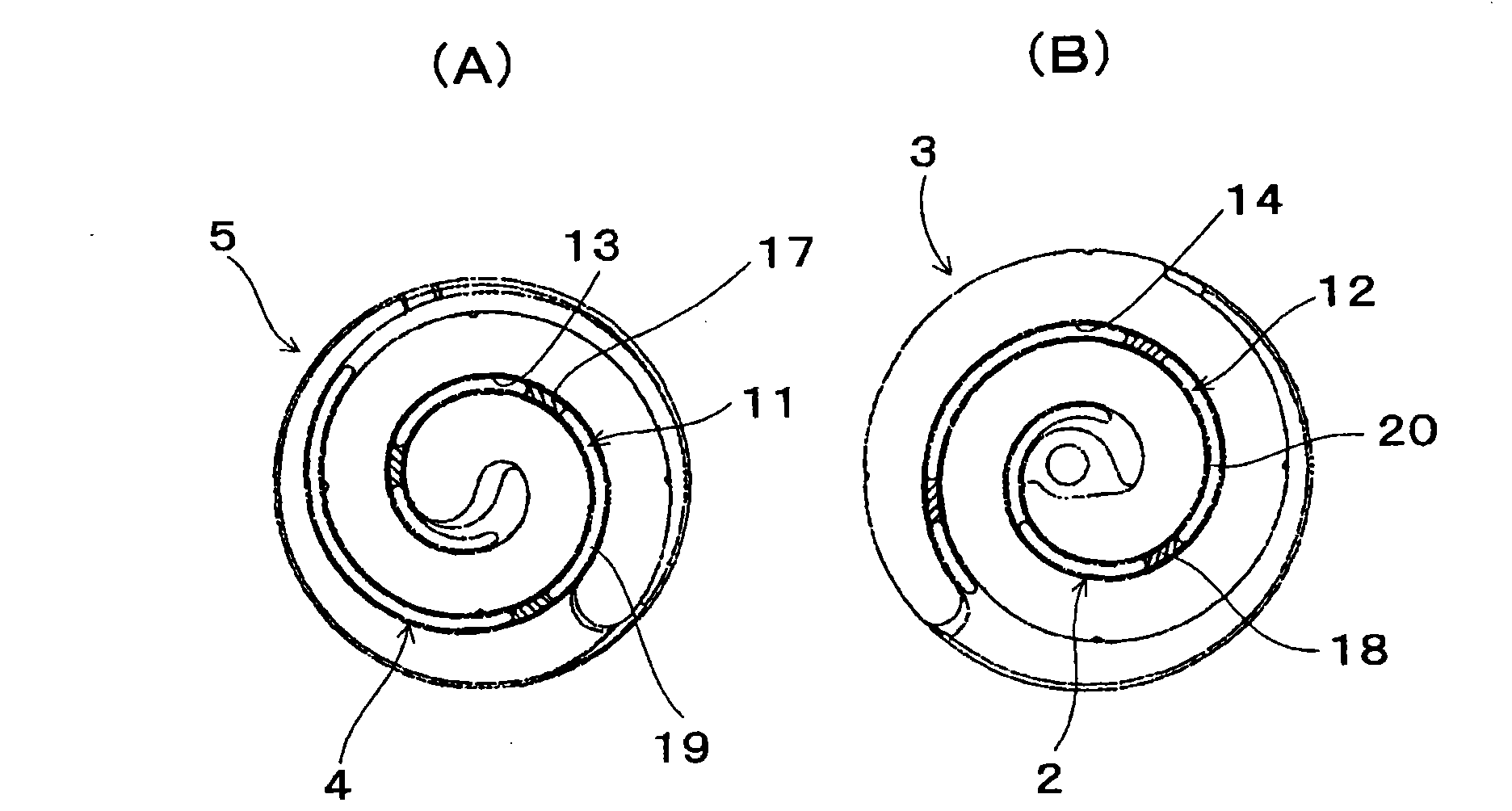

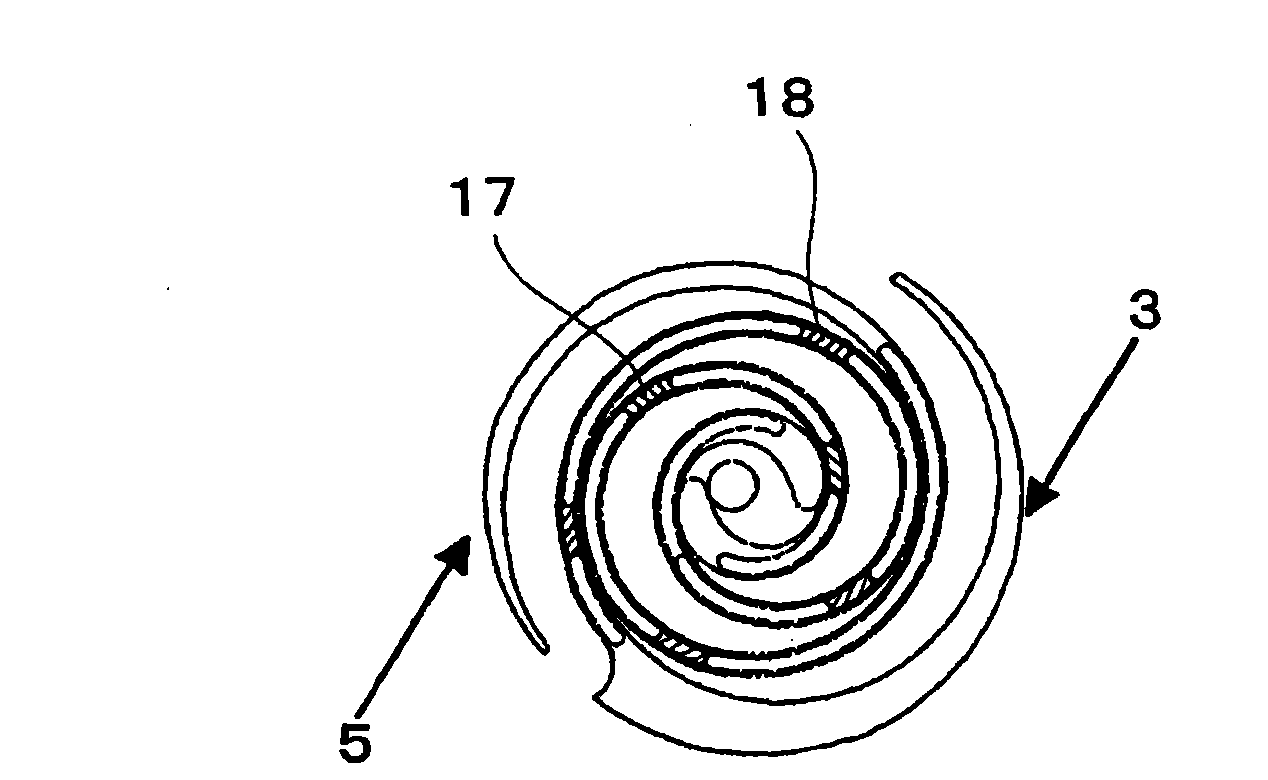

[0039] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings.

[0040] Figure 1 ~ Figure 3 A scroll compressor according to an embodiment of the present invention is shown. exist figure 1 Among them, symbol 1 represents the entire scroll compressor, which has a fixed scroll 3 and a movable scroll 5 meshing with each other, while the fixed scroll 3 includes a scroll body 2, and the movable scroll 5 includes a scroll body 4 . The movable scroll 5 orbits relative to the fixed scroll 3 while its rotation is blocked, and the fluid chamber 6 formed between the two scrolls moves toward the center to compress the fluid. The movable scroll 5 is driven by a drive shaft 7 constituted by a crankshaft, and a driving force for orbiting is transmitted to the movable scroll 5 through a drive bearing 8 press-fitted into the back side of the movable scroll 5 . figure 1 The symbol 9 in represents the main body shell, and the symbol 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com