Sewage circulating treatment system for wood soaking tank

A sewage recycling and treatment system technology, applied in the field of wood manufacturing industry, can solve problems such as environmental pollution, and achieve the effect of saving labor, improving performance, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

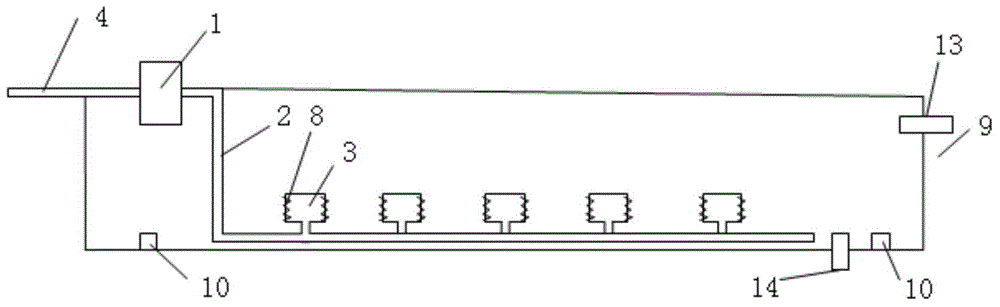

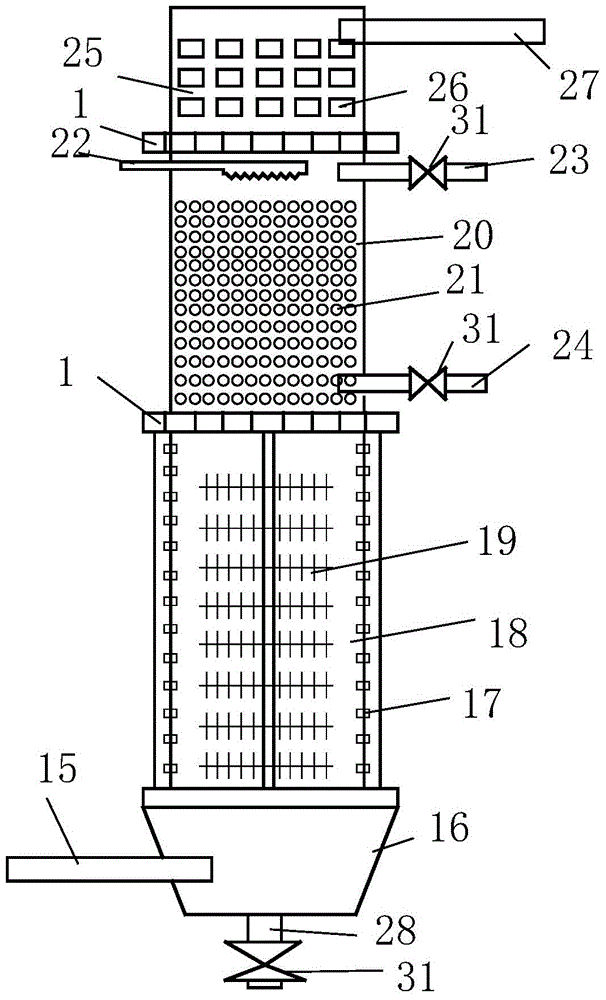

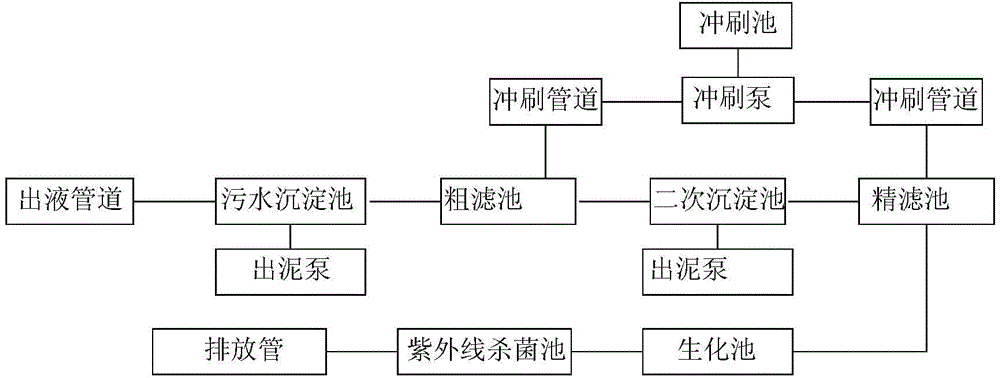

[0017] Embodiment: the sewage circulation treatment system of wood immersion tank, as figure 1 As shown, a closed soaking tank 12 is included, and the tank side of the soaking tank 12 is provided with a metering pump 1, and one side of the metering pump 1 is connected with a medicine feeding pipe 4, and the other side is connected with a networked drug delivery pipeline 2, The drug pipeline 2 is provided with a drug delivery mechanism 3; an air outlet pipeline 13 is arranged above the soaking tank 12, and a liquid outlet pipeline 14 is arranged below the soaking tank 12, and the liquid outlet pipeline 14 is connected to a sewage circulation treatment system; as attached image 3 As shown, due to the image 3 Each part is indicated by text, so no digital marking is carried out on this part of the parts. The sewage circulation treatment system includes a sewage sedimentation tank connected with the liquid outlet pipeline 14, and the sewage sedimentation tank is used for sedimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com