UV/H*O* advanced oxidized water treatment equipment and treatment method

A technology of H2O2 and treatment equipment, applied in the directions of oxidized water/sewage treatment, light water/sewage treatment, etc., can solve the problems of low photolysis efficiency and increase treatment cost, achieve simple process operation, save treatment cost, and reduce effluent smell taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

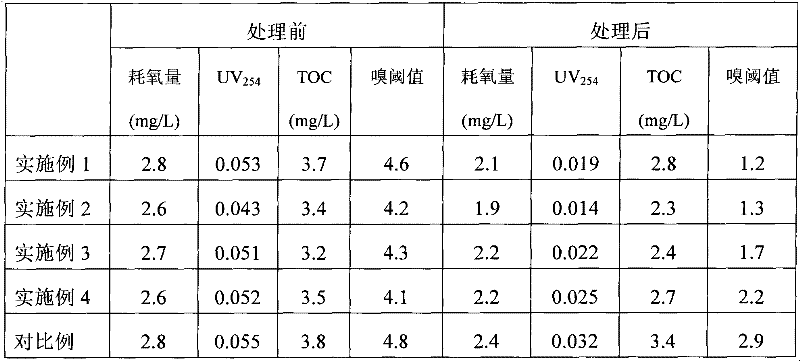

Embodiment 1

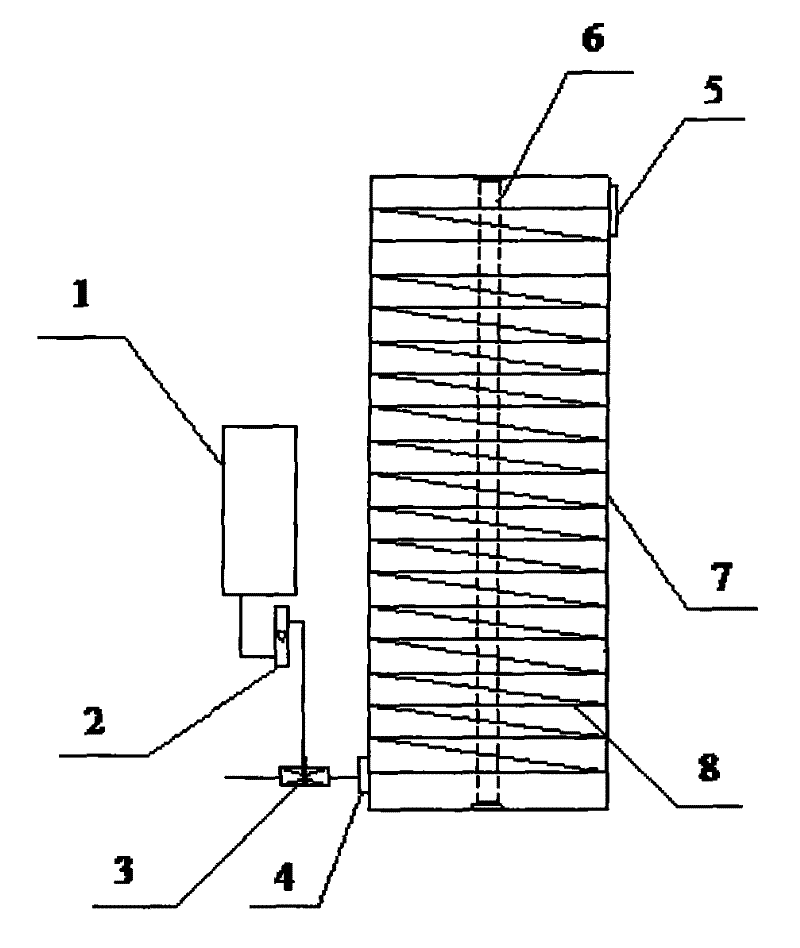

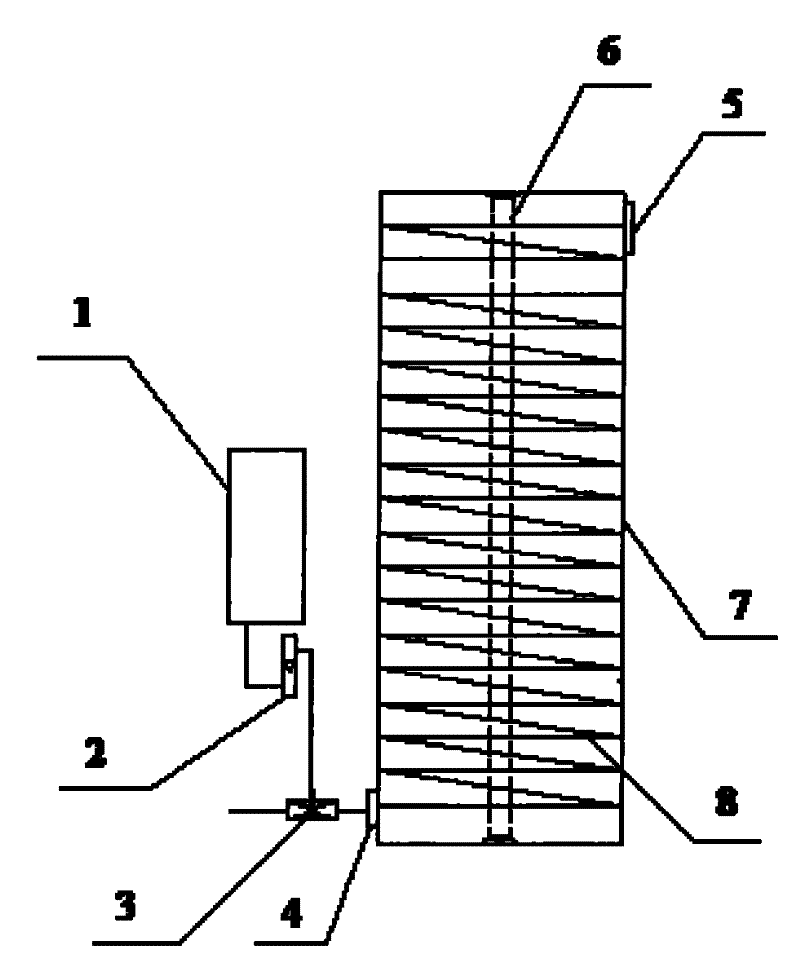

[0018] UV / H described in the present invention 2 o 2 Advanced oxidation water treatment equipment, including H 2 o 2 Dosing device and reactor, the H 2 o 2 The dosing device is composed of a dosing box 1, a flow meter 2 and an ejector 3 connected in sequence; the reactor includes a cylindrical stainless steel shell 7, the bottom of the shell 7 is provided with a water inlet 4, and the top is provided with a water outlet 5, The water outlet of the ejector 3 communicates with the water inlet 4 of the housing, and the inner axis of the housing 7 is provided with an ultraviolet lamp 6, and the two ends of the ultraviolet lamp 6 are respectively fixed on the bottom and the top of the housing 7, and Surrounded by an annular glass tube 8 , the annular glass tube 8 communicates with the water inlet 4 and the water outlet 5 of the casing 7 .

[0019] Apply the water treatment equipment of the present invention to carry out the method for water treatment as follows: (1) prepare the...

Embodiment 2

[0021] Except H 2 o 2 The dosing concentration is 0.6mg / L, the power of the ultraviolet lamp is 20W, the residence time of water in the annular glass tube is 20min, and the rest are the same as in Example 1.

Embodiment 3

[0023] Except H 2 o 2 The dosing concentration is 0.8 mg / L, the power of the ultraviolet lamp is 60W, the inner diameter of the annular glass tube is 150mm, the residence time of water in the annular glass tube is 10min, and the rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com