High-efficient thickener

A thickener and high-efficiency technology, applied in the direction of the settlement tank, etc., can solve the problems of difficult transmission stability and small application range, etc., and achieve the effect of simple and compact structure, wide application range and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

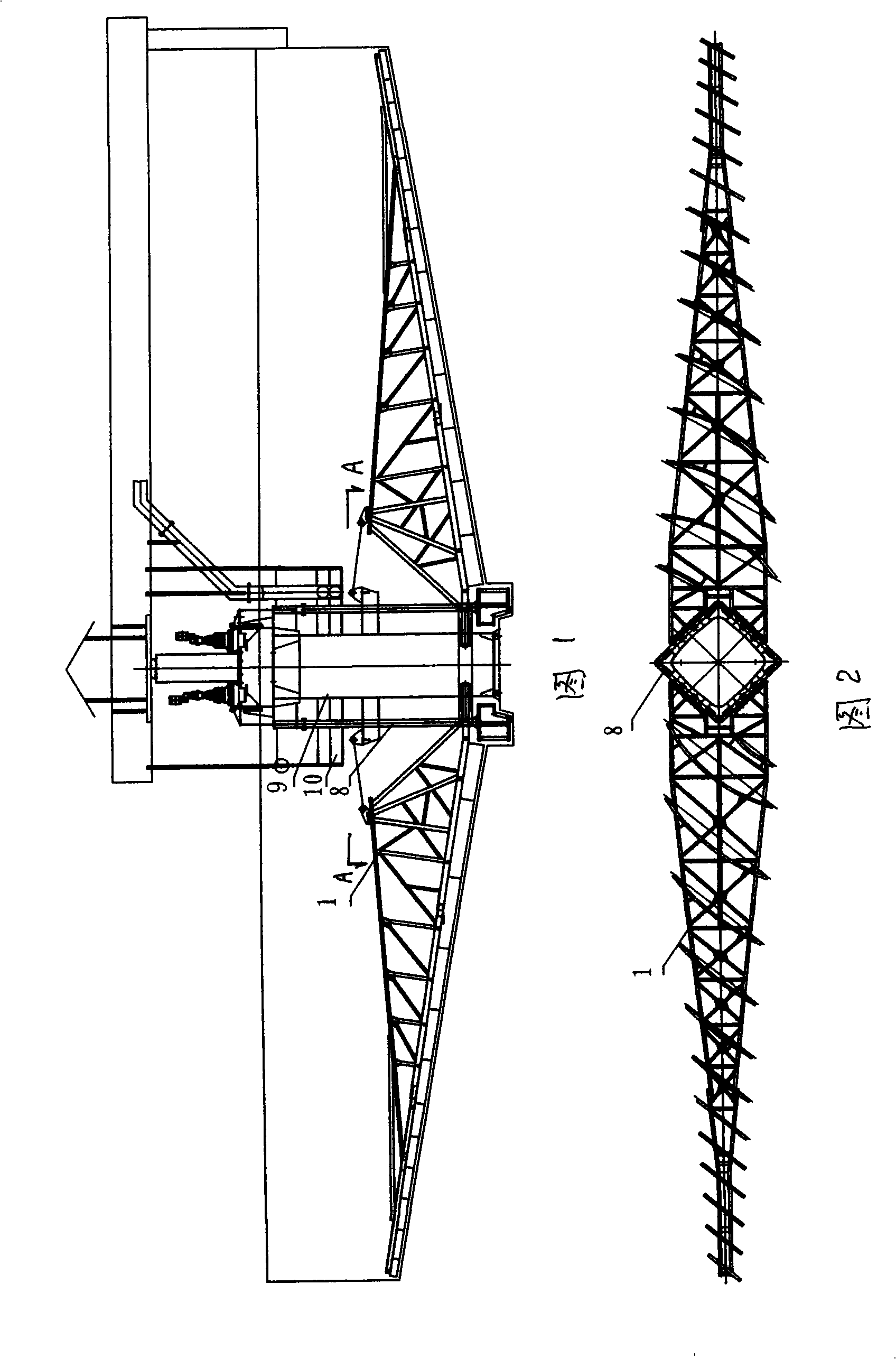

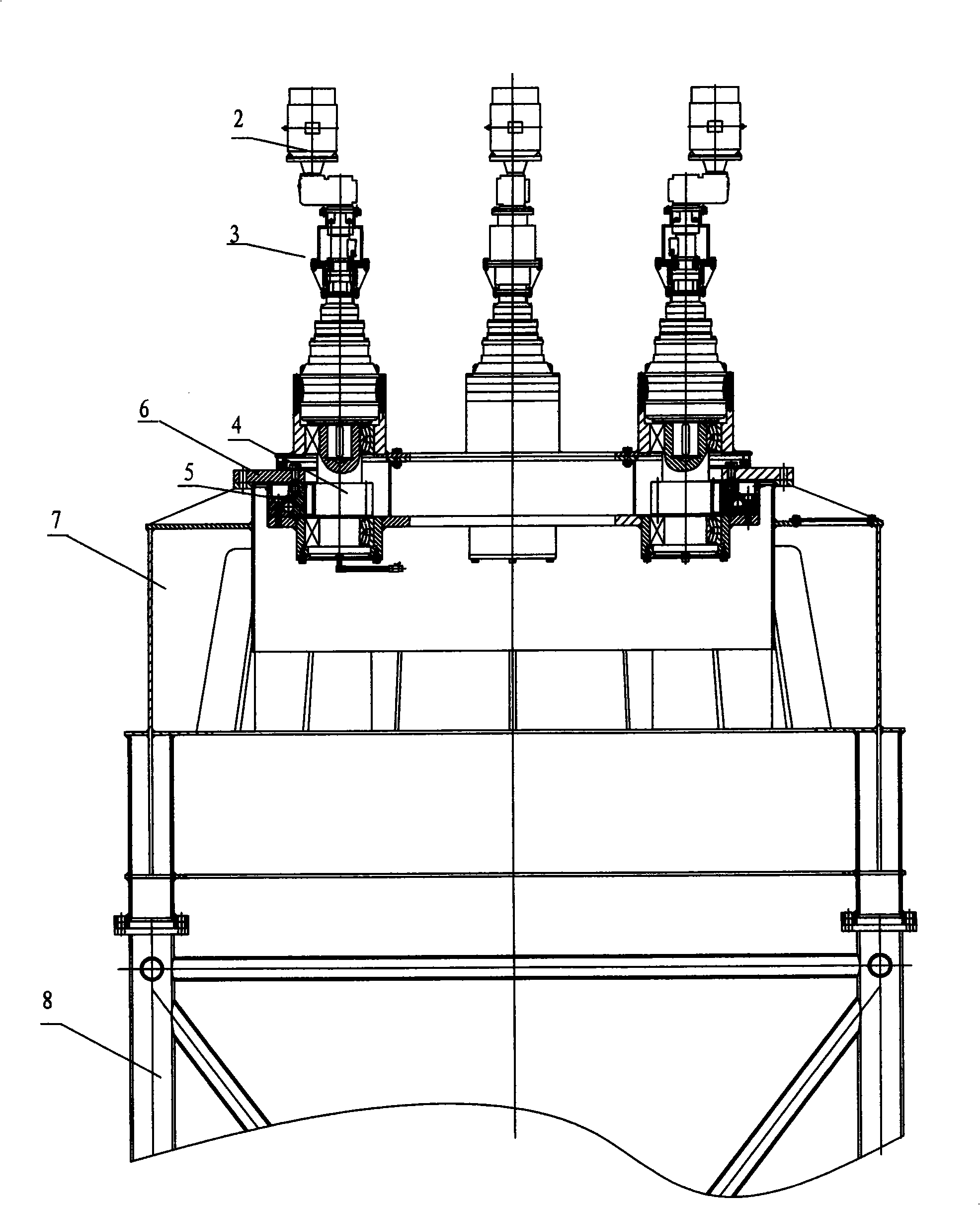

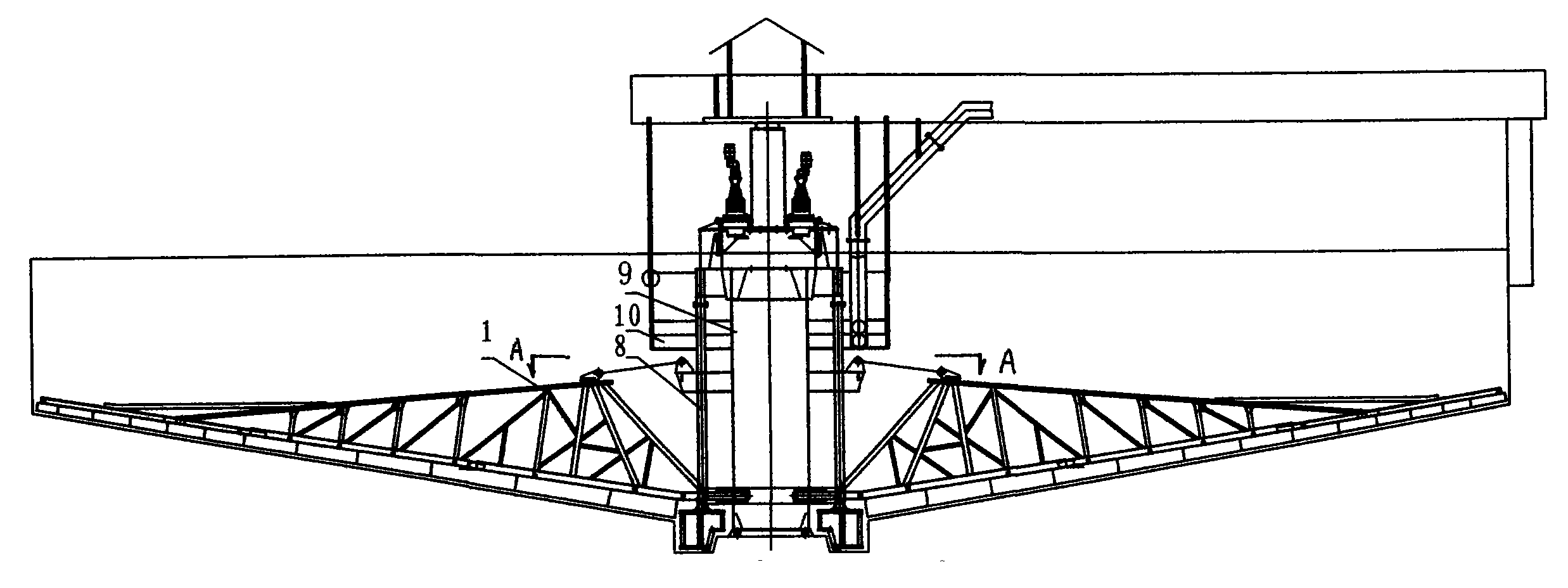

[0013] As shown in the figure, the present invention includes a rake 1 and a power source composed of a drive motor 2 and a reduction mechanism 3. The power sources are three groups and distributed in a triangle. The output shaft of the reduction mechanism 3 of each power source is provided with The pinion 4, the pinion 4 is internally meshed with the rotary support disc 5, the rotary support disc 5 is connected with the transmission cage top 7 through the external rotary disc 6, the lower end of the transmission cage top 7 is fixedly connected to the rotary main shaft 8, and the rake 1 is fixed on the rotary main shaft 8 sides. Due to the large power required by the equipment and the low speed, the driving part of the thickener adopts a tower combination, and the three motors drive the combination of several reducers respectively. What is used in the present invention is a two-stage deceleration. The output shaft of the reducer is equipped with pinions 4, and the three pinion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com