Automatic equipment capable of directly adding SNCR denitration agent and preparation method of SNCR denitration agent

A technology of automatic equipment and denitrification agent, applied in separation methods, chemical instruments and methods, mixer accessories, etc., can solve problems such as solution agglomeration, inability to solve urea moisture absorption, and affect the use effect, and achieve easy maintenance and low labor intensity Low, easy installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

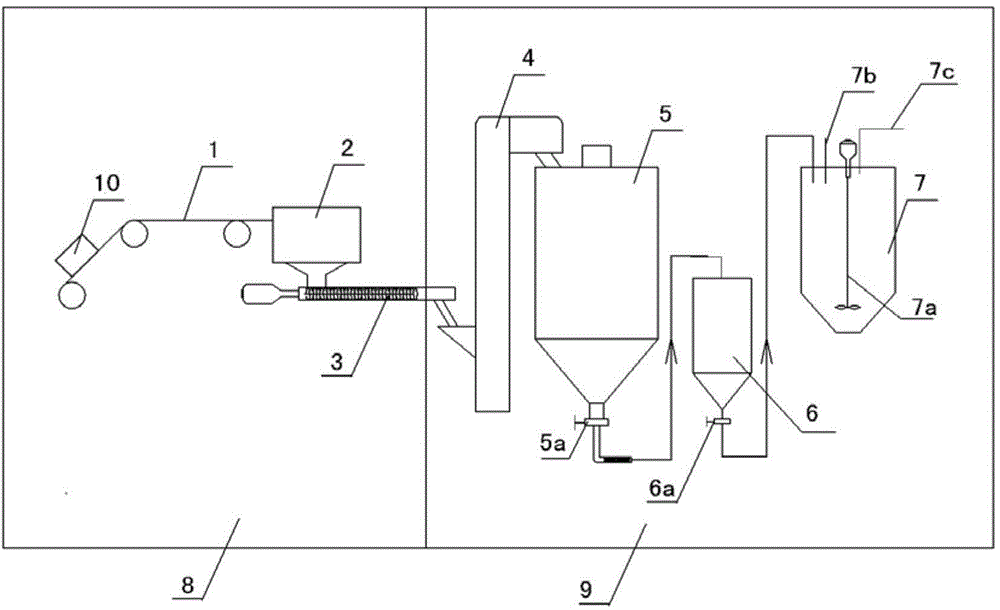

[0023] Such as figure 1 As described, the structure of the automatic equipment that can directly add SNCR denitrification agent in this embodiment is: a belt conveyor 1 is set, and the discharge end of the belt conveyor 1 is connected to the inlet of a breaking machine 2, and the opening of the breaking machine 2 The discharge port is connected to the feed port of a screw conveyor 3, the discharge port of the screw conveyor 3 is connected to the feed port of a bucket elevator 4, and the discharge port of the bucket elevator 4 is connected to the urea silo 5, the outlet of the urea silo 5 is connected to the inlet of the metering bin 6, and the outlet of the metering bin 6 is connected to the material inlet of the batching tank 7; the batching tank 7 is provided with a water inlet 7b and a feed liquid outlet 7c.

[0024] In the specific implementation, the belt conveyor 1 and the bag breaking machine 2 are set in the urea stacking room 8; the bucket elevator 4, the urea silo 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com